Chain Rating Chart

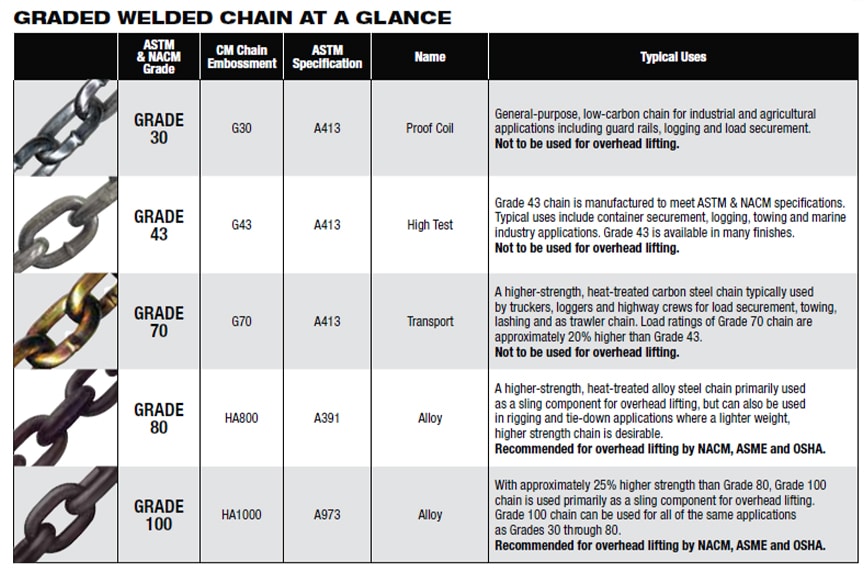

Chain Rating Chart - At 20%, it's pretty hefty. One of the safety measures implemented was to place chain in grades based on the ultimate breaking strength of that chain. This article embarks on a journey through the ratings of chain. Web there are five grades of chain in common use: For rigging purposes, there are six main grades of welded chain that are sold on the market, broken into two main categories: It is imperative to determine the maximum. This number is what we. Web how to measure chain quality and ratings. This limit is calculated according to the sling's grade, size, and angle of use. Web we know the strength of a chain by its grade. Web this specification covers the requirements for forged hooks used with grade 30, grade 43, and grade 70 chain as described in the nacm welded steel chain specifications. 5.5 mm or smaller 9 greater than 5.5 mm but less than 20.0 mm 7 20.0 mm or greater 3. In the intricate world of industrial chains, understanding the grading system is. Grade 30, grade 43, grade 70, grade 80, and grade 100. Web this specification covers the requirements for forged hooks used with grade 30, grade 43, and grade 70 chain as described in the nacm welded steel chain specifications. One of the safety measures implemented was to place chain in grades based on the ultimate breaking strength of that chain.. Web grade 120 chains are often used in heavy construction and industrial settings. Do not exceed working load. Identifying the correct chain grade is crucial to ensuring optimal performance and safety. But what do these grades mean? It was brought down to 5% and then 12.5% as the live music industry was. The welded steel chain specification pertains to the following chain grades: This number is what we. At 20%, it's pretty hefty. 5.5 mm or smaller 9 greater than 5.5 mm but less than 20.0 mm 7 20.0 mm or greater 3. Web size of chain minimum number of links in test specimen. The welded steel chain specification pertains to the following chain grades: But what do these grades mean? Alloy steel chain the cm chart featured in this section provides a general overview of graded welded chain and the differences between each of them. It is imperative to never exceed the chain sling's working load limit (wll). In the intricate world of industrial. But what do these grades mean? The higher the grade, the. Web take a look at the chart below to see the wll for each. One of the safety measures implemented was to place chain in grades based on the ultimate breaking strength of that chain. Grade 30, grade 43, grade 70, grade 80, and grade 100. Web size of chain minimum number of links in test specimen. At 20%, it's pretty hefty. Web take a look at the chart below to see the wll for each. Web we know the strength of a chain by its grade. The higher the grade, the. Web abide by load limits. The grade of chain is determined by the mean stress in the chain at the minimum breaking load. The welded steel chain specification pertains to the following chain grades: Web grade 120 chains are often used in heavy construction and industrial settings. Grade 100 alloy chain, grade 80 allow chain, grade 70 transport chain, grade. This article embarks on a journey through the ratings of chain. Grade 100 alloy chain, grade 80 allow chain, grade 70 transport chain, grade 43. Web size of chain minimum number of links in test specimen. Web how to measure chain quality and ratings. Web there are five grades of chain in common use: In the intricate world of industrial chains, understanding the grading system is paramount. It was brought down to 5% and then 12.5% as the live music industry was. At 20%, it's pretty hefty. Grade 30, grade 43, grade 70, grade 80, and grade 100. Grade 80 & grade 100 alloy chain. Chain working load limits by grade (lbs.) grade 70 chain has a load rating that's approximately 20% higher. 5.5 mm or smaller 9 greater than 5.5 mm but less than 20.0 mm 7 20.0 mm or greater 3. The grade of chain is determined by the mean stress in the chain at the minimum breaking load. Alloy steel chain the cm chart featured in this section provides a general overview of graded welded chain and the differences between each of them. Chain grades indicate the tensile. Identifying the correct chain grade is crucial to ensuring optimal performance and safety. Knowing the chain load ratings for a specific application is always essential. Web size of chain minimum number of links in test specimen. One of the safety measures implemented was to place chain in grades based on the ultimate breaking strength of that chain. At 20%, it's pretty hefty. The welded steel chain specification pertains to the following chain grades: Web this specification covers the requirements for forged hooks used with grade 30, grade 43, and grade 70 chain as described in the nacm welded steel chain specifications. It is imperative to determine the maximum. * large diameter chain manufactured at our jeannette facility. Web an improvement over high test chain, grade 70 transport chain meets stringent department of transportation (dot) regulations with a smaller, easier to handle chain. Web there are five grades of chain in common use:

Horse Power Rating Chart Rombo Chain

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

DID Motorcycle Chain Technical Information Chains and Sprockets

What Are the Different Grades of Chain?

Comparing Chain Grades U.S. Cargo Control US Cargo Control

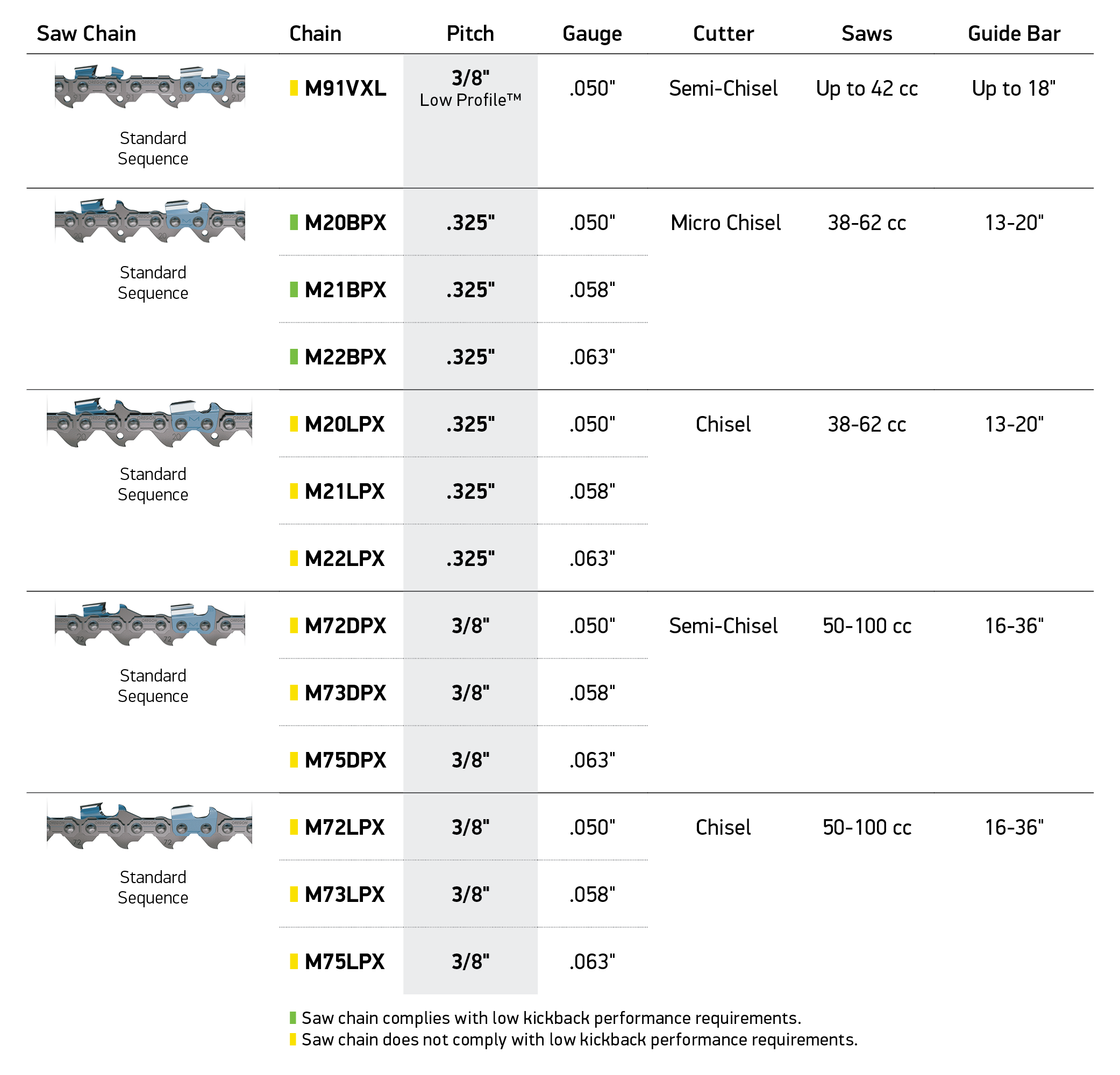

Husqvarna Chainsaw Chains Chart

3/8 inch PeerAlloy Grade 100 Chain Wesco Industries

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

What Are the Different Grades of Chain?

Comparing Chain Grades U.S. Cargo Control US Cargo Control

The Term Working Load Limit (Wll) Is A Chain Rating That.

Web Another Major Cost On Tickets In The Uk Is Vat (Value Added Tax).

This Limit Is Calculated According To The Sling's Grade, Size, And Angle Of Use.

In The Intricate World Of Industrial Chains, Understanding The Grading System Is Paramount.

Related Post: