Bandsaw Blade Tension Chart

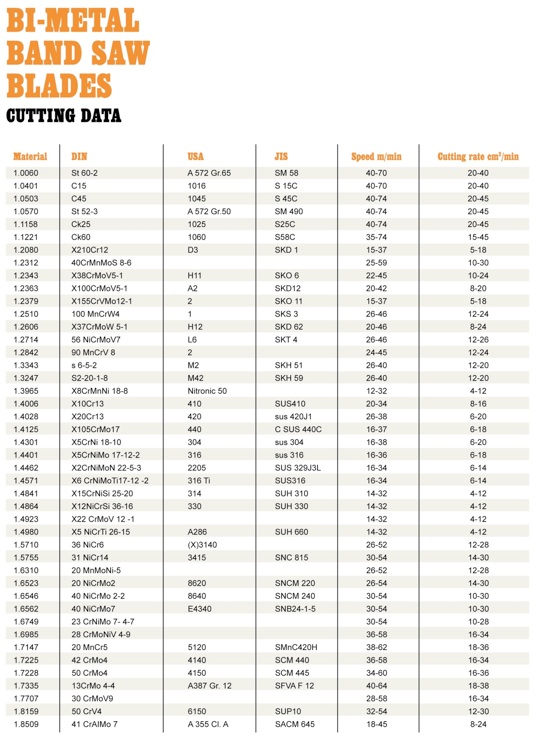

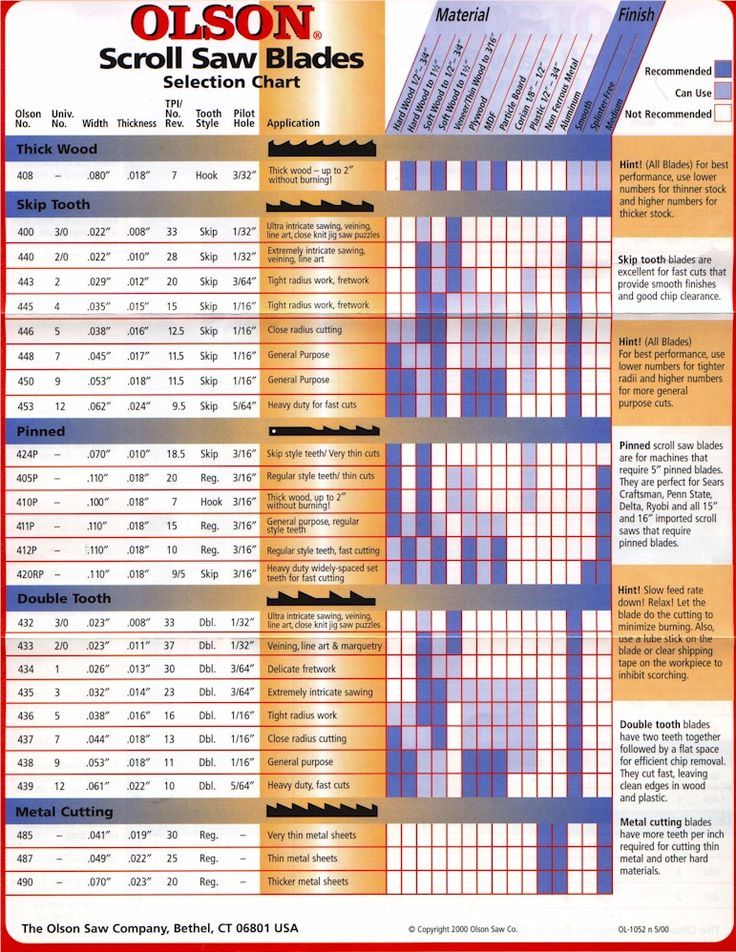

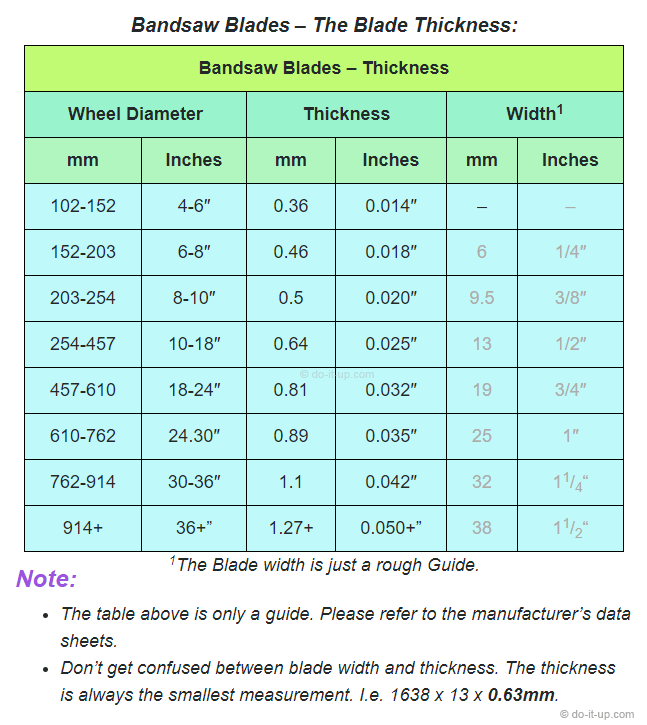

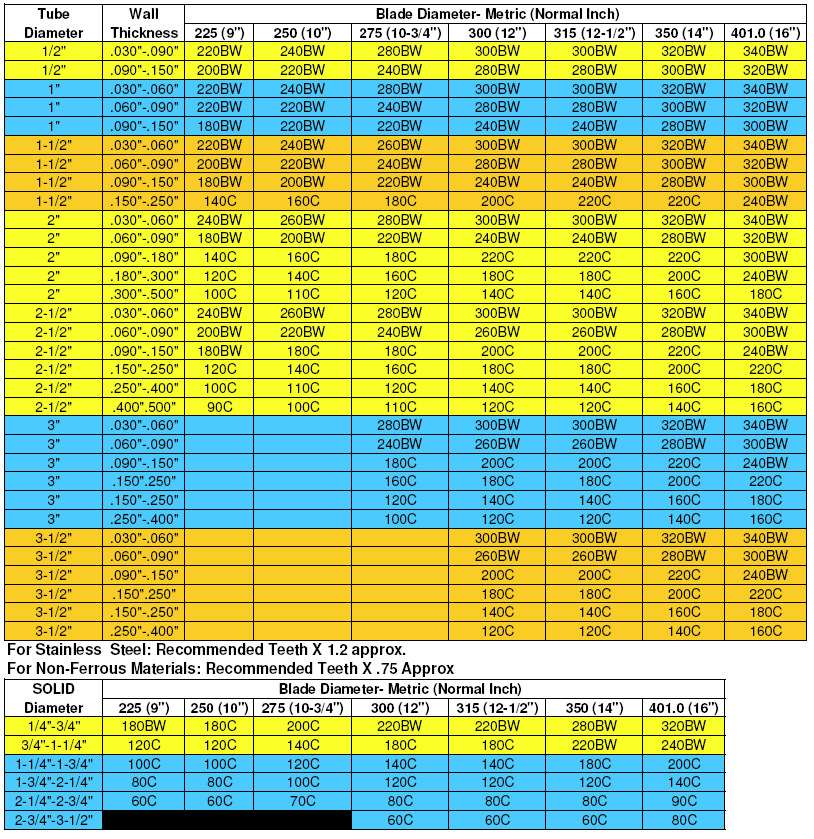

Bandsaw Blade Tension Chart - Web use a commercial gauge or a shop made one to measure the tension of your bandsaw blade. Learn how to tension your bandsaw blade correctly for accurate cuts and improved results. Web to get blade tension just right, simply place your finger on the side of the blade inside the door and push toward the spine of the saw. For example, a ½” x.025 blade requires 312.5 lbs of force to achieve 25,000 psi. Knowing how to properly tension a bandsaw blade is essential, whether you are a professional woodworker, a metal fabricator, or a hobbyist who appreciates the importance of precision in your creations. Allow the blade to run for approximately 30 seconds. 34k views 7 years ago. Web close all covers on the saw. If it deflects significantly more or less, adjust the tension accordingly. The 14 tpi constant pitch blade that comes on the. Web apply the recommended tension for the specific width of blade as per the band saw/band mill manufacturer. Web proper blade tension allows for greater beam strength, and all bandsaw blades — regardless of their width — require the same amount of tension for maximum beam strength. A bandsaw tension gauge is a useful tool for adjusting bandsaw blade tension.. Apply the recommended tension for the specific width of blade as per the band saw/band mill manufacturer. Web close all covers on the saw. Using the bandsaw blade length chart and manually measuring the blade length. Allow the blade to run for approximately 30 seconds. Learn how to tension your bandsaw blade correctly for accurate cuts and improved results. Different materials and cutting requirements may necessitate slight adjustments to the tension. The information below will give you the best blade recommendation in most cases. Feel free to use that as a guideline. Evan, an engineer at grizzly, introduces the topic of tensioning the blade on their band saws. Tension can make or break your blade's performance. Tension can make or break your blade's performance. Consider the material and cut: Web bandsaw blades require tension and lots of it to consistently produce straight, uniform cuts, especially in thick or dense stock. To calculate the material area, choose the tooth, speed and cutting rate, however correct the cutting feed (cutting time), by multiplying the time calculated by the. Tension can make or break your blade's performance. A bandsaw tension gauge is a useful tool for adjusting bandsaw blade tension. Web proper blade tension allows for greater beam strength, and all bandsaw blades — regardless of their width — require the same amount of tension for maximum beam strength. This is the ultimate guide to setting band saw blade. Web how to tension a bandsaw blade. Start the motor or engine on your saw and bring the blade to full cutting speed. 100k views 5 years ago. Web get the best, most efficient performance from your band saw with the proper blade. Most people don't have a gauge to measure psi (pounds per square inch). Allow the blade to run for approximately 30 seconds. Tension can make or break your blade's performance. However, to confirm you’re getting consistent tension readings, you should measure tension during each installation of a new blade on your bandsaw machinery. Using the bandsaw blade length chart and manually measuring the blade length. Few of us can correctly identify a blade's. Web 01 of 09. Including installing and testing the blade. If you're touching the spine with little pressure, the blade is under tensioned. The 14 tpi constant pitch blade that comes on the. Feel free to use that as a guideline. In this section, we will discuss two methods for measuring the bandsaw blade length: Tension can make or break your blade's performance. Most people don't have a gauge to measure psi (pounds per square inch). Using the bandsaw blade length chart and manually measuring the blade length. Start the motor or engine on your saw and bring the blade to. You are looking for around 3/8 (9.5mm) deflection here with moderate pressure. Web close all covers on the saw. Web apply the recommended tension for the specific width of blade as per the band saw/band mill manufacturer. Web how to tension a bandsaw blade. Web 01 of 09. 100k views 5 years ago. Tube or strucutural material cutting. Web a properly tensioned blade should deflect slightly, around 1/4 to 1/2 inch per foot of blade length. Consider the material and cut: After installing a bandsaw blade, it's important to set the blade tension properly. Web bandsaw blades require tension and lots of it to consistently produce straight, uniform cuts, especially in thick or dense stock. Web proper blade tension allows for greater beam strength, and all bandsaw blades — regardless of their width — require the same amount of tension for maximum beam strength. 34k views 7 years ago. For example, a ½” x.025 blade requires 312.5 lbs of force to achieve 25,000 psi. 72k views 8 years ago bandsaws. Evan, an engineer at grizzly, introduces the topic of tensioning the blade on their band saws. Consult this walkthrough whenever you need assistance with properly preparing your hardware before a. Web apply the recommended tension for the specific width of blade as per the band saw/band mill manufacturer. The eztension clamps onto the side of the blade and increases the tension until the magnet releases. Feel free to use that as a guideline. To calculate the material area, choose the tooth, speed and cutting rate, however correct the cutting feed (cutting time), by multiplying the time calculated by the correction factor, according to.

M42 Wood Bandsaw Blades Size UK Guide Tpi Chart Tension for Various

Bandsaw Blade Tension Chart

How to select a band saw blade for maximum productivity

Bandsaw Blade Selection Guide

Find the right blade, right tension, right results Wood

Bandsaw Blade Length Chart

Wood Bandsaw Blade Tpi Chart

Bandsaw Blade Tension Settings Hints & Tips DakinFlathers

Bandsaw Blade Selection Guide

bandsaw blade tension guide

A Bandsaw Tension Gauge Is A Useful Tool For Adjusting Bandsaw Blade Tension.

Web How To Tension A Bandsaw Blade.

Web Knowing The Correct Length Ensures That The Blade Will Fit Properly And Perform Optimally.

Start The Motor Or Engine On Your Saw And Bring The Blade To Full Cutting Speed.

Related Post: