Electrical Torque Specs Chart

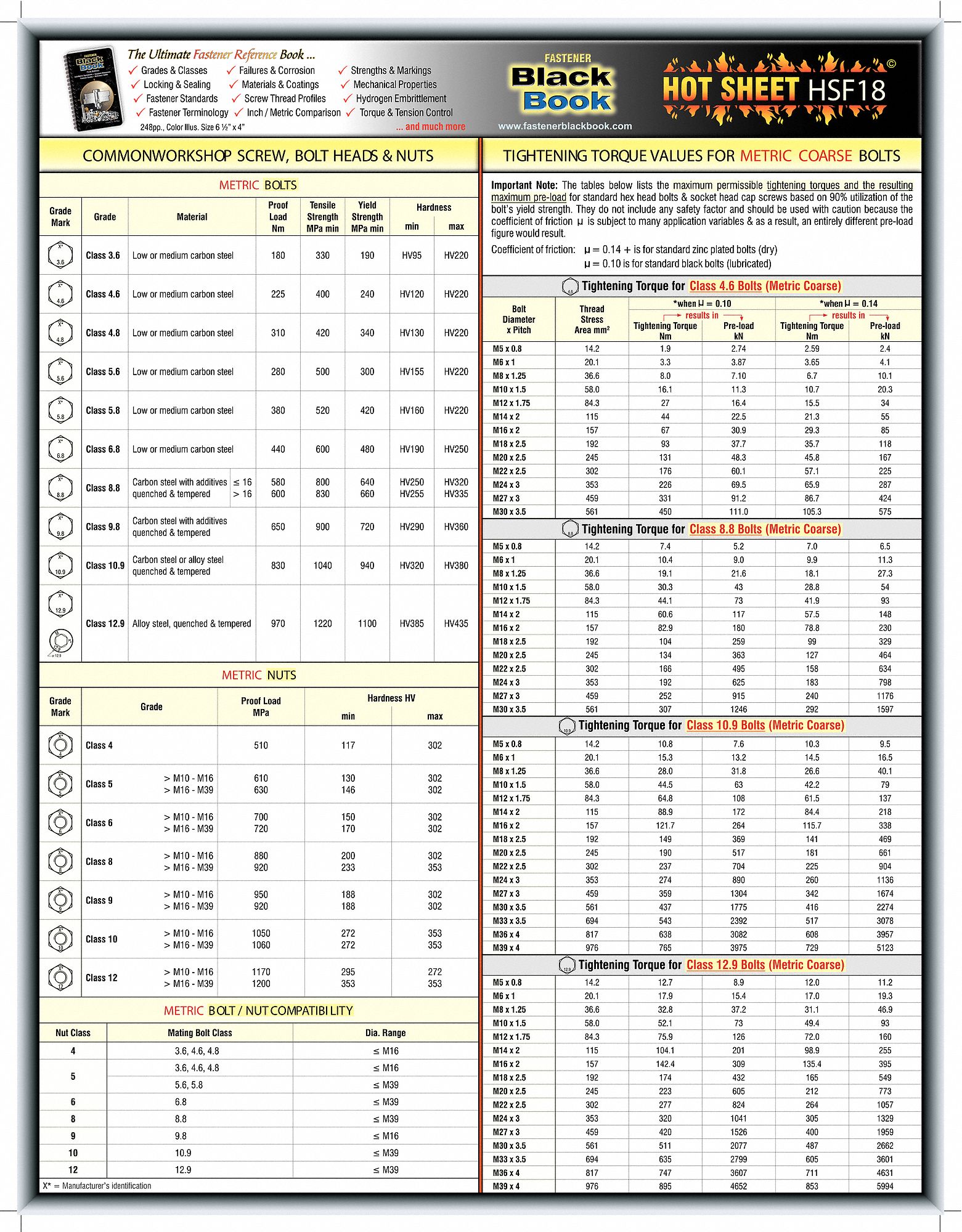

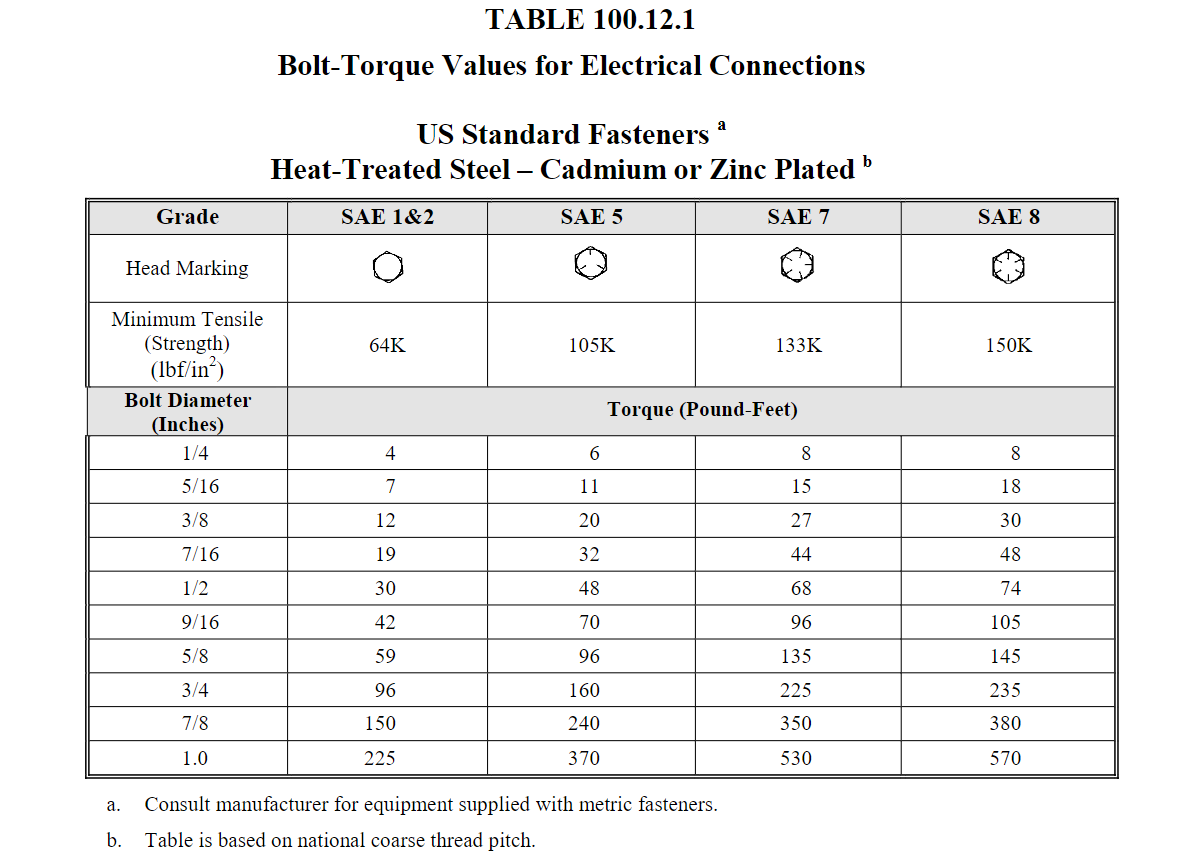

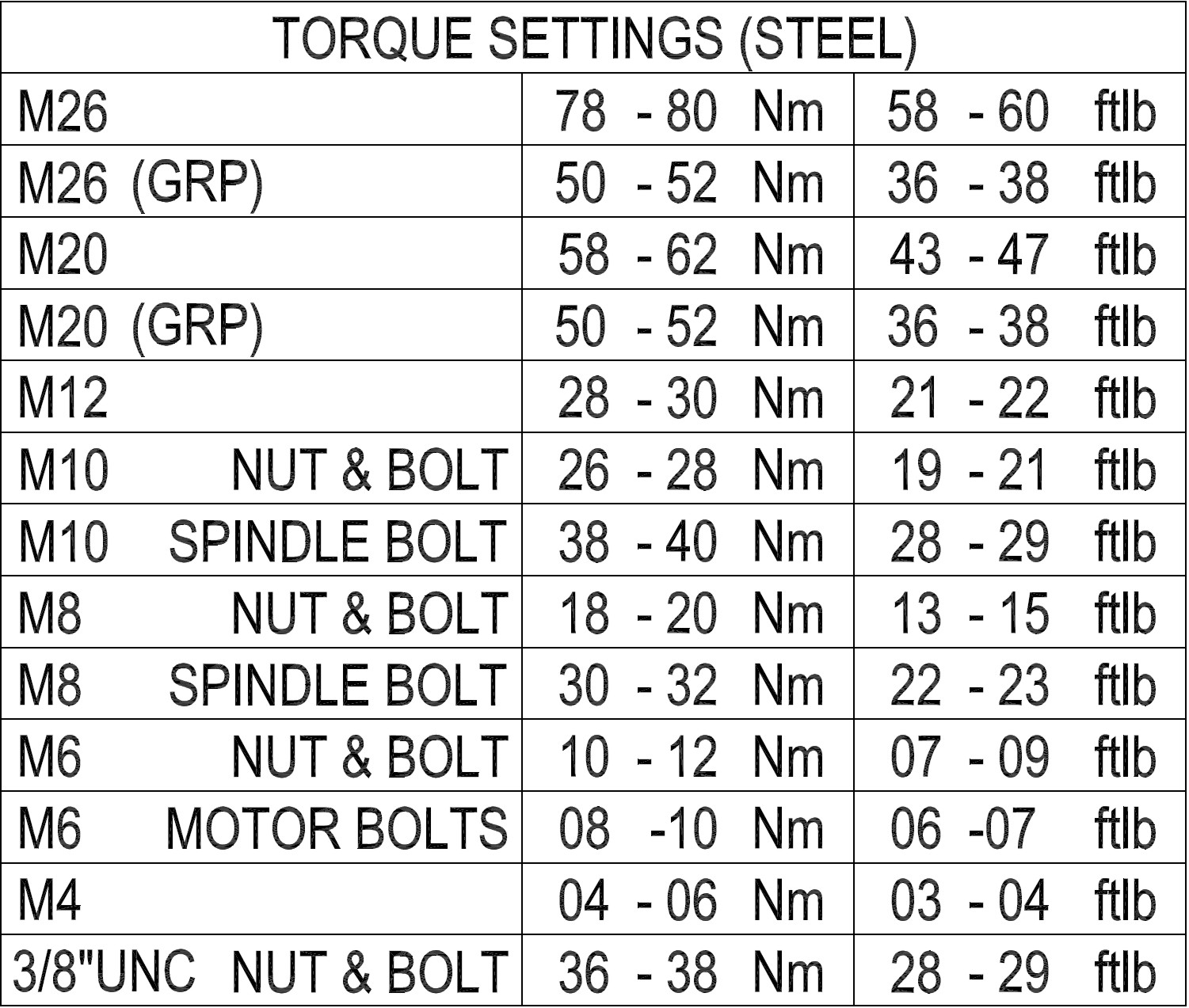

Electrical Torque Specs Chart - Metal and composite torque values per sae air 6151. The load will be 90% of the bolt yield strength. Bolt proof load is defined as the maximum force that the material can support without experiencing permanent deformation. Web bolt tightening torque chart: For additional guidance or values/conditions not listed, refer to sae air6151. This table is intended to help understand the size of stranded american wire gauge (awg) and mcm class b wires. The circles represent the diameter of the stranded wires. The above recommended clamp loads are based on 75% of the minimum specified proof loads for each grade and size. Web the table provides a reference chart that indicates the recommended torque values for different grades of fasteners, such as grade 2, grade 5, and grade 8. Web when it comes to electrical installations, perhaps one of the most violated sections of the national electrical code has been and continues to be proper torquing of electrical connections. The tightening torque values quoted below should be considered as absolute maximum values which should not be exceeded. Ground/neutral bars would be an added bonus. The following suggested tightening torques provide an excellent starting point for determining torque requirements. At 75% of the material proof strength. The circles represent the diameter of the stranded wires. Web when it comes to electrical installations, perhaps one of the most violated sections of the national electrical code has been and continues to be proper torquing of electrical connections. They are based upon practical laboratory measurements under standard climatic conditions (23°c / 50% relative humidity). Metal and composite torque values per sae air 6151. What are the electrical connection. Tools are used to precisely apply a specific torque to a fastener. Web the table provides a reference chart that indicates the recommended torque values for different grades of fasteners, such as grade 2, grade 5, and grade 8. The following suggested tightening torques provide an excellent starting point for determining torque requirements. At 75% of the material proof strength.. For additional guidance or values/conditions not listed, refer to sae air6151. Web in preparing this guide to torque values, the following basic assumptions have been made: For a307 grade a, 75% of 36,000 psi is utilized. Ground/neutral bars would be an added bonus. Also, for terminal screws on devices. Under/over tightening of fasteners can result in costly equipment failure or personal injury. The coefficient of friction (μ) is 0.14. At 75% of the material proof strength. The following table shows the torque value requirements for the wire binding screws and clamp plates of qo and qob circuit breakers: The circles represent the diameter of the stranded wires. Standard bolt sizes at a glance. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. Remember, you may need to vary these numbers somewhat based on the individual joint or the amount of fastener lubrication.. The load will be 90% of the bolt yield strength. Web torque requirements for qo and qob breakers' wire binding screws and clamp plates. Under/over tightening of fasteners can result in costly equipment failure or personal injury. This table is intended to help understand the size of stranded american wire gauge (awg) and mcm class b wires. Tools are used. Incoming, branch, and neutral lug. Web torque is only an indirect indication of tension. The coefficient of friction (μ) is 0.14. Web recommended tightening torque values for installation of pma fittings. Standard bolt sizes at a glance. What are the electrical connection torque specifications for a qed switchboard (swbd)? You can make ads in the engineering toolbox more useful to you! 1) the torque values can only be achieved if nut or tapped hole has a proof load greater than or equal to the bolt’s minimum tensile strength. Control and signal circuits may require different torque values,. Standard bolt sizes at a glance. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. The above recommended clamp loads are based on 75% of the minimum specified proof loads for each grade and size.. Web when it comes to electrical installations, perhaps one of the most violated sections of the national electrical code has been and continues to be proper torquing of electrical connections. Web loose electrical connections are one of the leading causes for electrical failures. Web bolt tightening torque chart: At 75% of the material proof strength. What are the electrical connection torque specifications for a qed switchboard (swbd)? Tools are used to precisely apply a specific torque to a fastener. The coefficient of friction (μ) is 0.14. Remember, you may need to vary these numbers somewhat based on the individual joint or the amount of fastener lubrication. Standard bolt sizes at a glance. This table is intended to help understand the size of stranded american wire gauge (awg) and mcm class b wires. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. The load will be 90% of the bolt yield strength. For additional guidance or values/conditions not listed, refer to sae air6151. Control and signal circuits may require different torque values, and the manufacturer should be contacted for guidance. Ground/neutral bars would be an added bonus. The tightening torque values quoted below should be considered as absolute maximum values which should not be exceeded.

Electrical Torque Specs Chart

Nec Electrical Lug Torque Specs Chart

Torque Chart Av1 PDF Electrical Connector Pump

Electrical Lug Torque Specs Chart Eaton

Wire Lug Torque Specs Chart

Electrical Lug Torque Specs Chart

Torque settings Het gereedschap is elektrisch

Electrical Bolt Torque Specs ubicaciondepersonas.cdmx.gob.mx

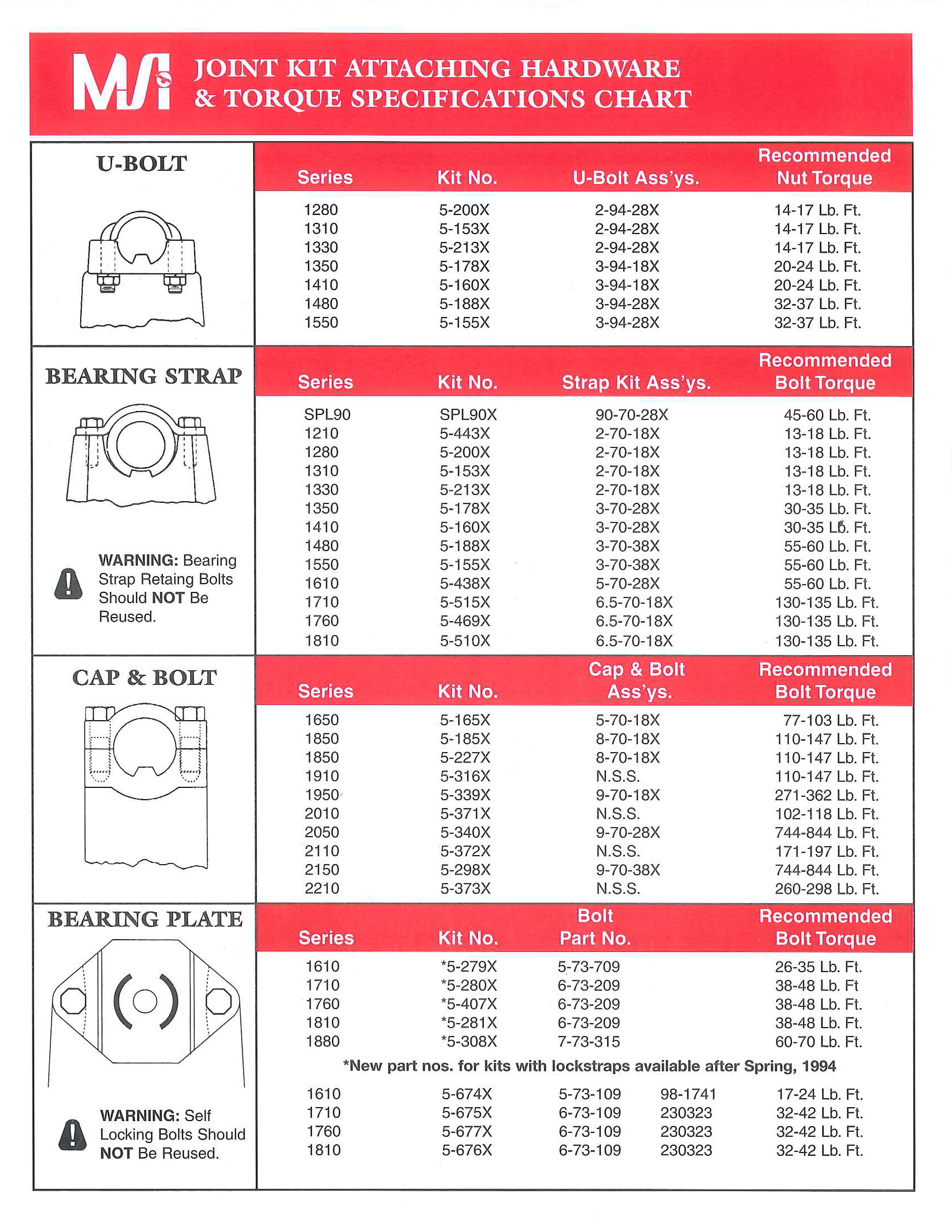

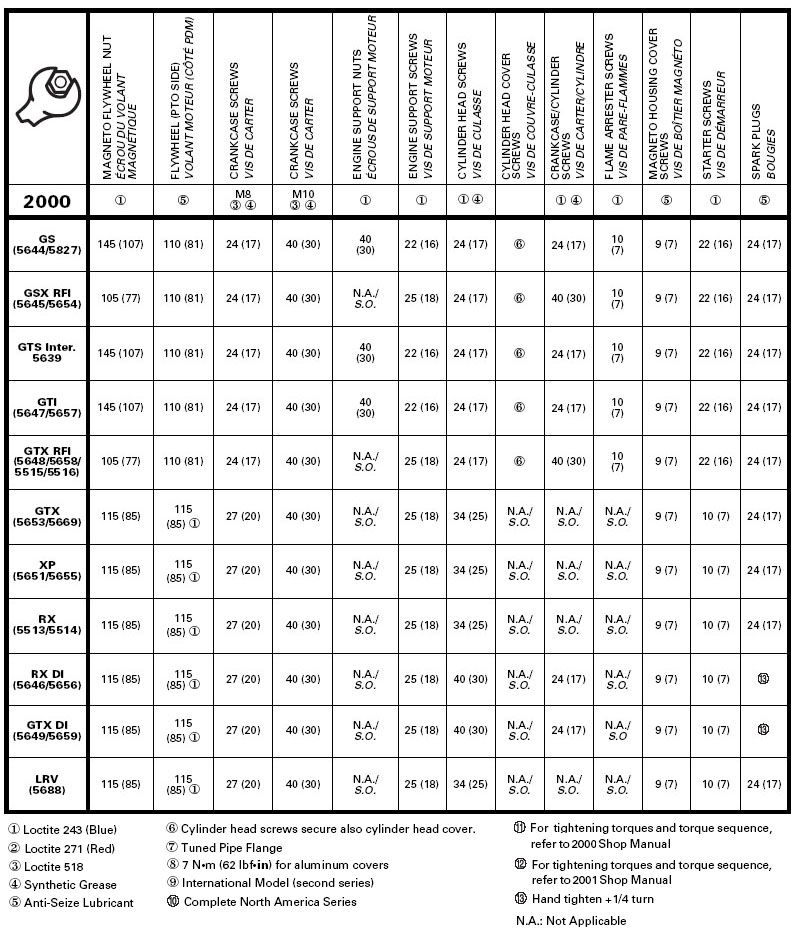

Torque Specifications Machine Service, Inc.

Gallery of 64 problem solving bolt torque chart asme b16 5 ansi

You Can Make Ads In The Engineering Toolbox More Useful To You!

Web Torque Requirements For Qo And Qob Breakers' Wire Binding Screws And Clamp Plates.

The Following Table Shows The Torque Value Requirements For The Wire Binding Screws And Clamp Plates Of Qo And Qob Circuit Breakers:

They Are Based Upon Practical Laboratory Measurements Under Standard Climatic Conditions (23°C / 50% Relative Humidity).

Related Post: