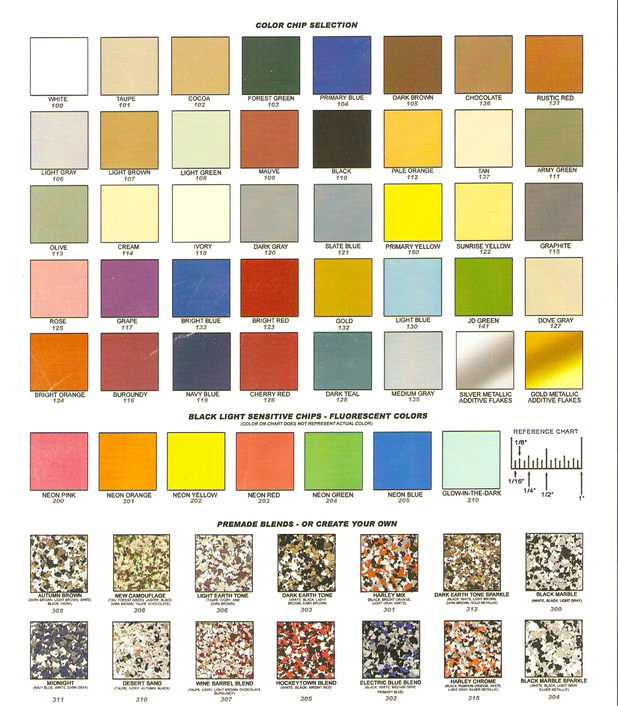

Armorseal Color Chart

Armorseal Color Chart - &ohdu 7loh5hg 'hfn*ud\ +d]h*ud\ and a wide range of tinted colors using &&(frorudqwv. See all armorseal® floor coatings products. Web order color chips, peel & stick or color to go® samples to see how your top color picks look and feel in your space. 31.5% ± 2%, (clear) 41% ± 2%, (colors) (may vary by color) voc (epa method 24): This dries rapidly to a tough, high gloss finish with excellent resistance to alkalies, abrasion, corrosion, and chemical attack. Available in a gloss or satin finish. Web excellent chemical resistance, color retention, and chalk resistance. Web from color options to cleanup methods, armorseap products offer protective & marine: 74% ± 2%, may vary by color voc (epa method 24): 67% ± 2%, white (calculated) may vary by color weight solids: Web data for individual products may vary and is subject to change. 74% ± 2%, may vary by color voc (epa method 24): 43% ± 2%, may vary by color. 41% ± 2%, mixed, may vary by color. Resists disbondment due to moisture vapor transmission (mvt) ease of application. Clear, haze gray, deck gray, white, sandstone, tile red, and wide range of colors possible. Web order color chips, peel & stick or color to go® samples to see how your top color picks look and feel in your space. Order color chips, peel & stick or color to go® samples to see how your top color picks look and. Web data for individual products may vary and is subject to change. 0.83 lb/gal, mixed mix ratio: Recommended spreading rate per coat: 31.5% ± 2%, (clear) 41% ± 2%, (colors) (may vary by color) voc (epa method 24): Web the grenadier guards colours in the age of line tactics, the unit colour was an important rallying point for infantry soldiers. Our full line of armorseal® heavy duty floor coatings will stand up to anything from light foot traffic in retail stores to facilities with heavy vehicular traffic. See all armorseal® floor coatings products. Ensure all required components are purchased for complete product performance. It is designed for use in commercial, industrial and residential fl oor applications. Recommended spreading rate per. • outstanding resistance a wide range of chemical, weather, and. Web from color options to cleanup methods, armorseap products offer protective & marine: 74% ± 2%, may vary by color voc (epa method 24): Web excellent chemical resistance, color retention, and chalk resistance. Available in a gloss or satin finish. 74% ± 2%, may vary by color voc (epa method 24): 67% ± 2%, white (calculated) may vary by color weight solids: 81% ± 2%, may vary by color voc (epa method 24): Clear, white, haze gray, deck gray, sandstone, and a wide range of colors possible volume solids: Our full line of armorseal® heavy duty floor coatings will stand. In military organizations, the practice of carrying colours, standards, flags, or guidons, both to act as a rallying point for troops and to mark the location of the. Armorseal 8100 is the next generation in water based epoxy fl oor coatings; Our full line of armorseal® heavy duty floor coatings will stand up to anything from light foot traffic in. 81% ± 2%, may vary by color voc (epa method 24): Minimum maximum wet mils (microns) 3.0 (75) 4.5 (112) dry. Wet mils (microns) 4.0 100 8.0 200. Developed specifically for sealing, smoothing and fairing applications on concrete, metals, plastics (frp) wood or masonry. Armorseal 8100 is the next generation in water based epoxy fl oor coatings; Minimum maximum wet mils (microns) 3.5 (88) 4.5 (112) dry mils (microns) 1.5 (40) 2.0 (50) ~coverage sq ft/gal (m2/l) 345 (8.4) 460. Web excellent chemical resistance, color retention, and chalk resistance. Order color chips, peel & stick or color to go® samples to see how your top color picks look and feel in your space. 0.83 lb/gal, mixed mix. Armorseal 1000hs (reduced 1 pt/gal with r7k54) 2 cts. • outstanding resistance a wide range of chemical, weather, and. 55% ± 2%, may vary by color. Order color samples pick the perfect sheen See all armorseal® floor coatings products. In military organizations, the practice of carrying colours, standards, flags, or guidons, both to act as a rallying point for troops and to mark the location of the. Minimum maximum wet mils (microns) 3.0 (75) 4.5 (112) dry. J / oe jdo pl[hg. Web from color options to cleanup methods, armorseap products offer protective & marine: 31.5% ± 2%, (clear) 41% ± 2%, (colors) (may vary by color) voc (epa method 24): Wide variety of colors available. 74% ± 2%, may vary by color voc (epa method 24): This product may be topcoated if required. Resists salt water, oils, fuels, and many other chemicals. 41% ± 2%, mixed, may vary by color. 2.8 lb/gal recommended spreading rate per coat: This dries rapidly to a tough, high gloss finish with excellent resistance to alkalies, abrasion, corrosion, and chemical attack. Stitching the standard by edmund leighton (1911), oil on canvas. Order color chips, peel & stick or color to go® samples to see how your top color picks look and feel in your space. Armorseal 8100 is a leed v4.1 compliant material that offers improved performance while maintaining. Web the grenadier guards colours in the age of line tactics, the unit colour was an important rallying point for infantry soldiers.

armorseal tread plex colors Be A Beautiful Weblogs Picture Library

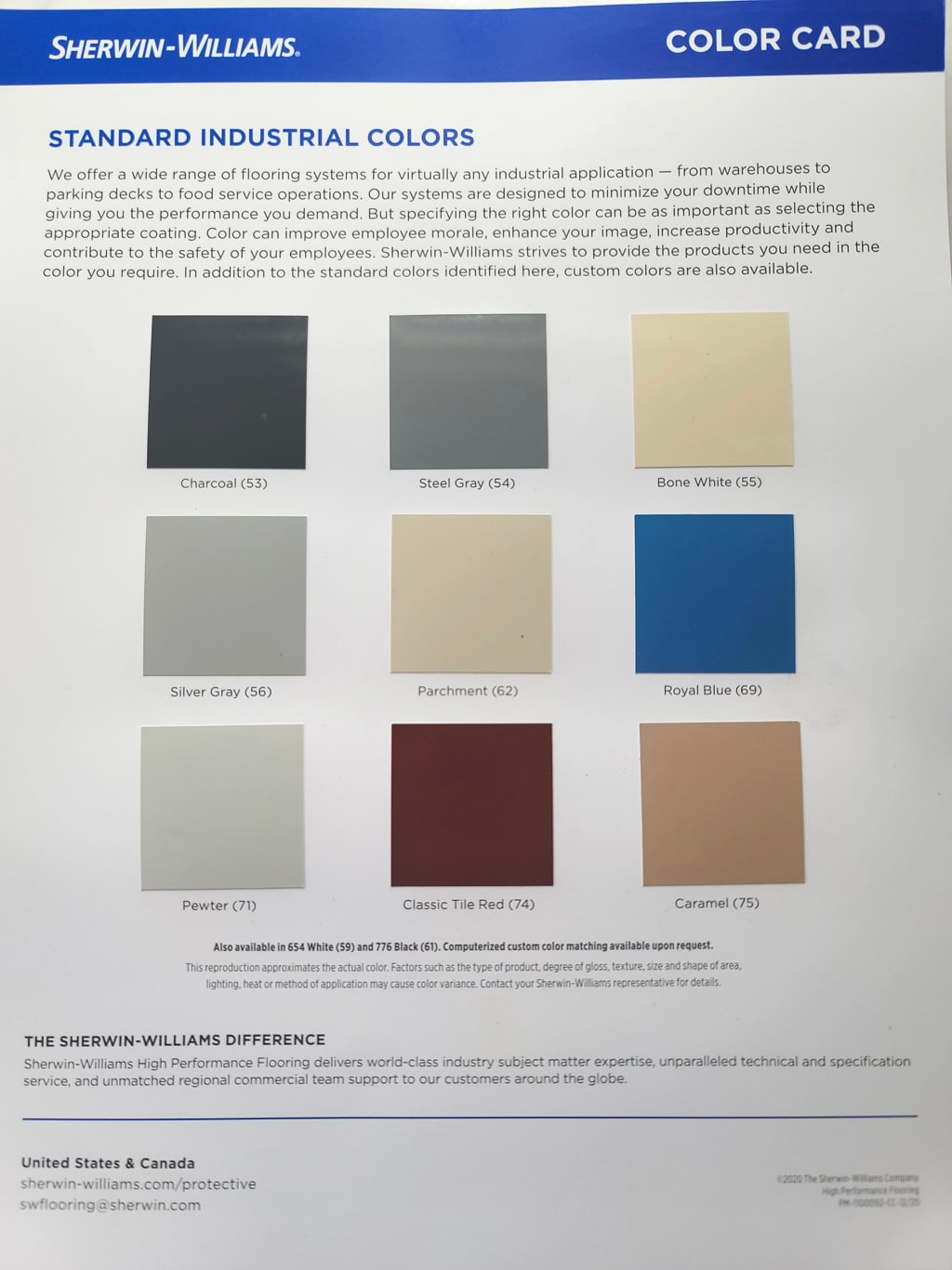

(PDF) ArmorSeal SherwinWilliams · PDF fileEPOXY 1000HS Epoxy 650SL

Armorseal 1000 Color Chart

Armorseal 1000 Color Chart

Armorseal 8100 Color Chart

Armorseal 8100 Color Chart

Armorseal 8100 Color Chart

Armorseal Color Chart

Armorseal Color Chart

Armorseal Color Chart

2 Component, Premeasured 2:1 By Volume.

The Coating Can Also Be Applied To Provide A Nonslip Texture.

Web Data For Individual Products May Vary And Is Subject To Change.

Web Order Color Chips, Peel & Stick Or Color To Go® Samples To See How Your Top Color Picks Look And Feel In Your Space.

Related Post: