Carbide Inserts Grades Chart

Carbide Inserts Grades Chart - Web look up grade descriptions and application ranges for grades from carbide insert manufacturers To choose the correct carbide grade for a particular application, look at the supplier's catalog or website for guidance. Web insert grades with inveio® sandvik coromant has successfully implemented this coating technology on the following grades: Web we divide the grades into several grade statuses : Web although there is no formal international standard, most suppliers use charts that describe grades’ recommended working envelopes based on their “ application range ” as. Web selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and chip breakers for each. Unlike a few decades ago, when. Pvd (physical vapor deposition) toughness. Component material (iso p, m, k, n, s, h) type of method (finishing, medium, roughing) machining. The insert grade is primarily selected according to: Web insert grades with inveio® sandvik coromant has successfully implemented this coating technology on the following grades: Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end. To choose the correct carbide grade for a particular application, look at the supplier's catalog or website for guidance.. Pvd (physical vapor deposition) toughness. Web carbide insert grade range chart. Web we divide the grades into several grade statuses : Web look up grade descriptions and application ranges for grades from carbide insert manufacturers The insert grade is primarily selected according to: Web look up grade descriptions and application ranges for grades from carbide insert manufacturers Grade range chart (click here for chart adjusted for deficient color vision) p steel. To choose the correct carbide grade for a particular application, look at the supplier's catalog or website for guidance. Web we divide the grades into several grade statuses : Web carbide insert. Unlike a few decades ago, when. We’ll start with the second one first. Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end. Web and why are there so many different grades of carbide inserts out there? Component material (iso p, m, k, n, s, h). Component material (iso p, m, k, n, s, h) type of method (finishing, medium, roughing) machining. Unlike a few decades ago, when. Web we divide the grades into several grade statuses : We’ll start with the second one first. Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide. Web insert grades with inveio® sandvik coromant has successfully implemented this coating technology on the following grades: Grade range chart (click here for chart adjusted for deficient color vision) p steel. Web we divide the grades into several grade statuses : Pvd (physical vapor deposition) toughness. Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades. Web although there is no formal international standard, most suppliers use charts that describe grades’ recommended working envelopes based on their “ application range ” as. Web we divide the grades into several grade statuses : To choose the correct carbide grade for a particular application, look at the supplier's catalog or website for guidance. Grade range chart (click here. Grade range chart (click here for chart adjusted for deficient color vision) p steel. The insert grade is primarily selected according to: Unlike a few decades ago, when. Web selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and chip breakers for each. Web we divide the grades into. Web we divide the grades into several grade statuses : Web and why are there so many different grades of carbide inserts out there? Web grade selection charts. Web look up grade descriptions and application ranges for grades from carbide insert manufacturers Web selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination. Web although there is no formal international standard, most suppliers use charts that describe grades’ recommended working envelopes based on their “ application range ” as. Unlike a few decades ago, when. Web selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and chip breakers for each. Component material. To choose the correct carbide grade for a particular application, look at the supplier's catalog or website for guidance. Pvd (physical vapor deposition) toughness. Web selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and chip breakers for each. Web and why are there so many different grades of carbide inserts out there? Web we divide the grades into several grade statuses : The insert grade is primarily selected according to: Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end. We’ll start with the second one first. Web carbide insert grade range chart. Unlike a few decades ago, when. Web insert grades with inveio® sandvik coromant has successfully implemented this coating technology on the following grades: Component material (iso p, m, k, n, s, h) type of method (finishing, medium, roughing) machining. Web look up grade descriptions and application ranges for grades from carbide insert manufacturers

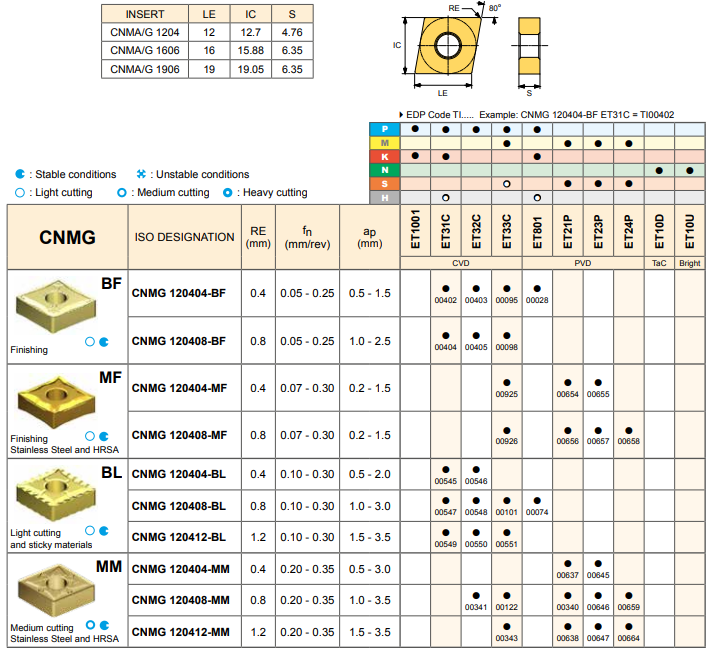

CNMG 120408 Universal Carbide Turning Inserts BY EdgeTech R.D. Barrett

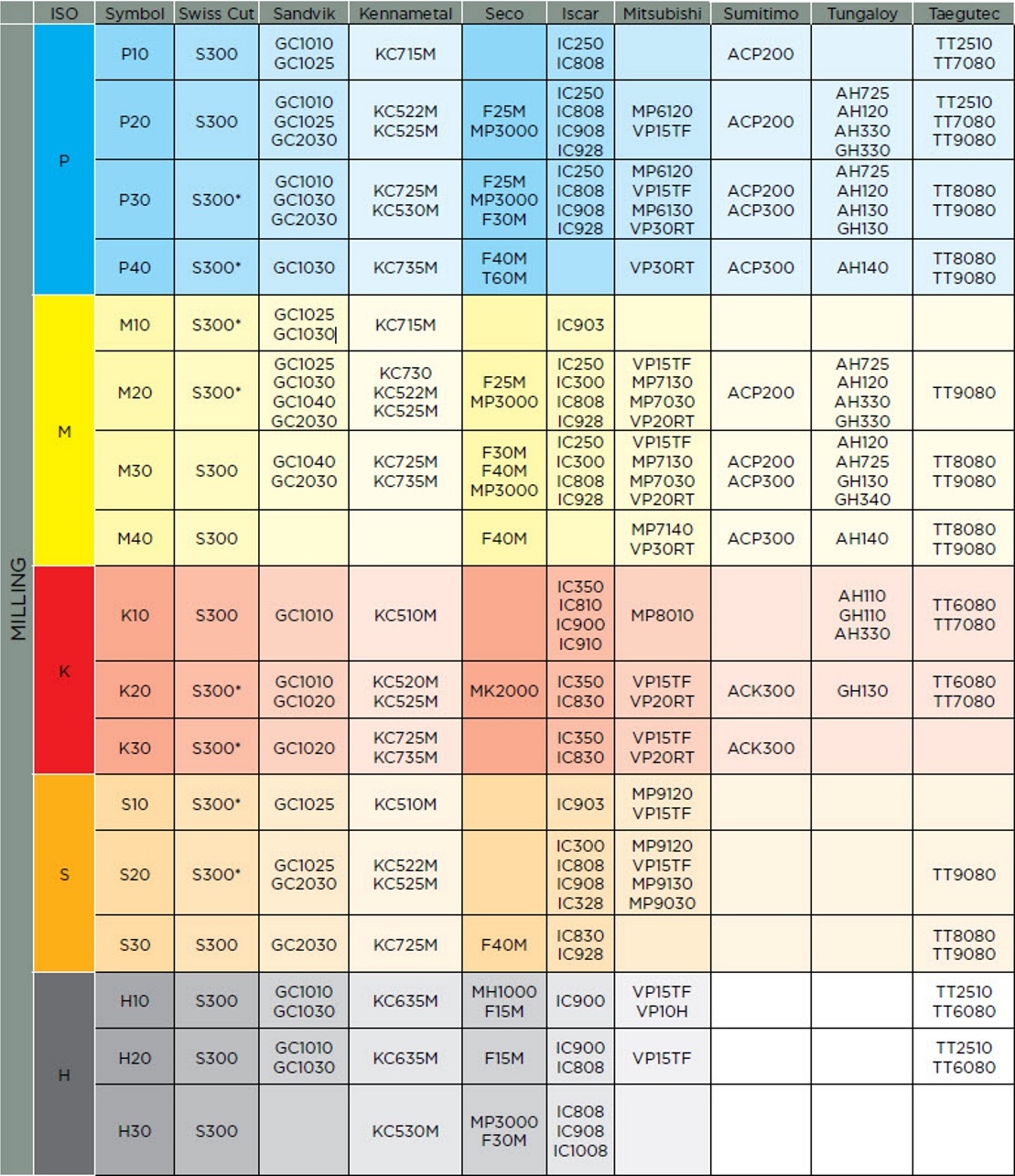

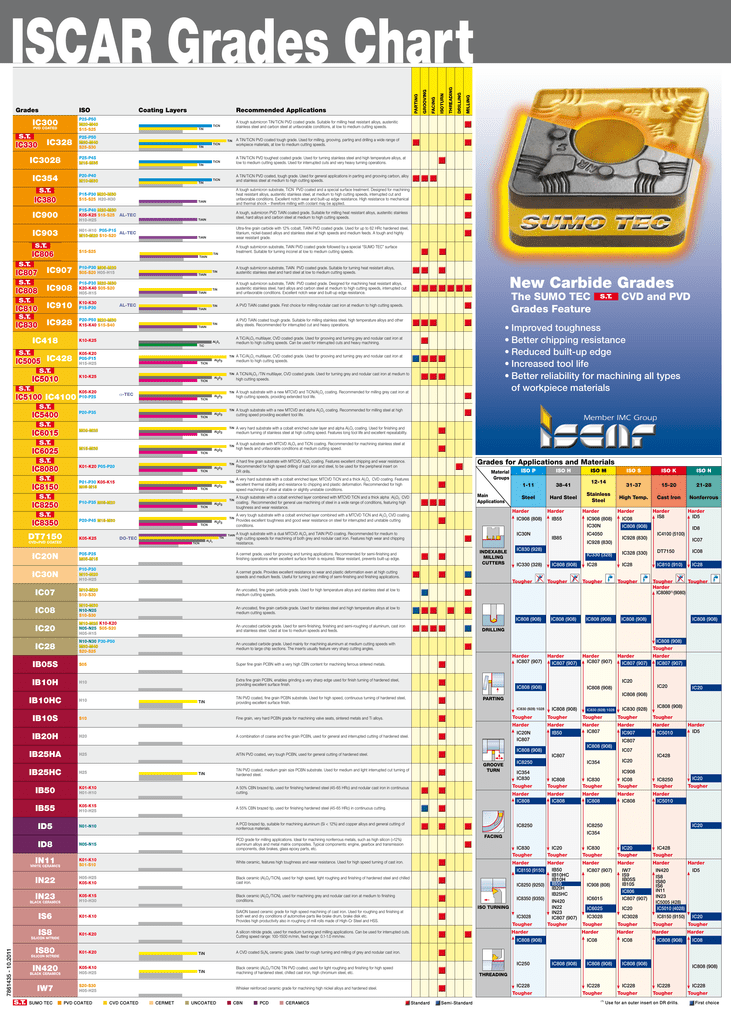

Carbide Insert Grade Comparison Chart Images

Carbide Inserts Grades Chart

Carbide Grades Revolver Carbide

Carbide Insert Grade Comparison Chart

Carbide Insert Model

Carbide Inserts Indexable

Selecting Carbide Inserts for Metalworking Kennametal

Insert Grade Comparison Chart

COMPARISON CHART— CARBIDE GRADES FOR Competitor... · COMPARISON CHART

Web Grade Selection Charts.

Web Although There Is No Formal International Standard, Most Suppliers Use Charts That Describe Grades’ Recommended Working Envelopes Based On Their “ Application Range ” As.

Web We Divide The Grades Into Several Grade Statuses :

Grade Range Chart (Click Here For Chart Adjusted For Deficient Color Vision) P Steel.

Related Post: