E8 Tolerance Chart

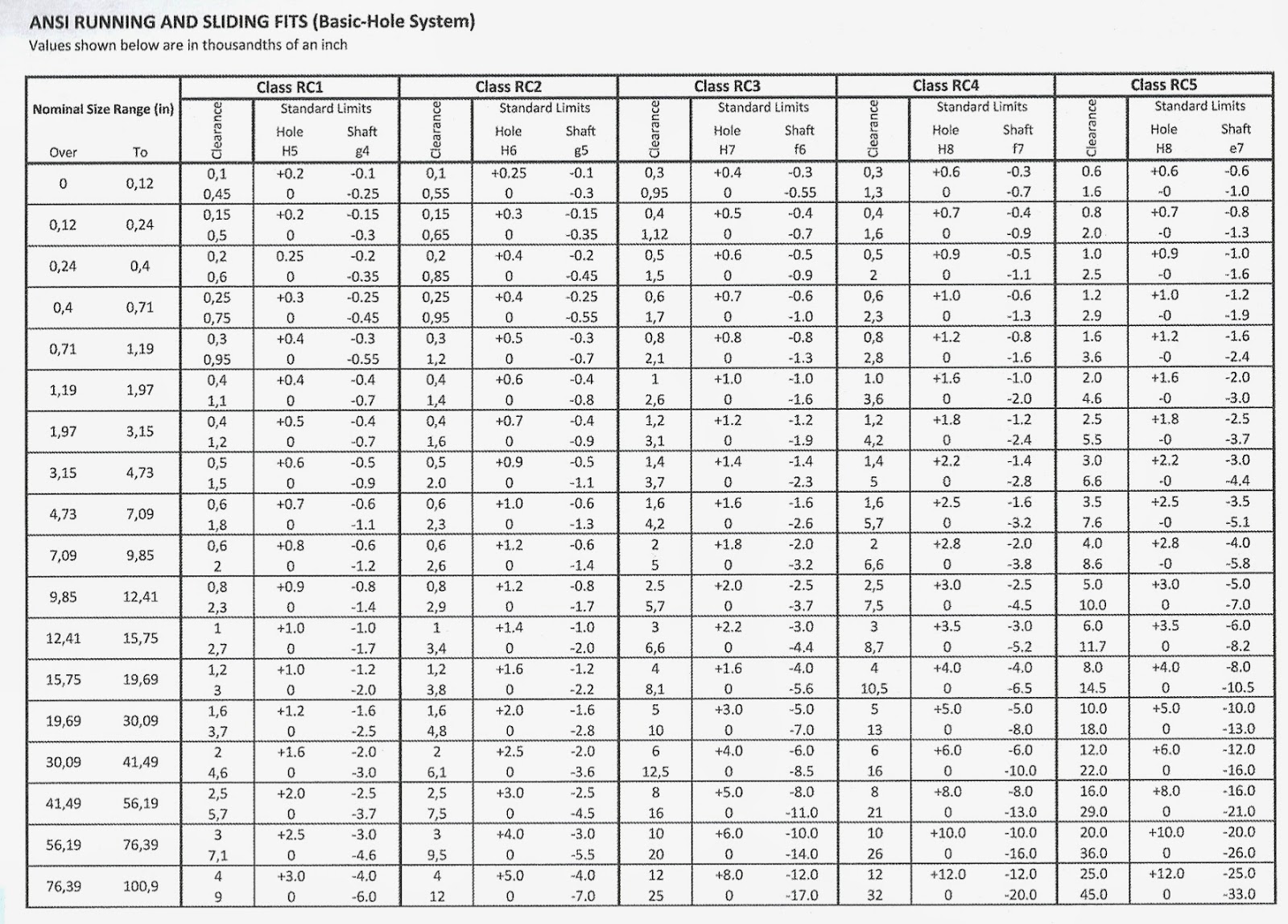

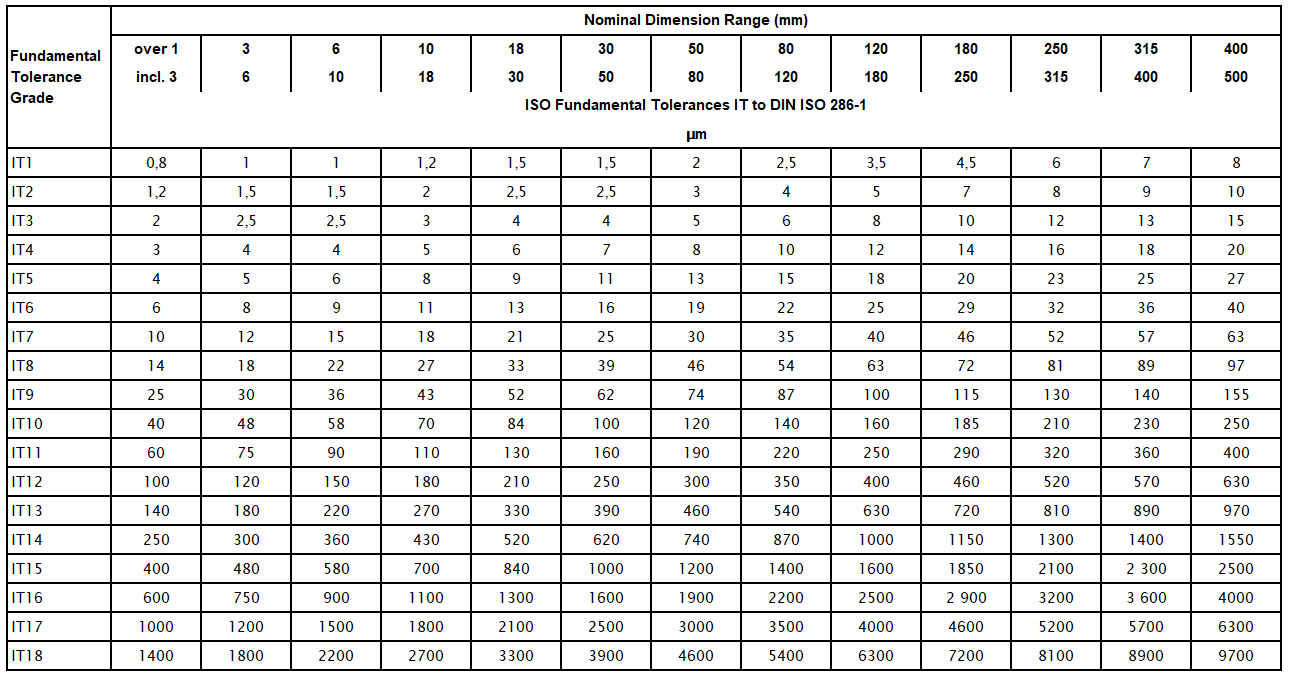

E8 Tolerance Chart - General fits of shafts, regulator bearings, machine tool spindles, sliding. (mm) more not more than than. Web for f7, the tolerance range is the same but the starting point is 25.020 mm, taking the last acceptable measurement to 25.041 mm. Web table of metric shaft tolerances per. Based on standard tolerances and limit deviations in accordance with iso 286. Web table of metric hole tolerances per. Use our free online calculator! A great way to find all the corresponding engineering tolerances to specific measurements is by using a limits & fits calculator. Lower limit deviation ei : The usage of these tolerances is advised for economic reasons. Tolerance calculator (all deviations) deviation switcher: Enter your desired preferred tolerance grade and the nomial size. Lower limit deviation ei : General fits of shafts, regulator bearings, machine tool spindles, sliding. Web ansi/asme b4.2 (1978) preferred metric limits and fits. The use of these tolerances is advised for economic reasons. Find your data faster with our fits and tolerance calculator. Green = prefered tolerance classes per iso 286. A, b, c, cd, d, e, ef, f, fg, g, h, js, j, k, m, n, p, r, s, t, u, v, x, y, z, za, zb, zc. The following engineering calculator. Find and calculate tolerances for holes and shafts. The use of these tolerances is advised for economic reasons. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Web for f7, the tolerance range is the same but the starting point is 25.020 mm, taking the last acceptable measurement to 25.041. A great way to find all the corresponding engineering tolerances to specific measurements is by using a limits & fits calculator. Lower limit deviation ei : All tolerances classes and sizes according to standard. Enter your desired preferred tolerance grade and the nomial size. Find your data faster with our fits and tolerance calculator. Web shaft tolerance table (iso) ≥ < c9. B10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6. Web maximum shaft diameter : Iso metric tolerance zone limits and fits. The use of these tolerances is advised for economic reasons. Enter your desired preferred tolerance grade and the nomial size. Upper limit deviation es : Also see table of hole tolerances per. These dimensions are standardized limits for assemblies of mechanical component. Use our free online calculator! (mm) more not more than than. Web class of tolerance range for holes m6 js6 k5 m6 n6 p6 f6 f7 g6 g7 h6 h7 js6 js7 k6 k7 m6 m7 n6 n7 p6 p7 r7 s7 t7 u7 x7 e7 f7 f8 h7 h8 d8 d9 e8 e9 f8 h8 h9 b10 c9 c10 d8 d9 d10 e8 e9. These dimensions are standardized limits for assemblies of mechanical component. The usage of these tolerances is advised for economic reasons. Web the hole basis fits have four preferred hole tolerances (h11, h9, h8, and h7); Find and calculate tolerances for holes and shafts. Upper limit deviation es : A great way to find all the corresponding engineering tolerances to specific measurements is by using a limits & fits calculator. Find and calculate tolerances for holes and shafts. Web h9/e9,h8/e8, h7/e7,e9/h9, e8/h8, e8/h7 running fits with greater clearances without any special requirements for fit accuracy main fits of machine tools. Also see table of hole tolerances per. Web shaft. B10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6. Web ansi/asme b4.2 (1978) preferred metric limits and fits. Tolerance calculator (all deviations) deviation switcher: The calculator has been tested, but no guarantee can be given for the accuracy of the results. Enter your desired preferred tolerance grade and the nomial size. Lower limit deviation ei : Click on to get additional tolerance options. All tolerances classes and sizes according to standard. A, b, c, cd, d, e, ef, f, fg, g, h, js, j, k, m, n, p, r, s, t, u, v, x, y, z, za, zb, zc. Tolerance calculator (all deviations) deviation switcher: Green = prefered tolerance classes per iso 286. General fits of shafts, regulator bearings, machine tool spindles, sliding. Find and calculate tolerances for holes and shafts. Web nominal hole sizes (mm) over 3 Find and calculate tolerances for holes and shafts. These dimensions are standardized limits for assemblies of mechanical component. Find your data faster with our fits and tolerance calculator. Lower limit deviation ei : B10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Based on standard tolerances and limit deviations in accordance with iso 286.Shaft Tolerance Table (Iso) ≥ < c9 d8 e7 e8 f7 g6 h5 h6 h7 h8 js6 js7

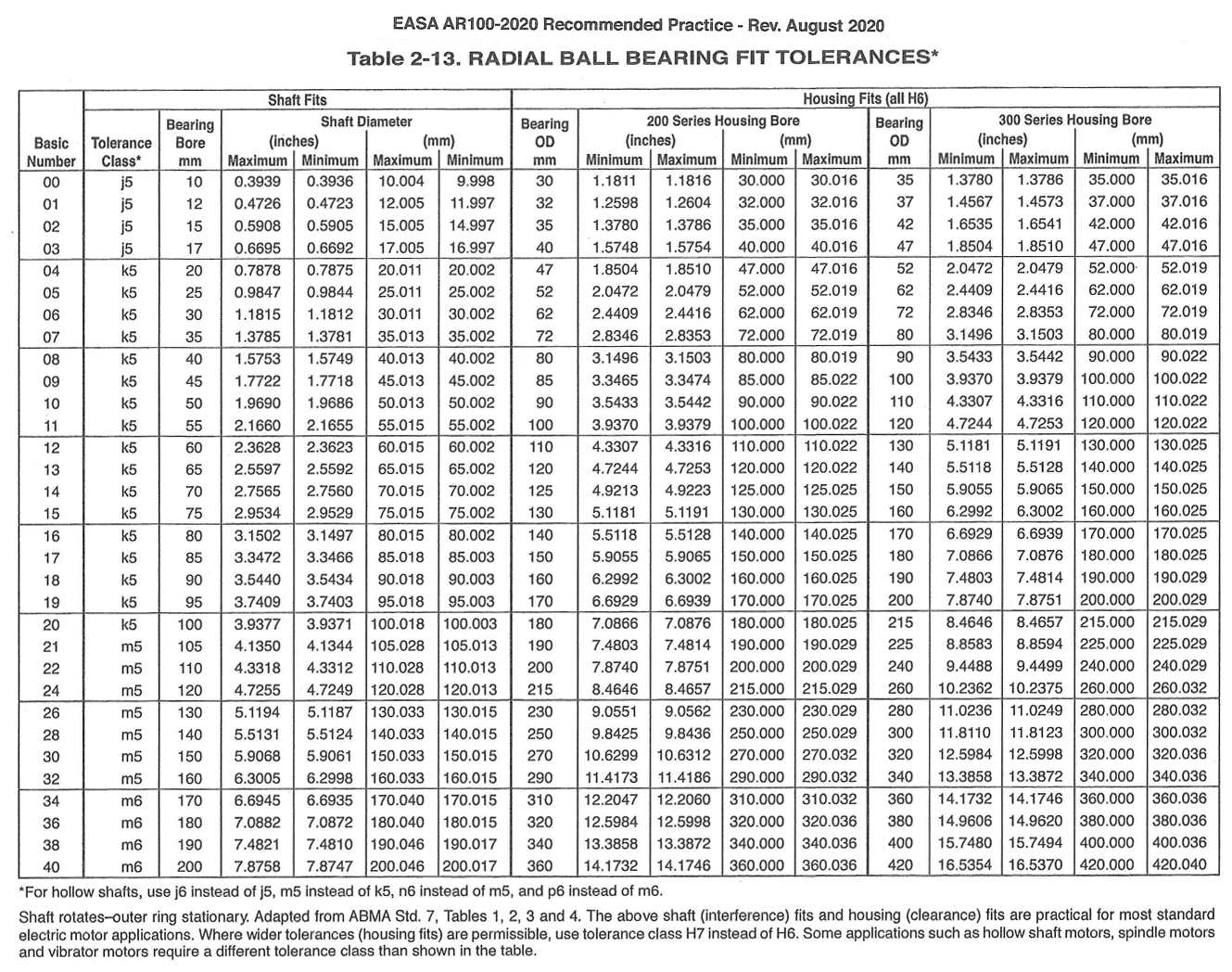

Press Fit Bearing Tolerance Chart

Iso fits and tolerances chart pasays

Iso 2768 Hole Tolerance Table downafile

Table for Values of ISO Fundamental Tolerances Grades Engineersfield

shaft and hole assembly tolerance table Spring Die Mould Part

Iso 2768 Hole Tolerances

Top 126+ rencol tolerance rings best xkldase.edu.vn

Iso 2768 Hole Tolerance Table

Bearing Tolerance Chart

Web For F7, The Tolerance Range Is The Same But The Starting Point Is 25.020 Mm, Taking The Last Acceptable Measurement To 25.041 Mm.

Web The Hole Basis Fits Have Four Preferred Hole Tolerances (H11, H9, H8, And H7);

Web H9/E9,H8/E8, H7/E7,E9/H9, E8/H8, E8/H7 Running Fits With Greater Clearances Without Any Special Requirements For Fit Accuracy Main Fits Of Machine Tools.

Web Shaft Tolerance Table (Iso) ≥ < C9.

Related Post: