6H Thread Tolerance Chart

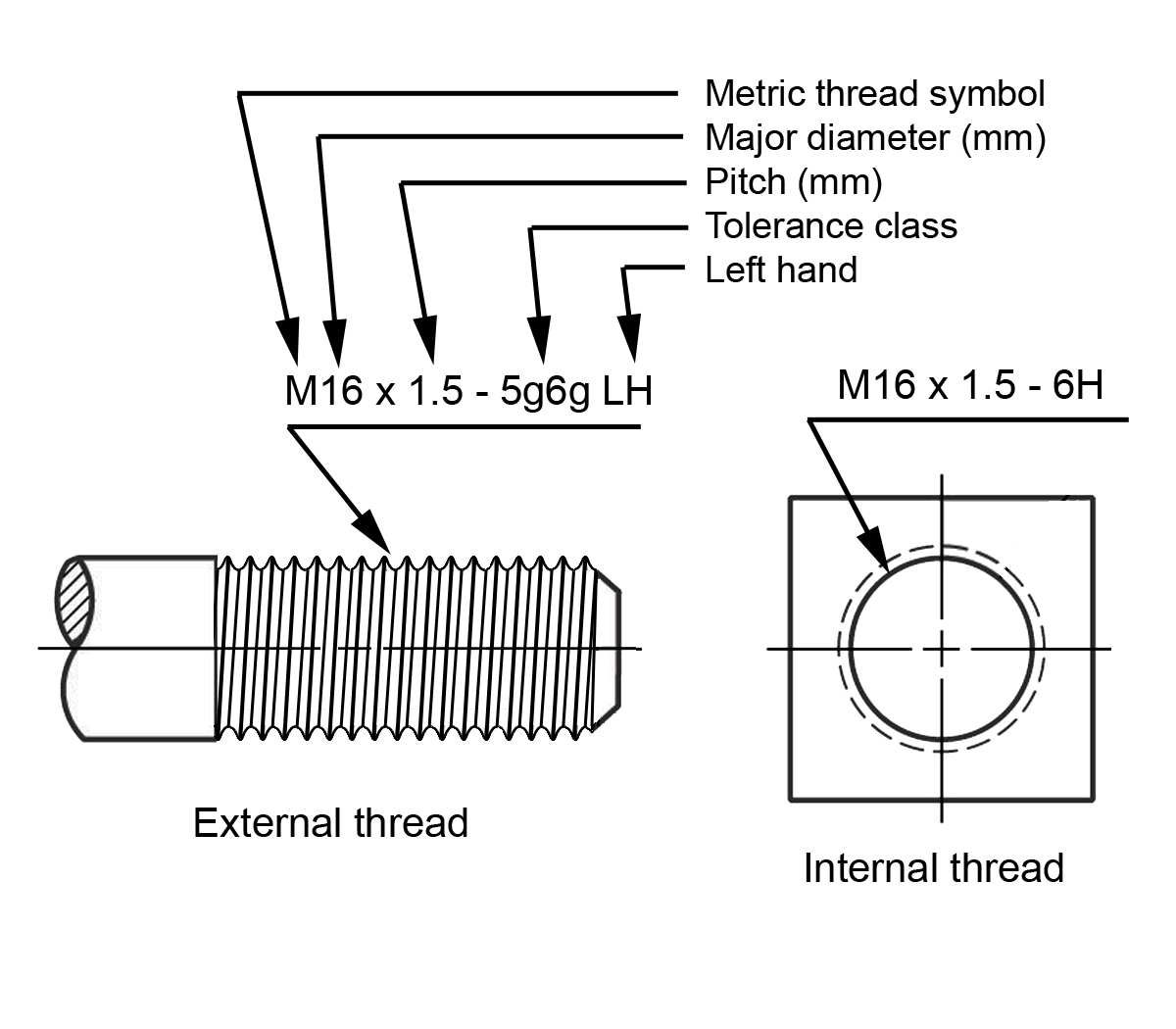

6H Thread Tolerance Chart - To manufacture or measure a thread, one has to know the maximum and minimum permissible values of the basic dimensions. Find your data faster with our fits and tolerance calculator. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks. Web normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Web external thread tolerance classes: Web metric thread calculator to calculate external and internal metric thread dimensions including major diameter, minor diameter, pitch diameter and thread tolerance according to iso. Web this document specifies the conforming limit deviations for pitch and crest diameters for iso general purpose metric screw threads. · 6h tap corresponds to iso 2. Web the metric screw thread is identified by the capital letter m, followed by the nominal diameter. Web normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Web external thread tolerance classes: Green = prefered tolerance classes per iso 286. Web 5.1 internal threads— coarse thread series table 1 tolerance quality: These values are calculated according to the thread class (see below). Normal tolerance classes:6az and6ax thread pitch internal thread p tolerance class pitch. Find out what 6 h and 6 g mean and how they affect the fit. Web the tolerance grades for the following screw thread diameters are standardized: Web the metric screw thread is identified by the capital letter m, followed by the nominal diameter. Web normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw. Web metric thread calculator to calculate external and internal metric thread dimensions including major diameter, minor diameter, pitch diameter and thread tolerance according to iso. Web threads— coarse thread series tolerance quality: Lower tolerance (iso 1) generates a fine fit without a gap on the flanks. Web the tolerance grades for the following screw thread diameters are standardized: Web metric. Web the approved tap tolerance system for metric iso threads is international standard iso 2857. Web this table relates to a medium tolerance grade screw nut combination (6h/6g) which is the grade implied if it is not specified. Web learn how to calculate the values of thread tolerances defined by iso 965/1 for internal and external metric threads. Lower tolerance. Web metric internal thread chart: · 6h tap corresponds to iso 2. Web 94 rows find the limiting dimensions of metric internal threads according to asme. Web the metric screw thread is identified by the capital letter m, followed by the nominal diameter. Find tables for fundamental deviation codes, minor diameter. Find tables for fundamental deviation codes, minor diameter. Web the tolerance grades for the following screw thread diameters are standardized: Web 94 rows find the limiting dimensions of metric internal threads according to asme. Web normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Web the metric screw thread is identified by. Web threads— coarse thread series tolerance quality: Fastener and screw / bolt design, formula and calculations. Web the approved tap tolerance system for metric iso threads is international standard iso 2857. 5h for threads up to and including m1,4. Web normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Find tables for fundamental deviation codes, minor diameter. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks. It applies to screw threads with the recommended. Lower tolerance (iso 1) generates a fine fit without a gap on the flanks. To manufacture or measure a thread, one has to know the maximum and minimum permissible values. Web 94 rows find the limiting dimensions of metric internal threads according to asme. Green = prefered tolerance classes per iso 286. Web the metric screw thread is identified by the capital letter m, followed by the nominal diameter. Web threads— coarse thread series tolerance quality: Find your data faster with our fits and tolerance calculator. Web 94 rows find the limiting dimensions of metric internal threads according to asme. Find out what 6 h and 6 g mean and how they affect the fit. Green = prefered tolerance classes per iso 286. · 6h tap corresponds to iso 2. Find tables for fundamental deviation codes, minor diameter. · 4h tap corresponds to iso 1. Normal tolerance classes:6az and6ax thread pitch internal thread p tolerance class pitch. Web learn how to calculate the values of thread tolerances defined by iso 965/1 for internal and external metric threads. Web this table relates to a medium tolerance grade screw nut combination (6h/6g) which is the grade implied if it is not specified. These values are calculated according to the thread class (see below). Web 94 rows find the limiting dimensions of metric internal threads according to asme. Find out what 6 h and 6 g mean and how they affect the fit. Web normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Web metric internal thread chart: Web a fit between threaded parts is indicated by the internal thread tolerance class followed by the external thread tolerance class separated by a stroke. Web the metric screw thread is identified by the capital letter m, followed by the nominal diameter. Find your data faster with our fits and tolerance calculator. To understand classes, you first need to understand the terms allowance (sometimes referred to as deviation) and. Find tables for fundamental deviation codes, minor diameter. To manufacture or measure a thread, one has to know the maximum and minimum permissible values of the basic dimensions. It applies to screw threads with the recommended.

6h Thread Tolerance Chart

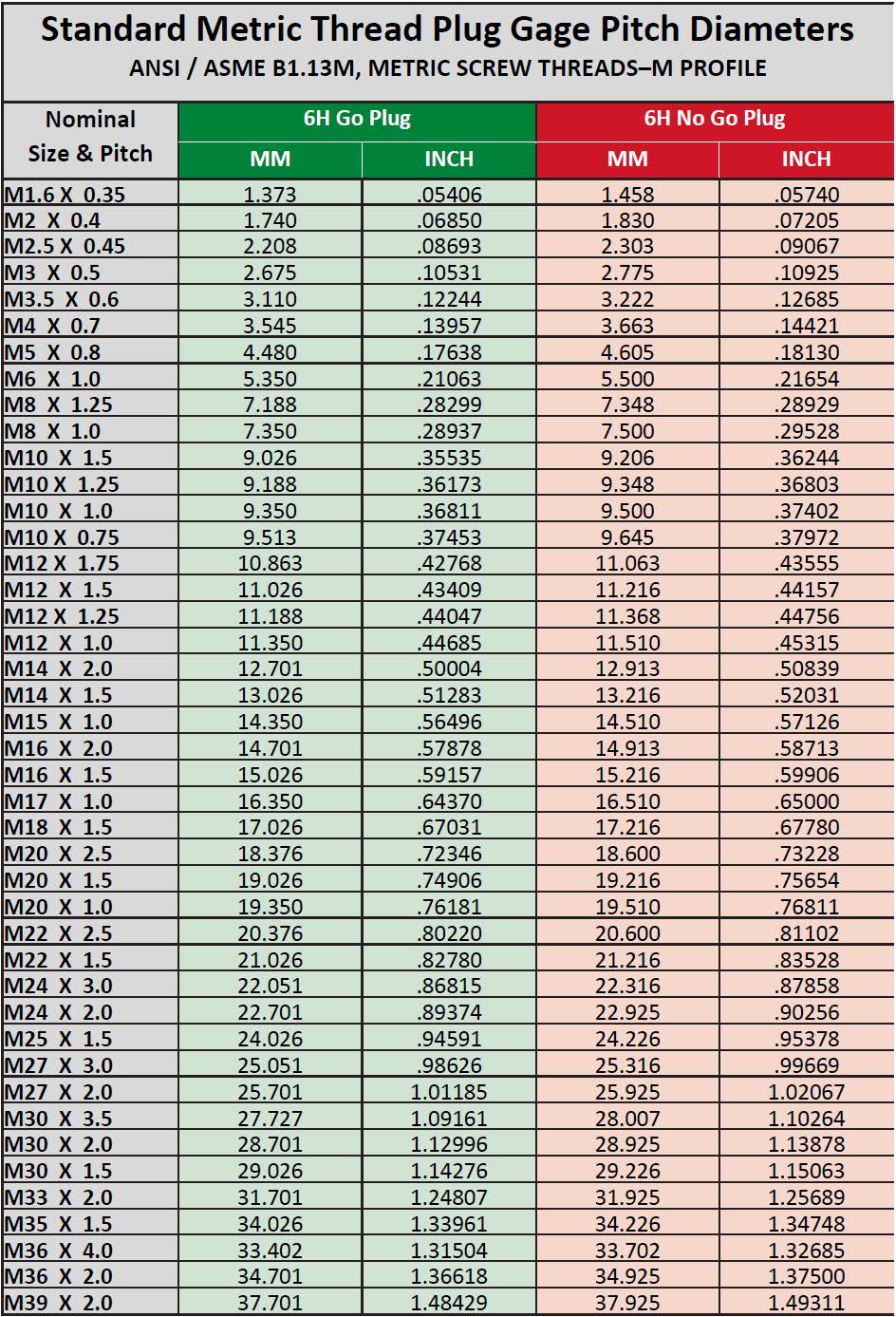

Business, Office & Industrial Industrial Tools Measuring Tools No Go

Iso 8015 Diameter Tolerance Chart

ISO Metric Thread Tolerance Tables Accu 17784 Hot Sex Picture

6h Tolerance Go No Go Thread Plug Gauge Buy Go No Go Gauge,Thread

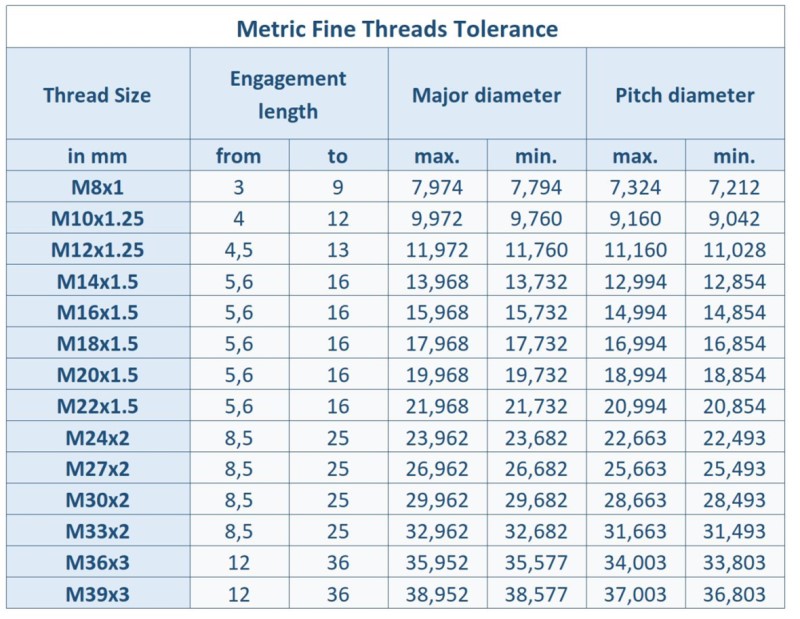

Limits for metric fine threads according to ISO 965

Limits for metric fine threads according to ISO 965 Bossard Group

Limits for metric (standard) coarse threads Bossard Group

6h Thread Tolerance Chart

Metric Thread Tolerance Chart

Lower Tolerance (Iso 1) Generates A Fine Fit Without A Gap On The Flanks.

Green = Prefered Tolerance Classes Per Iso 286.

Bs 3643 Part 1:2007.Iso Metric.

Fastener And Screw / Bolt Design, Formula And Calculations.

Related Post: