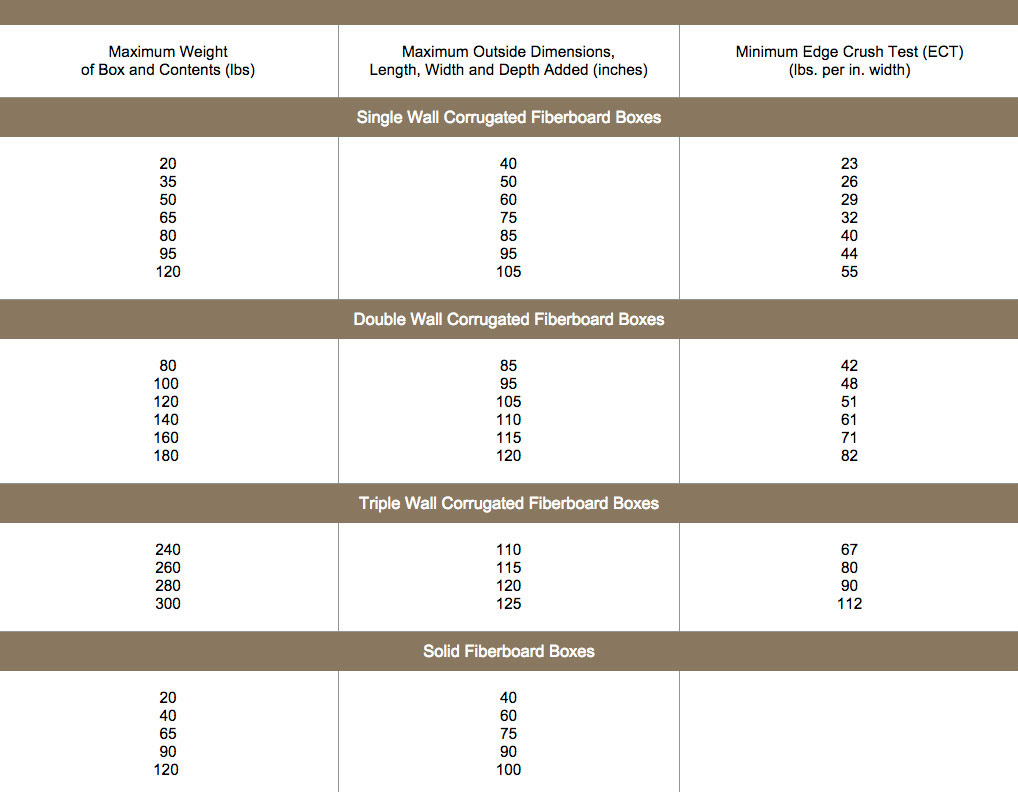

Edge Crush Test Chart

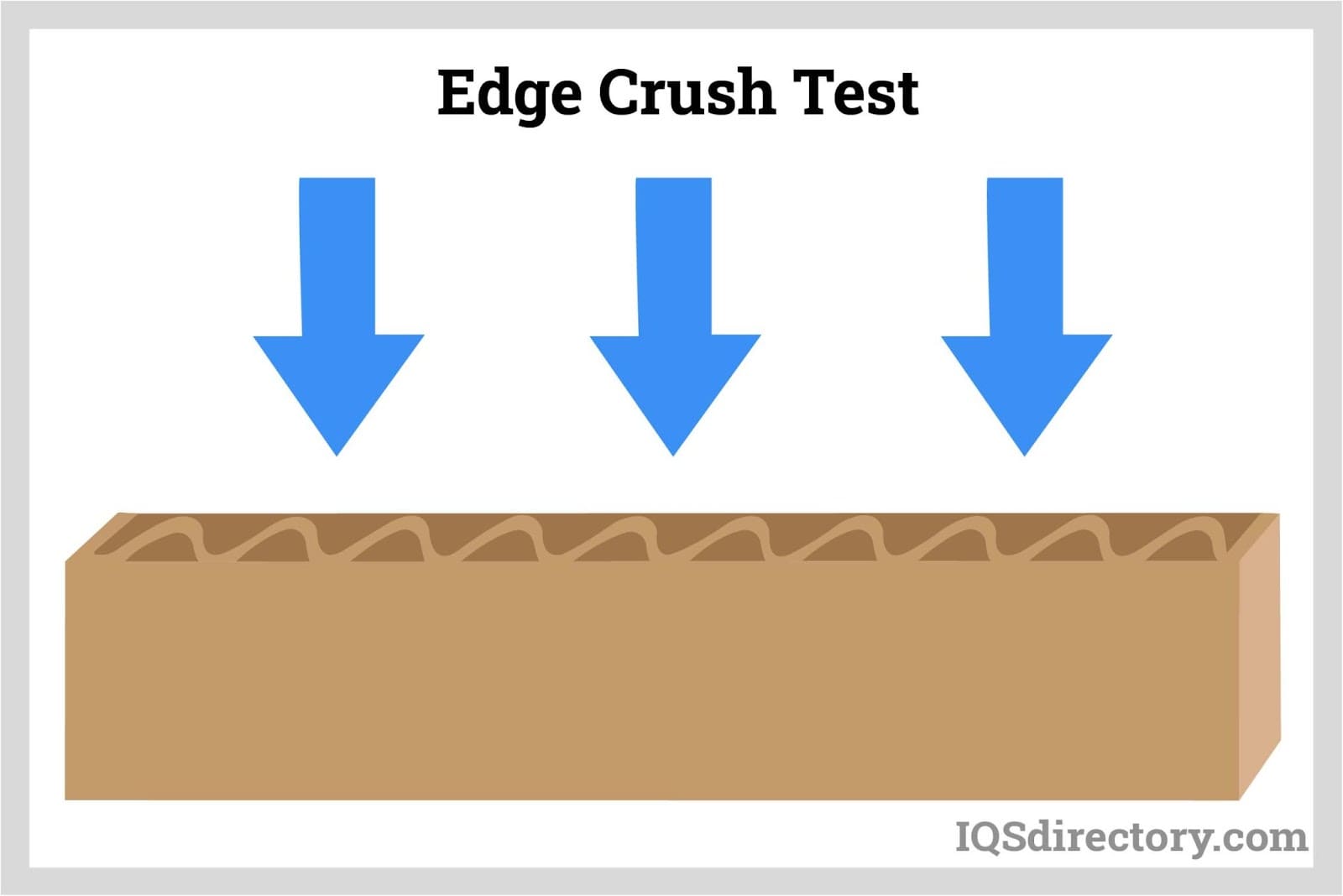

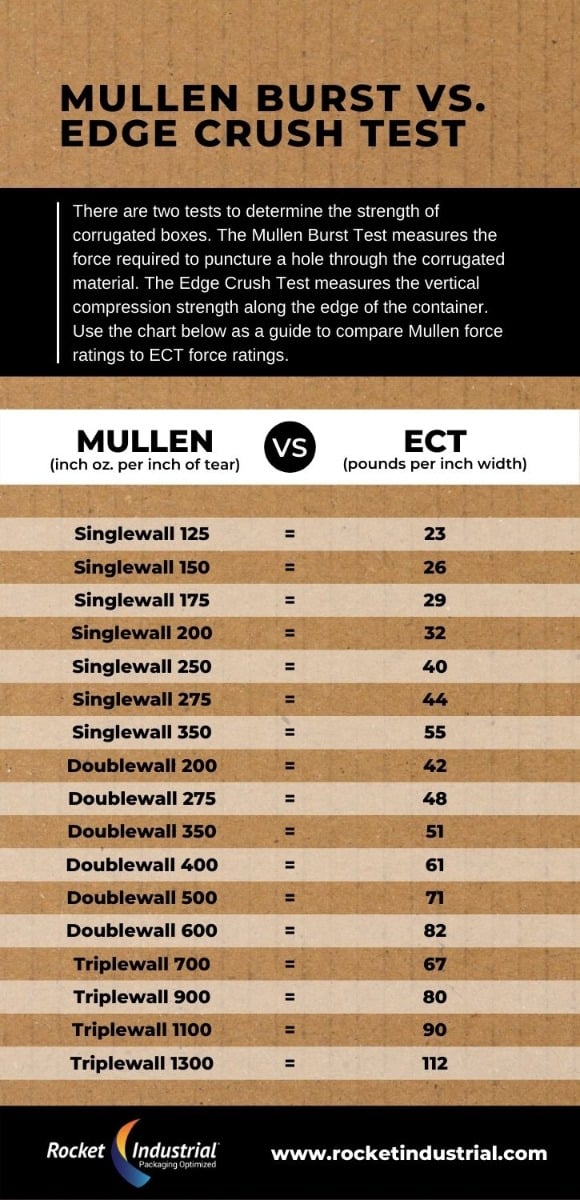

Edge Crush Test Chart - The edge crush test involves applying pressure to the edges of a corrugated box until it collapses. Web the edge crush test determines the capacity of a material, usually corrugated or paperboard materials, to withstand edge loading forces. Web the edge crush test (ect) to din en iso 3037 or tappi t 811 provides information on the strength of corrugated cardboard with flutes positioned vertically. This test provides essential insights into the corrugated cardboard’s capacity to withstand compressive forces. Web a newer standard that has achieved widespread acceptance is the edge crush test (ect). Until recently, the only method available for measuring the strength of corrugated was the bursting test, also known as the mullen test. Ect is a measure of the edgewise compressive strength of corrugated board. Edge crush testing, also known as ect, is a cost effective and convenient way to work out the peak load that a material can handle. By using simple test methods such as the edge crush test (ect), companies benefit from understanding the maximum weight a box can withstand and the overall stacking strength. The 32 ect, 44 ect, and 48 ect are the most common box varieties, due to both cost and stacking strength considerations. We normally measure ect using the clamp method to hold the sample. It involves the application of controlled compressive loads to a sample or specimen and monitoring its response to these forces. Many corrugated boxes are specified in terms of ect, expressed as lbs/inch. According to tappi test method t839. This test evaluates the edgewise compressive strength of corrugated board. Web conversion chart for edge crush testing. According to tappi test method t839. Ect is a measure of the edgewise compressive strength of corrugated board. The 32 ect, 44 ect, and 48 ect are the most common box varieties, due to both cost and stacking strength considerations. Pro pac offers all kinds of corrugated boxes and rsc shipping cases in. Web the edge crush test (ect) to din en iso 3037 or tappi t 811 provides information on the strength of corrugated cardboard with flutes positioned vertically. Below is a chart that breakdowns different types of corrugated material and their corresponding bursting test and ect rating, along with the maximum load per carton. Web below are tables that report bursting. Web crush testing is a method used to evaluate a material’s resistance to compressive forces or crushing. It gives information on the ability of a particular board construction to resist crushing. Ect is a measure of the edgewise compressive strength of corrugated board. The humble cardboard box is the unsung hero of countless deliveries every day. Many corrugated boxes are. It is one of the most popular ways of measuring the strength of cardboard, paperboard and corrugated paper. Ect is a measure of the edgewise compressive strength of corrugated board. Ect is a measure of the edgewise compressive strength of corrugated board. Web corrugated case comparison chart with minimum bursting test, minimum edge crush test (ect). Web the edge crush. The 32 ect, 44 ect, and 48 ect are the most common box varieties, due to both cost and stacking strength considerations. By using simple test methods such as the edge crush test (ect), companies benefit from understanding the maximum weight a box can withstand and the overall stacking strength. Web conversion chart for edge crush testing. Web the edge. Web testing the edge crush test chart of materials is essential for assessing the overall quality of the product, as well as ensuring that the material is suitable for its intended use. We normally measure ect using the clamp method to hold the sample. This test evaluates the edgewise compressive strength of corrugated board in pounds per inch of width,. It is also utilized in most analytical. Web below are tables that report bursting test measures, edge crust test measures, and the suggested loading limit per box. Until recently, the only method available for measuring the strength of corrugated was the bursting test, also known as the mullen test. Pro pac offers all kinds of corrugated boxes and rsc shipping. Web below are tables that report bursting test measures, edge crust test measures, and the suggested loading limit per box. This is a true performance test and is directly related to the stacking strength of a carton. By using simple test methods such as the edge crush test (ect), companies benefit from understanding the maximum weight a box can withstand. It involves the application of controlled compressive loads to a sample or specimen and monitoring its response to these forces. We normally measure ect using the clamp method to hold the sample. Ect is a measure of the edgewise compressive strength of corrugated board. Ect is a measure of the edgewise compressive strength of corrugated board. Until recently, the only. Web the edge crush test determines the capacity of a material, usually corrugated or paperboard materials, to withstand edge loading forces. Professional packaging systems is your resource for corrugated boxes, cases, shipping cases, corrugated trays, and display trays in texas. This parameter is widely used for the specification of the board by its producers. This is especially useful for today’s lighter weight corrugated cardboards, which include recycled composites that weigh less but can withstand more pressure than their traditional counterparts. It is also utilized in most analytical. This test provides essential insights into the corrugated cardboard’s capacity to withstand compressive forces. Ect is a measure of the edgewise compressive strength of corrugated board. Pro pac offers all kinds of corrugated boxes and rsc shipping cases in texas. The humble cardboard box is the unsung hero of countless deliveries every day. The edge crush test involves applying pressure to the edges of a corrugated box until it collapses. Note that the edge crush test gives a minimum value because corrugators may use different types of formulas to determine the ect for each corrugated box. Below is a chart that breakdowns different types of corrugated material and their corresponding bursting test and ect rating, along with the maximum load per carton. Ect is a measure of the edgewise compressive strength of corrugated board. The 32 ect, 44 ect, and 48 ect are the most common box varieties, due to both cost and stacking strength considerations. Web the edge crush test (ect) to din en iso 3037 or tappi t 811 provides information on the strength of corrugated cardboard with flutes positioned vertically. We normally measure ect using the clamp method to hold the sample.

Corrugated Box What Is It? How Is It Used? Types, Shipping

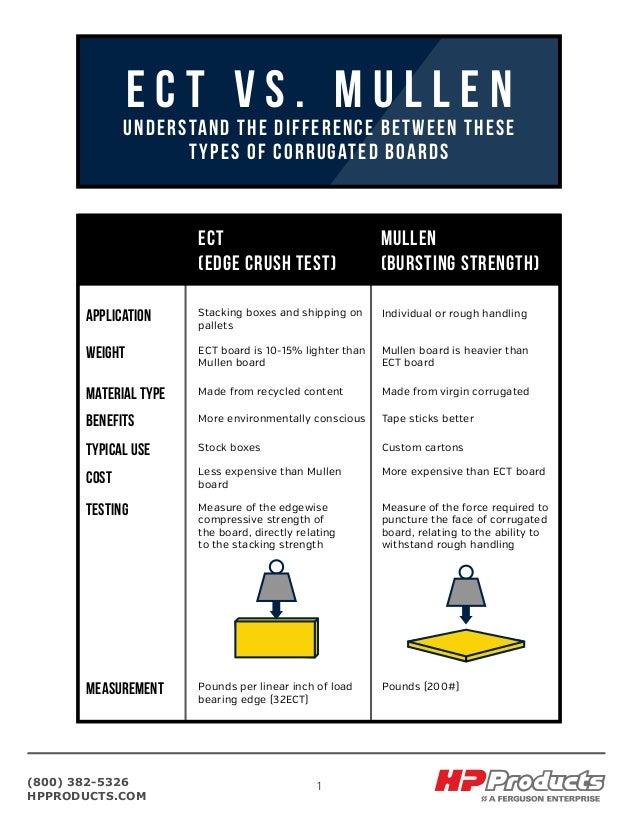

Corrugated Boards ECT vs. Mullen

ECT Edge Crush Test

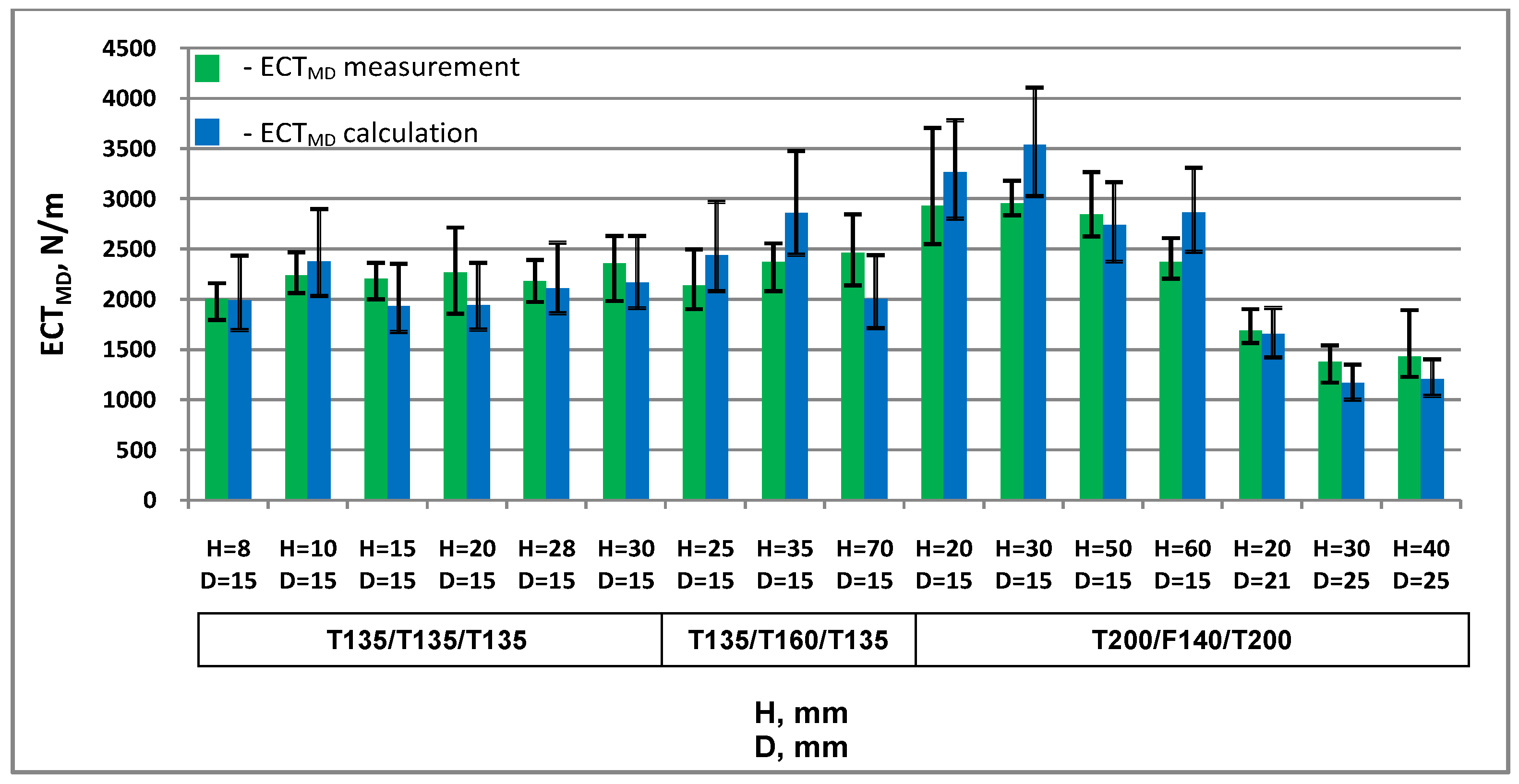

Materials Free FullText Calculation of Paperboard

Mullen vs ECT What's the Difference?

Edge Crush Test Là Gì? Khám Phá Bí Mật Đằng Sau Độ Bền Của Thùng Carton

Edge Crush Test (ECT) DIN EN ISO 3037, TAPPI T 811 ZwickRoell

Corrugated Boxes leanpack

How to Test Edge Crush Test ( ECT) of Corrugated Sheet Presto Group

Edge Crush Test for Corrugated Cartons ECT vs Mullens Test

Web Edge Crush Test Chart.

According To Tappi Test Method T839.

It Is Important That Force Application To The Specimen Is Exactly Perpendicular During These Tests.

Learn More About It Here.

Related Post: