Fastenal Bolt Torque Chart

Fastenal Bolt Torque Chart - = 0.13 when using ecoguardtm coated nut, bolt and washer. Web estimated fastener bolt clamp force torque calculator. Web is the estimated torque coeficient (for full details contact [email protected]). Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Identify the grade, size, and thread. = 0.15 for “lubricated” conditions. It cautions that these fasteners can gall without lubrication and. Web torque values calculated from formula t=kdf, where. The chart covers coarse and fine threads, and shows the clamp load. Web find the torque and tension values for different sizes and grades of bolts based on the a307a standard. Web is the estimated torque coeficient (for full details contact [email protected]). The size column also includes the thread count. Identify the grade, size, and thread. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions and 0.35 for dry note: 4) torque values for f835 countersunk and. Web is the estimated torque coeficient (for full details contact [email protected]). Web unlike most bolt torque charts, this particular chart also lists clamp loads and torque values that correspond with bolt material stresses of 10,000 and 25,000 psi. Identify the grade, size, and thread. 4) torque values for f835 countersunk and. Web the charts below show the ideal tightening torque. Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. = 0.13 when using ecoguardtm coated nut, bolt and washer. Web torque values calculated from formula t=kdf, where. The chart covers coarse and fine threads, and shows the clamp load. Web find the torque and tension values for different sizes and grades. 4) torque values for f835 countersunk and. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions k = 0.35 dry the torque values can only be achieved if nut (or tapped hole) has a proof. Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Web torque. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions and 0.35 for dry note: Values calculated using industry accepted formula t = kdp where t = torque, k = torque coefficient. Identify the grade, size, and thread. The size column also includes the thread count. = 0.15 for “lubricated” conditions. Web estimated fastener bolt clamp force torque calculator. = 0.15 for “lubricated” conditions. The chart covers coarse and fine threads, and shows the clamp load. Web torque values calculated from formula t=kdf, where. Values calculated using industry accepted formula t = kdp where t = torque, k = torque coefficient. Web find the torque and tension values for different sizes and grades of bolts based on the a307a standard. Web is the estimated torque coeficient (for full details contact [email protected]). Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Web torque values calculated from formula t=kdf, where k = 0.16 for. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions k = 0.35 dry the torque values can only be achieved if nut (or tapped hole) has a proof. Web find the torque and tension values for different sizes and grades of bolts based on the a307a standard. = 0.15 for “lubricated” conditions. It cautions that. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions and 0.35 for dry note: Web is the estimated torque coeficient (for full details contact [email protected]). = 0.13 when using ecoguardtm coated nut, bolt and washer. Web torque values calculated from formula t=kdf, where. 4) torque values for f835 countersunk and. See torque force design equations. The chart covers coarse and fine threads, and shows the clamp load. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions and 0.35 for dry note: The size column also includes the thread count. It cautions that these fasteners can gall without lubrication and. Fastener and screw / bolt design formula design data. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions and 0.35 for dry note: It cautions that these fasteners can gall without lubrication and. Web find the torque and tension values for different sizes and grades of bolts based on the a307a standard. Identify the grade, size, and thread. 4) torque values for f835 countersunk and. Download this as a pdf. Web the charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Web unlike most bolt torque charts, this particular chart also lists clamp loads and torque values that correspond with bolt material stresses of 10,000 and 25,000 psi. Web torque values calculated from formula t=kdf, where. See torque force design equations. Values calculated using industry accepted formula t = kdp where t = torque, k = torque coefficient. Web torque values calculated from formula t=kdf, where k = 0.16 for lubricated conditions k = 0.35 dry the torque values can only be achieved if nut (or tapped hole) has a proof. The size column also includes the thread count. = 0.15 for “lubricated” conditions.

Bolt Torque Chart 7 Free PDF Download

FREE 9+ Bolt Torque Chart Templates in PDF

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

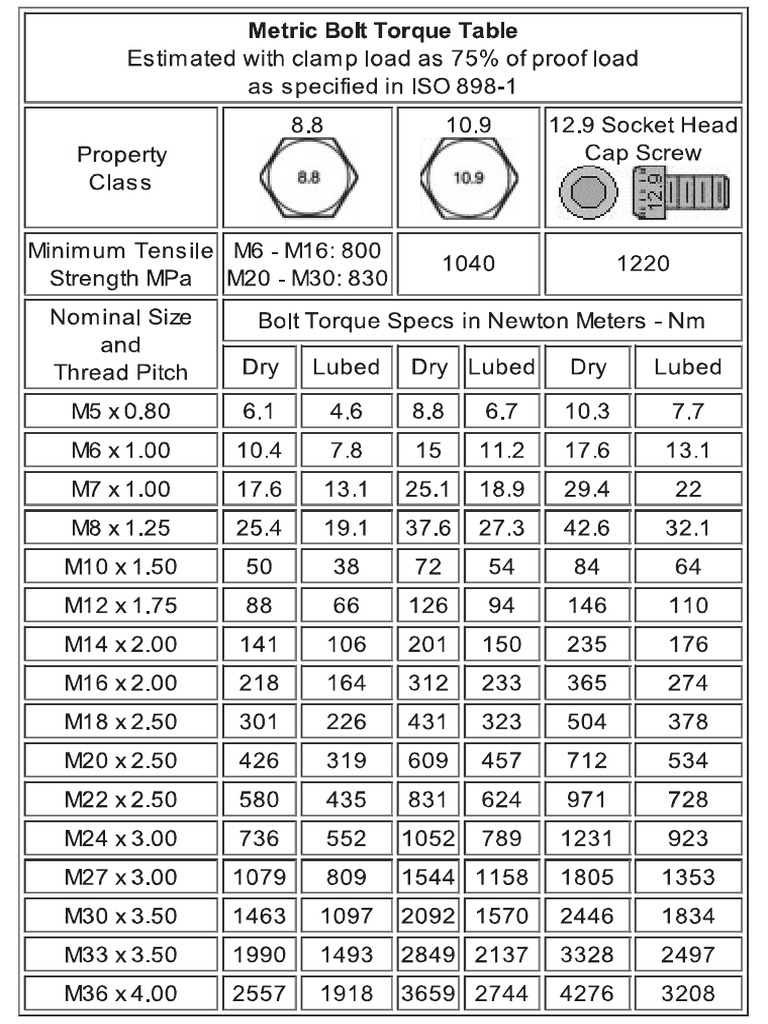

Metric Bolt Torque Chart Large

Bolt Torque Chart 5 Free Templates in PDF, Word, Excel Download

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Lubricated Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Metric Fastener Torque Chart

Fastener Torque Charts Free Download

= 0.13 When Using Ecoguardtm Coated Nut, Bolt And Washer.

Web Is The Estimated Torque Coeficient (For Full Details Contact [email protected]).

The Chart Covers Coarse And Fine Threads, And Shows The Clamp Load.

Web Estimated Fastener Bolt Clamp Force Torque Calculator.

Related Post: