6013 Welding Rod Amperage Chart

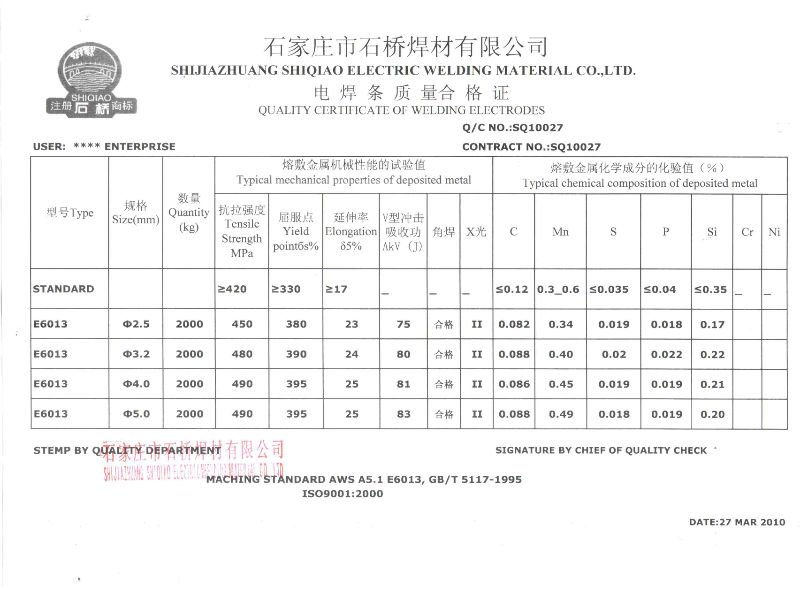

6013 Welding Rod Amperage Chart - Web various parameters have to be considered during welding rod selection; Versatile and easy to run. You might also find our welding calculators useful. Web welding rods compared: Comparison of 6010, 6011, 6013, 7018 and 7024 electrodes. Web our powerful calculator let's you easily determine which stick electrode you need. Plus you'll get the most complete welding rod chart on the internet in pdf! What to consider before selecting a stick welding rod type? 6013 welding rod sizes are 3/32, 1/8, 5/32 and 3/16 inches. High deposition, only suitable for flat and horizontal welds. Web various parameters have to be considered during welding rod selection; Web how to choose welding rod amperage. Web stick welding recommended amperages for electrodes by type and diameter current range, a electrode diameter (in.) electrode type 6010, 6011 6012 6013 6020. This wide amperage range allows welders to use the 6013 rods for various metal thicknesses and welding positions.. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Using the wrong electrode can lead to a bad weld and potential part rejection. This wide amperage range allows welders to use the 6013 rods for various metal thicknesses and welding positions. Plus you'll get the most complete. Hence, it is also known as ‘sheet metal rod’, ‘beginners’ rod’ or ‘easy rod’. Versatility and ease of use: E6013 is characterized as follows: Covering type of e6013 electrode. High deposition, only suitable for flat and horizontal welds. 6010, 6011, 6013, 7018 & 7024. Strong welds on clean metal. Web welding rods compared: Relationship between the thickness of the base metal, size of the electrode and the amperage; Repairing excessively machined or damaged mild steel. How to know if you are welding with the wrong amperage? Web table of contents. For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Comparison of 6010, 6011, 6013, 7018 and 7024 electrodes. E6013 is a high titania potassium rod designed for welding sheet metal. Relationship between the thickness of the base metal, size of the electrode and the amperage; Comparison of 6010, 6011, 6013, 7018 and 7024 electrodes. Hence, the rod literally gained the title of ‘easy rod’ and ‘novice rod’. Browse suggested weld parameter settings for stick welding. For example, a 1/8″ 6011 rod would be 100a at its middle amperage. It can be run on ac, dcep and dcen. Web how to choose welding rod amperage. Effect of temperature of base metal on amperage; Signs that you are welding with a. 6010, 6011, 6013, 7018 & 7024. Choosing the correct welding electrode, often called a rod or stick, is a challenging part of stick welding. High deposition, only suitable for flat and horizontal welds. Web stick welding recommended amperages for electrodes by type and diameter current range, a electrode diameter (in.) electrode type 6010, 6011 6012 6013 6020. Web e6012 sizes and amperage range e6013 size and. Signs that you are welding with a. Web e6012 sizes and amperage range e6013 size and amperage chart. Web the tensile strength of the e6013 rod is 60 ksi (414 mpa) and the yield strength is 48 ksi (331 mpa). The e6013 is a vastly used welding rod that is especially good for carbon steel. 6010, 6011, 6013, 7018 &. It can be run on ac, dcep and dcen. How to select amperage for a stick welding rod? Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Chemical and mechanical properties of e6013 rod. Versatility and ease of use: Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Comparison of 6010, 6011, 6013, 7018 and 7024 electrodes. Web table of contents. Versatility and ease of use: Hence, the rod literally gained the title of ‘easy rod’ and ‘novice rod’. When welding with it, you will see a steady and stable arc with low noise. 6010, 6011, 6013, 7018 & 7024. Relationship between the thickness of the base metal, size of the electrode and the amperage; Web the correct amperage for the 6013 welding rod? This wide amperage range allows welders to use the 6013 rods for various metal thicknesses and welding positions. 6013 welding rod sizes are 3/32, 1/8, 5/32 and 3/16 inches. Once you determine these three main variables, you can set your welding machine and start laying a weld bead. It can be run on ac, dcep and dcen. Choosing the correct welding electrode, often called a rod or stick, is a challenging part of stick welding. They provide a stable arc, producing a quiet arc with a smooth bead surface and a fine ripple profile. The welding rod has to match the mechanical properties and chemical composition of the base metal, joint geometry, welding position, cost, and operational condition are also taken into consideration during the selection process.

Tig Welding Amperage Chart

Welding Rod Amp Chart

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Welding

Welding Rod Amperage Chart Pdf

Welding Rod Amp Chart

Welding Rod Amperage Chart Pdf

What are a reasonable rods to use ? Welding Site

Pin by Bill Poole on Metal fabrication Welding and fabrication

Free sample and Easy arc welding electrodes e6013 welding rods e6013 BV

Welding Around This Amperage Should Give Good Fusion, No Sticking And Not Too Much Heat.

Web What Material Are You Welding?

E6013 Is A High Titania Potassium Rod Designed For Welding Sheet Metal.

E6013 Is Characterized As Follows:

Related Post: