Epoxy Cure Time Chart

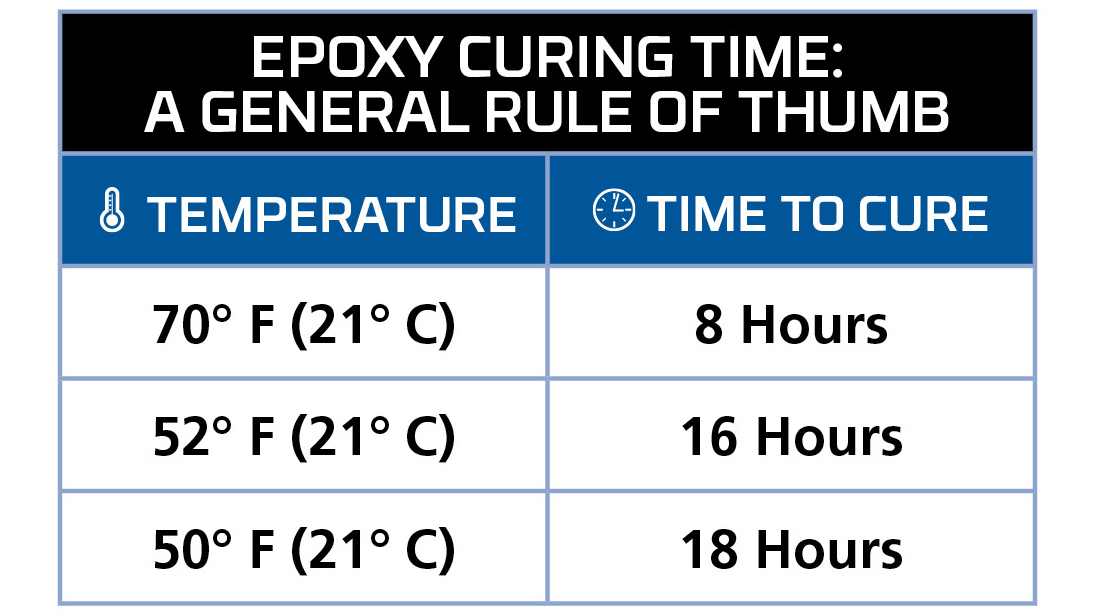

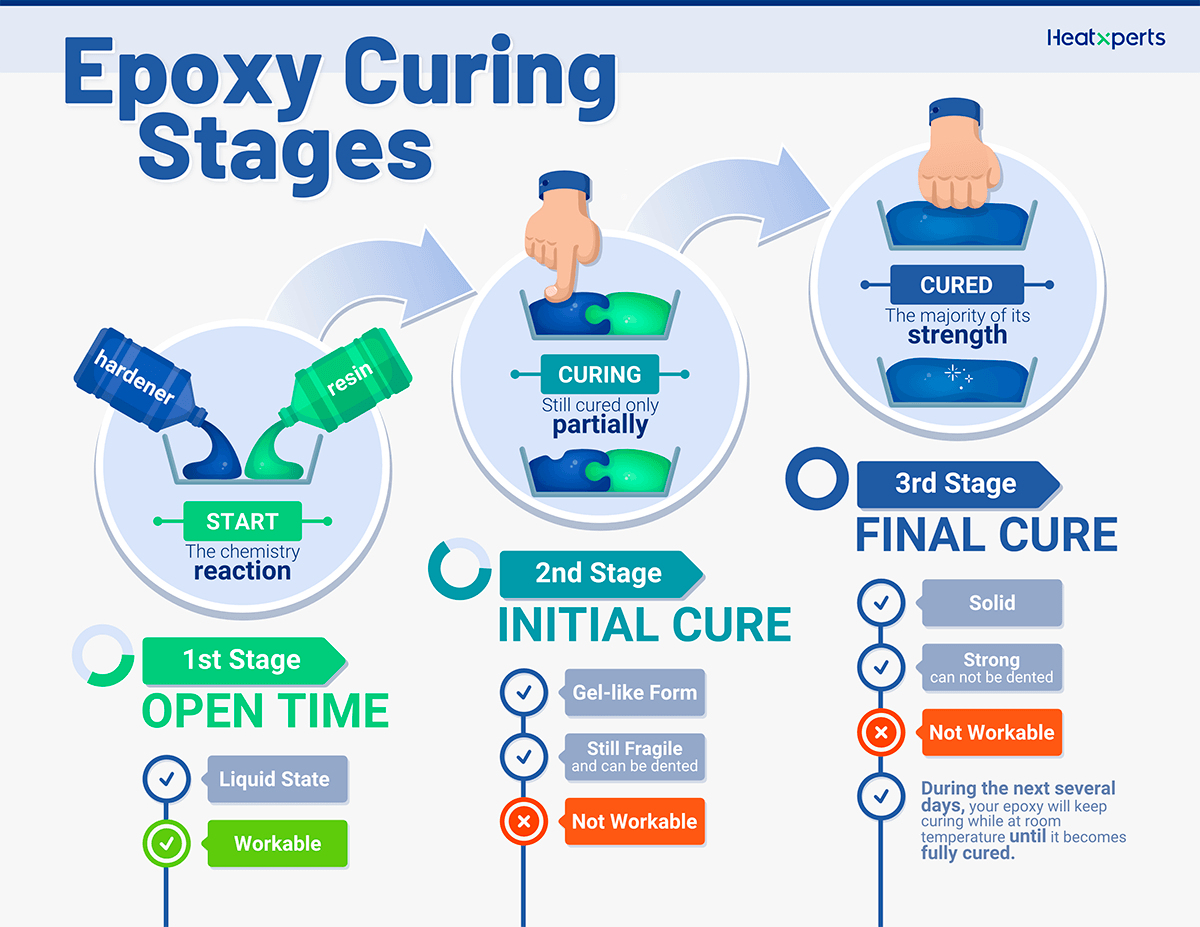

Epoxy Cure Time Chart - The drying time can vary based on the specific epoxy product used, environmental conditions, and the thickness of the applied coat. To get a general understanding of how long the particular variation will take to dry, read the manufacturer’s instructions carefully. Web epoxy technology's datasheets provide a great starting point for recommendations of cure temperatures and times. After the indicated times (minutes), at those temperatures, a batch of mixed resin and hardener ( 30z./100gr) will begin to gel. For more specific cure data, please refer to the cure graphs or talk to your ifs representative. After 3 days you should be able to apply light foot traffic, for instance, if you need to use the space to access other areas in your home. With epoxy, you cannot adjust cure time by altering the amount of hardener. The degree and rate of curing the super sap inr system is investigated using dsc. For a fast cure epoxy resin look to our lightning tumblers epoxy resin. A slow hardener will make the resin cure more slowly at higher temperatures of about 80°f. Initial cure to solid in thin film: It can be quicker depending on the type of epoxy and temperature. It cures within an hour. To place an order or for more information please call 866.437.2864 or visit www.ifscoatings.com. For more specific cure data, please refer to the cure graphs or talk to your ifs representative. A slow hardener will make the resin cure more slowly at higher temperatures of about 80°f. It can be quicker depending on the type of epoxy and temperature. The cure speed of your chosen hardener and the epoxy temperature. Warmer temperatures facilitate curing and colder temperatures slow curing. The degree and rate of curing the super sap inr system is. Cure time is affected by temperature: A slow hardener will make the resin cure more slowly at higher temperatures of about 80°f. Web the west system epoxy user manual & product guide is the definitive handbook on using epoxy safely and effectively. Set time refers to when the epoxy has stiffened enough to support pressure, while cure time is when. For a fast cure epoxy resin look to our lightning tumblers epoxy resin. Web pot life 100 grams: After the indicated times (minutes), at those temperatures, a batch of mixed resin and hardener ( 30z./100gr) will begin to gel. Web epoxy paint typically takes anywhere from 24 to 72 hours to fully dry and cure, depending on various factors. Factors. The drying time can vary based on the specific epoxy product used, environmental conditions, and the thickness of the applied coat. Web below we show a table with typical cure speeds. Knowing these times is essential for ensuring a successful epoxy application. The cure speed of your chosen hardener and the epoxy temperature. Factors affecting epoxy cure time. A typical dsc thermogram, which is used to assess the degrees and rates of curing, is shown in figure 1. Web it generally takes about 24 to 72 hours for the epoxy floors to dry completely. With epoxy, you cannot adjust cure time by altering the amount of hardener. Whatever the dry time, the resin should be allowed to fully. Knowing these times is essential for ensuring a successful epoxy application. Factors affecting epoxy cure time. Web usually, it takes around 72 hours to fully cure the epoxy. To get a general understanding of how long the particular variation will take to dry, read the manufacturer’s instructions carefully. Web pot life 100 grams: It can be quicker depending on the type of epoxy and temperature. Web epoxy paint typically takes anywhere from 24 to 72 hours to fully dry and cure, depending on various factors. This is designed for people who live in hotter regions and need more time to actually apply the epoxy to their surfaces before it begins hardening too much.. A slow hardener will make the resin cure more slowly at higher temperatures of about 80°f. It’ll need a little more time to cure completely, and then you’ll need to finish it off by sanding and planing if you’d like to, adding a few more hours. Web epoxy paint typically takes anywhere from 24 to 72 hours to fully dry. Knowing these times is essential for ensuring a successful epoxy application. Web the times and temperatures stated are for minimum metal temperatures. Web two factors determine an epoxy mixture’s open time and overall cure time: For a fast cure epoxy resin look to our lightning tumblers epoxy resin. Warmer temperatures facilitate curing and colder temperatures slow curing. The degree and rate of curing the super sap inr system is investigated using dsc. Light foot traffic 24 hours. Knowing these times is essential for ensuring a successful epoxy application. Web increase the temperature: The drying time can vary based on the specific epoxy product used, environmental conditions, and the thickness of the applied coat. After the indicated times (minutes), at those temperatures, a batch of mixed resin and hardener ( 30z./100gr) will begin to gel. After 3 days you should be able to apply light foot traffic, for instance, if you need to use the space to access other areas in your home. A typical dsc thermogram, which is used to assess the degrees and rates of curing, is shown in figure 1. Place a space heater or heat lamp near your piece to encourage the resin to cure faster. To get a general understanding of how long the particular variation will take to dry, read the manufacturer’s instructions carefully. For a fast cure epoxy resin look to our lightning tumblers epoxy resin. It can be quicker depending on the type of epoxy and temperature. The cure speed of your chosen hardener and the epoxy temperature. Web epoxy paint typically takes anywhere from 24 to 72 hours to fully dry and cure, depending on various factors. A slow hardener will make the resin cure more slowly at higher temperatures of about 80°f. To place an order or for more information please call 866.437.2864 or visit www.ifscoatings.com.

Epoxy Cure Time Chart

5 Tips for Applying an Epoxy Floor Coating System in Cold Weather or

The Science Behind the Epoxy Curing Process

Qual o Tempo de Cura da Resina Epóxi Saiba Aqui

Epoxy Cure Time Chart

Temperature profile in the epoxy resin cure process. The upper right

How Long Does 2Part Epoxy Resin Take To Cure Epoxy Resins Art

PPT Thermosetting resins PowerPoint Presentation ID308435

How to determine the curing temperature and time for an epoxy/hardener

Cure reaction rate versus cure time for 890RTM epoxy resin Download

Web The Epoxy Dry Time Highly Depends On The Brand And The Type Of Epoxy Resin That You Are Willing To Use.

If The Epoxy Isn’t Allowed To Rest Until Fully Cured, Your Project Will Be Prone To Surface Contamination.

Balance Longer Work Times With Shorter Cure Times.

Web The Times And Temperatures Stated Are For Minimum Metal Temperatures.

Related Post: