Draw Ratio

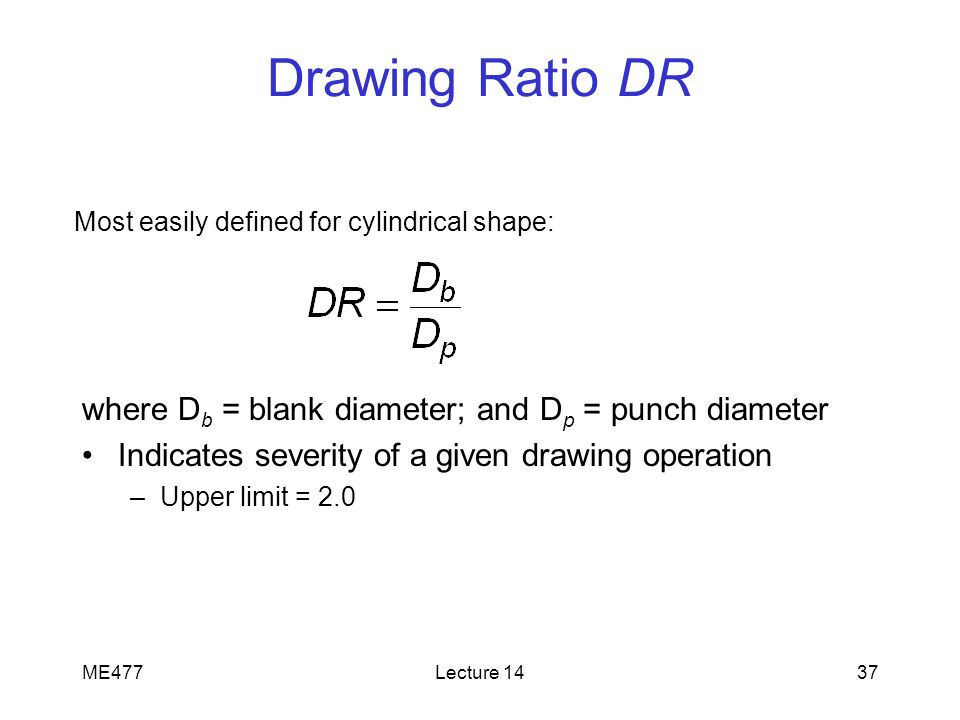

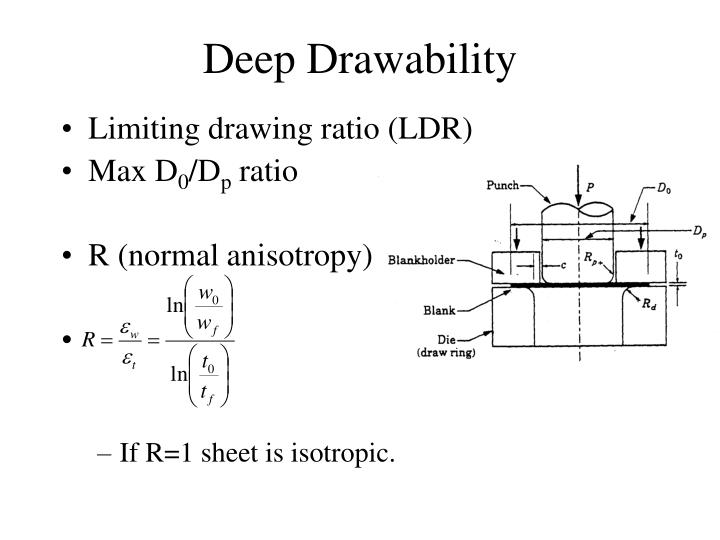

Draw Ratio - Although i promised not to. It divides the surface area of the mold by the footprint, or top surface, of the heated sheet. The resulting spiral approximates the golden spiral, a form of the golden ratio. Web the formula for expressing the draw ratio is as follows: Effect of draw ratio and triggering temperature on properties of hydrothermal responsive shape memory microcomposite filaments. Web the draw ratio is the relationship between the size of the draw punch and the diameter of the blank. The draw ratio is the depth of the part divided by the narrower of width or length. The draw ratio is a crucial concept in the realm of vacuum forming. Web the draw ratio is controlled by several basic factors: 2(48” x 12”) + 2(36” x 12”) + (48” x 36”) 1,152” + 864” + 1,728” surface area = 3,744” step 2: Simply put, it describes the relationship between the initial size of the plastic. Web the draw ratio is among the most important elements to be considered when attempting to deep draw a round cup. 48” x 36” = 1,728” step 3:. In general the draw ratio should be restricted to 1:1. Web how to calculate drawing ratio (dr) and reduction. In general the draw ratio should be restricted to 1:1. In other words, it is the ratio of the maximum blank. This process is the combination of metal forming. 2(48” x 12”) + 2(36” x 12”) + (48” x 36”) 1,152” + 864” + 1,728” surface area = 3,744” step 2: Draw ratio = the surface area of the part. In other words, it is the ratio of the maximum blank. The draw ratio must fall within acceptable limits to allow metal to flow. Web the formula for expressing the draw ratio is as follows: The draw ratio is the depth of the part divided by the narrower of width or length. In general the draw ratio should be restricted. It divides the surface area of the mold by the footprint, or top surface, of the heated sheet. The draw ratio must fall within acceptable limits to allow metal to flow. 2 shows that the punch diameter equals the. The draw ratio is a crucial concept in the realm of vacuum forming. In general the draw ratio should be restricted. It divides the surface area of the mold by the footprint, or top surface, of the heated sheet. 2(48” x 12”) + 2(36” x 12”) + (48” x 36”) 1,152” + 864” + 1,728” surface area = 3,744” step 2: Draw ratio = the surface area of the part / footprint of the part. 48” x 36” = 1,728” step. Assume a part is 10”x 12”x 2” deep. Although i promised not to. The draw ratio in the stable. In other words, it is the ratio of the maximum blank. Web draw refers to the ratio of height to width of the part at any location. Web deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. Assume a part is 10”x 12”x 2” deep. Effect of draw ratio and triggering temperature on properties of hydrothermal responsive shape memory microcomposite filaments. Web draw down ratio is the ratio of the cross sectional area of. Web the draw ratio is the relationship between the size of the draw punch and the diameter of the blank. The draw ratio is the relationship between the size of the draw. The draw ratio is the depth of the part divided by the narrower of width or length. Tensile and impact properties improve but adhesion reduces as draw ratio. Web deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. Web the formula for expressing the draw ratio is as follows: Web the draw ratio is controlled by several basic factors: In general the draw ratio should be restricted to 1:1. The draw ratio must fall within. 48” x 36” = 1,728” step 3:. In other words, it is the ratio of the maximum blank. Web the formula for expressing the draw ratio is as follows: Web the draw ratio is among the most important elements to be considered when attempting to deep draw a round cup. The draw ratio must fall within acceptable limits to allow. The draw ratio is the depth of the part divided by the narrower of width or length. Web the formula for expressing the draw ratio is as follows: It divides the surface area of the mold by the footprint, or top surface, of the heated sheet. Tensile and impact properties improve but adhesion reduces as draw ratio increases. Web the limiting draw ratio (ldr) is the relationship between the diameter of the draw punch and the diameter of the blank; Web the draw ratio is the relationship between the size of the draw punch and the diameter of the blank. In general the draw ratio should be restricted to 1:1. 2(48” x 12”) + 2(36” x 12”) + (48” x 36”) 1,152” + 864” + 1,728” surface area = 3,744” step 2: 48” x 36” = 1,728” step 3:. Web learn the concept of draw ratio, a measure of the ratio of the area or length of the part to the original sheet or line, and its applications in thermoforming. Effect of draw ratio and triggering temperature on properties of hydrothermal responsive shape memory microcomposite filaments. 2 shows that the punch diameter equals the. Web draw down ratio is the ratio of the cross sectional area of the extruded. The resulting spiral approximates the golden spiral, a form of the golden ratio. The mechanical properties of the metal, primary its “r” value or thickness strain ratio, which is its ability to flow plastically and. A draw ratio of less than 1 to 1 is preferable.

How to draw the Golden Ratio SUPER FAST in Illustrator CC YouTube

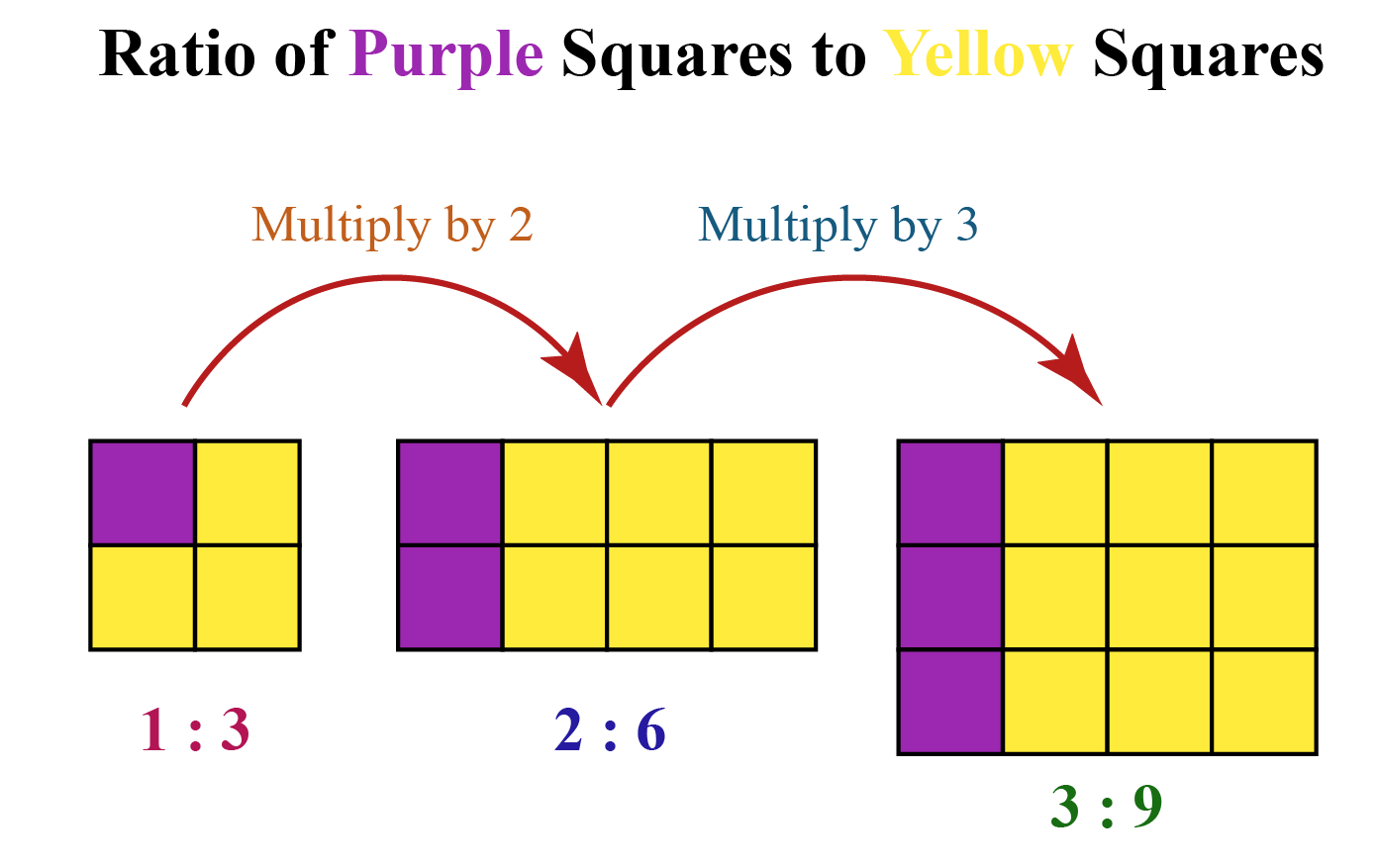

What is Ratio in Math? Definition & Overview Video & Lesson

Ratios and Proportions Scale Drawing YouTube

Drawing Ratio at Explore collection of Drawing Ratio

03_04_P2 Drawing Ratio and Reduction in Deep or Cup Drawing YouTube

How To Draw a Golden Ratio Rectangle & Spiral Sacred Geometry

Proportion Formula Examples What is Proportions Cuemath

How to draw the golden ratio correctly YouTube

Drawing Ratio at Explore collection of Drawing Ratio

Prediction of Draw Ratio in Deep Drawing through Software Simulations

Web The Draw Ratio Is Among The Most Important Elements To Be Considered When Attempting To Deep Draw A Round Cup.

Simply Put, It Describes The Relationship Between The Initial Size Of The Plastic.

Web Deep Drawing Is The Process Of Converting A Blank Of Sheet Metal Into A Cylindrical Container With A Flat Or Hemispherical Base.

Draw Ratio = The Surface Area Of The Part / Footprint Of The Part.

Related Post: