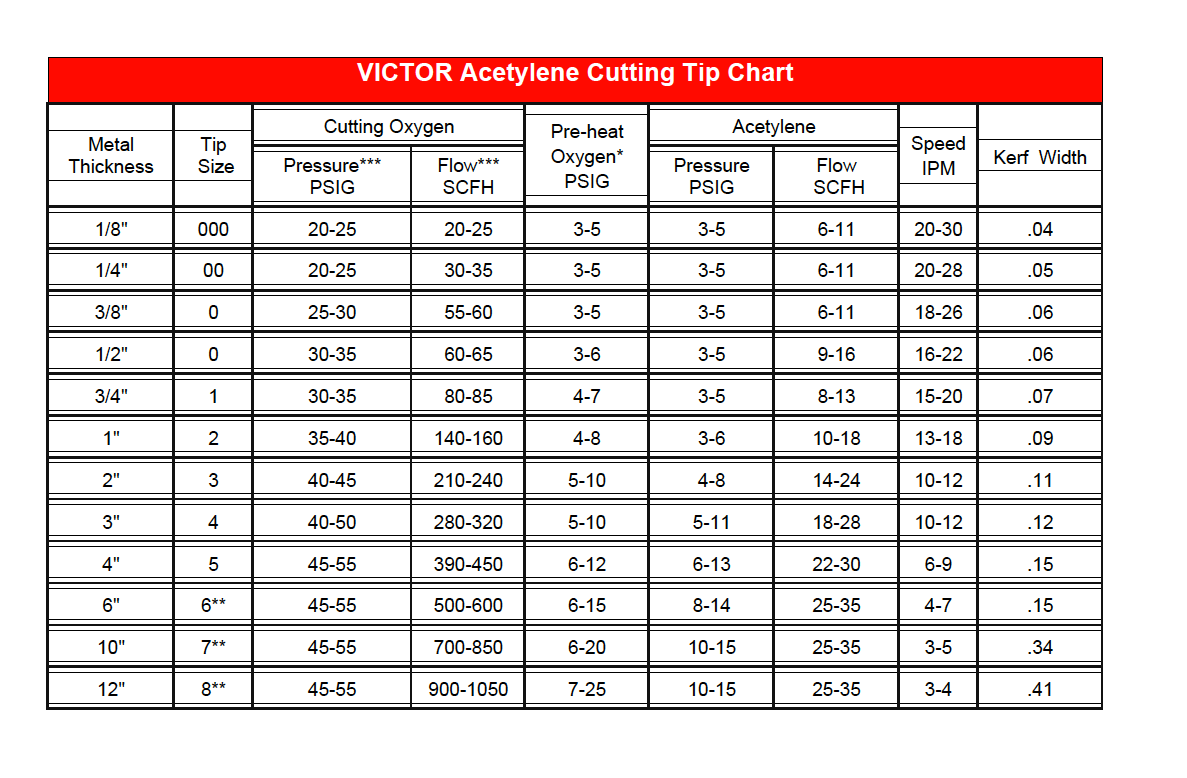

Cutting Torch Pressure Settings Chart

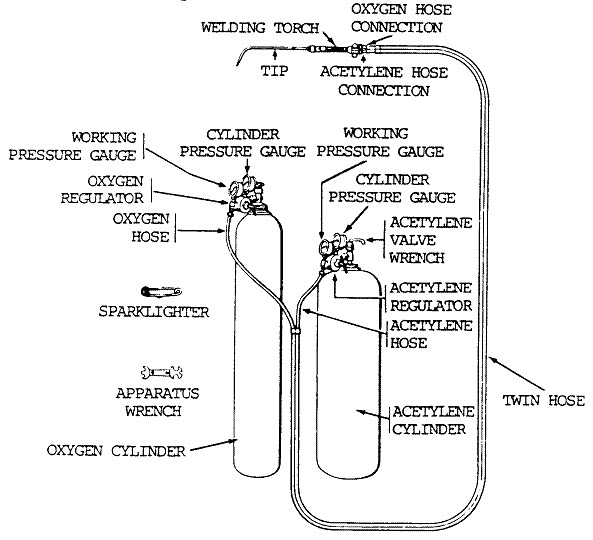

Cutting Torch Pressure Settings Chart - Set supply pressure for cutting oxygen pressure at supply regulator to approximately 90 psi adjust cutting oxygen pressure on hi/low preheat manifold regulator to the value shown in. For additonal information refer to www.harrisproductsgroup.com. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). All pressure settings are flowing pressures. Retro systems 430 clay valley center, ks 67147. Web it uses extreme heat to function, and setting it up properly is one of the most important steps in using it safely. Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Adjust to the correct flame setting. If more than 100 ft (31 m) of hose is required, use 1/2 in. How does an oxy acetylene cutting torch work? Make use of correct welding & cutting technique. Adjust to the correct flame setting. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Increase regulator pressures if longer hose or smaller i.d. All pressure settings are flowing pressures. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Remember to prioritize safety at all times and regularly maintain. Web cutting torch tip flow charts. Web · open oxygen valve and adjust to neutral flame. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi. For additonal information refer to www.harrisproductsgroup.com. Web oxy acetylene welding set up and pressure settings chart : Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Attach the oxygen and acetylene regulators to the cylinders. What metals can be cut using an oxy acetylene cutting. Selecting the correct welding attachment/ nozzles. By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you can enhance your cutting capabilities. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Hose for size 4 and larger. All pressure settings are flowing pressures. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Retro systems 430 clay valley center, ks 67147. Open regulator oxygen and acetylene, set until the pressure matches with what you want or. Web cutting torch tip flow charts. Selecting the correct welding attachment/ nozzles. All pressure settings are flowing pressures. Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Web follow these steps carefully: Frequently asked questions for using oxy acetylene cutting torch. Web oxy acetylene welding set up and pressure settings chart : By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you can enhance your cutting capabilities. Use the charts below as recommended settings to use on your regulators for your cutting torch. Oxy acetylene cutting settings are crucial for achieving clean and precise cuts in metal fabrication. For additonal information refer to www.harrisproductsgroup.com. Web follow these steps carefully: What metals can be cut using an oxy acetylene cutting. What are the safety precautions when using an oxy acetylene cutting torch? Web · open oxygen valve and adjust to neutral flame. Cutting data charts are intended as a guide for quality cutting. Use the charts below as recommended settings to use on your regulators for your cutting torch tips. What are the safety precautions when using an oxy acetylene cutting torch? All pressure settings are flowing pressures. Web cutting tips come in different sizes so you'll need to look at a chart depending on what thickness metal you will be cutting. What metals can be cut using an oxy acetylene cutting. · close fuel gas torch valve. Tighten them, but not too forcefully, as you’ll need to remove. Set supply pressure for cutting oxygen pressure at supply. Selecting the correct welding attachment/ nozzles. Use the charts below as recommended settings to use on your regulators for your cutting torch tips. Before you start using the cutting torch, it’s crucial to set up the equipment properly. Make use of correct welding & cutting technique. Web let’s break down how you can master your cutting torch settings and never lack confidence when facing down an instruction manual or inquisitive neighbor ever again. By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you can enhance your cutting capabilities. Web follow these steps carefully: Web pressure and flow data: Web cutting tips come in different sizes so you'll need to look at a chart depending on what thickness metal you will be cutting. Shutting down the torch (with a positive/equal pressure mixer): Web oxy acetylene welding set up and pressure settings chart : What are the safety precautions when using an oxy acetylene cutting torch? What metals can be cut using an oxy acetylene cutting. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. For additonal information refer to www.harrisproductsgroup.com. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient cuts.

Cutting Torch Settings Chart

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

Cutting Torch Guide

Cutting Torch Pressure Chart

Oxyacetylene Torch Settings Chart

Cutting Torch Tip Flow Charts Baker's Gas & Welding Supplies, Inc.

Cutting Torch Pressure Chart

4 Best Images of Victor Acetylene Cutting Tip Chart Victor Acetylene

Cutting Torch Chart

Oxyacetylene Torch Settings Chart

Torches With Flashback Arrestors Require Up To 25% More Pressure As Tip Size Increases (15 Psi Maximum Acetylene Pressure).

** For Best Results Use Appropriate Capacity Torches And 3/8 Hose When Using Tip Size 6 Or Larger.

Open Regulator Oxygen And Acetylene, Set Until The Pressure Matches With What You Want Or For Acetylene 5 To 7 Psi And Oxygen 7 To 10 Psi.

Setting The Correct Working Pressures.

Related Post: