Acetylene Torch Settings Chart

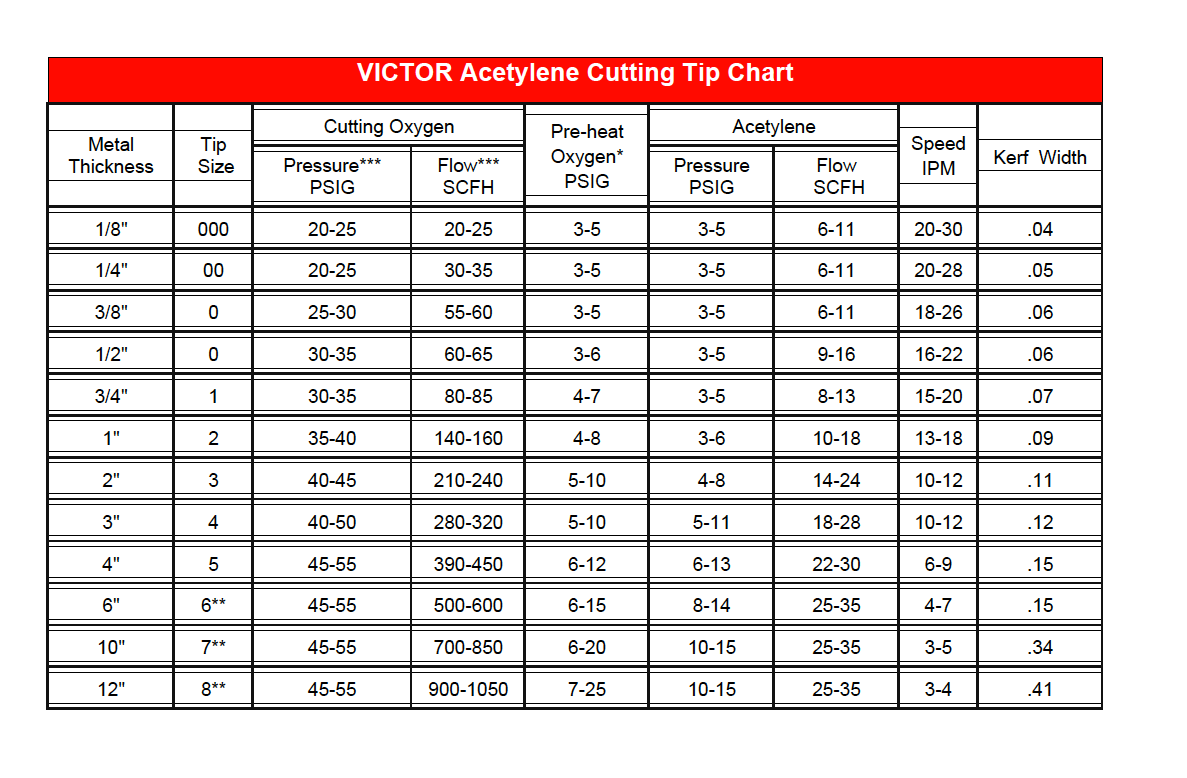

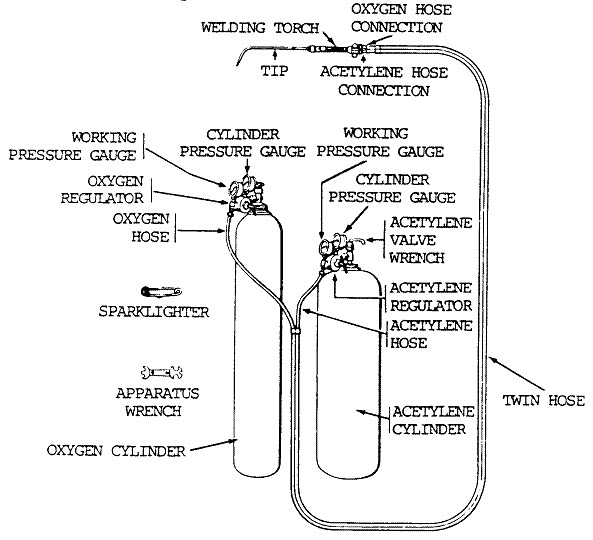

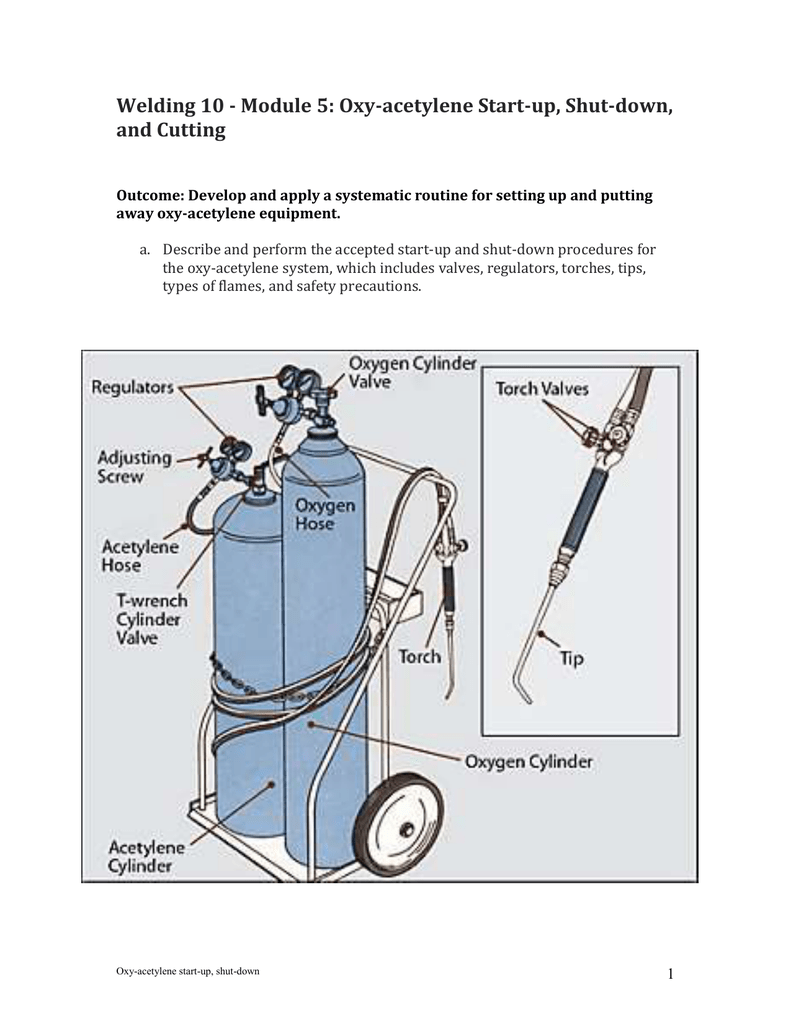

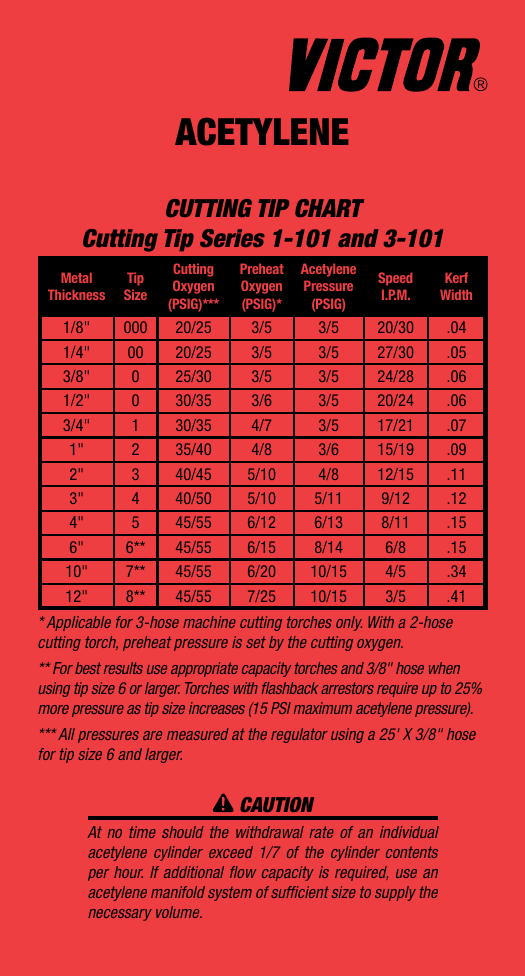

Acetylene Torch Settings Chart - Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. If the gas has out from the nozzle you can use a lighter and light the torch. It’s ideal for cutting and melting metals as it provides maximum heat output. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or commercial gas to provide the preheat flames. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web simply open and close the valves on your fuel cylinder about a quarter of the way each time. The tip size is determined by the orifice for cutting oxygen gas. Connect regulators to your fuel cylinders' valves and ensure they’re tightly screwed in. Tip number metal thickness pressure − psig kerf width consumption − scfh speed ipm drill size cutting oxygen preheat oxygen fuel preheat cutting jet preheat in. It’s ideal for cutting and melting metals as it provides maximum heat output. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. In this article, we will provide you with a comprehensive guide on oxy acetylene cutting torch settings in the year 2023. In addition to these easy to follow. Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. Connect regulators to your fuel cylinders' valves and ensure they’re tightly screwed in. Once everything is assembled, test the. Adjust to the correct flame setting. How to set up and use. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. It’s ideal for cutting and melting metals as it provides maximum heat output. Medium preheat 22 degree v splines for max heat transfer fast piercing/starting 2 piece. Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. In today's video, western welding academy's, colton pfeil, goes through. Rules of thumb for oxy acetylene torch settings. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. You'll also need to connect the gas supplies, like the oxygen and the acetylene hoses, to the torch. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to. In today's video, western welding academy's, colton pfeil, goes through the components of a cutting torch, how to set it up and clean it after use. A larger tip will generate more heat, while a. It’s ideal for cutting and melting metals as it provides maximum heat output. Pure oxygen is used for the cutting jet and it's mixed with. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. Assemble the torch by attaching the oxygen and acetylene regulators, hoses, and torch handle. You will see the steps to connect the hoses, regulators, tanks and torch, as well as how to adjust the gas flow and. Best oxy acetylene torch kit. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. Web this article covers the standard type of cutting torch which is an acetylene torch set up. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to. An oxidizing flame has excess oxygen and appears bluish. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. The third open valve in the torch is the first acetylene after that you can open the oxygen valve. The recommended setting is for the fuel gas regulator to be set at 10. Once everything is assembled, test the. Setting the correct working pressures. An oxidizing flame has excess oxygen and appears bluish. Use the right tip size for every job. Web learn how to set up an oxy acetylene cutting torch in this informative video. If the gas has out from the nozzle you can use a lighter and light the torch. You will see the steps to connect the hoses, regulators, tanks and torch, as well as how to adjust the gas flow and. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. An oxidizing flame has excess oxygen and appears bluish. Web simply open and close the valves on your fuel cylinder about a quarter of the way each time. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. For a metal thickness over 7’ use 164 styles. By carefully adjusting the gas pressures, flame characteristics, and cutting speed, operators can optimize their. Adjust to the correct flame setting. Tip number metal thickness pressure − psig kerf width consumption − scfh speed ipm drill size cutting oxygen preheat oxygen fuel preheat cutting jet preheat in. This should forcefully blow out any trapped debris, allowing you to operate your torch without fear. You'll also need to connect the gas supplies, like the oxygen and the acetylene hoses, to the torch. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. How to set up and use. Web whether you are a professional welder or a diy enthusiast, understanding the correct settings is essential for optimal performance and safety.

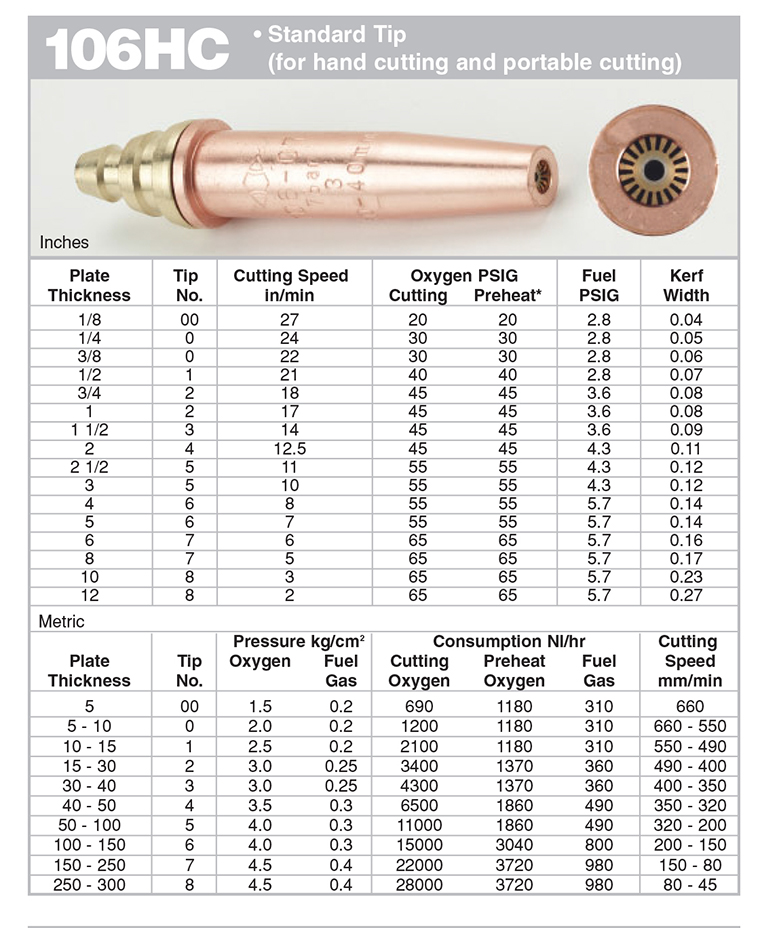

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

4 Best Images of Victor Acetylene Cutting Tip Chart Victor Acetylene

Oxy Acetylene Torch Tip Chart

Cutting Torch Guide

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Victor Torch Tip Chart A Visual Reference of Charts Chart Master

Oxy Acetylene Torch Tip Chart

In Today's Video, Western Welding Academy's, Colton Pfeil, Goes Through The Components Of A Cutting Torch, How To Set It Up And Clean It After Use.

The Third Open Valve In The Torch Is The First Acetylene After That You Can Open The Oxygen Valve.

Tip Sizes Are Often Labeled Differently Depending On The Manufacturer, As Companies Have No Industry Standards To Follow.

Keep Your Oxygen Regulator Gauge In Good Condition.

Related Post: