Chain Grades Chart

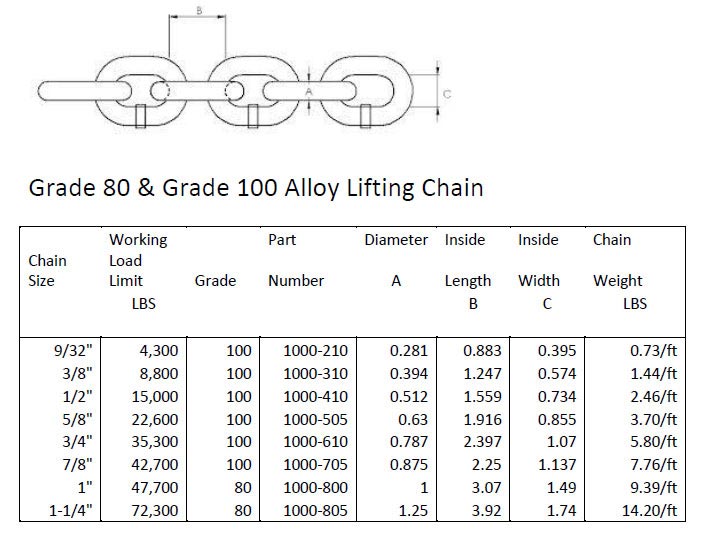

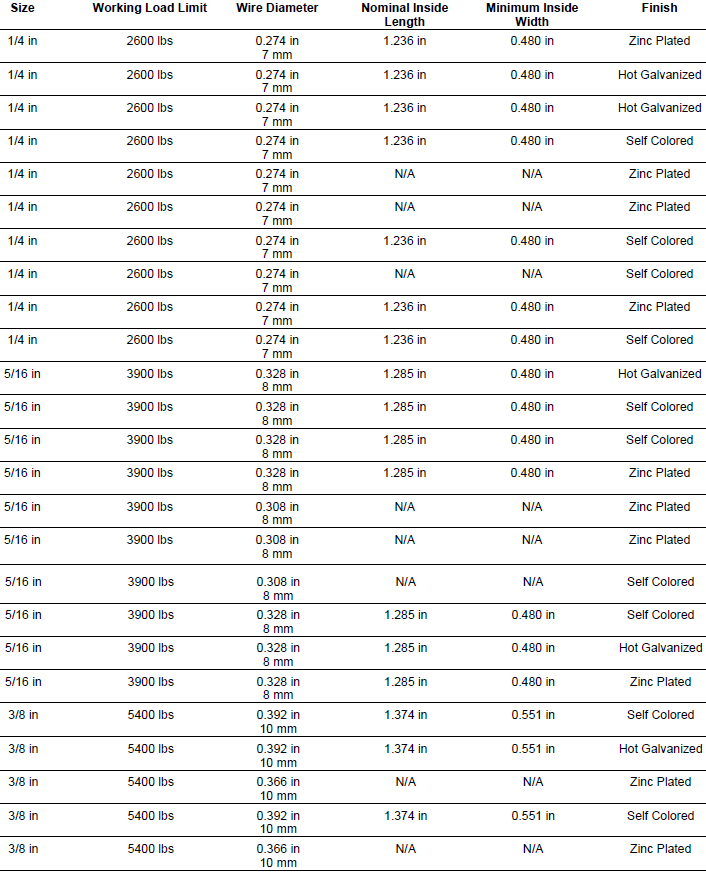

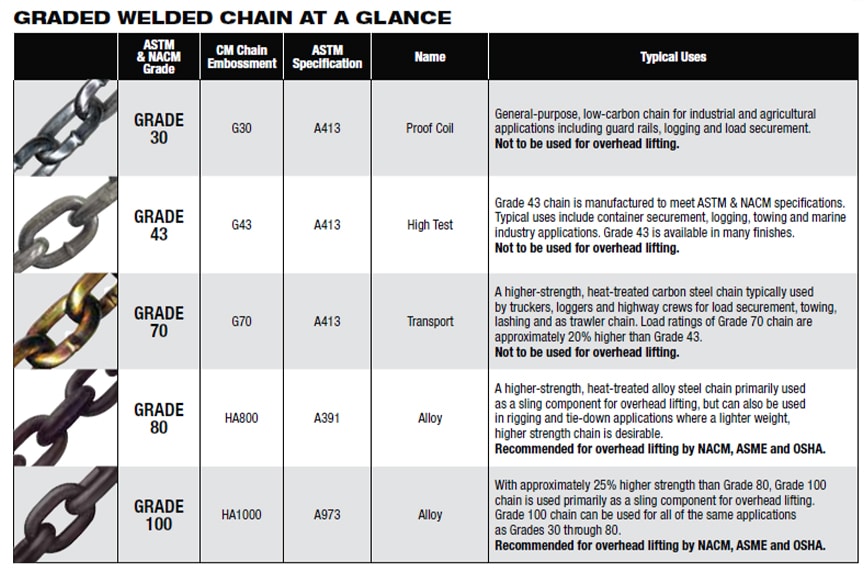

Chain Grades Chart - Web tow chain grades defined: Web chains come in various grades, each denoting specific characteristics and applications. It is used to determine what sort of applications are appropriate for. Web learn the difference and applications of five grades of chain: Web there are five grades of chain in common use: Grade 120 chain is a new category of high performance chain. Understanding the differences and applications. In the intricate world of industrial chains, understanding the grading system is paramount. Grade (metal tensile strength) diameter (thickness of chain) coil. Various chain grades categorize by numbers that reflect their maximum strength and application suitability. Web find properties and grades of welded steel chains for industrial and commercial uses from nacm. Web chain grades describe the ultimate breaking strength or tensile strength of a given type of chain. In the world of rigging, the choice of chain can make all the difference. Explore the technical aspects of lifting chains with certex. This article embarks on. Comparing grades of lifting chains: For example, g80 means that the maximum stress on the chain at. This number is what we see today. Grades help determine what sort of applications are appropriate for. Web the biggest difference between grades of chain is that carbon steel chain (grade 30, 43, and 70) is not recommended for overhead lifting, while alloy. The number after each letter is n/mm2. Web learn the difference and applications of five grades of chain: From grade 30 to grade 100, each grade has distinct characteristics that determine its. G30, g43, g70, g80, and g100. Understanding the differences and applications. When selecting anchor or windlass chain, there are 4 basic considerations: Grades help determine what sort of applications are appropriate for. Grade 120 chain is a new category of high performance chain. Web learn how to identify chain grade by looking for markings, interpreting symbols, examining material and finish, consulting standards, and considering application requirements. Grade (metal tensile strength) diameter. Web usage, wear, twists, overloading, corrosion, alteration and misuse all affect the chain load rating of any chain. Grade 120 chain is a new category of high performance chain. Common grades include grade 30, grade 43, grade 70, grade 80, and grade 100,. Web types of chain grades. Explore the technical aspects of lifting chains with certex. The most common grades include: This number is what we see today. In the intricate world of industrial chains, understanding the grading system is paramount. Web chain grades describe the ultimate breaking strength or tensile strength of a given type of chain. Whether you’re hoisting heavy loads in. Web today g30, g43, g70, g80 & g100 and the common chain grades. This number is what we see today. When selecting anchor or windlass chain, there are 4 basic considerations: Find out how to calculate chain grades, common mistakes, and uses of each. When it comes to lifting chains, the difference between. The number after each letter is n/mm2. In the world of rigging, the choice of chain can make all the difference. Web tow chain grades defined: Grade (metal tensile strength) diameter (thickness of chain) coil. One of the safety measures implemented was to place chain in grades based on the ultimate breaking strength of that chain. See the size and working load limit charts for each grade of chain. One of the safety measures implemented was to place chain in grades based on the ultimate breaking strength of that chain. Chain grades indicate the tensile. This number is what we see today. Web chain grades are a standard method for showing the ultimate breaking strength (tensile. Common grades include grade 30, grade 43, grade 70, grade 80, and grade 100,. From grade 30 to grade 100, each grade has distinct characteristics that determine its. See the size and working load limit charts for each grade of chain. Web find properties and grades of welded steel chains for industrial and commercial uses from nacm. Web today g30,. Understanding the differences and applications. Grade 120 chain is a new category of high performance chain. It is used to determine what sort of applications are appropriate for. The most common grades include: See a chart of the six main grades of welded. Web find properties and grades of welded steel chains for industrial and commercial uses from nacm. In the intricate world of industrial chains, understanding the grading system is paramount. But what do these grades mean? Web learn the differences between carbon and alloy chain, and how to choose the right grade of chain for your rigging applications. In the world of rigging, the choice of chain can make all the difference. Web chains come in various grades, each denoting specific characteristics and applications. See online chart for chain specifications and size for different chain types and. Comparing grades of lifting chains: Web chain grades are a standard method for showing the ultimate breaking strength (tensile strength) of a chain. This number is what we see today. This article embarks on a journey through the ratings of chain.

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Chain Grade Rating Chart A Visual Reference of Charts Chart Master

Chain Grade Chart A Visual Reference of Charts Chart Master

Comparing Chain Grades U.S. Cargo Control US Cargo Control

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Chain Grades And Strengths Chart

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

What Are the Different Grades of Chain?

Comparing Chain Grades U.S. Cargo Control US Cargo Control

What Are the Different Grades of Chain?

The Number After Each Letter Is N/Mm2.

Web There Are Five Grades Of Chain In Common Use:

It’s A Square Link Format, Which Reduces Pressure On Every Part Of The Chain And Can Yield A.

Grade (Metal Tensile Strength) Diameter (Thickness Of Chain) Coil.

Related Post: