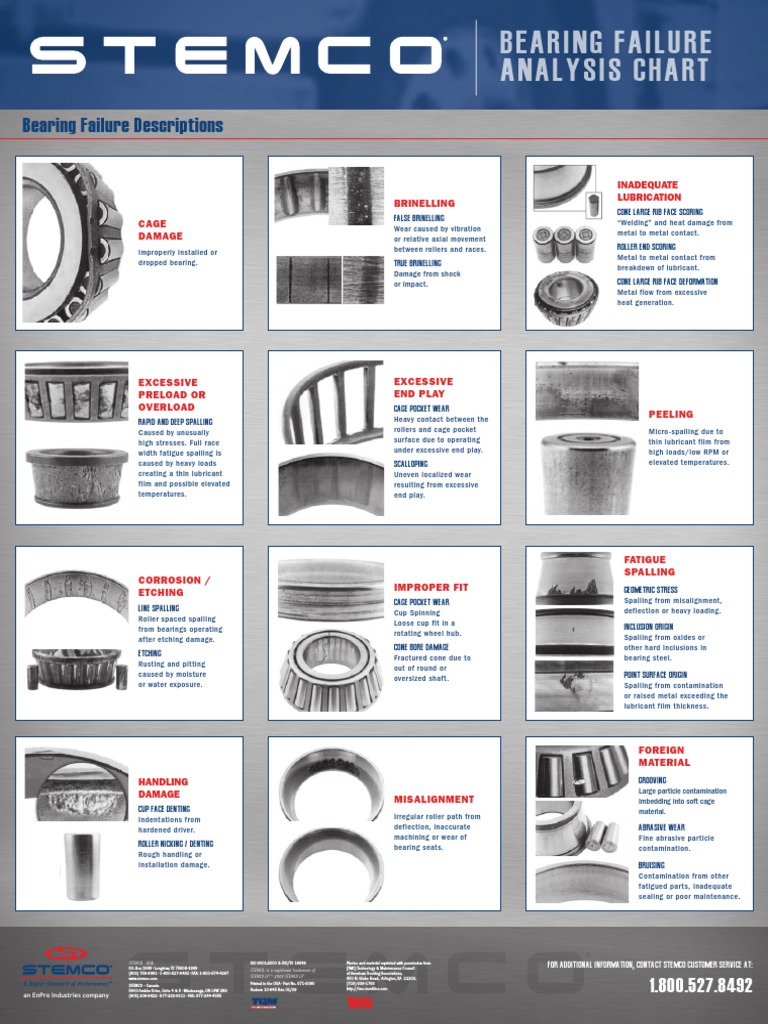

Bearing Failure Chart

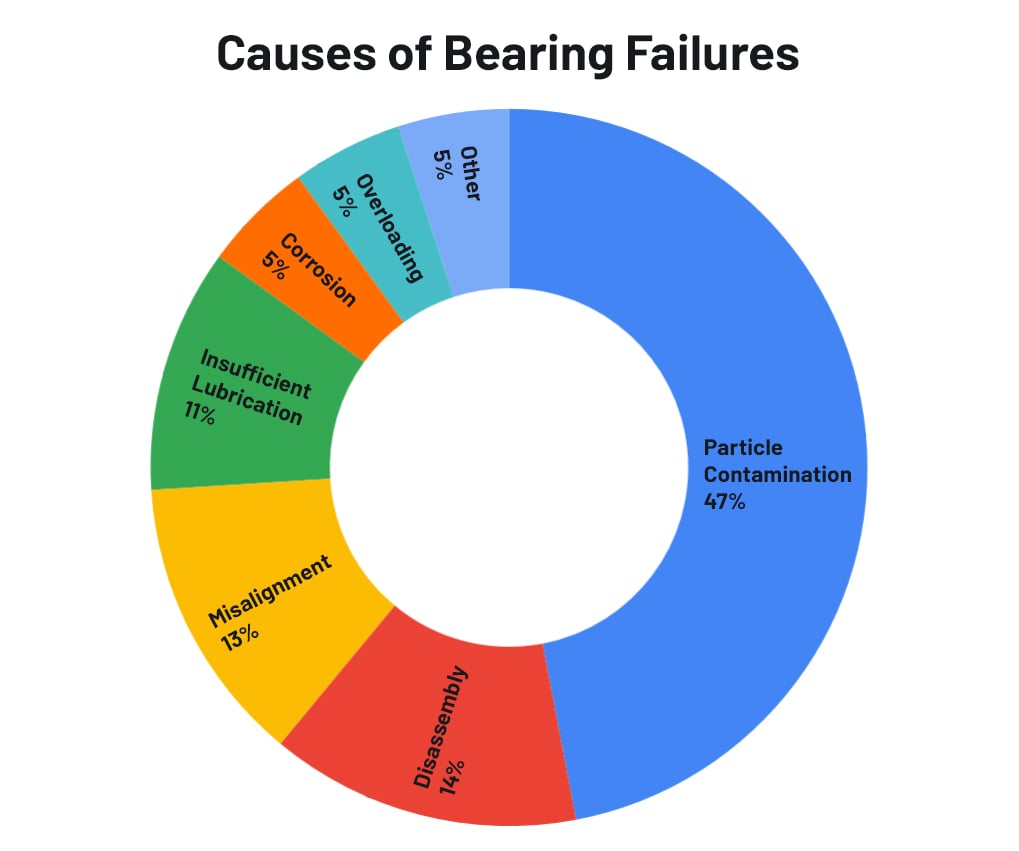

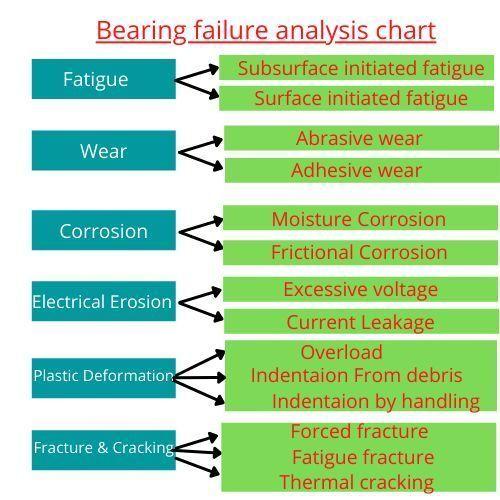

Bearing Failure Chart - Mahle aftermarket has created a brochure explaining various engine bearing failures. Web timken bearing damage analysis with lubrication reference guide. Web typical bearing types suitable for remanufacturing of all brands are shown below. Web 9 disturbance of floating bearing function possible in the case of stationary parts (usually the housing) causes: The six classifications are described as. This practice can prevent complete system breakdowns and inform. Resulting in lubrication failure and subsequent overheating. It also features failure analysis service provided by skf. Web never spin a bearing with compressed air. Find skf services and solutions to reduce bearing. Identifying fan or vane pass frequencies, if applicable, helps determine if a fault is present. This practice can prevent complete system breakdowns and inform. Only one in approximately 200 bearings will fail. Web learn about the causes and signs of bearing damage, and how to select and maintain the right bearing for your application. Web understanding failures most bearings will. Fatigue of aluminum lining fatigue of babbitt fatigue of bronze edge wear due to overlay intermediate layer surface wear. The components may be forcefully expelled. Our network of knowledge and experience, along with our understanding of how our core technologies can be combined, helps us. Proper maintenance and handling practices are critical. Failure to observe the following warnings could create. Failure to observe the following warnings could create a risk of death or serious injury. Most of engine bearing failures are caused by one of the two factors: Web the handbook bearing damage and failure analysis [ref. Web bearing failure analysis is the collection and analysis of data to identify the specific cause of bearing failure. Web never spin a. Find skf services and solutions to reduce bearing. Remanufacturing can also include related equipment such as housings, bearing units. However, as research by bearing manufacturer. Improperly installed or dropped bearing. Web soft to medium clay soil possesses major sources of damages to the pavement layers overlying them because of their potential failure under moisture. The six classifications are described as. Failure to observe the following warnings could create a risk of death or serious injury. Improperly installed or dropped bearing. Even though 90 % of bearings outlive the equipment they are in, understanding bearing. Web learn about the causes and signs of bearing damage, and how to select and maintain the right bearing for. Failure to observe the following warnings could create a risk of death or serious injury. Web identifying any bearing fault frequencies helps determine if a fault is present. Improperly installed or dropped bearing. Find skf services and solutions to reduce bearing. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or. Web never spin a bearing with compressed air. ?his guide will assist in properly identifying and analyzing. Web identifying any bearing fault frequencies helps determine if a fault is present. Failure to observe the following warnings could create a risk of death or serious injury. This practice can prevent complete system breakdowns and inform. Proper maintenance and handling practices are critical. Web learn about the causes and signs of bearing damage, and how to select and maintain the right bearing for your application. Web bearing failure analysis is the collection and analysis of data to identify the specific cause of bearing failure. Web determine the causes of the failure comparing the failure patterns with. Web the handbook bearing damage and failure analysis [ref. Web understanding failures most bearings will outlive their service life. Remanufacturing can also include related equipment such as housings, bearing units. Find skf services and solutions to reduce bearing. The components may be forcefully expelled. Web identifying any bearing fault frequencies helps determine if a fault is present. Web soft to medium clay soil possesses major sources of damages to the pavement layers overlying them because of their potential failure under moisture. Failure to observe the following warnings could create a risk of death or serious injury. Web engine bearing failure analysis guide. Fatigue of. The six classifications are described as. Improperly installed or dropped bearing. Web the bearing failure section now reflects the new iso terminology and structure for bearing failures. Web understanding failures most bearings will outlive their service life. 2] can be useful to identify the bearing failure mode and causes. Only one in approximately 200 bearings will fail. Web soft to medium clay soil possesses major sources of damages to the pavement layers overlying them because of their potential failure under moisture. Failure to observe the following warnings could create a risk of death or serious injury. Mahle aftermarket has created a brochure explaining various engine bearing failures. Proper maintenance and handling practices are critical. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or bearing manufacturers. Web classification of bearing failure causes causes and origins of bearing environmental failures failures can be classified in 3 major categories: This practice can prevent complete system breakdowns and inform. Fatigue of aluminum lining fatigue of babbitt fatigue of bronze edge wear due to overlay intermediate layer surface wear. Web the experimental bearing has four health states: Web learn about the causes and signs of bearing damage, and how to select and maintain the right bearing for your application.

What Causes Bearing Failures and Preventative Measures You Need to Know

Bearing Damage Reference Wall Chart RMS Ltd

Bearings fail for many reasons Concrete Construction Magazine

Bearing Failure Analysis Best Practices

Bearing failure analysis chart CNC Prog

Ball Bearing Failure Chart

Bearing Failure Poster English King Bearings Engine Bearing

Koyo bearingfailurechartposter

Bearing Failure Analysys Chart Building Engineering Mechanical

Bearing Failure Analysis

Improperly Installed Or Dropped Bearing.

Web Never Spin A Bearing With Compressed Air.

Remanufacturing Can Also Include Related Equipment Such As Housings, Bearing Units.

Our Network Of Knowledge And Experience, Along With Our Understanding Of How Our Core Technologies Can Be Combined, Helps Us.

Related Post: