Aluminum Series Chart

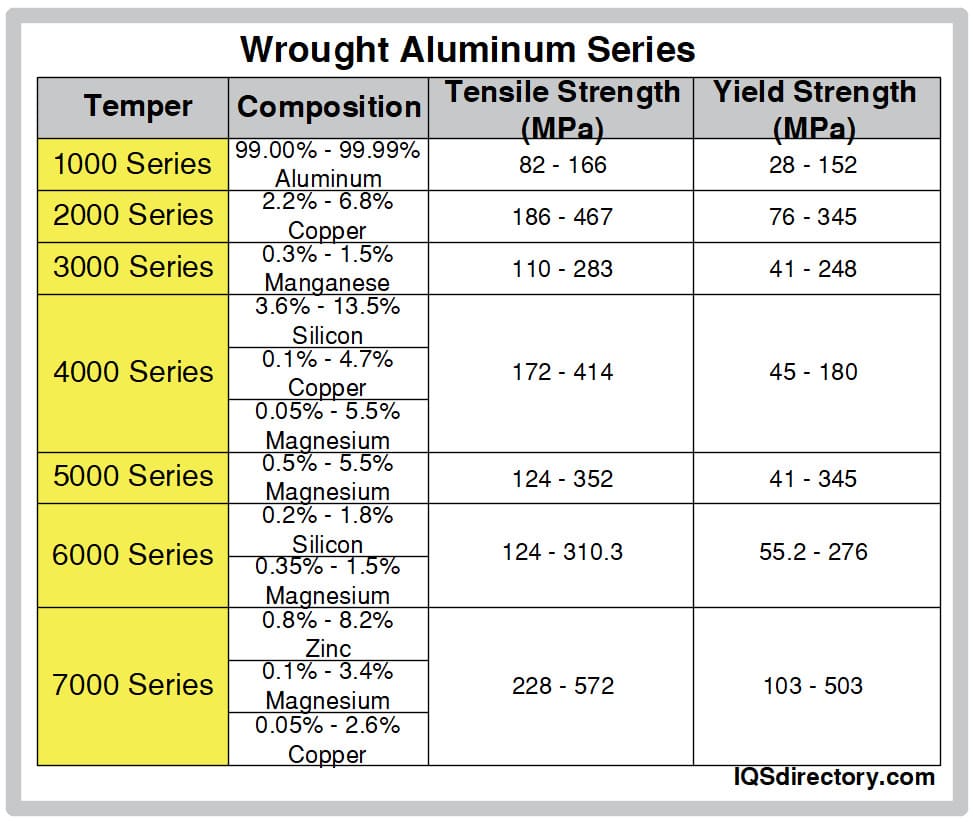

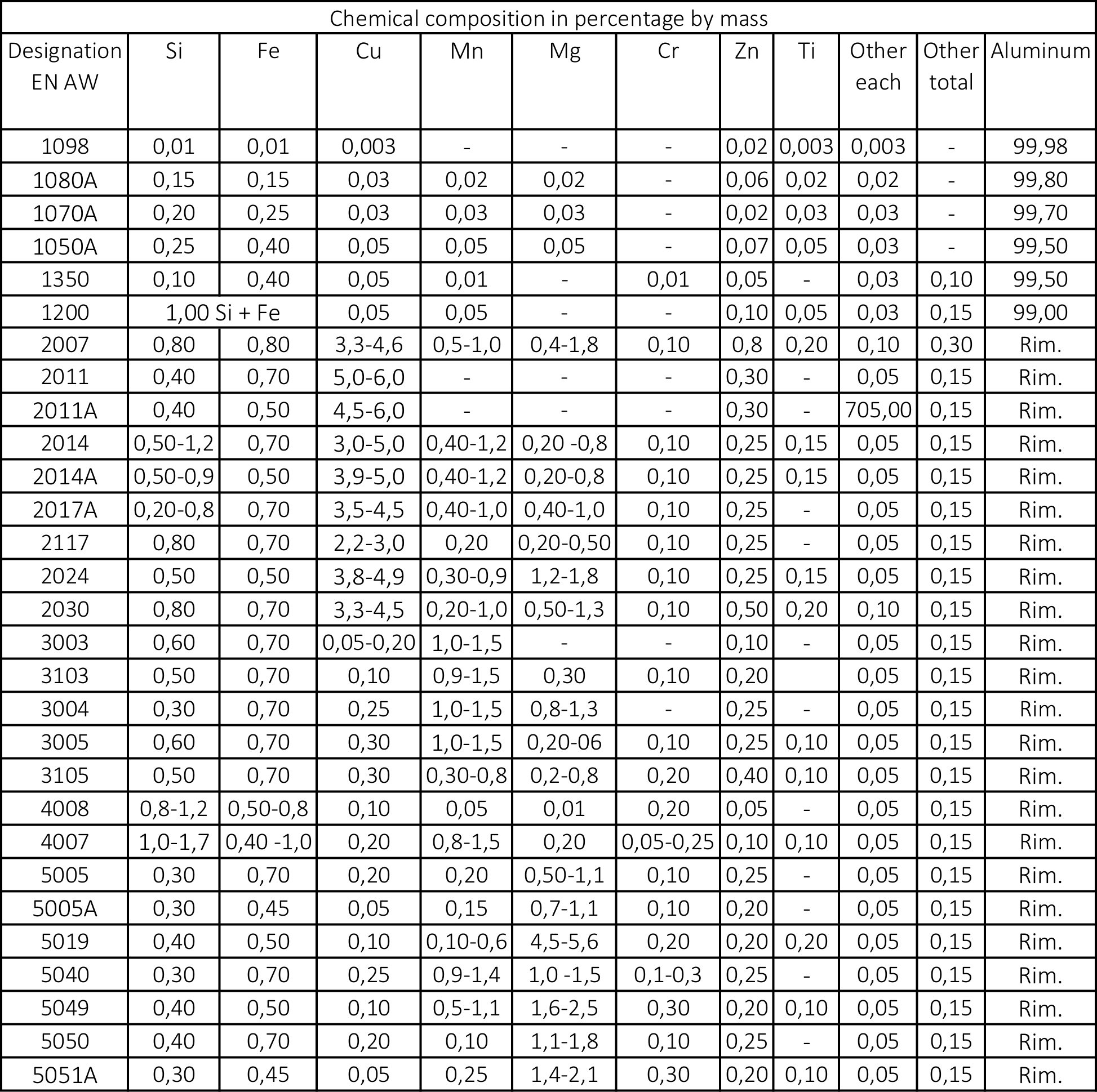

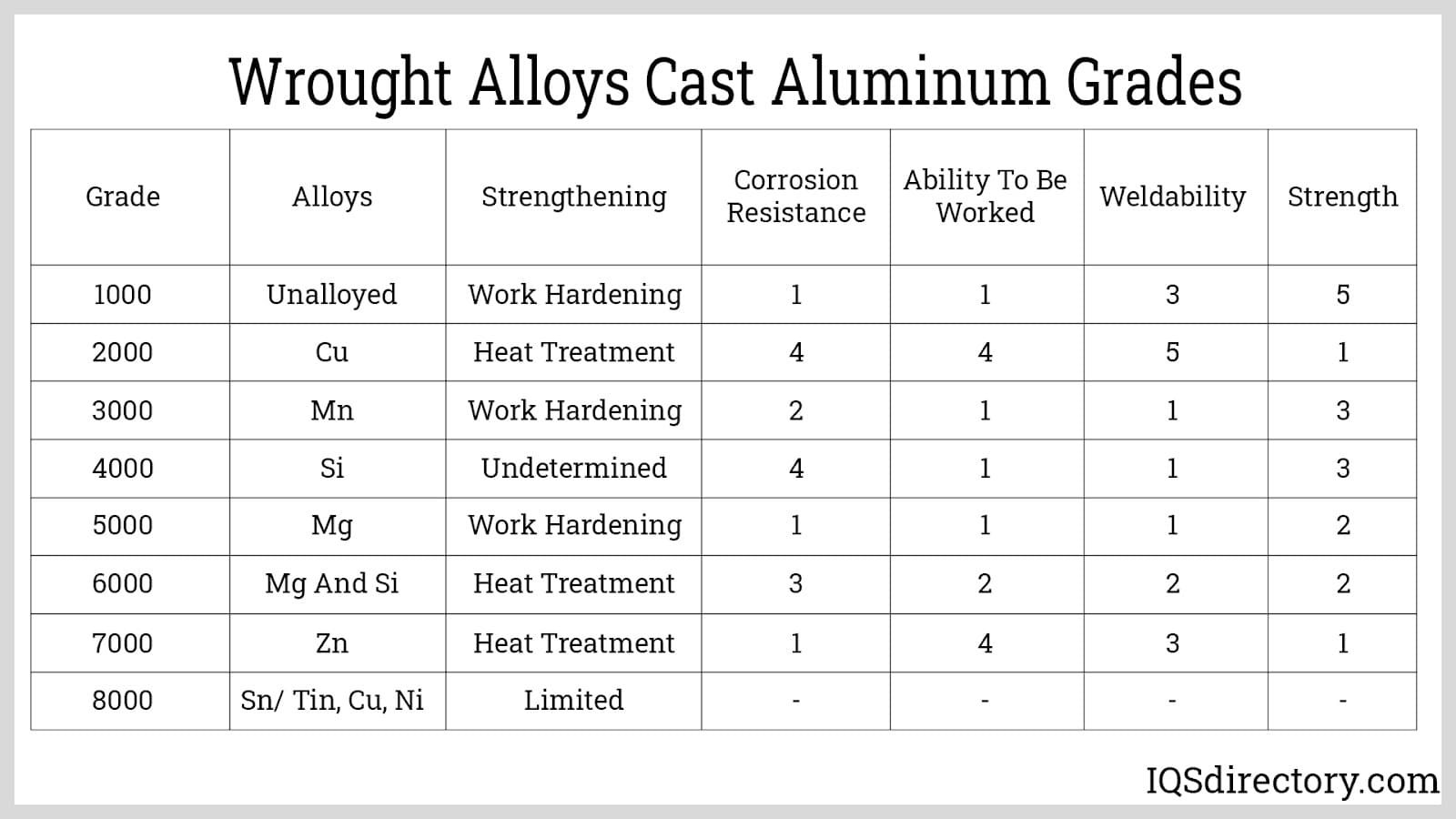

Aluminum Series Chart - These metals are added in specific proportions to achieve the desired properties for a given application. These are essentially pure aluminum and are used for their excellent corrosion resistance. Note the overlaps between alloys of different groups. Aluminum is often selected for its electrical conductivity, Each grade has its own specific applications. Web the first digit (xxxx) indicates the principal or major alloying element, which has been added to the aluminum alloy and is often used to describe the aluminum alloy series, i.e. Few judgment decisions are needed unless there are equal amounts of two or more alloys. Web aluminium alloy and its recommended end use lm 0 alloy suitable for sand casting, components for electrical, chemical and food processing industries. Web the following table shows which are the main alloying elements for each cast aluminum series, as well as the main characteristics that highlight each series and some example applications: The 6000 series includes both magnesium and silicon. For example, 1000 series aluminium alloys are the purest form of aluminium, with 99% aluminium content. Each grade has its own specific applications. These characteristics make it ideal for aluminum extrusions. How the system is applied. See spelling differences) is an alloy in which aluminium (al) is the predominant metal. For example, 1000 series aluminium alloys are the purest form of aluminium, with 99% aluminium content. Aluminum alloys fall into two main classifications: Web the chart below shows different alloy series and what makes them unique. Have you ever wondered how aluminum goes from being a mineral to becoming those shiny sheets and bars we see in various products? The. Web the following table shows which are the main alloying elements for each cast aluminum series, as well as the main characteristics that highlight each series and some example applications: Web according to the processing method, aluminum alloy can be divided into deformed aluminum alloy and cast aluminum alloy, and the serial number of aluminum and aluminum alloy is mainly. Aluminum grades are metrics that aim to differentiate the specific alloy compositions, hardening processes, and heat treatability of unique types of aluminum. For example, 1000 series aluminium alloys are the purest form of aluminium, with 99% aluminium content. Industry standards for aluminum casting alloys have been governed by many different documents for many years. How the system is applied. These. Web the wrought aluminum series names elements with four numerical digits where the first digit represents the principal alloying element, the second digit indicates a modification of a specific alloy, and the third and fourth digits are arbitrary numbers assigned to specific alloys in the series. Web according to the processing method, aluminum alloy can be divided into deformed aluminum. Web here are some common aluminum alloy series: Web the chart below shows different alloy series and what makes them unique. These metals are added in specific proportions to achieve the desired properties for a given application. Web aluminum is available in different grades, each with varying alloying elements and properties. So, you must know the differences between these aluminum. Web understanding the identification system for wrought and cast aluminum and what each series number says about the different characteristics will help you make good choices for your application. Wrought aluminum alloy lookup table. How the system is applied. They are often used for chemical equipment and food processing. Web aluminium alloy and its recommended end use lm 0 alloy. Web the most common grades are 1000, 2000, 3000, 4000, 5000, 6000 and 7000 series. Web the chart below shows different alloy series and what makes them unique. Have you ever wondered how aluminum goes from being a mineral to becoming those shiny sheets and bars we see in various products? Web get insights into the classifications of aluminium alloys.. Wrought aluminum alloy lookup table. These are essentially pure aluminum and are used for their excellent corrosion resistance. Have you ever wondered how aluminum goes from being a mineral to becoming those shiny sheets and bars we see in various products? Aluminium has many uses in its purest form, such as electrical busbars and heat exchangers. In general, the aluminum. Aluminum alloys fall into two main classifications: 1000 series, 2000 series, 3000 series, up to 8000 series (see table 1). Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; These classes have distinct identification numbering systems for differentiation. So, you must know the differences between these aluminum alloying grades to choose the right one for your. They are the equivalent to the last two digits after the decimal point when aluminium purity is expressed to the nearest 0.01 percent. Let’s take a dive behind the scenes: Web the following table shows which are the main alloying elements for each cast aluminum series, as well as the main characteristics that highlight each series and some example applications: These classes have distinct identification numbering systems for differentiation. Web the wrought alloy series. Web understanding the identification system for wrought and cast aluminum and what each series number says about the different characteristics will help you make good choices for your application. Web aluminium alloy and its recommended end use lm 0 alloy suitable for sand casting, components for electrical, chemical and food processing industries. Industry standards for aluminum casting alloys have been governed by many different documents for many years. Web here are some common aluminum alloy series: Web the wrought aluminum series names elements with four numerical digits where the first digit represents the principal alloying element, the second digit indicates a modification of a specific alloy, and the third and fourth digits are arbitrary numbers assigned to specific alloys in the series. Web the aluminum association categorized standard aluminum grades based on the primary alloying element (s) and their response to thermal or mechanical treatments. Aluminium has many uses in its purest form, such as electrical busbars and heat exchangers. 1000 series, 2000 series, 3000 series, up to 8000 series (see table 1). Web aluminum is a metal that can be combined with other elements including copper, magnesium, silicon, zinc, and manganese, to alter its mechanical and physical qualities. This guide explores the aluminum alloy types, their features, benefits, and applications. What exactly are aluminum grades?

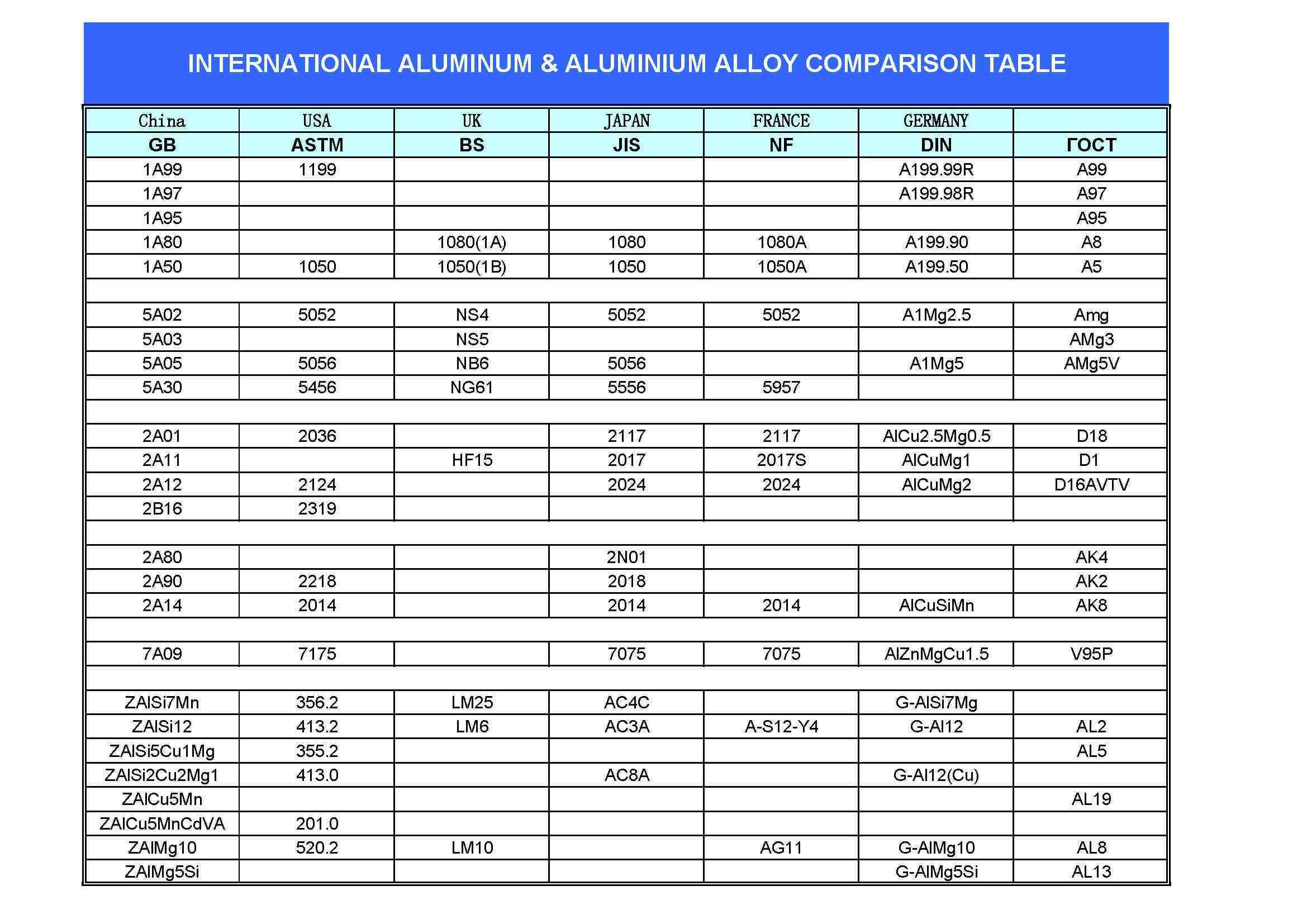

INTERNATIONAL ALUMINUM & ALUMINIUM ALLOY COMPARISON TABLE Technology

Types of Aluminum Types, Uses, Features and Benefits

3003 or 5052 aluminium All MetalShaping

Aluminum Filler Alloy Selection Chart PDF Welding Construction

Aluminum and his alloys Custom Online Laser Cutting

Standard Aluminum Extrusions Shapes Chart

Alloys Superior Extrusion

Aluminum Bar Which Grades Make the Grade? Ryerson

Aluminum Casting What Is It? How Is it Made? Advantages

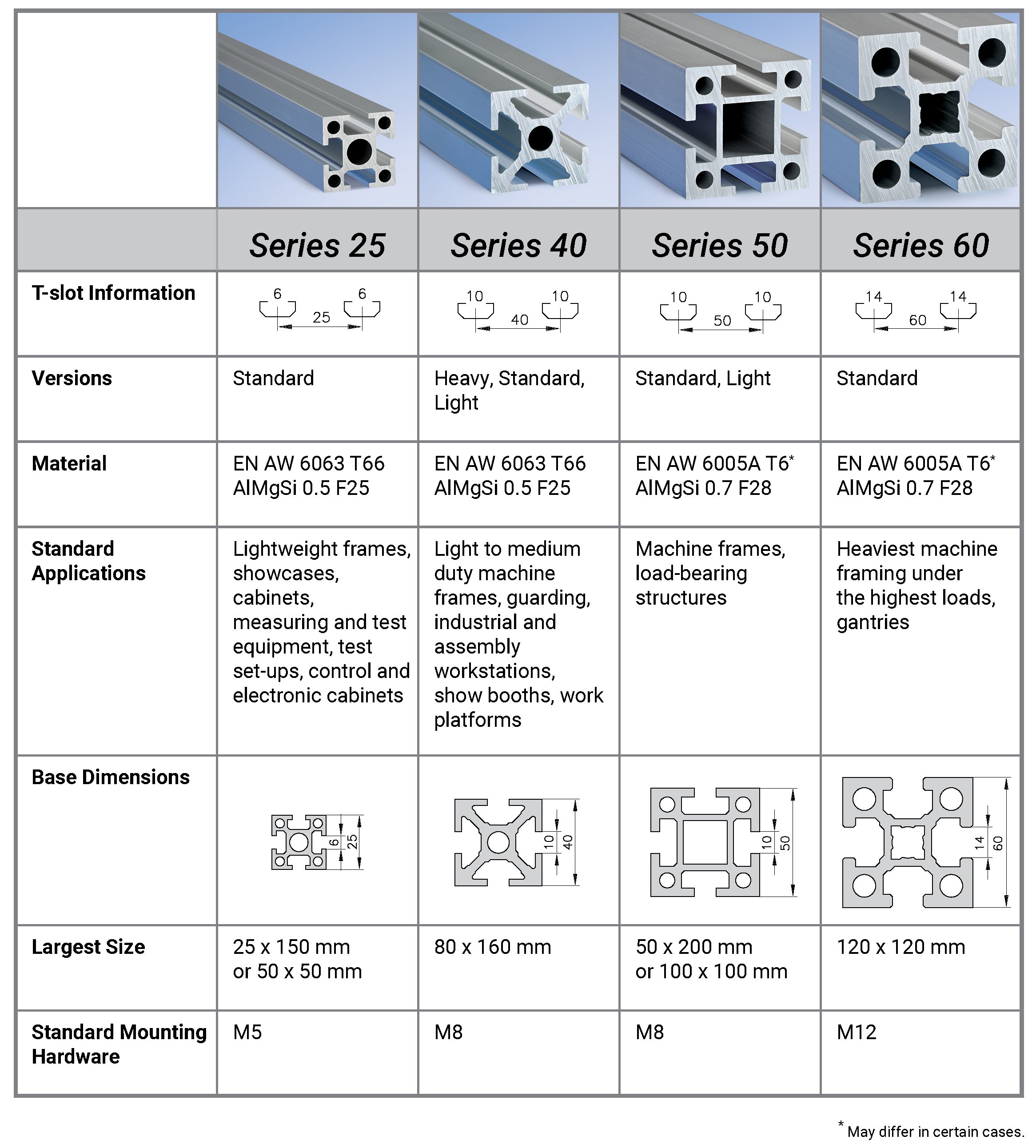

TSlot Aluminum Extrusions Structural Framing Systems mk

Wrought Aluminum Alloy Lookup Table.

Few Judgment Decisions Are Needed Unless There Are Equal Amounts Of Two Or More Alloys.

Note The Overlaps Between Alloys Of Different Groups.

In General, The Aluminum Association (Aa) Is Looked At To Establish The Main Alloy Category Designations.

Related Post: