Cone Temp Chart

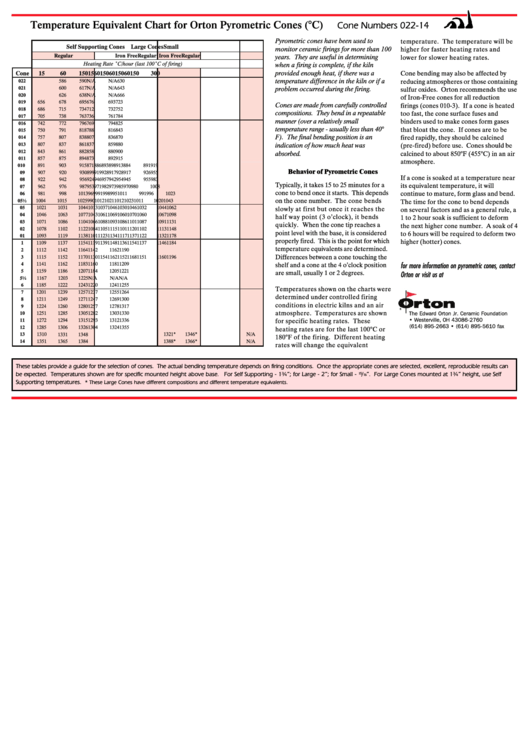

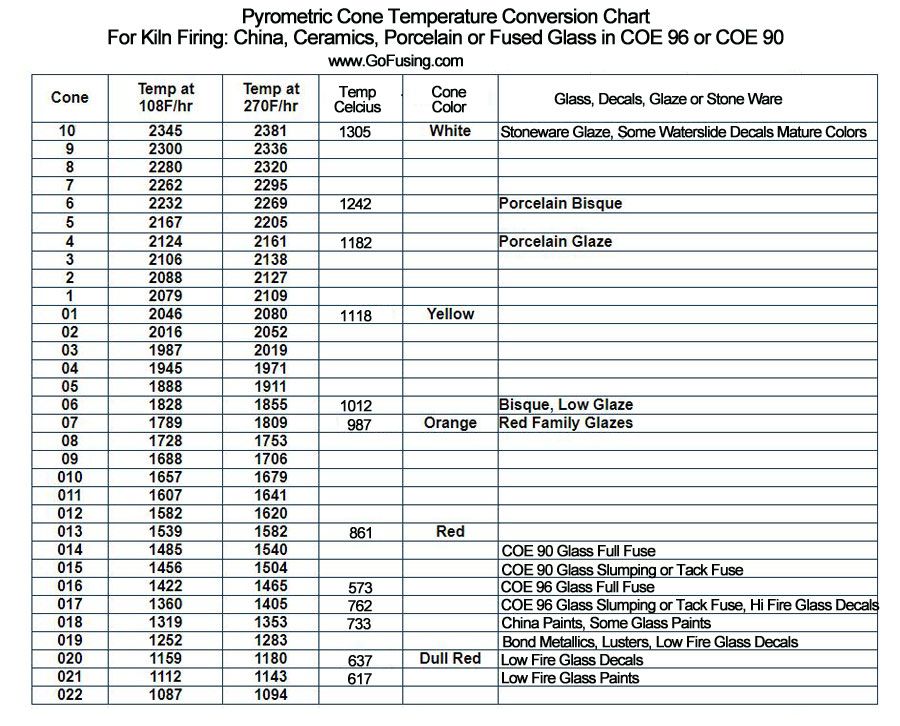

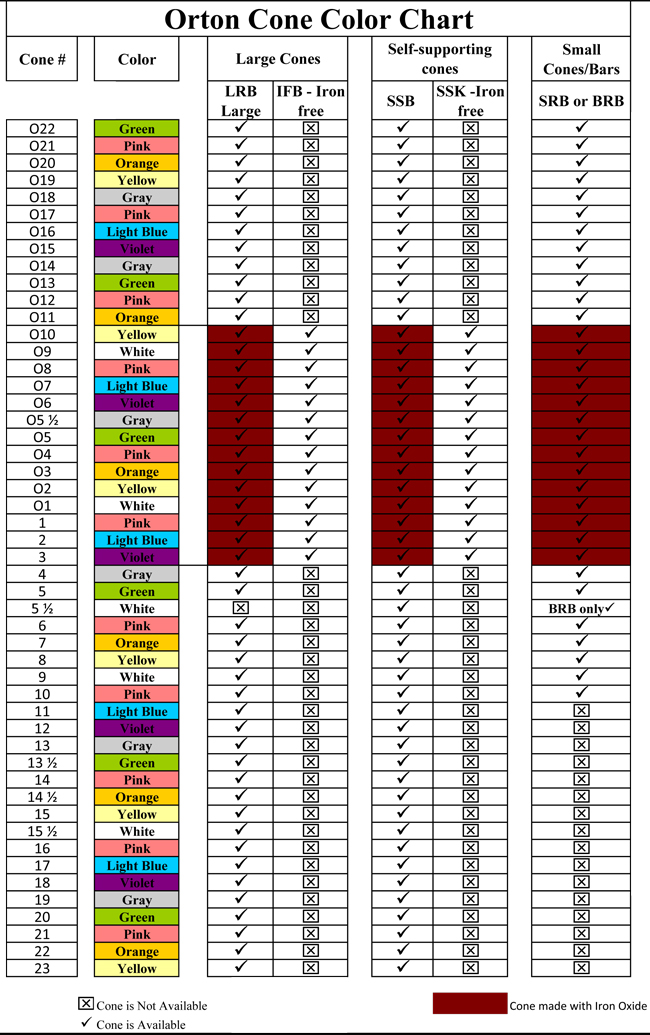

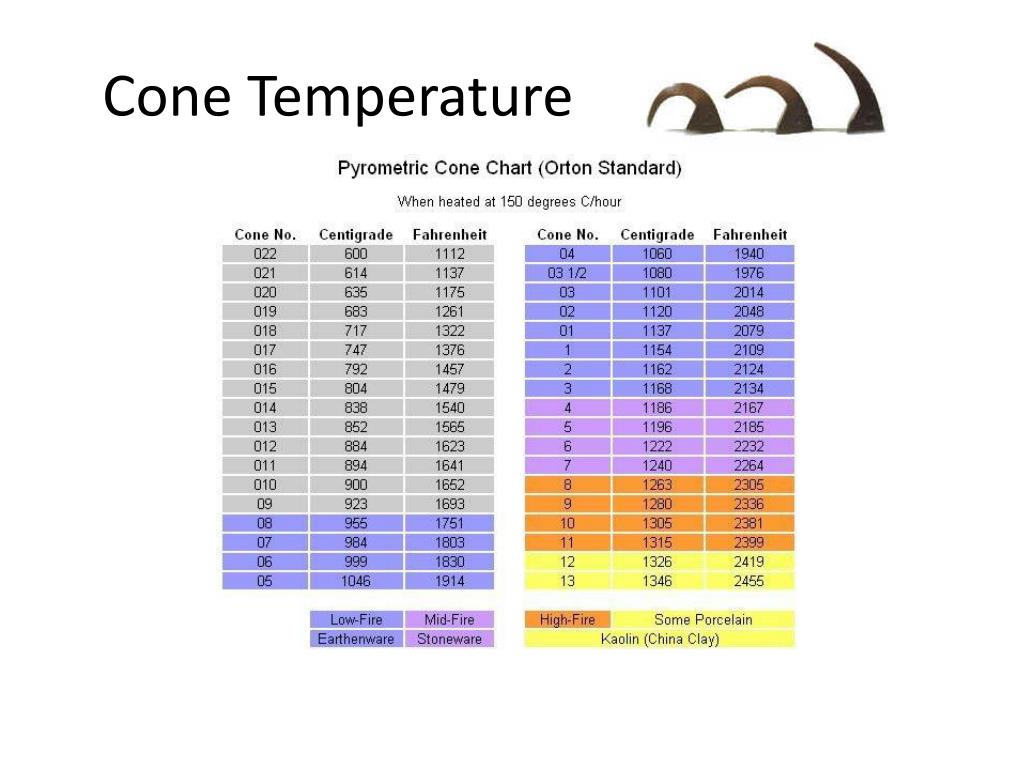

Cone Temp Chart - Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. As discussed above, the equivalent cone temperature depends upon how fast one gets to it. Web pyrometric kiln cones measure heat absorption as kiln temperatures reach heating ranges. The actual bending temperature depends on firing conditions. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Used for glass fusing and slumping. Web there are 4 styles of pyrometric cone: Once the appropriate cones are selected, excellent, reproducible results can be expected. Web helpful for firing porcelain. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. These heating rates are for the last 100°c or 180°f of the firing. A digital pyrometer can give an accurate temperature, but pyrometric cones are useful for determining how the firing went for your ceramic ware, and they can be useful. Explore the art of firing and glazing with confidence. Used for glass fusing and slumping. These heating rates are for the last 100°c or 180°f of the firing. Refer to this cone temperature chart before firing. Carbon and sulphur are burnt off, causing strong smells. Discover the significance of cone temperatures in art and crafts with our comprehensive cone temperature guide. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Keep the chart near your kiln for quick reference. These heating rates are for the last 100°c or 180°f of the firing. Once the appropriate. The actual bending temperature depends on firing conditions. Web they measure “heat work” during a firing, or time plus temperature. Web cone packs generally come in boxes of 50, with low fire packs including cone 07, cone 06, cone 05, and cone 04, and high fire packs containing cone cone 4, cone 5, cone 6, and cone 7. Keep the. These heating rates are for the last 100°c or 200°f of the firing. Different heating rates will change the equivalent temperature. Available cone numbers range from 022 to 20, with lower cone numbers denoting lower melting temperatures. Temperatures are shown for specific heating rates. Discover the significance of cone temperatures in art and crafts with our comprehensive cone temperature guide. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. As discussed above, the equivalent cone temperature depends upon how fast one gets to it. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase. Web pyrometric kiln cones measure heat. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered what they truly signify? Web as shown in the chart below, as the temperature in the kiln rose, the color would move. They are composed of materials which are carefully measured and compressed into the shape of a tetrahedron. Different heating rates will change the equivalent temperature. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. Please note that the cone chart gives 3 different temperatures for each cone number. Temperatures shown on these. This makes them a visual indicator that firing has reached the intended heat work. This guide provides useful information on cones and how firings can affect your pottery. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. These heating rates are for the last 100°c or 180°f of the firing.. Web they measure “heat work” during a firing, or time plus temperature. The actual bending temperature depends on firing conditions. They are composed of materials which are carefully measured and compressed into the shape of a tetrahedron. The clay surface will start to seal off, trapping any unburnt organic materials. As discussed above, the equivalent cone temperature depends upon how. Once the appropriate cones are selected, excellent, reproducible results can be expected. Web they measure “heat work” during a firing, or time plus temperature. Keep the chart near your kiln for quick reference. Web as shown in the chart below, as the temperature in the kiln rose, the color would move from red to yellow to white. These heating rates are for the last 100°c or 180°f of the firing. Web temperature equivalents for ortontm standard pyrometric cones. The actual bending temperature depends on firing conditions. This guide provides useful information on cones and how firings can affect your pottery. What does a cone do in a kiln? Enhance your understanding of cone temperatures and their impact on your creative projects. Temperatures shown are for specific mounted. Please note that the cone chart gives 3 different temperatures for each cone number. Temperature before this stage should be increased steadily with vents open to allow these materials to burn out before this stage. Temperatures are shown for specific heating rates. Large cones are used in a cone pack. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase.

What is a Cone? A Guide to Pyrometric Cones and Kilns Soul Ceramics

Temperature Equivalent Chart For Orton Pyrometric Cones printable pdf

How to Convert a Cone to Fahrenheit or Celsius Temperatures

cone chart Temperature chart, Cones, Cone

Pyrometric Cone Chart xiymachine

Orton Cone Chart Cone Temperature Chart

PPT Stages of Clay PowerPoint Presentation, free download ID2278112

Fahrenheit Cone Chart

Pyrometric Cone Temperature Conversion Chart

Pyrometric Cone Chart for Kiln Firing

Heating Rate In °C/Hr 60°C/Hr.

The Cone Number Is Significant Because It Indicates The Amount Of Heatwork Required To Vitrify Your Artwork Or Ceramics.

These Heating Rates Are For The Last 100°C Or 200°F Of The Firing.

Generally Speaking, The Temperatures In The 108°F/Hour Column Are Used When Discussing Ceramics, Porcelain And China.

Related Post: