Corrugated Thickness Chart

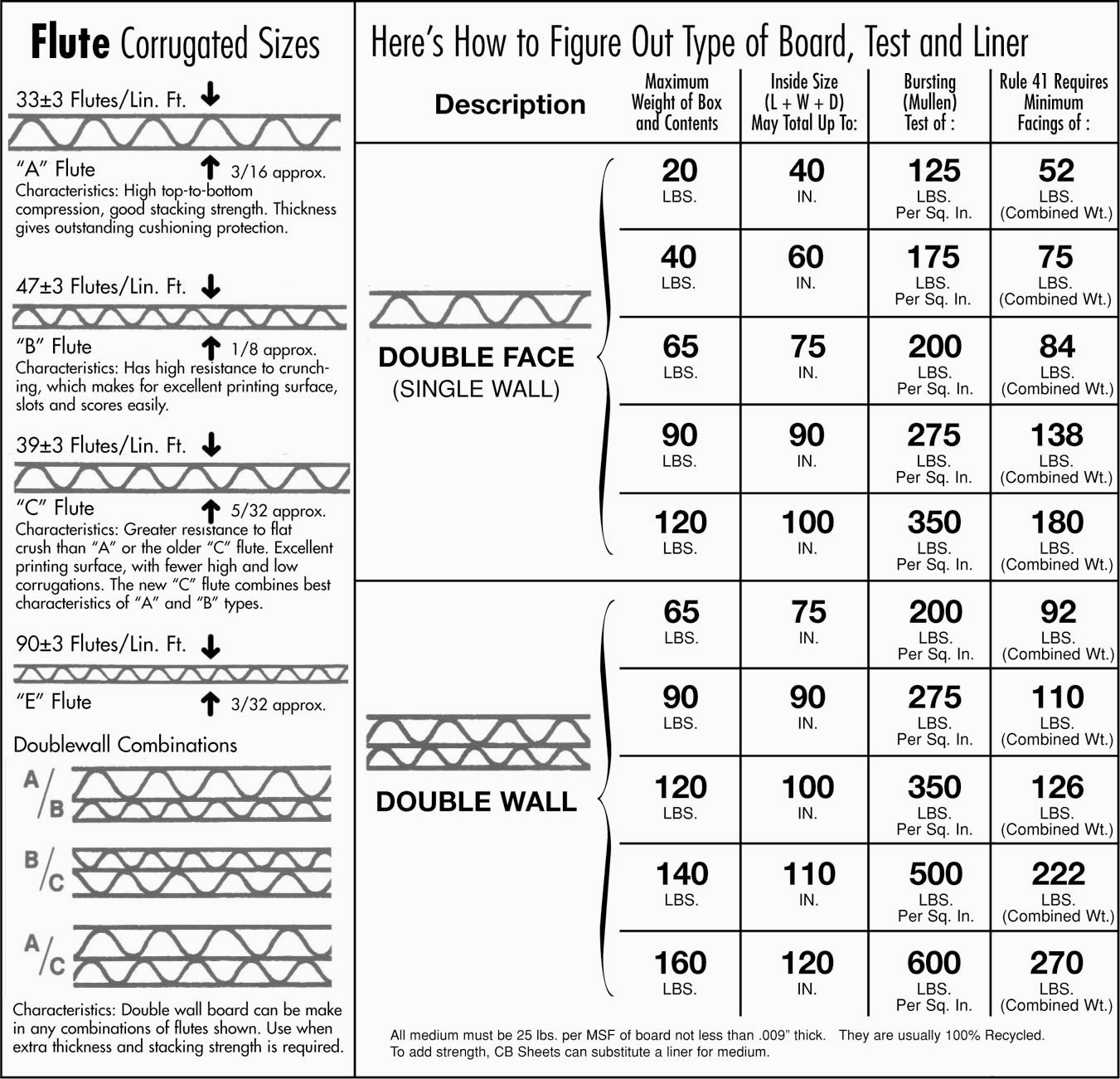

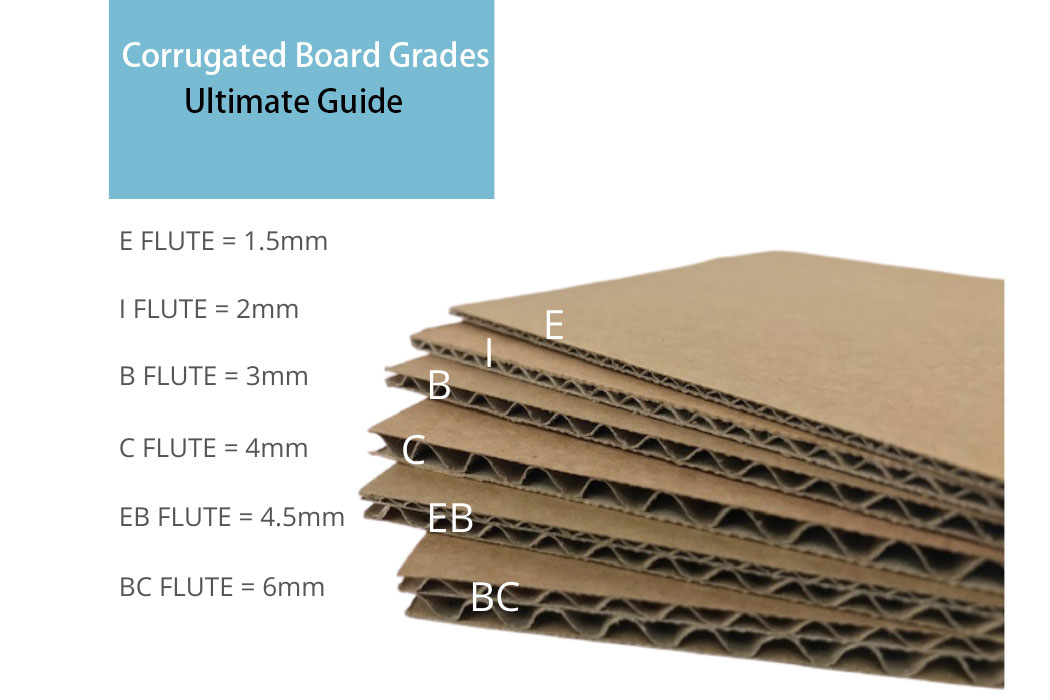

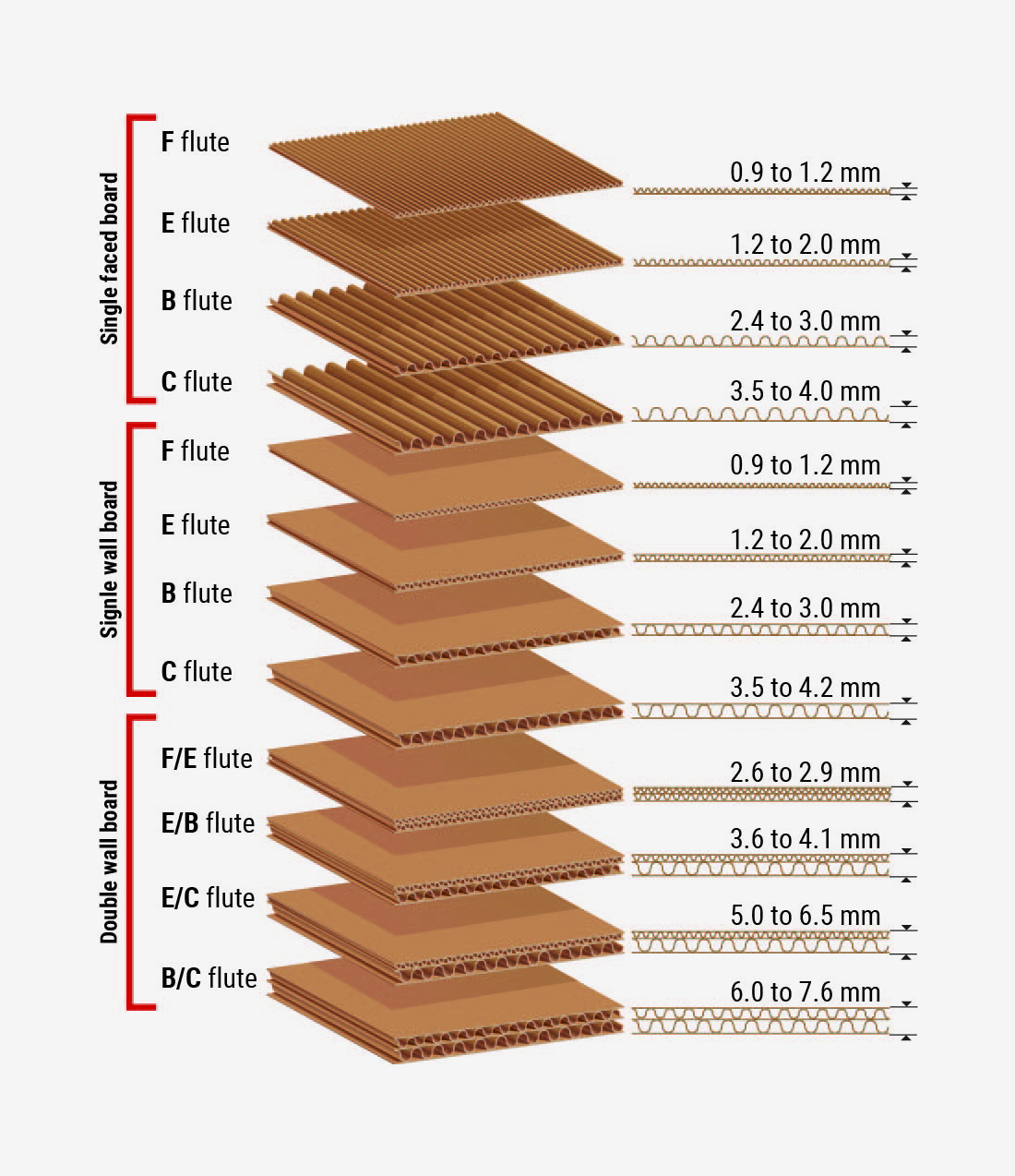

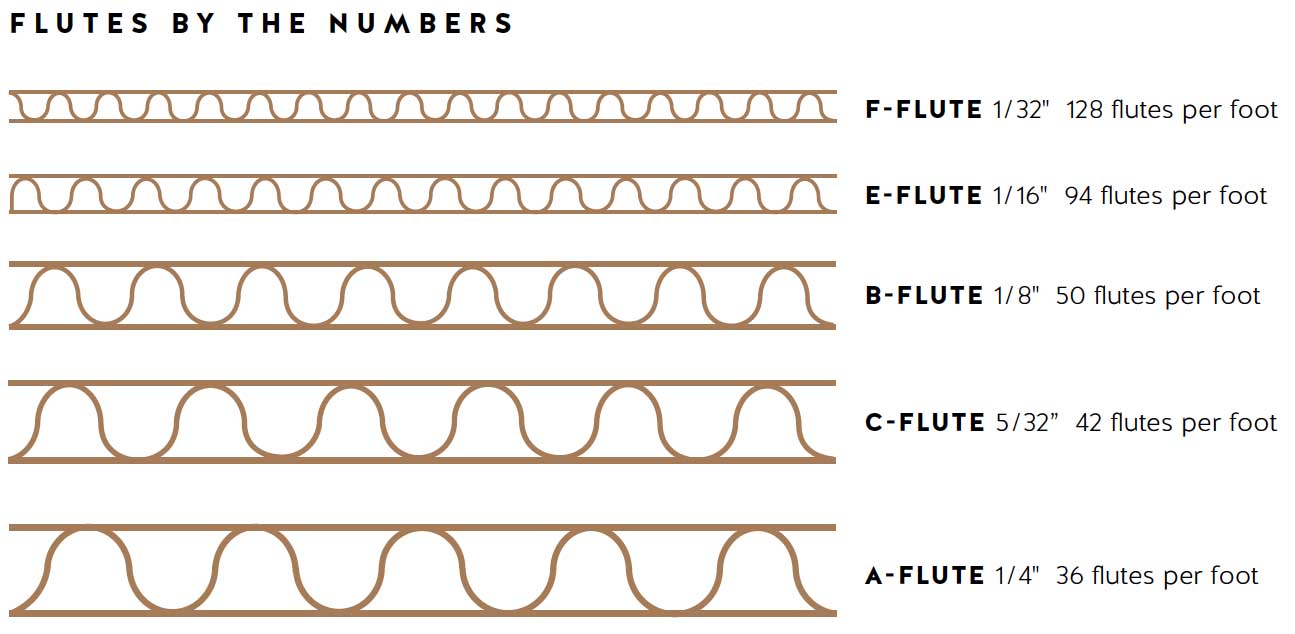

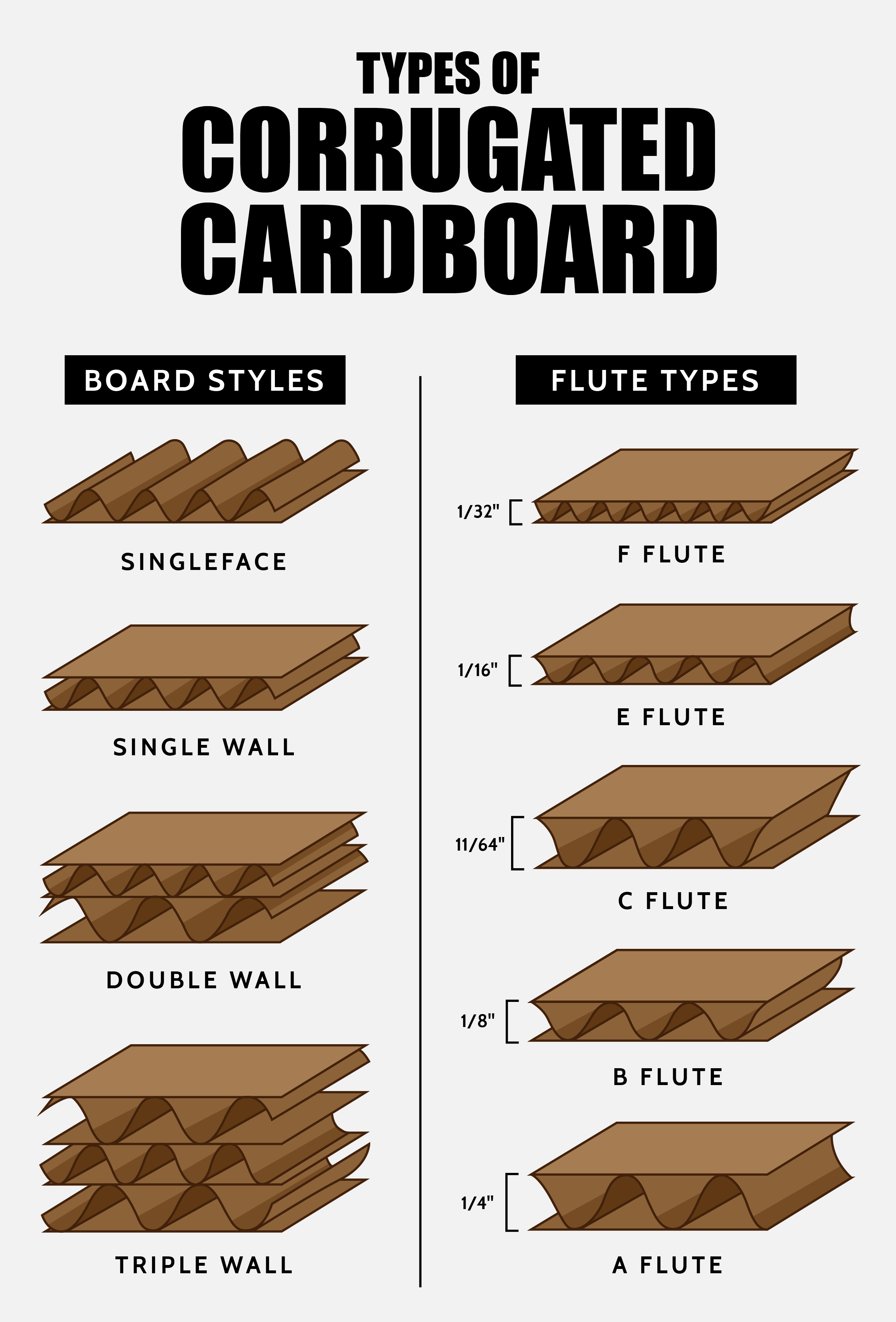

Corrugated Thickness Chart - Web learn about the various types of corrugated boxes and what the different corrugated flute types mean. What are the components of corrugated board made of? The 3 x 1 corrugation is available in diameters of 48 to 126. The most common, used in most typical shipping boxes,. Web do you know what determines the strength and price of the corrugated boards? Two plies of fluted paper which are glued together by one ply of unfluted paper or cardboard and the exposed outer surfaces of which are each covered with one ply of paper or cardboard. These boxes are designed to keep moisture and bacteria away from products within the box. ‘ridged’ or ‘crimped’) material glued between two layers of paper, also known as the outer and inner liners. They act as another layer of protection during shipping. Each flute size has a particularly useful function, from shipping strength to reducing storage space to improved printability. The 3 x 1 corrugation is available in diameters of 48 to 126. They act as another layer of protection during shipping. Need a box that’s stronger, but not double wall stronger? Web corrugated board and material grades. Web smooth cor is available in diameters ranging from 18 inches to 66 inches in 2 2/3 x 1/2 corrugation. Here's a closer look at the size and thickness guide, from least durable to most durable: Web corrugated board and material grades. Corrugated material is very protective and durable, especially compared to regular cardboard boxes. Web there are a number of different thicknesses of corrugated fiberboard made. Web learn about the various types and thickness grades of corrugated cardboard, including. If you are using high volumes of packaging, chances are you will be familiar with corrugated. Web corrugated material is available in different wall thicknesses, known as flutes sizes. Premium materials, premium performance, single wall board. A detailed guide to corrugated board grades / cardboard types. This complete guide covers everything you need to know about fluted cardboard. Web corrugated board and material grades. Web there are a number of different thicknesses of corrugated fiberboard made. Corrugated fibre board, the backbone of much of our packaging, indeed presents an. Corrugated fiberboard boxes are widely utilized in retail packaging, shipping cartons, product displays and many other applications requiring a lightweight, but sturdy material. Web cardboard boxes are really chipboard. The most common are designated by the fluting letters 'a', 'b', 'c', 'd', 'e', and 'f'. Each flute size has a particularly useful function, from shipping strength to reducing storage space to improved printability. When shipping food contents, these boxes are a great solution to ensure freshness. The most common, used in most typical shipping boxes,. Corrugated material is very. Pro pac distributes packaging materials and packaging machinery across the country. Specifying cmp products involves some familiarity with the industry publications, and this specification guide serves as a locus of these standards. We’ve filled the gap between single wall and lighter duty double grades with something truly different. What type of corrugated is best suited to ship your product? A. Web learn about the various types and thickness grades of corrugated cardboard, including flute profiles, paper liners, and paper types. Premium materials, premium performance, single wall board. Web this cardboard thickness guide will walk you through everything you need to know about the properties of corrugated cardboard and how to choose the right specifications for your packaging needs. Corrugated fiberboard. Corrugated material is very protective and durable, especially compared to regular cardboard boxes. Pro pac distributes packaging materials and packaging machinery across the country. Corrugated flutes are essentially the wavy medium that exists between the pieces of straight liner board. Premium materials, premium performance, single wall board. What type of corrugated is best suited to ship your product? If you cut any box, you'll. A corrugated “flute” refers to the wavy sheets of paper that are sandwiched in between the cardboard liners in corrugated cardboard boxes. Web corrugated board and material grades. Web smooth cor is available in diameters ranging from 18 inches to 66 inches in 2 2/3 x 1/2 corrugation. They act as another layer of. If you are using high volumes of packaging, chances are you will be familiar with corrugated. This is the most common type of flute, usually slightly thicker than b flutes at 3/16 of an inch, and are the preferred type of flutes for everyday shipments. Pro pac distributes packaging materials and packaging machinery across the country. Web corrugated flute type. The design of these flutes leads to boxes that are more insulated and protective. Pro pac distributes packaging materials and packaging machinery across the country. What type of corrugated is best suited to ship your product? These boxes are designed to keep moisture and bacteria away from products within the box. Web b flutes are usually 1/8 of an inch thick and are best used in smaller cartons that aren’t going to be carrying heavy products. Web here is a handy chart to compare all of these variables. We’ve filled the gap between single wall and lighter duty double grades with something truly different. Web do you know what determines the strength and price of the corrugated boards? Web each sheet of corrugated cardboard has three components: Web there are a number of different thicknesses of corrugated fiberboard made. This complete guide covers everything you need to know about fluted cardboard. Need a box that’s stronger, but not double wall stronger? In general, the design engineer will need to: What are the components of corrugated board made of? Corrugated fiberboard boxes are widely utilized in retail packaging, shipping cartons, product displays and many other applications requiring a lightweight, but sturdy material. Premium materials, premium performance, single wall board.

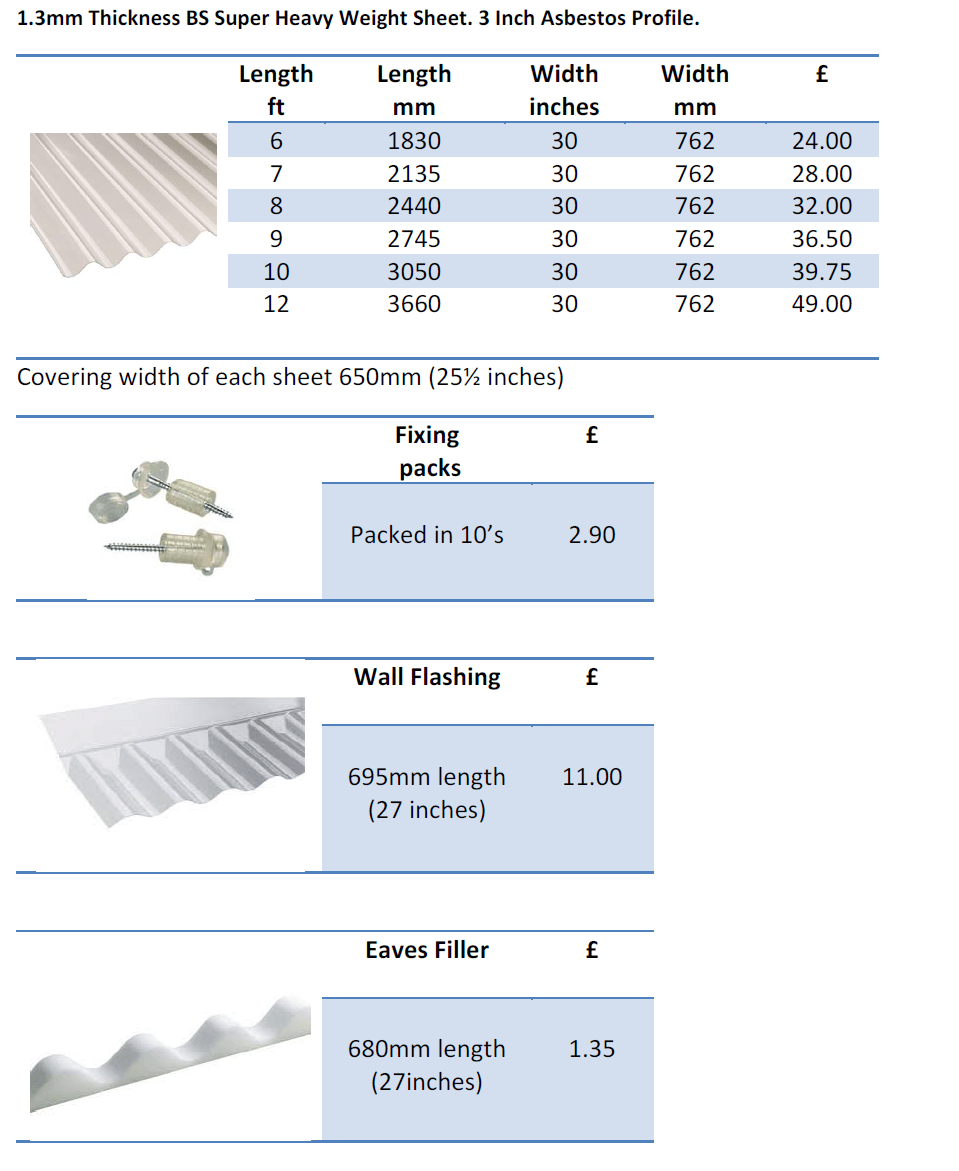

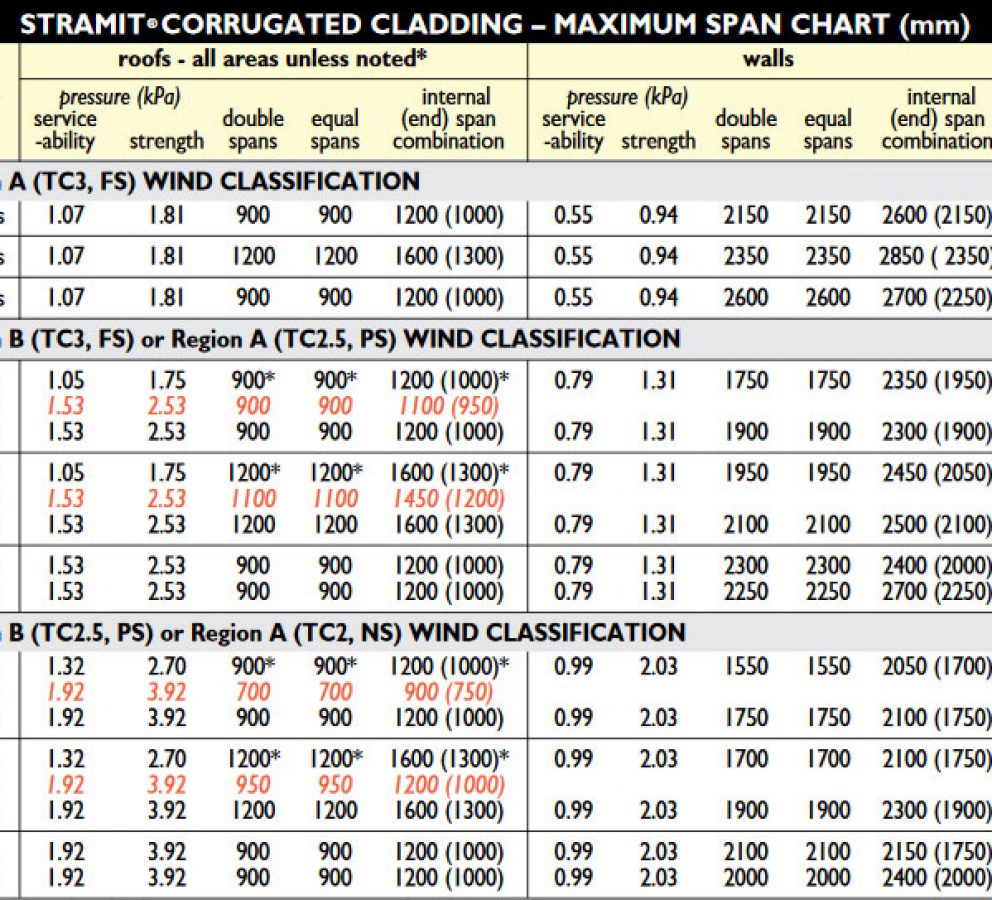

Francis sheet sales Ltd Vistalux Corrugated Sheet size and Price List

Corrugated Board Thickness Chart

Glossary

Corrugated Board Grades Everything You Need to Know

How to Determine the Right Flute Packaging 101 WCP Solutions

Corrugated Roof A&A Flashings

How to Choose Right Corrugated for Your Boxes

Corrugated Board Grade Chart

9 Corrugated Box Testing Methods to Ensure Packaging Quality (2023)

Properties Of Corrugated Board

Corrugated Material Is Very Protective And Durable, Especially Compared To Regular Cardboard Boxes.

They Act As Another Layer Of Protection During Shipping.

Specifying Cmp Products Involves Some Familiarity With The Industry Publications, And This Specification Guide Serves As A Locus Of These Standards.

A Corrugated “Flute” Refers To The Wavy Sheets Of Paper That Are Sandwiched In Between The Cardboard Liners In Corrugated Cardboard Boxes.

Related Post: