Clearance Hole Size Chart

Clearance Hole Size Chart - 3.4 mm , loose fit: Web socket head screw thread and clearance hole gd&t tolerance table chart. Web find the drill sizes and thread drill sizes for different materials and machine screws in this table. Why is it important to have a clearance hole for fasteners? The tabulated drill and hole sizes, lists the inch fastener clearance hole recommendations. 4.5 mm , loose fit: Recommended clearance holes and drill tap sizes. What is tap drill size? Ch = (0.25 + 0.375) / 2 = 0.3125 inches. Clearance hole chart for inch fasteners. Choose from normal, close or loose tolerances for different applications. Web clearance holes for metric bolts: Why is it important to have a clearance hole for fasteners? Web metric clearance hole chart for metric bolts and screws according to asme b18.2.8. Tapping & clearance hole information. Compare close fit, free fit and decimal equivalents for clearance holes and tapping holes. Web 32 rows clearance hole chart for inch bolts and screws according to asme b18.2.8. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. Web by manufacturinget.org / april 26, 2012. Web find the. The following are recommended design installation mechanical tolerances table for cap head screws and the related clearance holes. Web 000 0.0340 65 0.0350 62 0.0380 00 0.0440 3/64 0.0469 55 0.0520 0 0.0600 52 0.0635 50 0.0700 1 0.0730 48 0.0760 46 0.0810 2 0.0860 43 0.0890 41 0.0960 3 0.0990 37 0.1040 35 0.1100 Ch = (0.25 + 0.375). Web learn how to calculate the size of the hole that allows a screw to pass through a substrate without damaging the material. Web the hole sizes for inch fasteners are patterned after usa common usage and the general clearances translated from the metric standard. Tapping & clearance hole information. “tap dill size” is the drill diameter we should use. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. The engineering toolbox privacy policy. 2.4 mm , loose fit: The tabulated drill and hole sizes, lists the inch fastener clearance hole recommendations. Hex head bolt installation & design tolerances. Why is it important to have a clearance hole for fasteners? Popular internal searches in the engineering toolbox. A clearance hole is a hole drilled through a part to allow a bolt to pass through. The recommended metric drill bit size for each class of clearance hole is shown in calculation results with nearest substitute inch drill bit size. Hex. 4.5 mm , loose fit: Thread depth (in %) calculation examples. Why is it important to have a clearance hole for fasteners? Dxf of 118 degree drill tip. Use this table to determine the clearance hole size for imperial bolts. Web find the minimum and maximum hole sizes for inch fasteners based on the nominal screw size and the drill size. Clearance holes are essential to ensure that fasteners fit securely and allow for expansion and contraction due to temperature changes. The following are recommended design installation mechanical tolerances table for cap head screws and the related clearance holes. The. So, the perfect clearance hole size for this fastener is 0.3125 inches. The recommended drill bit size for each class of clearance hole is shown in calculation results. The hole tolerances are based on the iso system of limits and fits, as required by iso 273. Web the hole sizes for inch fasteners are patterned after usa common usage and. This tap and clearance drill chart shows tap and. 2.4 mm , loose fit: Web complete charts for h11/c11 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. “tap dill size” is the drill diameter we should use before a tapping operation. The engineering toolbox privacy policy. A clearance hole is a hole drilled through a part to allow a bolt to pass through. Web find the clearance hole size for metric bolts with close, normal or loose fit. Use the table to compare the nominal diameter and clearance hole size for each bolt size from m1 to m150. “tap dill size” is the drill diameter we should use before a tapping operation. 4.5 mm , loose fit: Web complete charts for h8/h8 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. The engineering toolbox privacy policy. 3.4 mm , loose fit: By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. Clearance holes are essential to ensure that fasteners fit securely and allow for expansion and contraction due to temperature changes. Web clearance holes for metric bolts: Clearance hole chart for inch fasteners. The recommended metric drill bit size for each class of clearance hole is shown in calculation results with nearest substitute inch drill bit size. There are two classes of fit category; What is tap drill size? Web find the drill sizes and thread drill sizes for different materials and machine screws in this table.Metric Clearance Hole Chart PDF Screw Equipment

Hole Clearance Chart

Clearance Hole Chart amulette

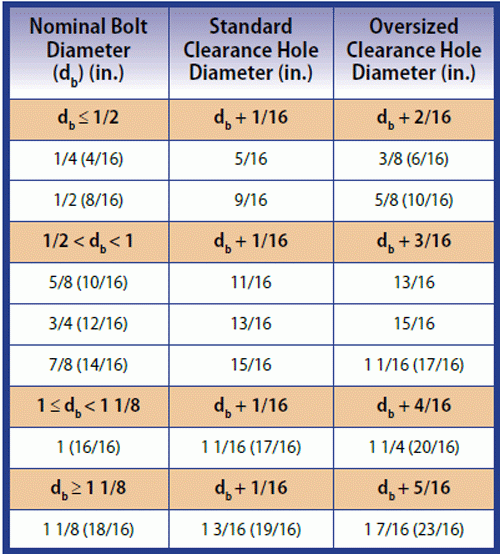

Sizing Clearance Holes for HDG… American Galvanizer's Association

Bolt Clearance Hole Size Chart Objektiv Lifestyle Blog

Chart ClearanceHoleDrillSizes PDF Screw Drill

Clearance Hole Size Chart

Clearance Hole Chart amulette

Clearance Hole Chart amulette

Clearance Hole Chart amulette

Popular Internal Searches In The Engineering Toolbox.

Web 56 Rows Tap & Clearance Drill Sizes.

Web Find The Minimum And Maximum Hole Sizes For Inch Fasteners Based On The Nominal Screw Size And The Drill Size.

Thread Depth (In %) Calculation Examples.

Related Post: