Control Chart Constants

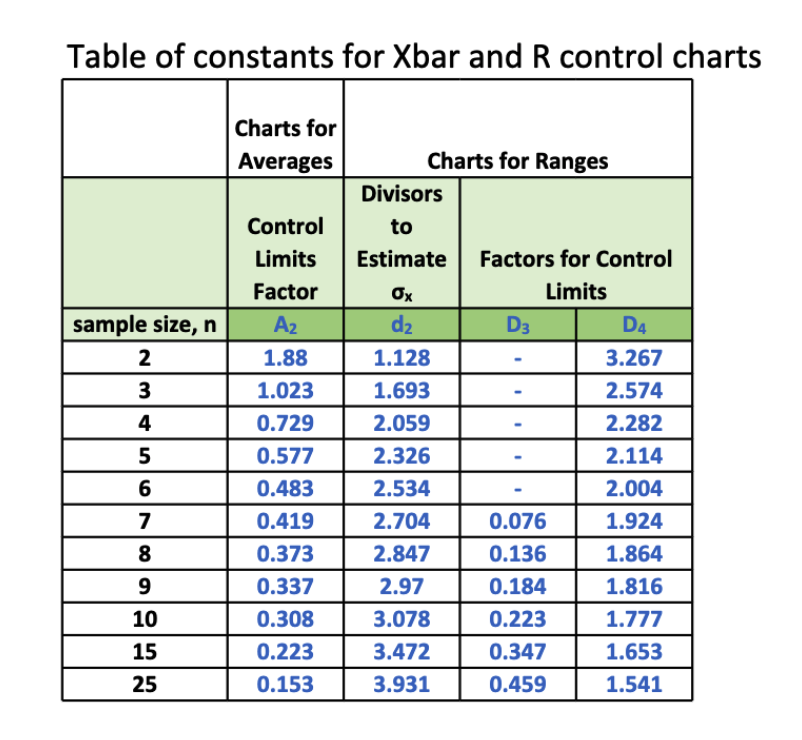

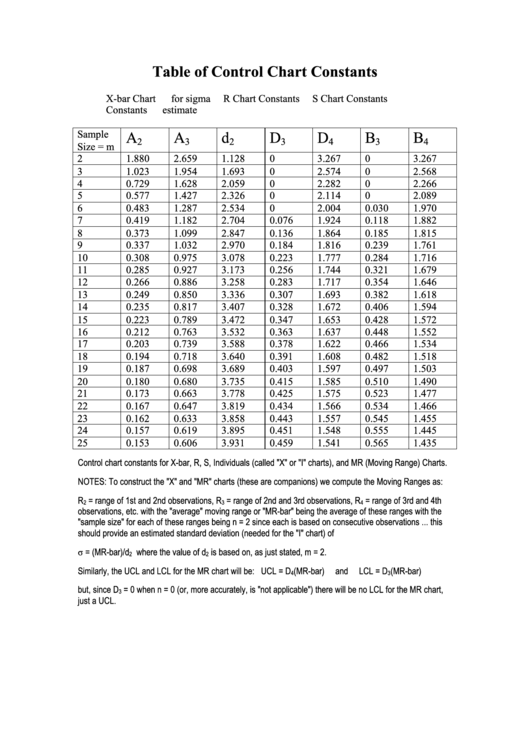

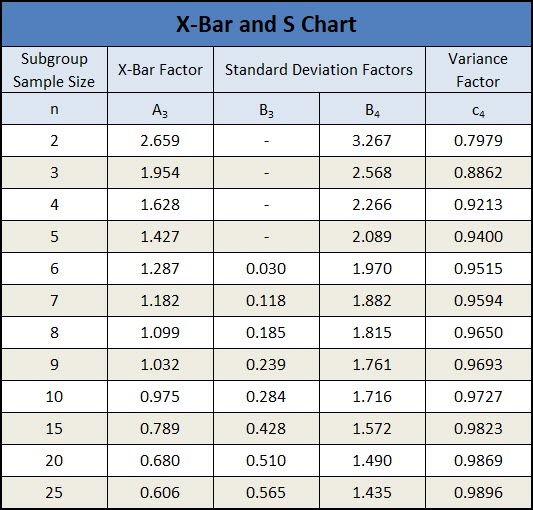

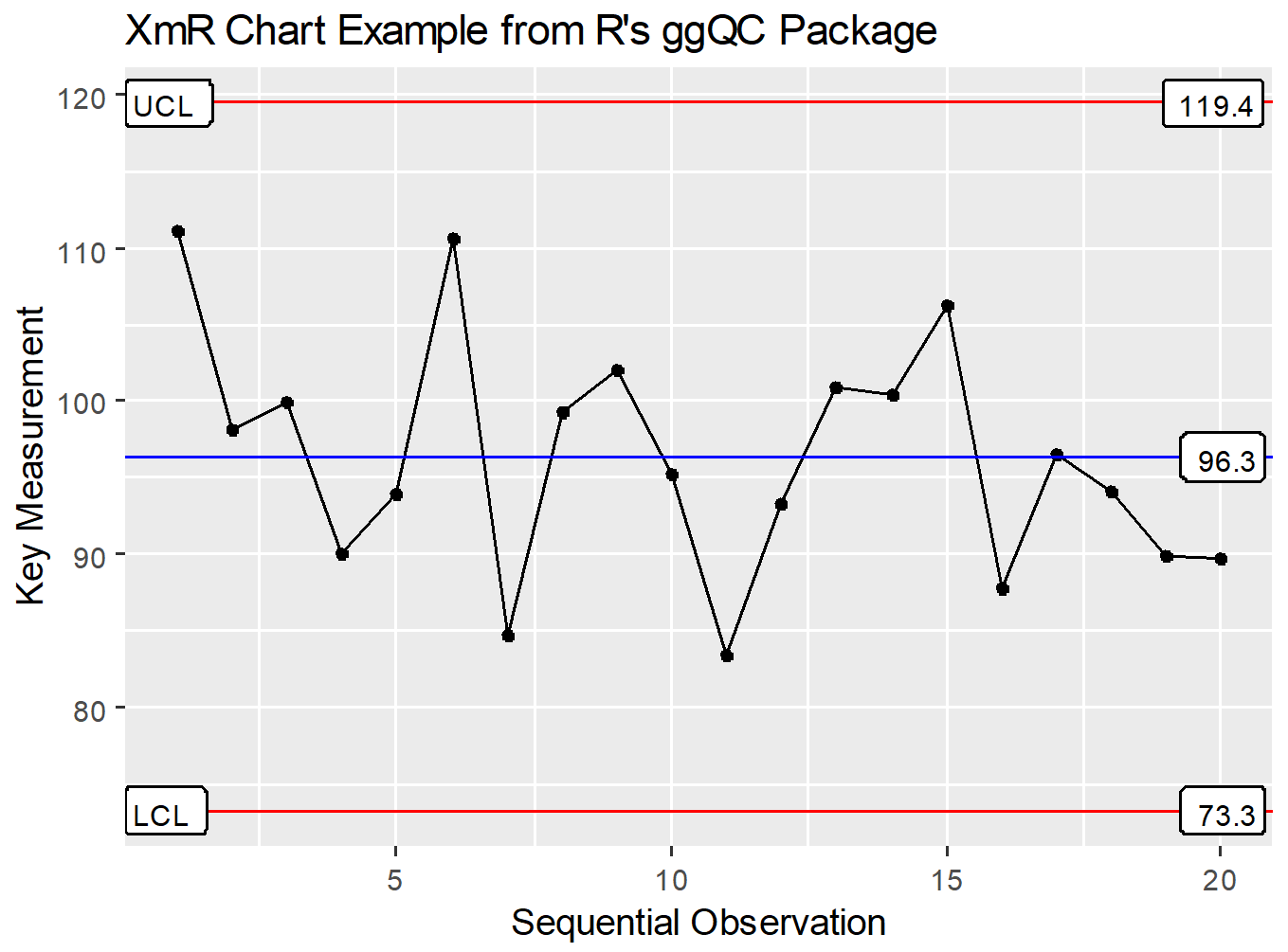

Control Chart Constants - Web a control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Web once you know the value of n, you can obtain the correct constants (a2, a3, etc.) to complete your control chart. Qi macros has the constants built in! Individuals and moving range chart. For example, if you are taking temperature measurements every min and there are three. It is more appropriate to say that the control charts are the graphical device for statistical process monitoring (spm). These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Web choose the appropriate control chart for your data. Quality improvement methods have been applied in the last few 10 years to fulfill the needs of consumers. Statistical methods for six sigma by anand m. Quality improvement methods have been applied in the last few 10 years to fulfill the needs of consumers. Subgroups falling outside the control limits should be removed from the calculations to. When one is identified, mark it on the chart and investigate the cause. X bar and s charts. Statistical methods for six sigma by anand m. These limits let you know when unusual variability occurs. It is more appropriate to say that the control charts are the graphical device for statistical process monitoring (spm). Determine the appropriate time period for collecting and plotting data. Web looking for a control chart constants table? Control charts are important tools of statistical quality control to enhance quality. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Web choose the appropriate control chart for your data. This relationship depends only on the sample size, n. Collect data, construct your chart and analyze the data. Web looking for a control chart constants table? Web a control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Quality improvement methods have been applied in the last few 10 years to fulfill the needs of consumers. Statistical methods for six sigma by anand m. The center line represents the process mean. Web. Web control chart constants home » spc for excel help » control charts help » control chart constants the control chart constants used in the calculations are shown below. Web once you know the value of n, you can obtain the correct constants (a2, a3, etc.) to complete your control chart. These limits let you know when unusual variability occurs.. Of constants for control charts. Walter shewhart had said that these control limits should be 3 times standard deviation from the center line in order to reduce the probability of error happening in detecting the special causes of variation. Web estimating control chart constants. Statistical methods for six sigma by anand m. Determine the appropriate time period for collecting and. Depending on the number of process characteristics to be monitored, there are two basic types of control charts. Web table of constants and formulas for control charts. The control limits represent the process variation. A control chart, also known as a statistical process control chart, is a statistical tool used to monitor, control, and improve the quality of processes. Web. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Subgroups falling outside the control limits should be removed from the calculations to. Statistical constants are used for both variable control charts. Determine the appropriate time period for collecting and plotting data. It is more appropriate to say that the control charts are the graphical device for statistical process monitoring (spm). But where do the a2 and e2 constants come from? The center line represents the process mean. Collect data, construct your chart and analyze the data. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Web once you know the value of n, you can obtain the correct constants (a2, a3, etc.) to complete your control chart.. The control limits represent the process variation. Web the range of a sample is simply the difference between the largest and smallest observation. Statistical formulas use historical records or sample data to calculate the control limits. Statistical methods for six sigma by anand m. There is a statistical relationship (patnaik, 1946) between the mean range for data from a normal distribution and σ , the standard deviation of that distribution. Web what are control charts? Walter shewhart had said that these control limits should be 3 times standard deviation from the center line in order to reduce the probability of error happening in detecting the special causes of variation. Most control charts include a center line, an upper control limit, and a lower control limit. The value of n is the number of subgroups within each data point. The product has to retain the desired properties with the least possible defects, while maximizing profit. It is more appropriate to say that the control charts are the graphical device for statistical process monitoring (spm). Web looking for a control chart constants table? Quality improvement methods have been applied in the last few 10 years to fulfill the needs of consumers. Determine the appropriate time period for collecting and plotting data. This relationship depends only on the sample size, n. The center line represents the process mean.table_of_control_chart_constants_old.pdf Descriptive Statistics

Table Of Control Chart Constants

Solved Table of constants for Xbar and R control charts

XMR Control Chart Constants / Control Chart Constants How to Derive

Table Of Control Chart Constants printable pdf download

Control Chart Constants Table Descriptive Statistics Statistics

Control Chart Constants Table

Control Chart Constants Tables and Brief Explanation (2022)

Table Of Control Chart Constants

Control Chart Constants and Formulas.pdf Mathematics Statistical

Web Table Of Constants And Formulas For Control Charts.

Statistical Constants Are Used For Both Variable Control Charts Like The Xmr, Xbarr And Xands Charts And In Process Capability Calculations.

Wheeler, D.j., & Chambers, D.s.

Control Charts Are Important Tools Of Statistical Quality Control To Enhance Quality.

Related Post: