Bolt Torque Chart Printable

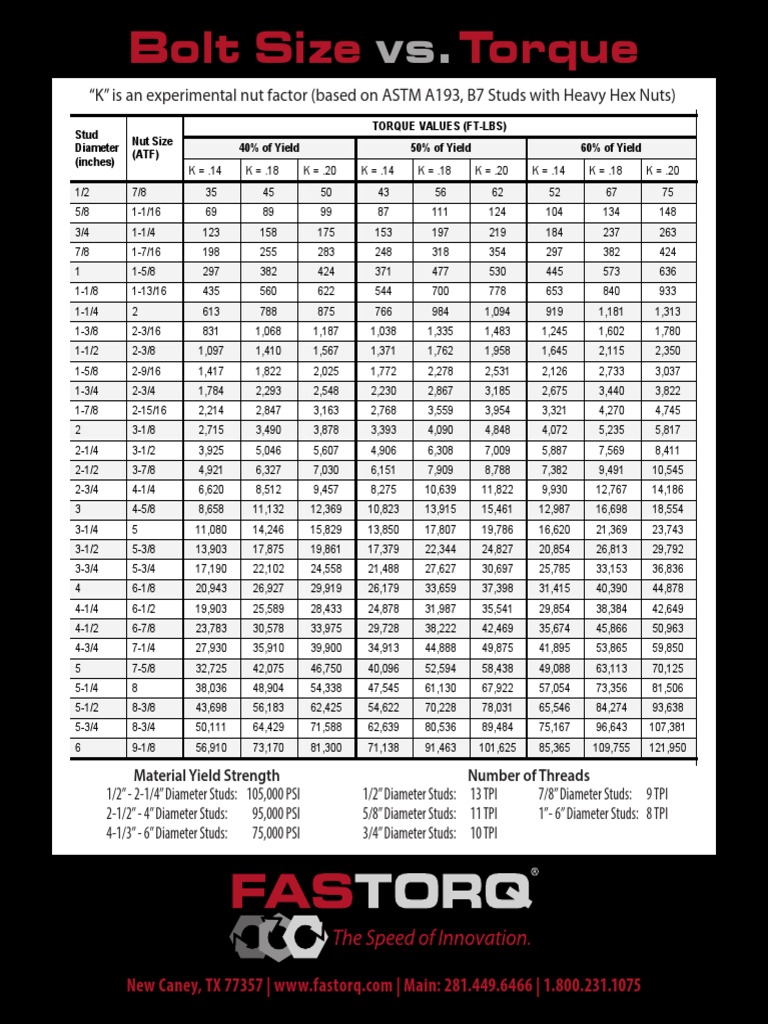

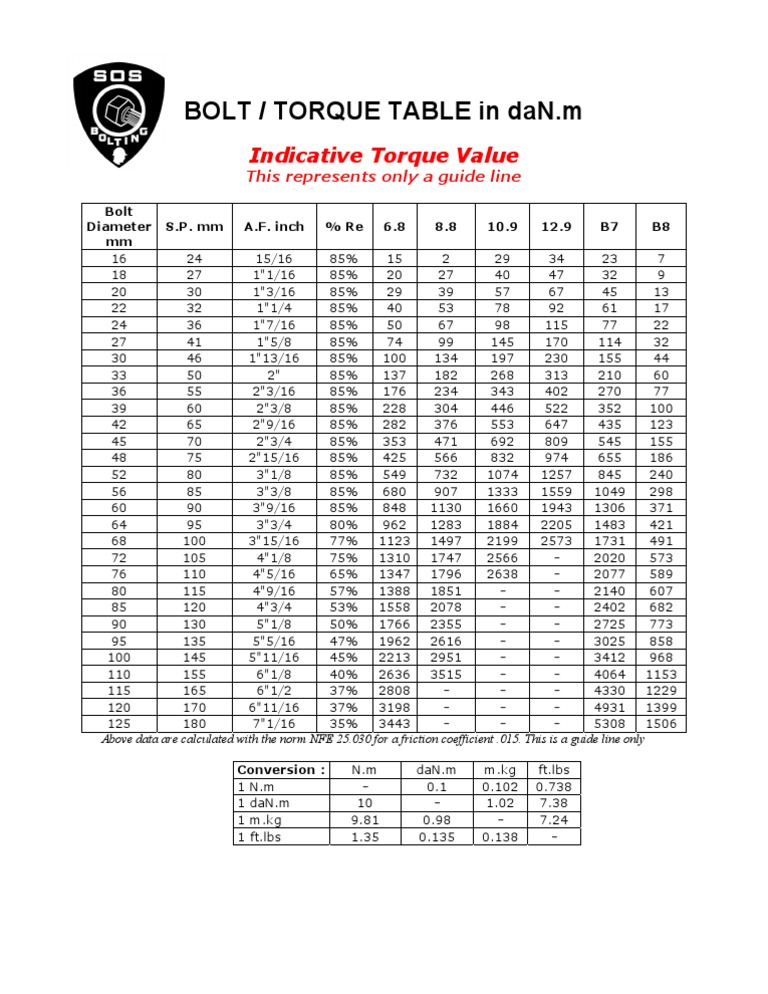

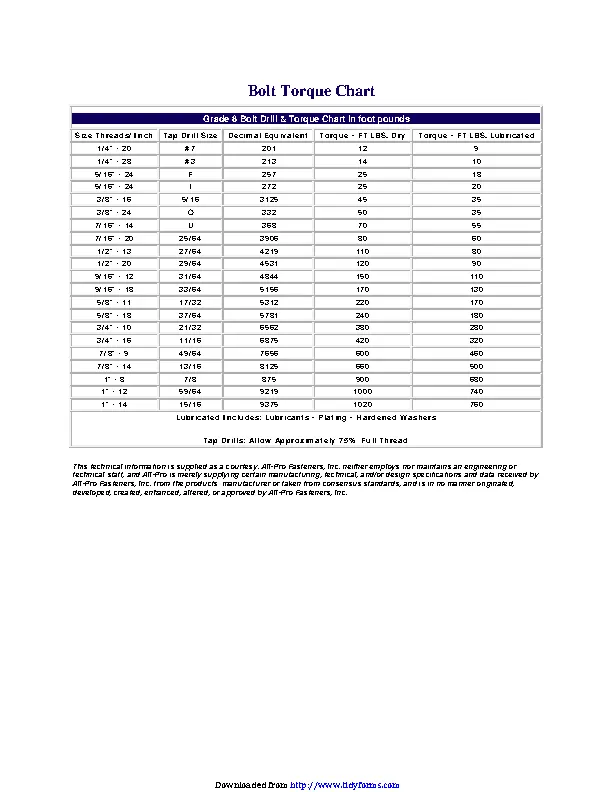

Bolt Torque Chart Printable - The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. Use a wire brush to remove dirt and rust. 1) the torque values can only be. Metric bolts, screws & nuts: Web torque is only an indirect indication of tension. Web use correct size, new, bolts/ studs, nuts, washers (multiply torques by 0.70 for ptfe coated bolting). The torque tables are built on specific assumptions regarding bolt and nut factor. Web before you use the torque sticks, check all parts, including wheels, studs and mounting faces of hub and wheels for dirt, rust or damage. Fill, sign and download bolt torque chart online on handypdf.com. Web if lubrication has been applied to the bolt and/or the nut (other than the normal protective oil film), multiply the recommended torque by the appropriate factor shown in the table. Bolt size, type and grade. Web these metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The bolt’s class indicates its material strength,. Web these torque values are intended for use as quidelines only & are based on perfect conditions. Fill, sign and download bolt torque chart. The best part is that you can find bolt. Web *this chart is for general practice purposes only and should not be used in the engineering or design of any products. Web torque specifications, especially for critical joints, should be determined under actual assembly conditions due to the many variables involved which are difficult to predict and. The most current. Clamp load calculated as 75%. The torque tables are built on specific assumptions regarding bolt and nut factor. Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. Web this chart helps you figure out the correct torque settings for different bolts and nuts so that you get the perfect fit without overtightening. Metric bolts, screws & nuts: Identify the grade, size, and thread. Clamp load calculated as 75%. Web before you use the torque sticks, check all parts, including wheels, studs and mounting faces of hub and. Web *this chart is for general practice purposes only and should not be used in the engineering or design of any products. The most current edition of the api specification may be. Under/over tightening of fasteners can result in costly equipment failure or personal injury. Identify the grade, size, and thread. 1) the torque values can only be. Web instant flange bolt sizes and torque patterns: Use a wire brush to remove dirt and rust. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. Metric bolts, screws & nuts: Web the charts below show the ideal tightening torque for each bolt grade for a. Web use correct size, new, bolts/ studs, nuts, washers (multiply torques by 0.70 for ptfe coated bolting). Lubricate on bolt threads and nut faces with compatible antiseize*. Web *this chart is for general practice purposes only and should not be used in the engineering or design of any products. Web fillable and printable bolt torque chart 2024. Web instant flange. Web torque specifications, especially for critical joints, should be determined under actual assembly conditions due to the many variables involved which are difficult to predict and. The best part is that you can find bolt. Web these metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Identify. Web flange bolting torque table. Web torque is only an indirect indication of tension. The most current edition of the api specification may be. 1) the torque values can only be. The bolt’s class indicates its material strength,. Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Under/over tightening of fasteners can result in costly equipment failure or personal injury. Web *this chart is for general practice purposes only and should not be used in the engineering or design of any products. The torque values can only be achieved. Clamp load calculated as 75%. The size column also includes the thread count. The best part is that you can find bolt. Web torque specifications, especially for critical joints, should be determined under actual assembly conditions due to the many variables involved which are difficult to predict and. Web bolt torque depends on: Web *this chart is for general practice purposes only and should not be used in the engineering or design of any products. Web these torque values are intended for use as quidelines only & are based on perfect conditions. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the. The bolt’s class indicates its material strength,. Web fillable and printable bolt torque chart 2024. The torque tables are built on specific assumptions regarding bolt and nut factor. Web before you use the torque sticks, check all parts, including wheels, studs and mounting faces of hub and wheels for dirt, rust or damage. Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Web if lubrication has been applied to the bolt and/or the nut (other than the normal protective oil film), multiply the recommended torque by the appropriate factor shown in the table. Identify the grade, size, and thread. Metric bolts, screws & nuts:

Bolt Torque Chart 5 Free Templates in PDF, Word, Excel Download

Bolt Torque Chart A325

Bolt Torque Chart PDFSimpli

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Bolt Torque Chart Template Free Download

Standard Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Standard Torque Chart For Bolts

Bolt+Torque+Chart+Printable Free Printable Templates

Printable Bolt Torque Chart

Bolt Size, Type And Grade.

The Torque Values Can Only Be Achieved If Nut (Or Tapped Hole) Has A Proof Load Greater Than Or Equal To The Bolt's.

The Most Current Edition Of The Api Specification May Be.

Web Torque Is Only An Indirect Indication Of Tension.

Related Post: