Cellulose Coverage Chart

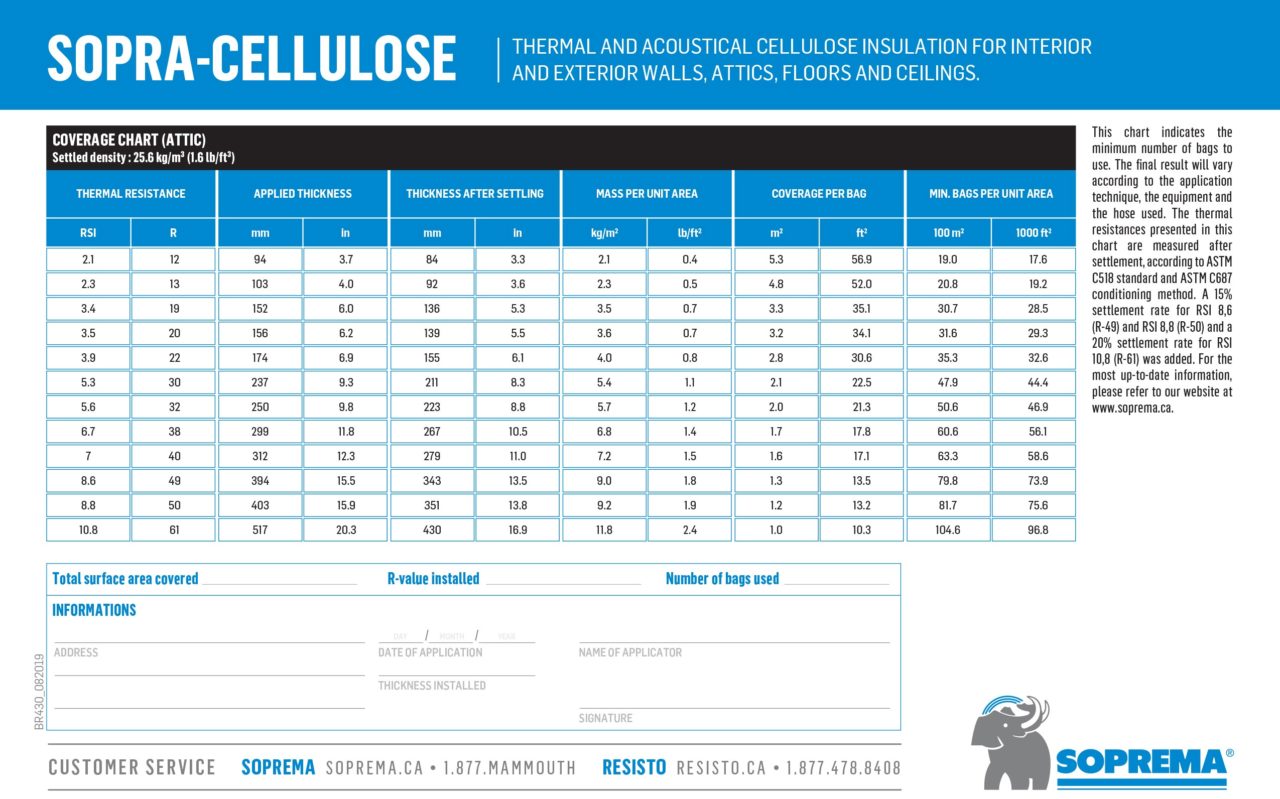

Cellulose Coverage Chart - Job conditions, application techniques, equipment, and settings can influence actual coverage. Dense pack cellulose (walls or enclosed cavities) loose fill cellulose (attic floors or open cavities) Web th e expanded coverage chart reflect recommended densities from a danish research study to provide self supporting installations. Web this coverage chart is for dry applications only and is based on the krendl ks200, with material applied dry. The final result will vary according to the application technique, the equipment and the hose used. Web the above coverage chart is based on a nominal bag weight of 30 lbs using a volumatic iii, 3rd gear and 8” gate. The amount of insulation you need depends mainly on the climate you live in. The minimum number of bags required takes into account the volume of the wood structure. Web how many bags of cellulose and/or fiberglass do you need for a given job? Superior flame resistance and exceptional acoustic properties. The amount of insulation you need depends mainly on the climate you live in. For 24 oc stud spacing the framing factor is 6.25%. The chart is based on settled thickness and is for estimating purposes only. The final result will vary according to the application technique, the equipment and the hose used. Web we use the manufacturer’s coverage chart. Web this coverage chart is for dry applied applications only and is based on the krendl ks200, with material applied dry. The above coverage chart is based on a nominal bag weight of 30 lbs using a volumatic iii, 3rd gear and 8” gate. Web the manufacturer recommends that energy control cellulose be. For 24 oc stud spacing the framing. Bag of cellulose in framing cavities from 2 in. There are other factors to consider. Job conditions, application techniques, equipment, and settings can influence actual coverage. Web expanded bag coverage chart for national fiber's cellulose insulation. Machine settings are not adjust able. Web this coverage chart is for dry applied applications only and is based on the krendl ks200, with material applied dry. Web we use the manufacturer’s coverage chart (click here for more info on the chart) to calculate how many bags it takes to achieve the correct density. Below is a calculator to help you determine the amount of bags. Web this coverage chart is for dry applications only and is based on the krendl ks200, with material applied dry. The minimum number of bags required takes into account the volume of the wood structure. Our proprietary wet separation and infusion process floats off contaminants. R means resistance to heat flow. The chart is based on settled thickness and is. The final result will vary according to the application technique, the equipment and the hose used. Web expanded bag coverage chart for national fiber's cellulose insulation. Minimum net weight is 23.75 lbs. Web this chart indicates the minimum number of bags to use. The final result will vary according to the application technique, the equipment and the hose used. For 24 oc spacing the framing factor is 6.25%. The minimum number of bags required takes into account the volume of the wood structure. The chart is based on settled thickness and is for estimating purposes only. For 24 oc stud spacing the framing factor is 6.25%. Job conditions, application techniques, equipment, and settings can influence actual coverage. Bag of cellulose in framing cavities from 2 in. The above coverage chart is based on a nominal bag weight of 25 lbs a. Web th e expanded coverage chart reflect recommended densities from a danish research study to provide self supporting installations. Job conditions, application techniques, equipment, and settings can influence. The minimum number of bags required takes into. Machine settings are not adjust able. Web we use the manufacturer’s coverage chart (click here for more info on the chart) to calculate how many bags it takes to achieve the correct density. Web this chart indicates the minimum number of bags to use. For 24 oc spacing the framing factor is 6.25%. The above coverage chart is based on. Below is a calculator to help you determine the amount of bags you need for coverage. For 24 oc spacing the framing factor is 6.25%. The above coverage chart is based on a nominal bag weight of 25 lbs a. Web this coverage chart is for dry applied applications only and is based on the krendl ks200, with material applied. Minimum net weight is 23.75 lbs. Dense pack cellulose (walls or enclosed cavities) loose fill cellulose (attic floors or open cavities) Web this chart indicates the minimum number of bags to use. Web the manufacturer recommends that energy control cellulose be. Machine settings are not adjust able. R means resistance to heat flow. Chart based on settled thickness, a nominal bag weight of 26.5 lbs and coverage based on the krendl 500 blowing machine. For maximum coverage per bag (adjusted for framing), the framing factor for 16 oc spacing is 9.375%; Product test results, spec books, installation guides, and coverage charts are available for dense pack & loose fill insulation. Web expanded bag coverage chart for national fiber's cellulose insulation. Web this coverage chart is for dry applications only and is based on the krendl ks200, with material applied dry. Web how many bags of cellulose and/or fiberglass do you need for a given job? Our proprietary wet separation and infusion process floats off contaminants. For walls with metal structure, additional bags may be required. For walls with metal structure, additional bags may be required. The amount of insulation you need depends mainly on the climate you live in.

Exploring The Green Fiber Cellulose Coverage Chart In 2023 MartLabPro

Green Fiber Cellulose Insulation Coverage Chart Best Picture Of Chart

Cellulose Insulation Chart

_lit.jpg)

Cellulose Insulation R Value Chart

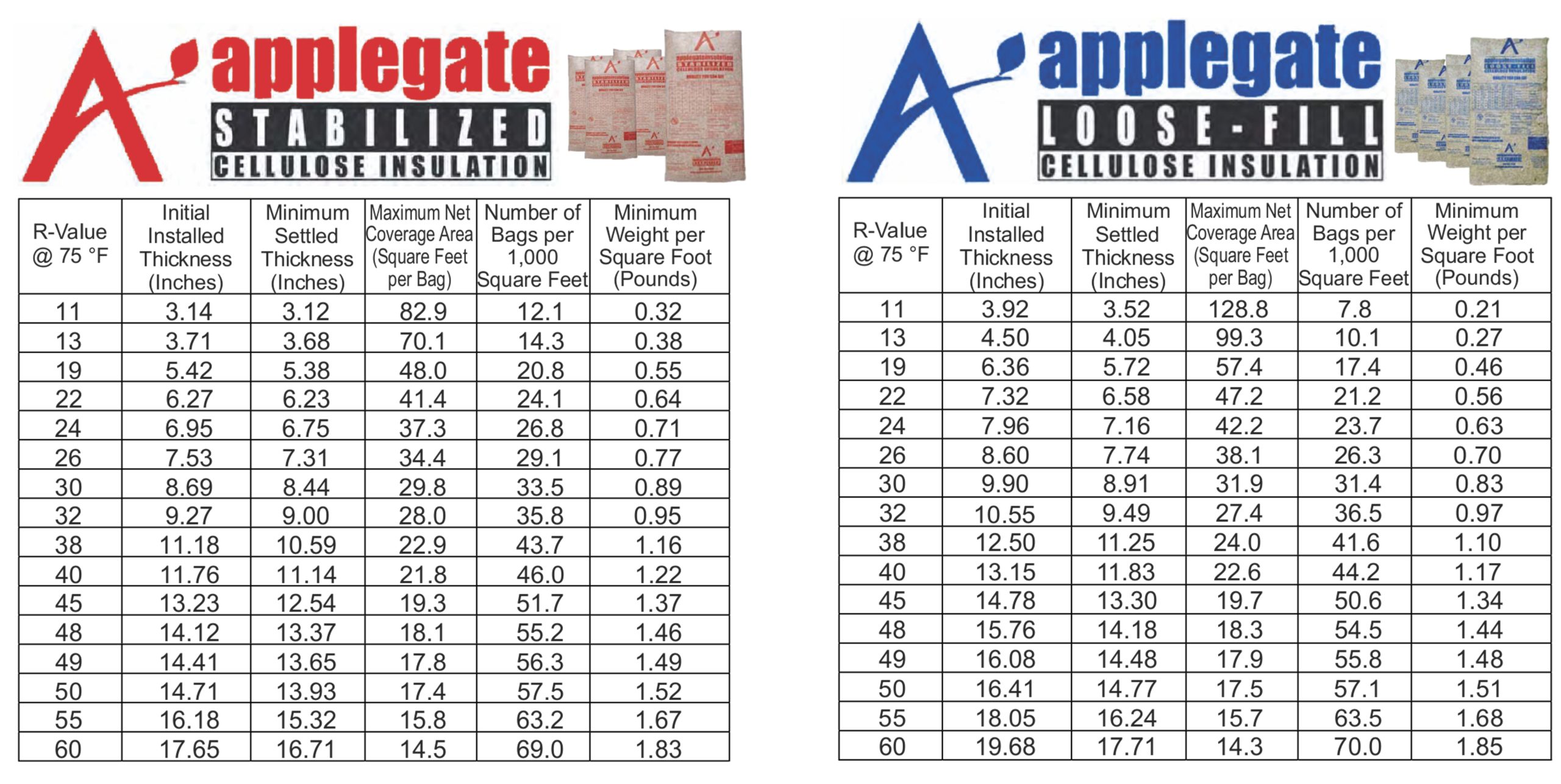

Applegate Cellulose

Applegate Cellulose Coverage Chart Fill Online, Printable, Fillable

Green Fiber Cellulose Insulation Coverage Chart

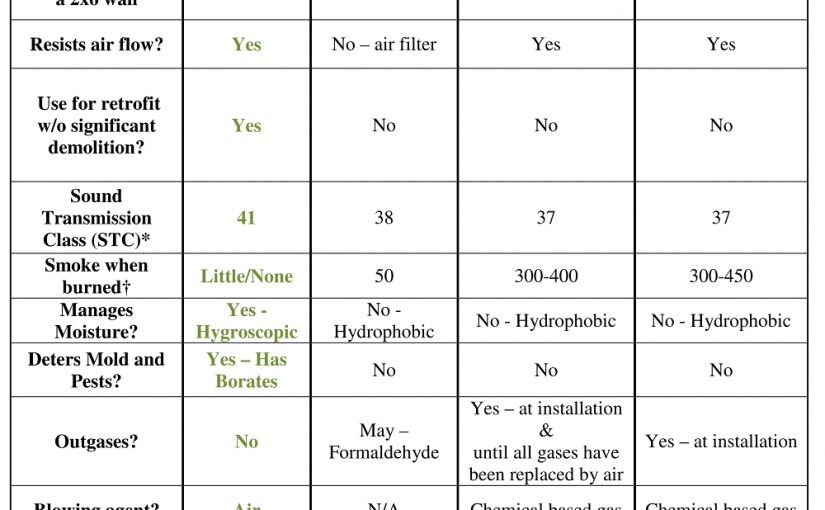

Cellulose Comparison Chart Dolphin Insulation

Exploring The Green Fiber Cellulose Coverage Chart In 2023 MartLabPro

Cellulose Blown Insulation Contact 6043064211

Web Cache Valley's Premier Cellulose Insulation Manufacturer.

The Final Result Will Vary According To The Application Technique, The Equipment And The Hose Used.

Job Conditions, Application Techniques, Equipment, And Settings Can Influence.

The Final Result Will Vary According To The Application Technique, The Equipment And The Hose Used.

Related Post: