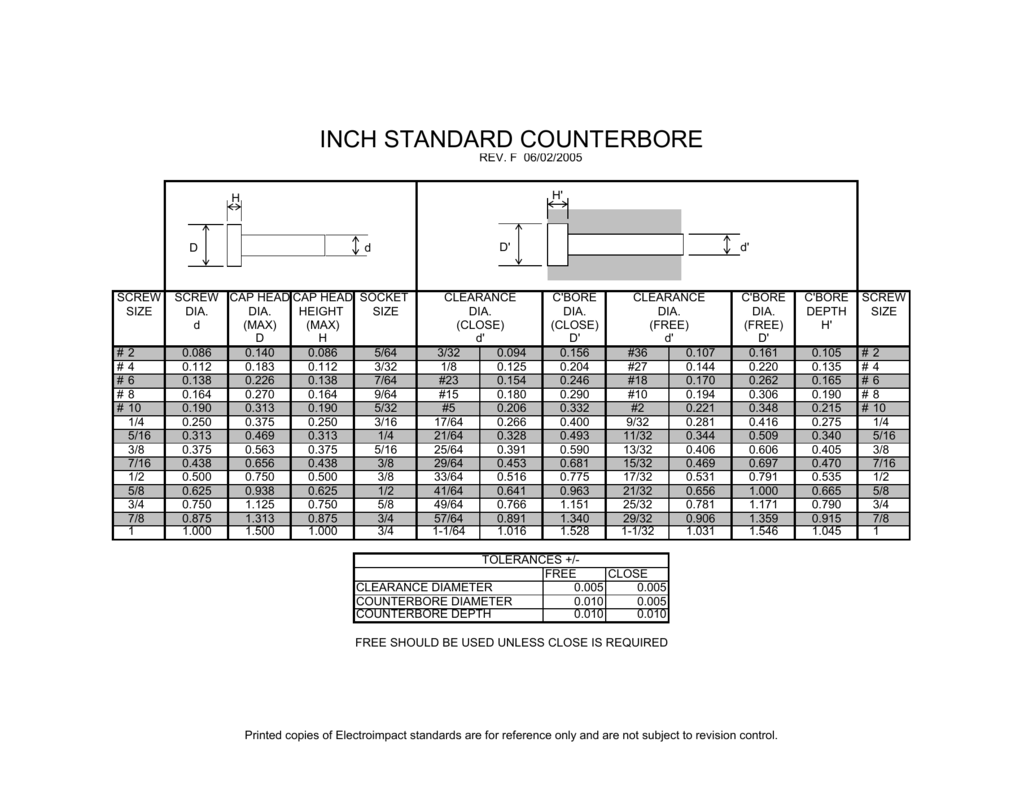

Counterbore Diameter Chart

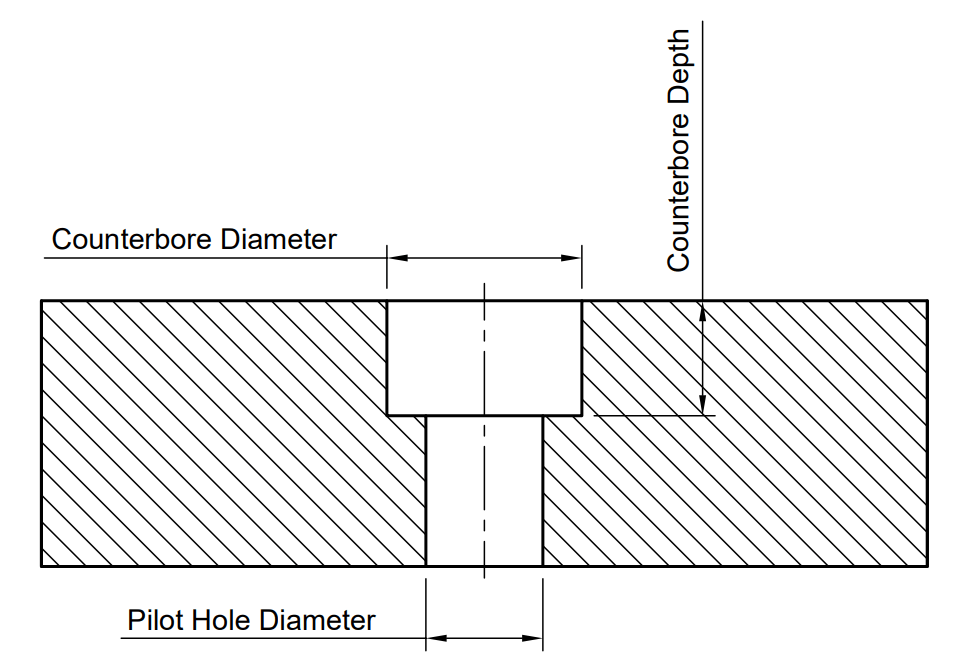

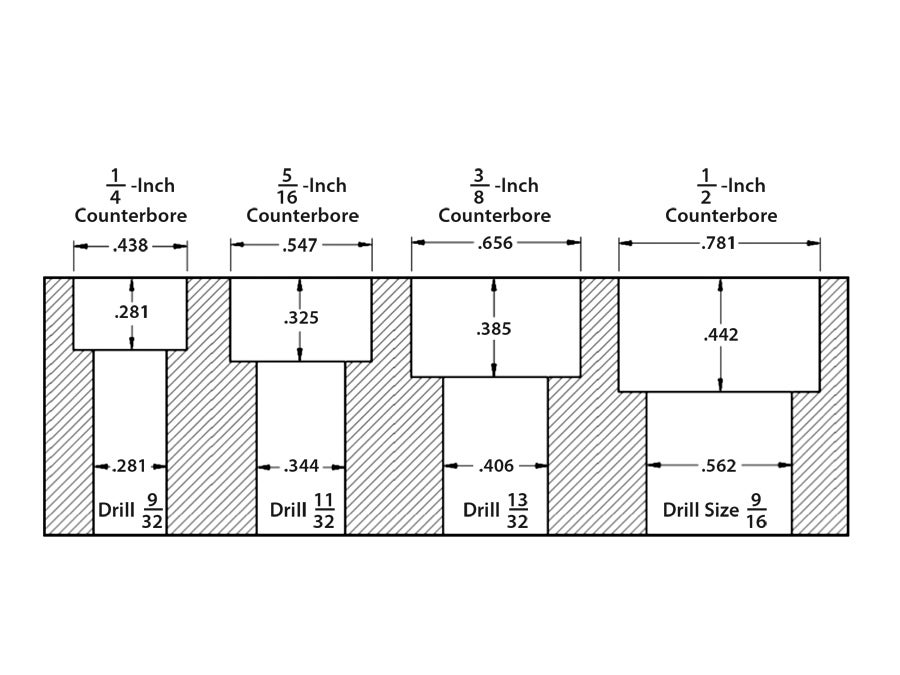

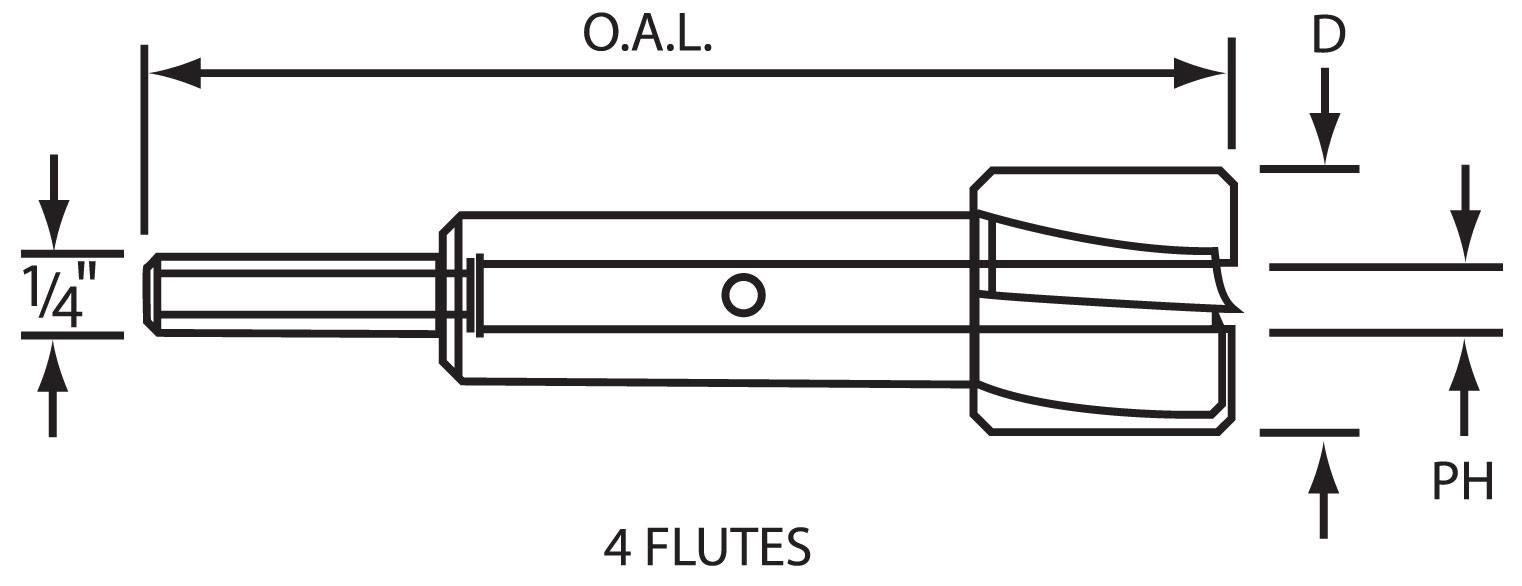

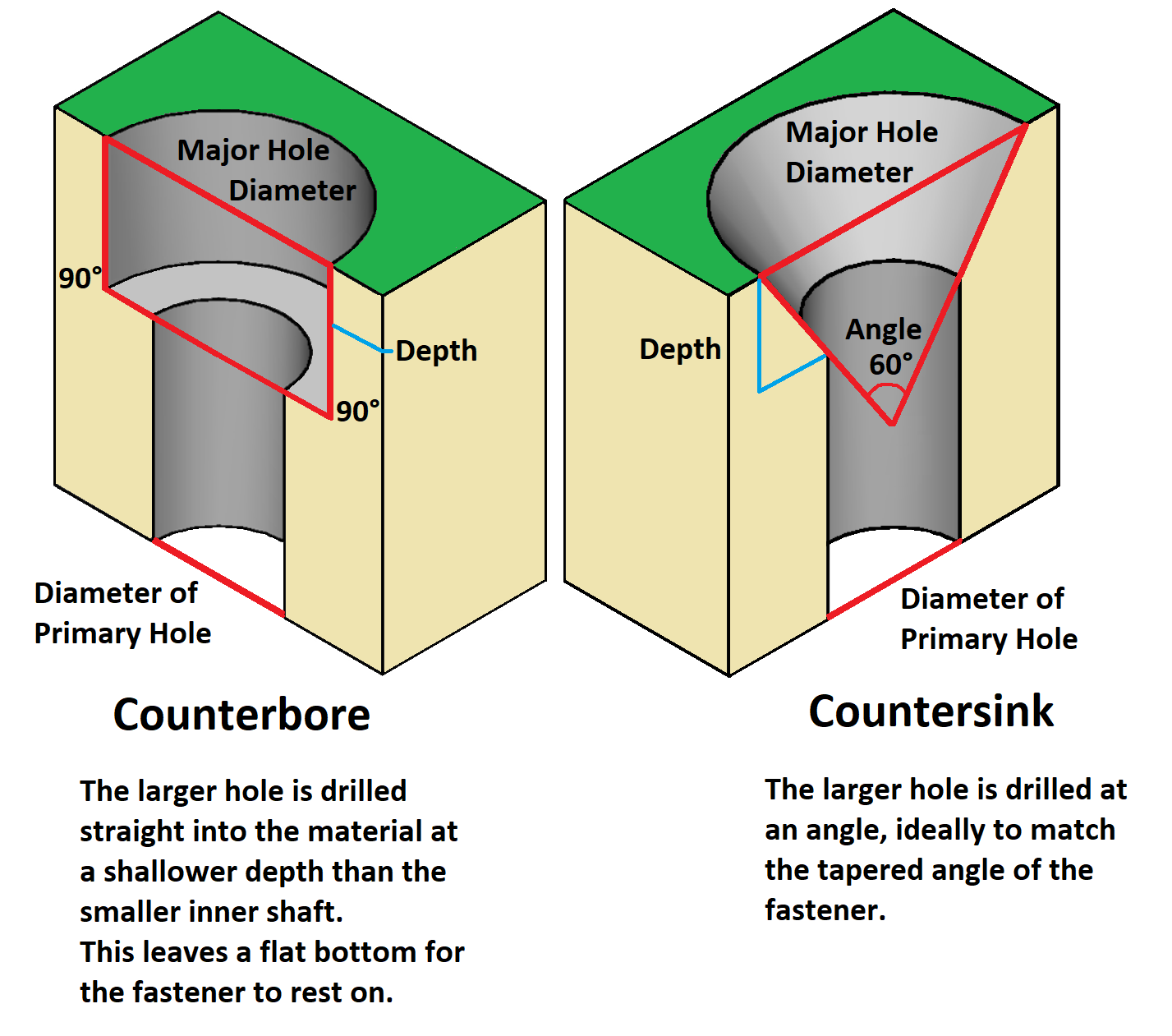

Counterbore Diameter Chart - For example, an iso 4762 m6 socket cap head bolt with a normal fit counterbored hole will require a pilot hole diameter of 6.6 mm, a counterbore diameter of 11 mm, and a counterbore depth of 6.8 mm. Below are visuals of countersinking and counterboring in cutting and forming applications. Both approaches are acceptable and frequently used. Web use the image and chart below to determine what dimensions to use, all dimensions are in millimetres. Web counterbore diameter (this should be larger than the diameter of the fastener head, seal, or gasket) counterbore angle (this is a standard 90 degrees for any fastener) pilot hole diameter (defined by the fastener thread diameter) Where is a counterbore used? For example, an ansi inch 2″ socket cap head bolt with a normal fit counterbored hole will require a pilot hole diameter of 2 1/8″, a counterbore diameter of 3 1/8″, and a counterbore depth of 2 1/16″. For example, an ansi inch 5/8″ shoulder screw with a normal fit counterbored hole will require a pilot hole diameter of 13/16″, a counterbore diameter of 1 1/8″, and a counterbore depth of 1/2″. If such holes are not countersunk, the. There are two classes of fit category; If such holes are not countersunk, the. Web counterbore dimensions size chart for recommended standard clearance and counterbore hole sizes for metric socket head cap screws from m1.6 through m48 size including m5, m6 and m8. This short post will give you the exact dimensions you need for your countersunk screws. The below chart illustrates counterbore compatibility with carr lane. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Web counterbored hole dimensions for us socket head cap screws. Clearance diameter (normal fit) clearance diameter (close fit) #0. Web 7 min read. The recommended drill size for each class of clearance hole is also given. Web use the image and chart below to determine what dimensions to use, all dimensions are in millimetres. The below chart illustrates counterbore compatibility with carr lane drill bushings of various sizes. Web countersink diameters are based on the theoretical maximum head diameter at a depth of.005 to.015 and an angle of 82 degrees. This short post will give you. The below chart illustrates counterbore compatibility with carr lane drill bushings of various sizes. Web diameter and depth:the diameter of the countersink hole is determined by the size of the fastener head, ensuring a proper fit and allowing the head to sit flush or below the material surface. Web countersink diameters are based on the theoretical maximum head diameter at. The leftover material's thickness or the counterbore's depth are the two ways to specify the depth. Web a countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. When sizing a counterbore, it is vital to provide both the depth and the counterbore's diameter. A counterbore involves adding a stepped hole, that recesses. 9/32 0.138 0.158 #18 #23 #8. For example, an iso 4762 m6 socket cap head bolt with a normal fit counterbored hole will require a pilot hole diameter of 6.6 mm, a counterbore diameter of 11 mm, and a counterbore depth of 6.8 mm. For ansi/imperial fasteners, it is commonly at 82°, 90° for metric fasteners, 100° for ba threaded. When sizing a counterbore, it is vital to provide both the depth and the counterbore's diameter. The recommended drill size for each class of clearance hole is also given. There are several types to choose from, depending on your type and length of your drill bushings. Where is a counterbore used? The leftover material's thickness or the counterbore's depth are. Web 7 min read. 1/8 0.06 0.074 #49 #51 #2. Web drill and counterbore sizes for socket head cap screws per. There are several types to choose from, depending on your type and length of your drill bushings. For example, an ansi inch 5/8″ shoulder screw with a normal fit counterbored hole will require a pilot hole diameter of 13/16″,. Web countersink diameters are based on the theoretical maximum head diameter at a depth of.005 to.015 and an angle of 82 degrees. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Both approaches are acceptable and frequently used. For ansi/imperial fasteners, it is commonly at 82°, 90° for metric fasteners, 100° for. Inch cap screw metric cap screw; Web dimensions of a counterbore. Web metric shcs hole & counterbore sizes nominal screw size clearance hole dia. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Web diameter and depth:the diameter of the countersink hole is determined by the size of the fastener head, ensuring. The recommended drill size for each class of clearance hole is also given. Web metric shcs hole & counterbore sizes nominal screw size clearance hole dia. A counterbore involves adding a stepped hole, that recesses the head of the fastener (and washers where fitted). 5/16 0.164 0.188 #10 #15 #10. There are two classes of fit category; The leftover material's thickness or the counterbore's depth are the two ways to specify the depth. Many products seek to improve their appearance by “burying” fasteners. Web counterbore diameter (this should be larger than the diameter of the fastener head, seal, or gasket) counterbore angle (this is a standard 90 degrees for any fastener) pilot hole diameter (defined by the fastener thread diameter) Web dimensions of a counterbore. The below chart illustrates counterbore compatibility with carr lane drill bushings of various sizes. Web use the image and chart below to determine what dimensions to use, all dimensions are in inches. 1/8 0.06 0.074 #49 #51 #2. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Web in essence, a spotface is a shallow counterbore. One way to achieve this is with a counterbore. Web drill and counterbore sizes for socket head cap screws per.

Counterbore Hole Size for Socket Head (ANSI Metric) The Engineer's Bible

Counterbore Chart

Counterbore and Countersink Dimensions Chart

Metric Countersunk Hole Dimensions Chart A Pictures Of Hole 2018

Metric Counterbore Sizes Chart

Counterbore Chart

Shars 7pcs HSS Metric Counterbore Set 3 4 5 6 8 10 12mm New A} eBay

Metric Counterbore Sizes Chart

PCB Hole Types Counterbore vs Countersink ABL Circuits

QMS0003 Standards

There Are Several Types To Choose From, Depending On Your Type And Length Of Your Drill Bushings.

Both Approaches Are Acceptable And Frequently Used.

For Ansi/Imperial Fasteners, It Is Commonly At 82°, 90° For Metric Fasteners, 100° For Ba Threaded Fasteners, And 120° For Sheet Metal Rivets.

Inch Cap Screw Metric Cap Screw;

Related Post: