6 Sigma Control Chart

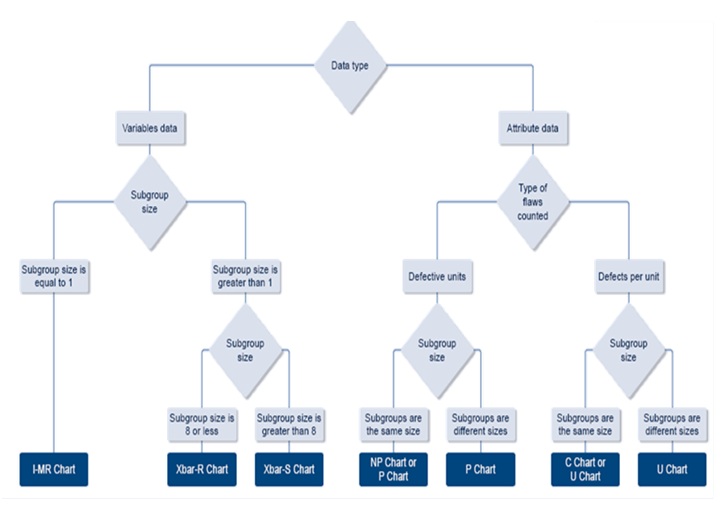

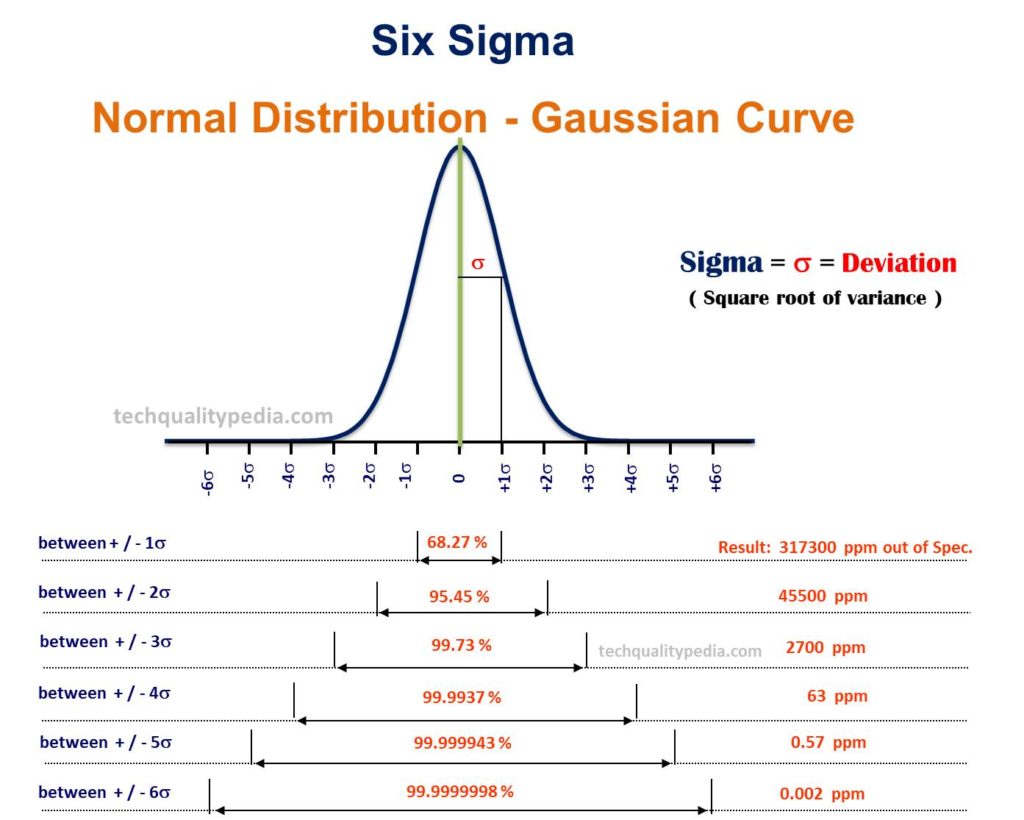

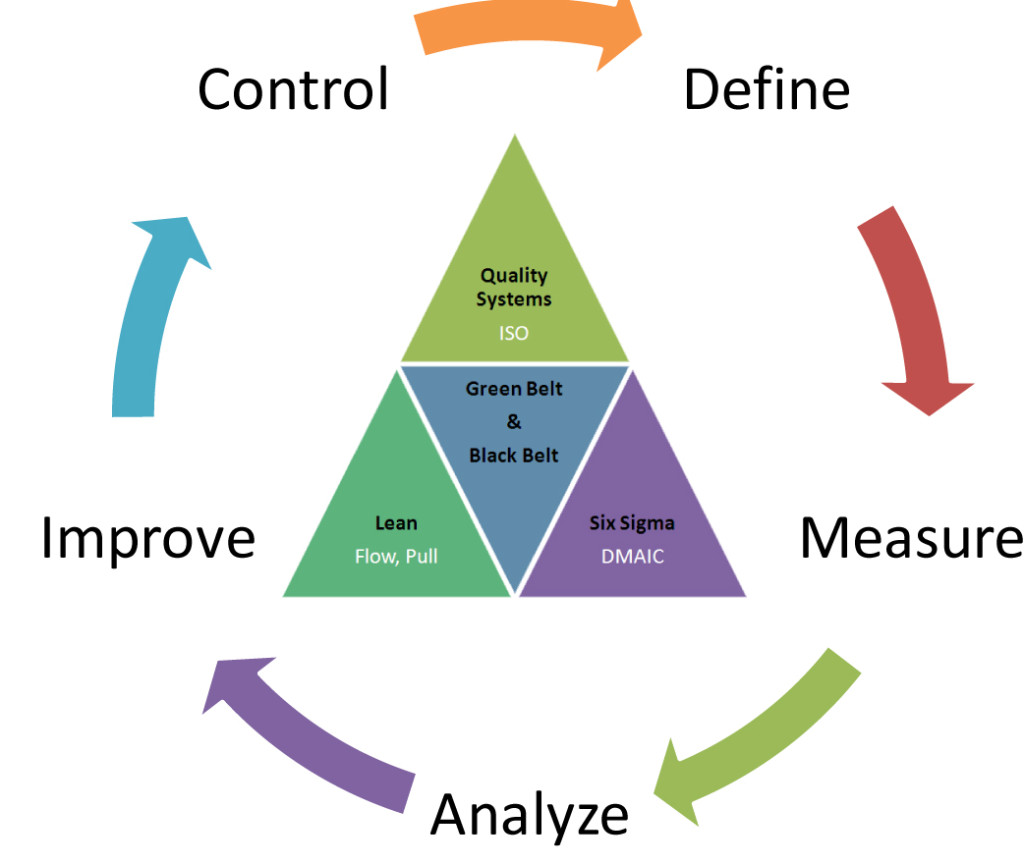

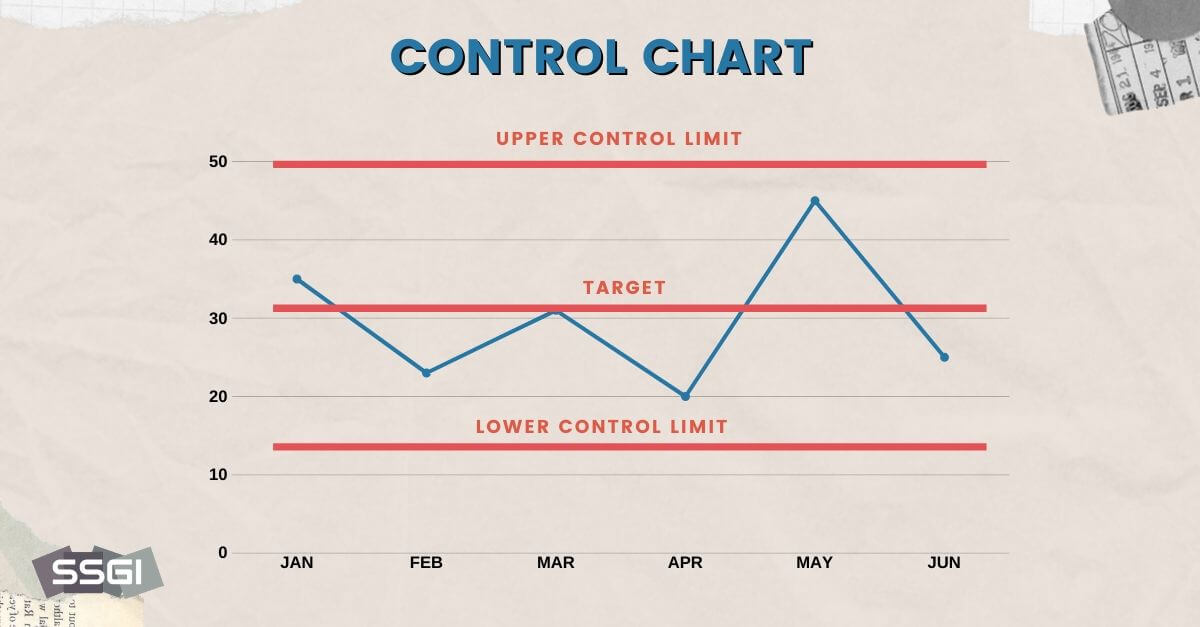

6 Sigma Control Chart - Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. • lcl line shows the lower control limit. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable variations and controlled/correctable variations in a system. Web control charts are a key tool used in the six sigma methodology. Web control charts play a crucial role in the six sigma methodology by enabling statistical process control (spc). They are used extensively during the measure and analyze phases of the dmaic approach to understand process capabilities and identify sources of variation. They help you measure and track process performance, identify potential problems, and determine corrective actions. Total sales = sum(sales[extendedamount]) 2. Special cause variation, as distinct from common cause variation, refers to changes in process performance due to sporadic or rare events indicating that a process is not “in control.”. Web six sigma control charts are an essential tool in the six sigma methodology, allowing businesses to monitor their processes and identify any variations or defects. The charts help us track process statistics over time and help us understand the causes of the variation. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable variations and controlled/correctable variations in a system. It aims to reduce variation and defects in products or services and to achieve near. • lcl line. I then used dax formulas and power bi visuals to arrive at this six sigma chart. • lcl line shows the lower control limit. Control charts are a great tool for monitoring your processes over time. Control charts help a user to identify special causes of variation, shifts, trends and cycles. Web a six sigma control chart is a simple. Donald wheeler, or shewhart charts by some practitioners named after walter shewhart. Web the five phases of the six sigma method, known as dmaic, are defining, measuring, analyzing, improving, and controlling. They help you measure and track process performance, identify potential problems, and determine corrective actions. Web here is a list of some of the more common control charts used. This allows us to see how the process behaves over time. Web control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting when a process is out of control. Web the method to create six sigma control charts in power bi. Control charts are a great tool for monitoring your processes over. It aims to reduce variation and defects in products or services and to achieve near. Web six sigma terms. I then used dax formulas and power bi visuals to arrive at this six sigma chart. Web six sigma control charts are known as process behavior charts. Web the method to create six sigma control charts in power bi. It shows data points in a time series or a sequence, with a centreline indicating the process average and upper and lower limits representing acceptable variation. Control charts are a great tool for monitoring your processes over time. • ucl line shows the upper control limit. This way, you can easily see variation. The charts help us track process statistics. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. Web posted by ted hessing. The charts help us track process statistics over time and help us understand the causes of the variation. • lcl line shows the lower control limit. Read. • lcl line shows the lower control limit. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. Web six sigma control charts are an essential tool in the six sigma methodology, allowing businesses to monitor their processes and identify any variations. Creating a control chart requires a graph that covers a period of time, a center line that shows the results of a process during that time, and upper and lower control limits that indicate whether process variation is within. Web the main focus of control charts is to detect and monitor the process variation. The charts help us track process. Creating a control chart requires a graph that covers a period of time, a center line that shows the results of a process during that time, and upper and lower control limits that indicate whether process variation is within. Web control charts are commonly used in six sigma control today, as a means of overall process improvement. The control limits. Web here is a list of some of the more common control charts used in each category in six sigma: The control limits are ±3σ from the centerline. Special cause variation, as distinct from common cause variation, refers to changes in process performance due to sporadic or rare events indicating that a process is not “in control.”. Web control charts are a key tool used in the six sigma methodology. Web the main focus of control charts is to detect and monitor the process variation. This way, you can easily see variation. Well, it is a graphical tool that helps organisations understand the nature of process variation. A control chart, sometimes referred to as a process behavior chart by the dr. Donald wheeler, or shewhart charts by some practitioners named after walter shewhart. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable variations and controlled/correctable variations in a system. Web posted by ted hessing. While the underlying principle is relatively straightforward, designing an effective chart. Control charts help a user to identify special causes of variation, shifts, trends and cycles. Web the five phases of the six sigma method, known as dmaic, are defining, measuring, analyzing, improving, and controlling.

What is Control Charts in Six Sigma and How to Create them?

6 Sigma Control Chart Introduction Toolkit from Leanscape

Six Sigma DMAIC Process Control Phase Control Chart Selection

What is Six Sigma? Six Sigma Levels Methodology Tools

6 Essential Lean Six Sigma Tools To Use to Maintain The Quality

6 Sigma Control Chart Introduction Toolkit from Leanscape

What is Six Sigma? Six Sigma Levels Methodology Tools

6 Sigma Control Chart Introduction Toolkit from Leanscape

Lean Six Sigma LectureUnderstanding Control ChartsVideo 5 of 7. Xbar

Lean Six Sigma The Definitive Guide (2020) SSGI

It Shows Data Points In A Time Series Or A Sequence, With A Centreline Indicating The Process Average And Upper And Lower Limits Representing Acceptable Variation.

Control Charts Are A Great Tool For Monitoring Your Processes Over Time.

Designing An Effective Cusum Chart.

Web Control Charts Are Used In The Control Phase Of The Dmaic (Define, Measure, Analyze, Improve, And Control) Process.

Related Post: