Ansi Glove Rating Chart

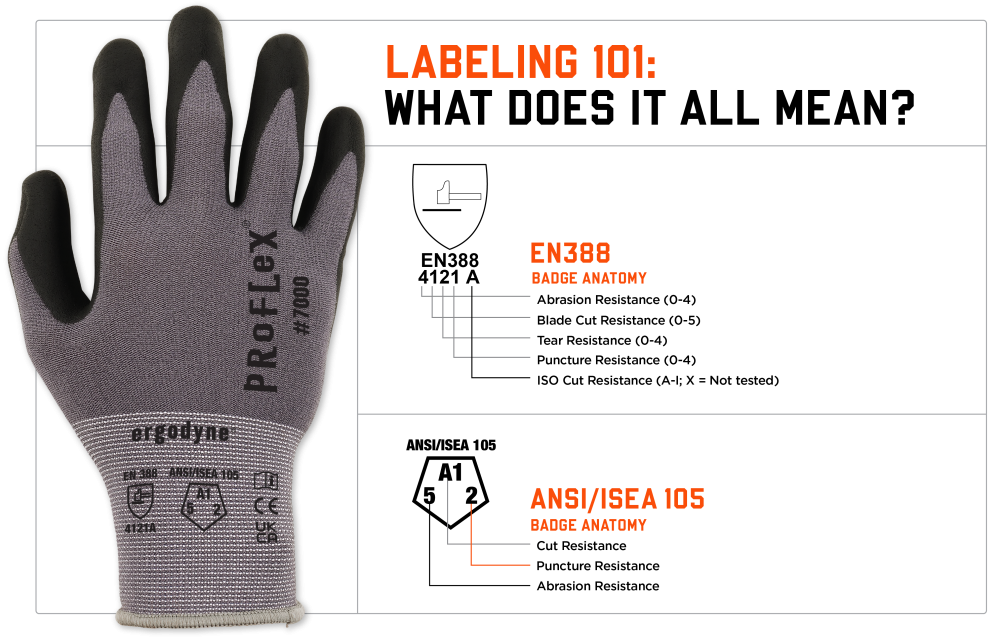

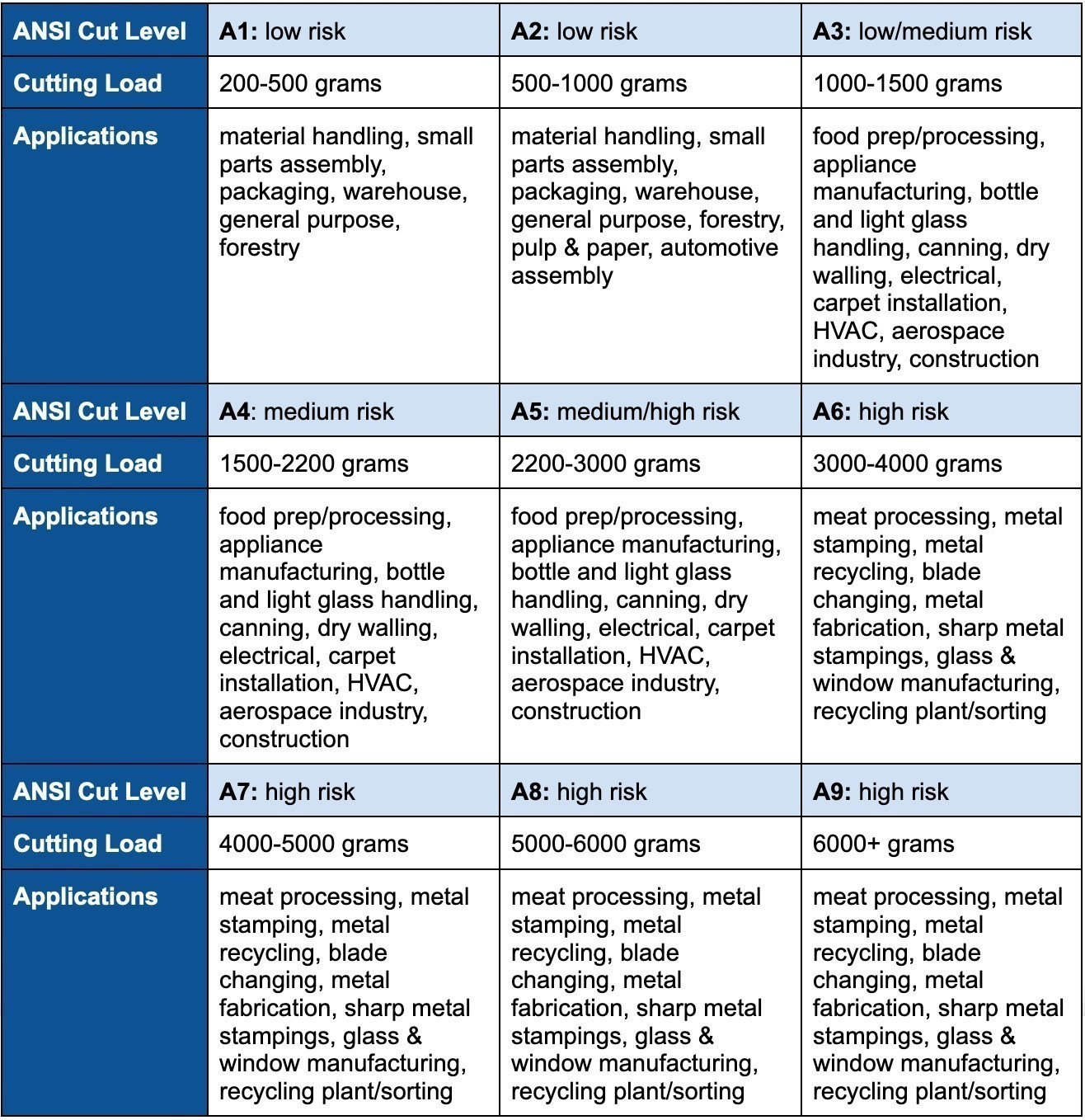

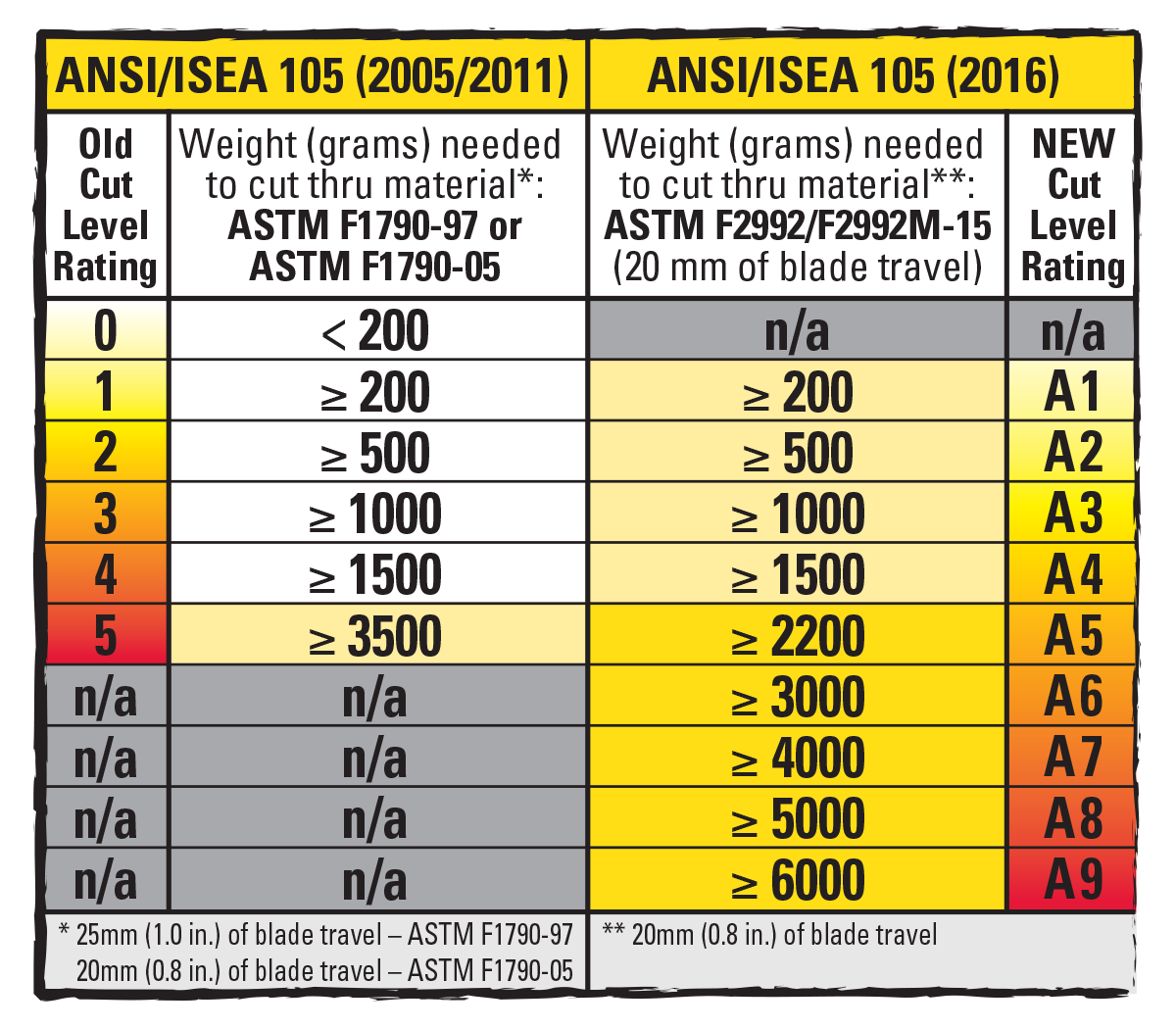

Ansi Glove Rating Chart - Our blog dives into ansi cut levels, from what they mean to how they're determined, plus advice on how to find the right cut level for cut resistant gloves! Ansi/isea 105 puncture testing identifies the performance characteristics of hand and arm protection products against punctures from pointed objects. The standard rates the material between level 1 (under 176°f) and level 5 (608°f). The difference between levels is measured by kilonewtons (kn) that can be seen in. Compare the cut levels, resistance ratings and protection levels for each standard. Web the glove’s rating is determined by the highest contact temperature where time to second degree burn is over 15 seconds and time to pain is over 4 seconds. Look for the new ansi cut score badge throughout the catalog. See the performance levels, test methods and glove markings for different levels of impact resistance. The graph below shows the differences between the old scale and the new scale. Web learn how to understand abrasion resistance levels of gloves according to the ansi/isea 105:2016 standard. See examples of gloves for each level and compare them with the old system. Our blog dives into ansi cut levels, from what they mean to how they're determined, plus advice on how to find the right cut level for cut resistant gloves! It might be difficult to visualize how protective each cut rating is. Appliance manufacturing, light glass handling,. Web learn how to understand abrasion resistance levels of gloves according to the ansi/isea 105:2016 standard. See examples of gloves for each level and compare them with the old system. See testing methods, rating scales, glove labeling and material options. What performance level is appropriate for application needs? Web understanding the ansi cut level chart is crucial for selecting gloves. The ansi/isea 138:2019 standard fills a critical gap in the industrial glove standards infrastructure. See examples of gloves for each level and compare them with the old system. See the chart of abrasion cycles to fail and protection levels for different applications. It could be even harder to pick the right pair of. Ansi/isea 105 and en 388. Compare the cut levels, resistance ratings and protection levels for each standard. It might be difficult to visualize how protective each cut rating is. The original blade cut test score (rating position b) and the new en iso cut resistance score (rating position e). See the performance levels, test methods and glove markings for different levels of impact resistance. See. This chart categorizes gloves from level a1, offering minimal cut resistance, to level a9, designed for the most hazardous environments. What performance level is appropriate for application needs? Ansi/isea 105 puncture testing identifies the performance characteristics of hand and arm protection products against punctures from pointed objects. Metal fabrication & handling, food prep & processing, packaging, electrical, canning, automotive assembly,. This short video offers insights into cut protection and cut resistance levels. This chart categorizes gloves from level a1, offering minimal cut resistance, to level a9, designed for the most hazardous environments. It could be even harder to pick the right pair of. Web this means that if a glove has a performance level of “3” in finger protection and. See the chart of abrasion cycles to fail and protection levels for different applications. What performance level is appropriate for application needs? The standard rates the material between level 1 (under 176°f) and level 5 (608°f). In addition, the number of Web understanding the ansi cut level chart is crucial for selecting gloves that provide adequate protection without compromising on. Web learn about the american standard that sets requirements of gloves to protect the knuckles and fingers from impact forces. Web learn how to understand abrasion resistance levels of gloves according to the ansi/isea 105:2016 standard. Web this means that if a glove has a performance level of “3” in finger protection and a performance level of “2” in knuckle. The new en 388 shield pictogram can report up to 6 separate mechanical performance measures. Ansi/isea 105 puncture testing identifies the performance characteristics of hand and arm protection products against punctures from pointed objects. The difference between levels is measured by kilonewtons (kn) that can be seen in. See the chart of abrasion cycles to fail and protection levels for. Compare the cut levels, resistance ratings and protection levels for each standard. The original blade cut test score (rating position b) and the new en iso cut resistance score (rating position e). What performance level is appropriate for application needs? See examples of gloves for each level and compare them with the old system. These ratings include complementary scores for. The original blade cut test score (rating position b) and the new en iso cut resistance score (rating position e). Web learn how to understand abrasion resistance levels of gloves according to the ansi/isea 105:2016 standard. Web based on the chart below, a1 rated gloves provide the least protection, while a9 provide the greatest. Appliance manufacturing, light glass handling, canning, food processing, metal fabrication, hvac, electrical. Web learn about the american standard that sets requirements of gloves to protect the knuckles and fingers from impact forces. The new ansi standard now features nine cut levels significantly reducing the gaps between each level and better defining protection levels for the cut resistant gloves and sleeves with the highest gram scores. The new en 388 shield pictogram can report up to 6 separate mechanical performance measures. Web gloves rated level 4 in the old range can be rated a4, a5 or a6 in the new range. These ratings include complementary scores for cut performance: The difference between levels is measured by kilonewtons (kn) that can be seen in. Metal fabrication & handling, food prep & processing, packaging, electrical, canning, automotive assembly, packaging. See the chart of abrasion cycles to fail and protection levels for different applications. The standard rates the material between level 1 (under 176°f) and level 5 (608°f). This short video offers insights into cut protection and cut resistance levels. See the performance levels, test methods and glove markings for different levels of impact resistance. The ansi/isea 138:2019 standard fills a critical gap in the industrial glove standards infrastructure.

Ansi Glove Rating Chart

The NEW ANSI/ISEA 1382019 Impact Resistant Glove Standard Workplace

Brass Knuckle Protection Testing and Standards New Ansi Standards for

Ansi Cut Level Chart Printable Templates Free

ANSI 105 & EN 388 CutResistant Glove Standards Explained Ergodyne

What You Need to Know About Puncture Resistant Gloves Feature Friday

Which ANSI Cut Level Glove is Right for You PalmFlex Blog

Ansi Glove Rating Chart

What Do Glove ANSI Cut Ratings Mean???

ANSI / ISEA 138 Impact Standard for Work Gloves Mechanix Wear

Web The Glove’s Rating Is Determined By The Highest Contact Temperature Where Time To Second Degree Burn Is Over 15 Seconds And Time To Pain Is Over 4 Seconds.

This Chart Categorizes Gloves From Level A1, Offering Minimal Cut Resistance, To Level A9, Designed For The Most Hazardous Environments.

Web This Means That If A Glove Has A Performance Level Of “3” In Finger Protection And A Performance Level Of “2” In Knuckle Protection, It Will Overall Be Rated At A Performance Level “2”.

New Scale To Determine Cut Scores.

Related Post: