6 Sigma Chart

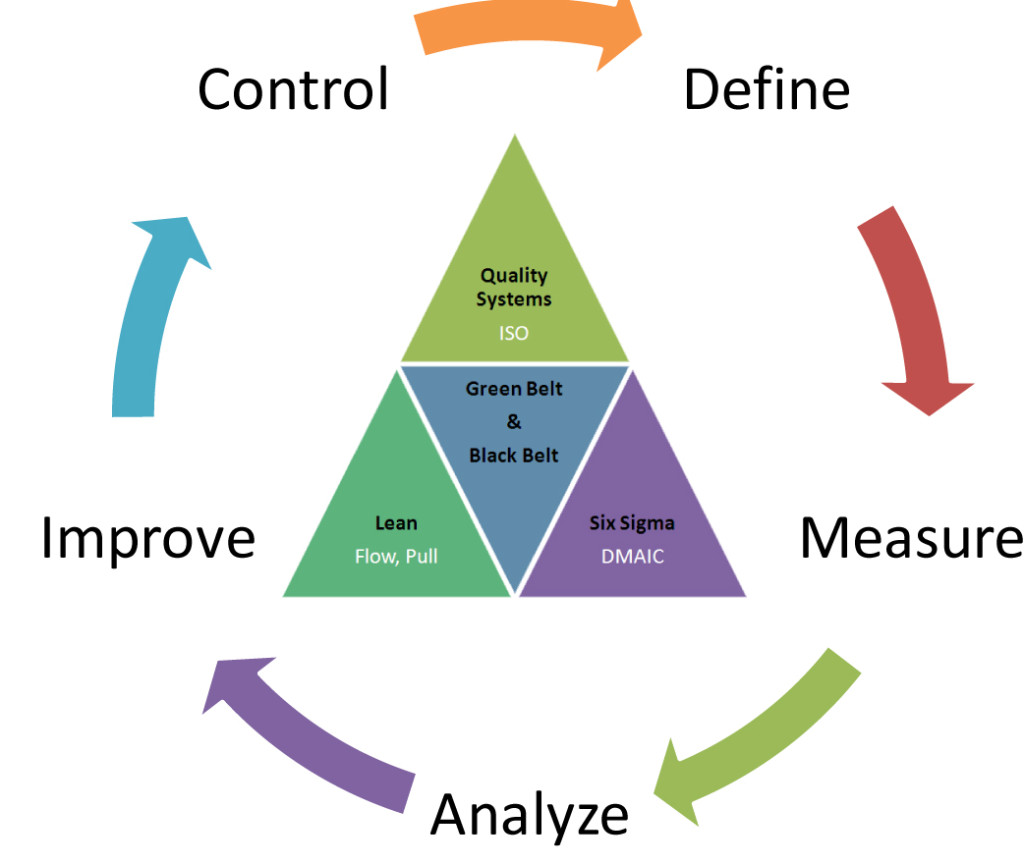

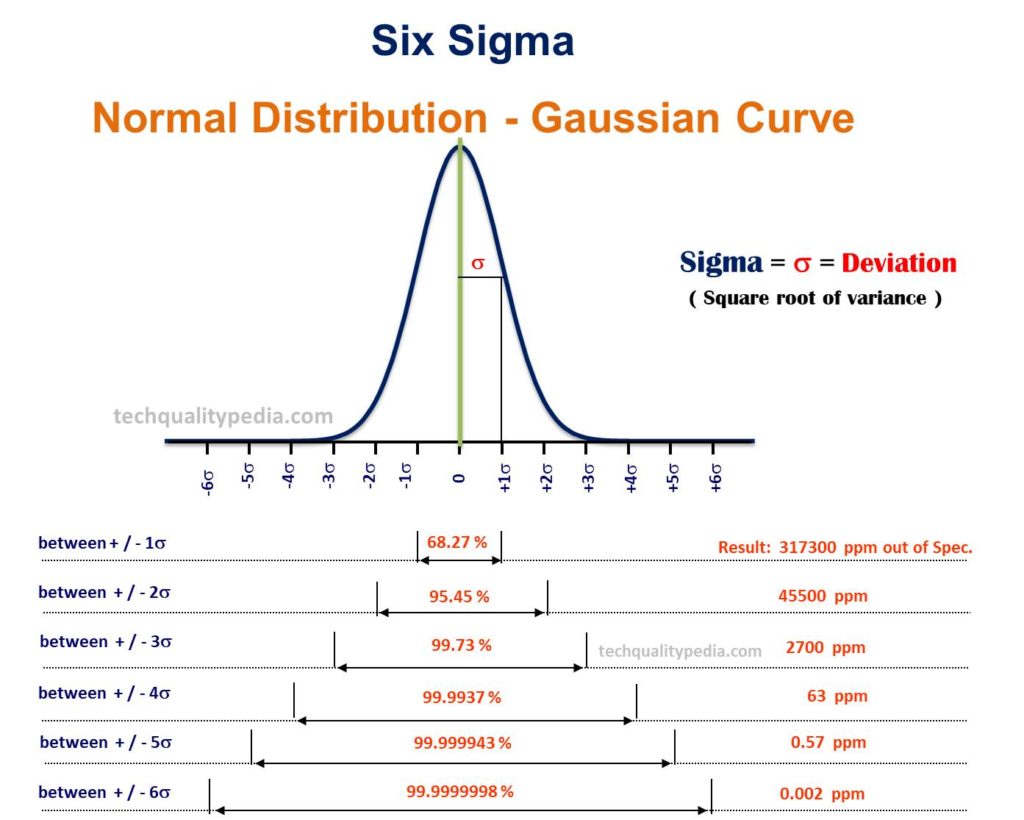

6 Sigma Chart - Web imagine you’re trying to hit a bullseye with a dart. Web control charts are an essential tool used in six sigma to monitor process stability and improve quality. Different types of control charts serve different purposes based on the process parameters being measured and the data being collected. It aims to make processes more predictable and reduce variability. Web in this article, we’ll explain six sigma, its origins in american manufacturing and development, what tools it uses, and how you can train to become certified to practice six sigma. Web statistical process control (spc) is a statistical method to measure, monitor, and control a process. Scatter diagrams, also known as correlation charts or xy graphs, plot the relationship between two continuous variables. Six sigma is like being able to hit near the bullseye almost every single time because you’ve figured out all the little things that could go wrong (like the wind, the weight of the dart, or how you throw it) and you’ve fixed them. Web the five phases of the six sigma method, known as dmaic, are defining, measuring, analyzing, improving, and controlling. The control chart is a tool used to distinguish between assignable (special) and random (common) kinds of variation. Define the problem, area for improvement, or customer requirements. Web the main focus of control charts is to detect and monitor the process variation. Web six sigma (6σ) is a set of techniques and tools for process improvement. A histogram is the graphical representation of a frequency distribution. The control chart is a tool used to distinguish between assignable (special). Learn how to integrate lean and six sigma at asq.org. Different types of control charts serve different purposes based on the process parameters being measured and the data being collected. A histogram is the graphical representation of a frequency distribution. Six sigma is like being able to hit near the bullseye almost every single time because you’ve figured out all. Plus, experts explain the benefits that. Analyze the process to determine the root cause of defects or inefficiencies. The control chart was invented by walter shewhart at bell labs in 1920. It aims to make processes more predictable and reduce variability. Web a six sigma control chart is a simple yet powerful tool for evaluating the stability of a process. Web the main focus of control charts is to detect and monitor the process variation. Six sigma emphasizes understanding and meeting customer needs and specifications. Define the problem, area for improvement, or customer requirements. Web in a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to. Web the five phases of the six sigma method, known as dmaic, are defining, measuring, analyzing, improving, and controlling. Web in a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to implement some necessary improvement steps and adopt some corrective measures to keep the project under. Web here are the five steps: Web in this article, we’ll explain six sigma, its origins in american manufacturing and development, what tools it uses, and how you can train to become certified to practice six sigma. It is a scientific visual method to monitor, control, and improve the process by eliminating special cause variations in a process. Measure performance. Web here are the five steps: Creating a control chart requires a graph that covers a period of time, a center line that shows the results of a process during that time, and upper and lower control limits that indicate whether process. Web statistical process control (spc) is a statistical method to measure, monitor, and control a process. Six sigma. Web control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting when a process is out of control. Creating a control chart requires a graph that covers a period of time, a center line that shows the results of a process during that time, and upper and lower control limits that indicate. Web six sigma is defined as a method that provides tools to improve business process capabilities. Web use this sigma calculator to easily calculate process sigma level, defects per million opportunities (dpmo, ppm), yield, rolled throughput yield (rty), percent defects, percent defect units, as well as defects per million units (dpm). Measure performance of the current process. Web the control. Six sigma is like being able to hit near the bullseye almost every single time because you’ve figured out all the little things that could go wrong (like the wind, the weight of the dart, or how you throw it) and you’ve fixed them. It provides a systematic framework to identify and eliminate variations. Define the problem, area for improvement,. Web six sigma is defined as a method that provides tools to improve business process capabilities. Web use this sigma calculator to easily calculate process sigma level, defects per million opportunities (dpmo, ppm), yield, rolled throughput yield (rty), percent defects, percent defect units, as well as defects per million units (dpm). Web the control chart is a graphical display of quality characteristics that have been measured or computed from a sample versus the sample number or time. Web key elements include: It was introduced by american engineer bill smith while working at motorola in 1986. Scatter diagrams, also known as correlation charts or xy graphs, plot the relationship between two continuous variables. Web imagine you’re trying to hit a bullseye with a dart. It is a scientific visual method to monitor, control, and improve the process by eliminating special cause variations in a process. Six sigma strategies seek to improve manufacturing quality by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. Web six sigma (6σ) is a set of techniques and tools for process improvement. Web the six sigma method lets organizations identify problems, validate assumptions, brainstorm solutions, and plan for implementation to avoid unintended consequences. Control the improved process to ensure high performance. Measure performance of the current process. Web here are the five steps: Web the five phases of the six sigma method, known as dmaic, are defining, measuring, analyzing, improving, and controlling. The control chart is a tool used to distinguish between assignable (special) and random (common) kinds of variation.

Six Sigma Process Flow Chart

Lean Six Sigma Pie Chart Lean six sigma, Change management

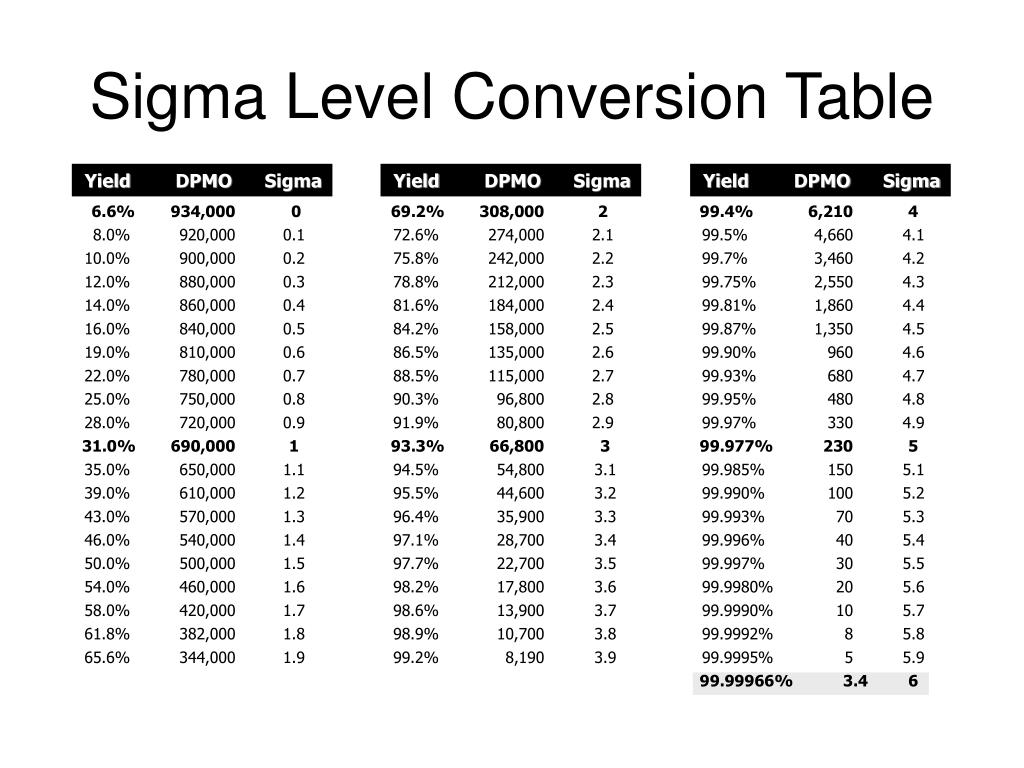

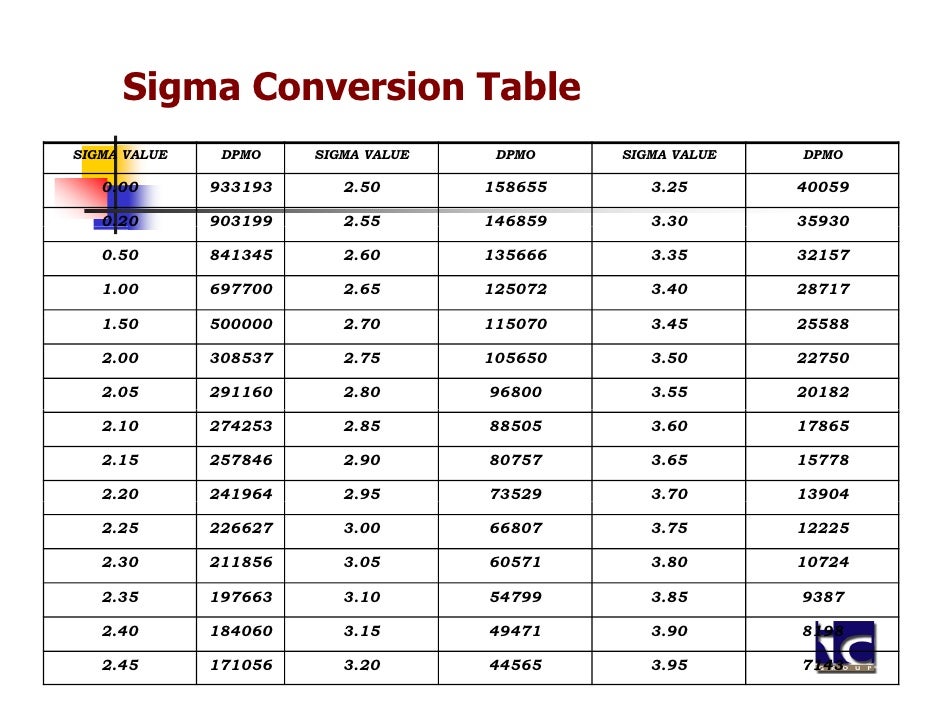

6SigmaConversionTable.pdf Six Sigma Quality

What is Six Sigma? Six Sigma Levels Methodology Tools

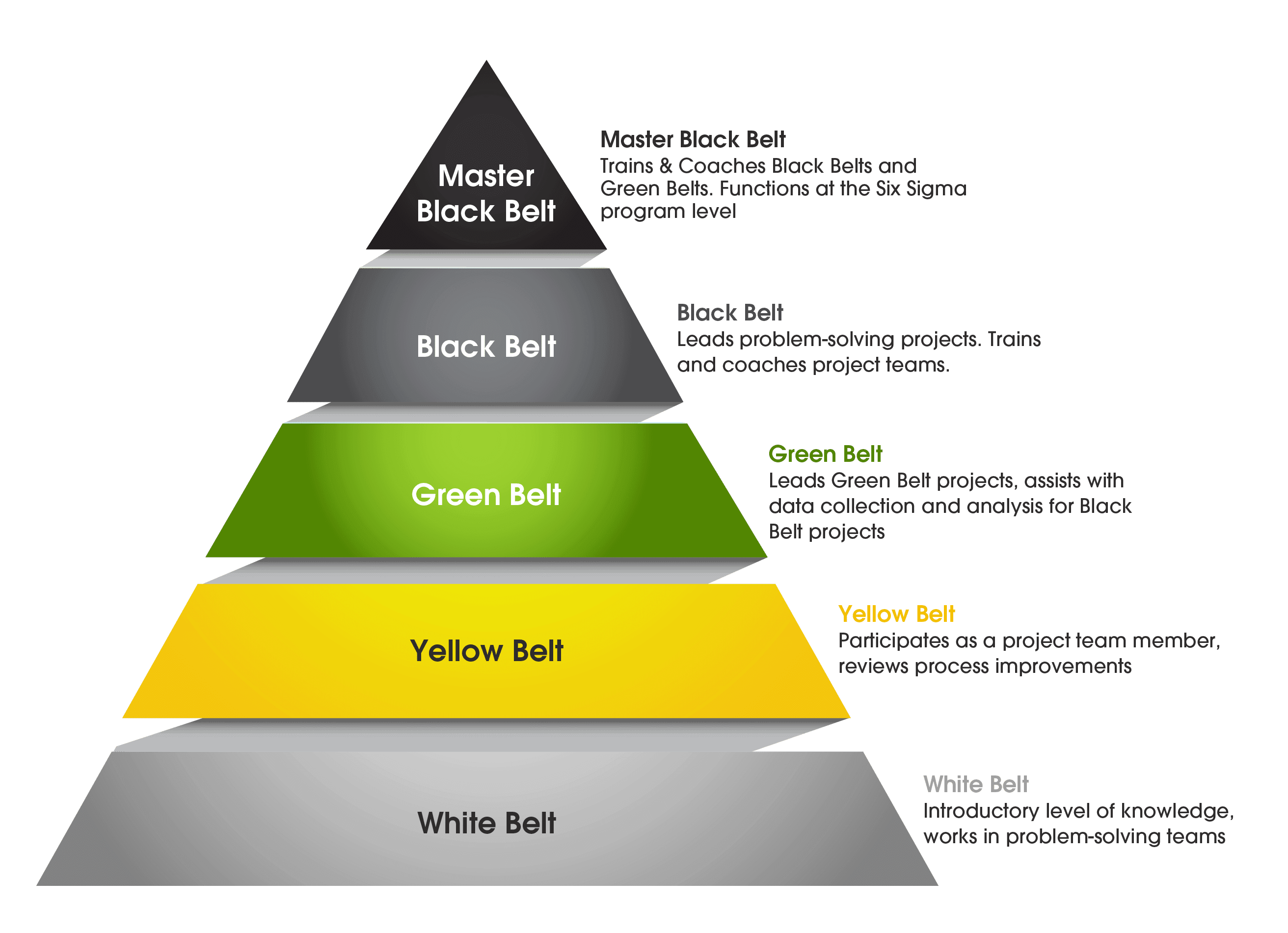

The Hierarchy of Six Sigma Belts What Does It Mean? Hygger.io

6 Sigma Control Chart Introduction Toolkit from Leanscape

Article Everything You Wanted to Know About Six Sigma

Six sigma

6 Essential Lean Six Sigma Tools To Use to Maintain The Quality

What is Six Sigma? Six Sigma Levels Methodology Tools

Web The Main Focus Of Control Charts Is To Detect And Monitor The Process Variation.

Creating A Control Chart Requires A Graph That Covers A Period Of Time, A Center Line That Shows The Results Of A Process During That Time, And Upper And Lower Control Limits That Indicate Whether Process.

Different Types Of Control Charts Serve Different Purposes Based On The Process Parameters Being Measured And The Data Being Collected.

It Spans Several Popular Focal Lengths From 28Mm To 45Mm, With Image Quality Comparable To Prime Lenses.

Related Post: