Aluminum Grades Chart

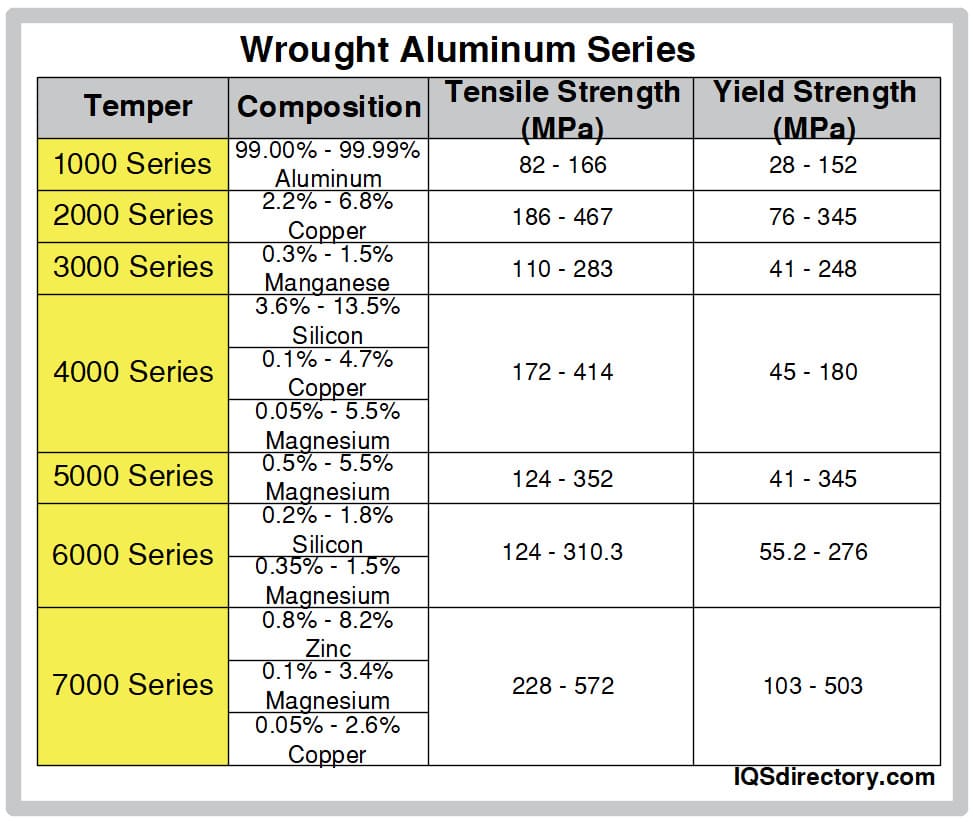

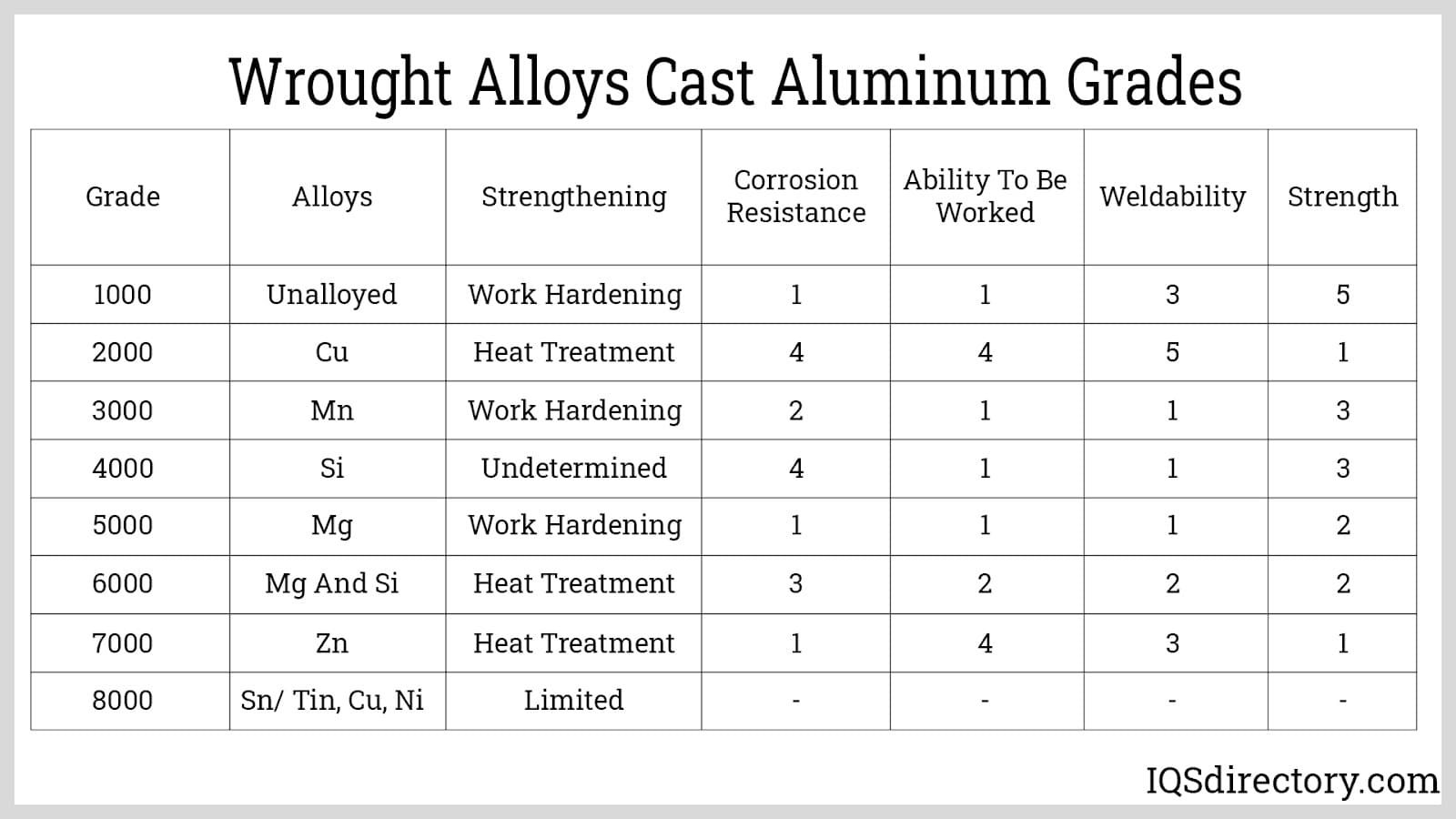

Aluminum Grades Chart - Web aluminium is the world¡¯s most abundant metal. 1xxx indicates that it ispure aluminum series with more than 99% such as 1050 and 1100. Explain each grade so you can be sure the. Numerical designations are assigned in accordance with the recommendation—international designation system for wrought aluminum and wrought aluminum alloys, which is printed on pages 28 through 30. Web use the quick reference chart at the end of this article to quickly and easily find the aluminum grade that is right for you. This material possesses excellent strength, outstanding resistance to corrosion, heat treatability, good weldability, and formability. The versatility of aluminium makes it the most widely used metal after steel. Web there are two types of aluminum alloys — wrought and cast. Various combinations of the main alloying elements with other alloying elements. A commonly used alloy with excellent corrosion resistance and moderate strength, suitable for applications requiring formability and weldability. Web aluminium is the world¡¯s most abundant metal. Web use the quick reference chart at the end of this article to quickly and easily find the aluminum grade that is right for you. Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. Here are some of the most notable ones: Its machinability is not as strong. International brand (using four arabic numerals, now commonly used): When working with aluminium there are currently eight series of grades used to categorise the different types of alloy available. Web aluminium alloy and its recommended end use lm 0 alloy suitable for sand casting, components for electrical, chemical and food processing industries. Aluminum alloys are among the most versatile and. The 3103 alloy, which is stronger than the 1050. Known for its strength, workability, corrosion resistance and ease of joining, aluminum bar grade 6061 is in use across a wide variety of industries and applications. Lightly stressed panels, architectural flashings, name plates, heat exchangers, food and chemical handling and storage equipment, drawn or. The 2000 series grade s are known. It comes in a range of grades, each tailored for specific uses and scenarios. Known for its strength, workability, corrosion resistance and ease of joining, aluminum bar grade 6061 is in use across a wide variety of industries and applications. Its machinability is not as strong as in the 2000 series. Web representation of alloy grades. Aluminum alloys are second. Web wrought aluminum alloys registered with the aluminum association. Known for its strength, workability, corrosion resistance and ease of joining, aluminum bar grade 6061 is in use across a wide variety of industries and applications. This material possesses excellent strength, outstanding resistance to corrosion, heat treatability, good weldability, and formability. In most cases, it can be difficult to choose the. Web grades of aluminum. The 3103 alloy, which is stronger than the 1050. Its machinability is not as strong as in the 2000 series. When choosing an aluminum grade, consider if the following are important factors: Web the choice of aluminum grade depends on your intended use for the sheet metal. 1xxx indicates that it ispure aluminum series with more than 99% such as 1050 and 1100. Lightly stressed panels, architectural flashings, name plates, heat exchangers, food and chemical handling and storage equipment, drawn or. Web representation of alloy grades. A commonly used alloy with excellent corrosion resistance and moderate strength, suitable for applications requiring formability and weldability. Aluminum alloys fall. The 5083 and 6063 among other varieties that are best suited for different applications in the aerospace and construction industry. Its machinability is not as strong as in the 2000 series. Web aluminum comes in three basic types: The 3103 alloy, which is stronger than the 1050. Web aluminium grades with higher levels of corrosion resistance, such as the 5000. In this short guide, we’ll cover everything you need to know to make the right choice, from the different grade series to their applications. Web unless you’re an expert in metals, you probably need aluminium grades explained in simple terms. When choosing an aluminum grade, consider if the following are important factors: Web use the quick reference chart at the. Aluminum alloys are second only to steels in use as structural. When working with aluminium there are currently eight series of grades used to categorise the different types of alloy available. The 3103 alloy, which is stronger than the 1050. Web the following article will cover the different grades of aluminium available, their physical and mechanical properties, and some of. Web wrought aluminum alloys registered with the aluminum association. The versatility of aluminium makes it the most widely used metal after steel. Known for its strength, workability, corrosion resistance and ease of joining, aluminum bar grade 6061 is in use across a wide variety of industries and applications. In most cases, it can be difficult to choose the correct aluminum grade for your intended application. Aluminum alloys are second only to steels in use as structural. Aluminum alloys are among the most versatile and effective materials for designing products for use in various industries. Web there are two types of aluminum alloys — wrought and cast. In this short guide, we’ll cover everything you need to know to make the right choice, from the different grade series to their applications. Web aluminium alloy and its recommended end use lm 0 alloy suitable for sand casting, components for electrical, chemical and food processing industries. Explain each grade so you can be sure the. Web aluminium grades with higher levels of corrosion resistance, such as the 5000 and 7000 series, are preferred for these applications. This material possesses excellent strength, outstanding resistance to corrosion, heat treatability, good weldability, and formability. The 3103 alloy, which is stronger than the 1050. A commonly used alloy with excellent corrosion resistance and moderate strength, suitable for applications requiring formability and weldability. Web aluminum comes in three basic types: Web aluminium is the world¡¯s most abundant metal.

Metal Grades Designations for grading sheet metals

Aluminum Sheet Metal Fabrication T/J Fabricators, Inc.

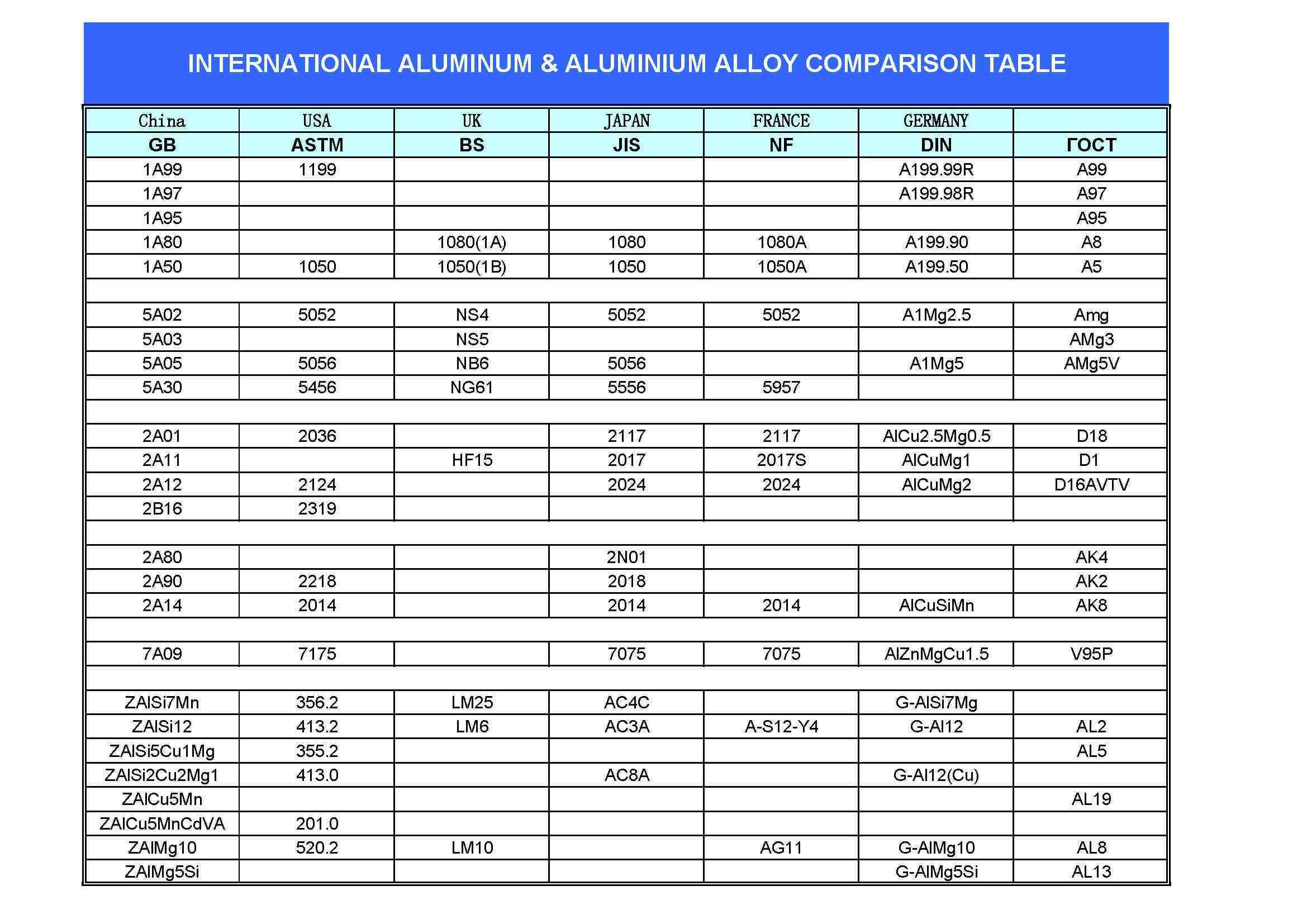

INTERNATIONAL ALUMINUM & ALUMINIUM ALLOY COMPARISON TABLE Technology

Aluminum Aluminum Grades

Aluminium grade Comparison Industries Building Engineering

Aluminum Bar Which Grades Make the Grade? Ryerson

Comparison Chart Aluminium_ USA Popular Grades V Aluminium Chemistry

Types of Aluminum Types, Uses, Features and Benefits

Aluminum Casting What Is It? How Is it Made? Advantages

Aluminum Types Chart A Visual Reference of Charts Chart Master

Web Use The Quick Reference Chart At The End Of This Article To Quickly And Easily Find The Aluminum Grade That Is Right For You.

Numerical Designations Are Assigned In Accordance With The Recommendation—International Designation System For Wrought Aluminum And Wrought Aluminum Alloys, Which Is Printed On Pages 28 Through 30.

Aluminum Alloy 6061 Is One Of The Most Widely Used.

Various Combinations Of The Main Alloying Elements With Other Alloying Elements.

Related Post: