Flange Torque Chart

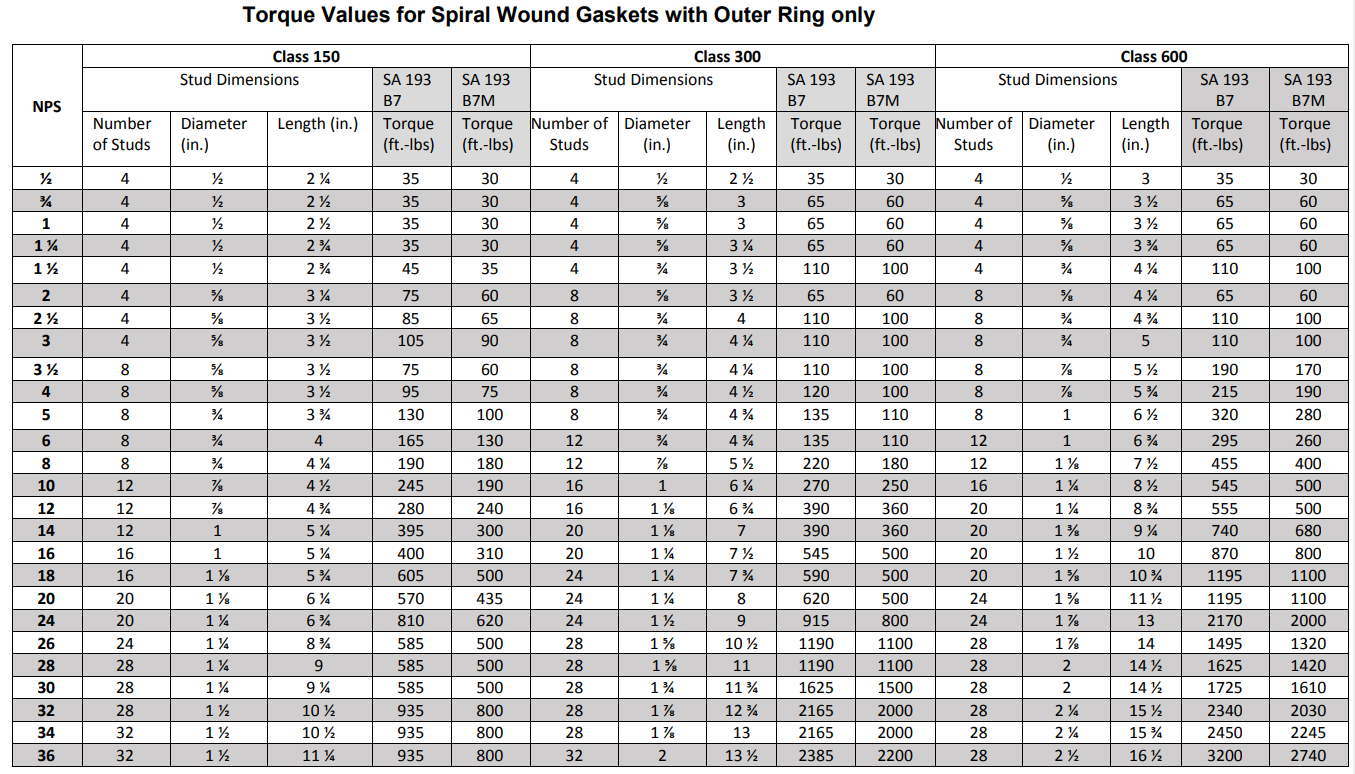

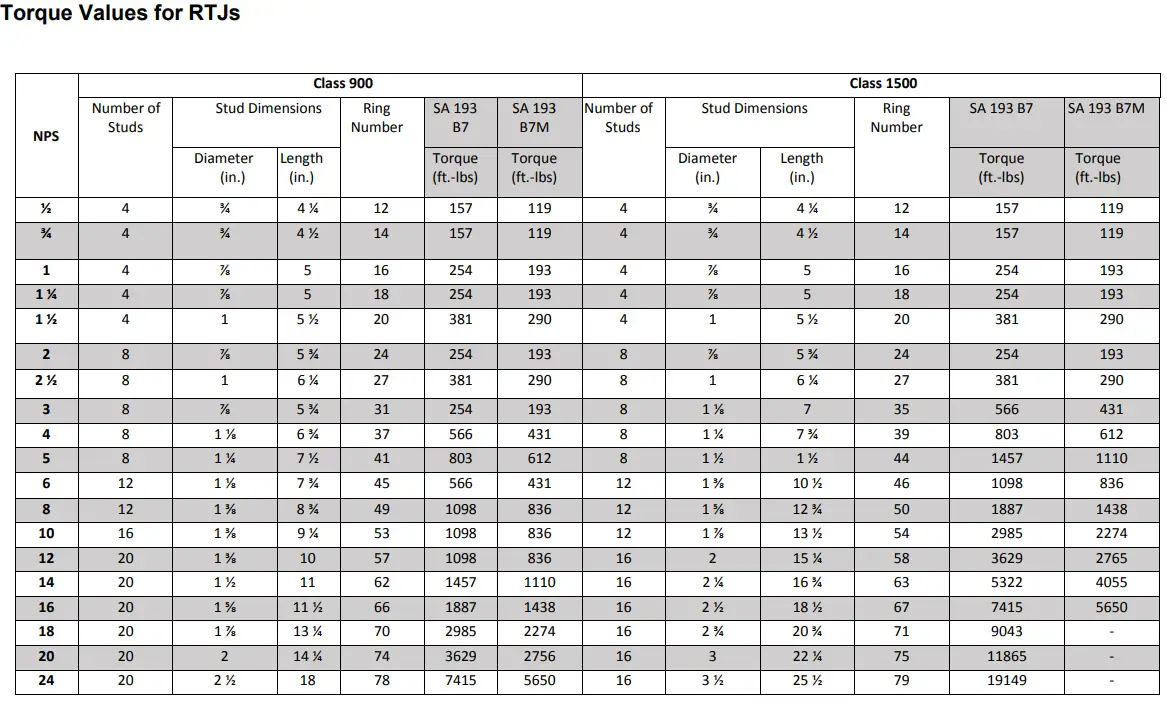

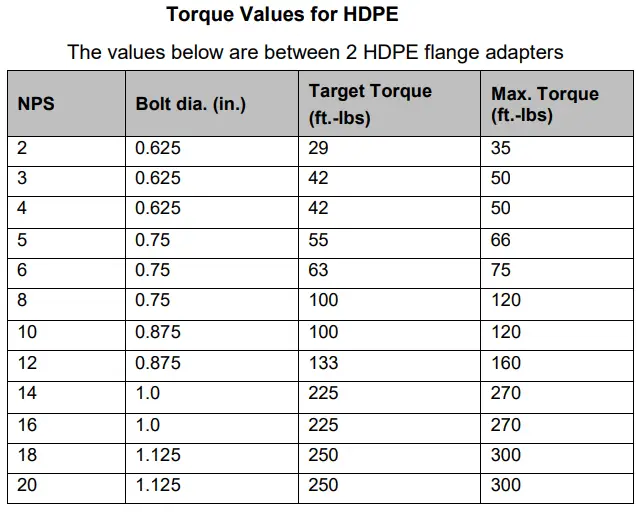

Flange Torque Chart - Web links to the flange torque charts maintained by flange bolt chart for class 300 flanges. Web key charts for stud bolts: Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. For full face homogenous elastomeric gaskets. Access essential information for secure and reliable connections in your piping projects. Class 600 flange torque charts listed by nominal pipe size. Even though flange blot toque calculation is possible, they are normally selected from the pipe flange bolt torque chart. Flange bolting chart (inches) stud bolts and nuts for flanges. The above table is applicable only for astm a193 grade b7 and a193 grade b16 stud bolts. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web links to the flange torque charts maintained by flange bolt chart for class 600 flanges. Stud bolt torque chart (tightening sequence and load to ensure proper flanged joints) stud bolts charts. Web key charts for stud bolts: Access essential information for secure and reliable connections in your piping projects. This torque table applies for 1/16” and 1/8” thick homogenous. Flange bolting chart (inches) stud bolts and nuts for flanges. Links to the flange torque charts maintained by flange bolt chart for class 1500 flanges. The chart also shows the hydro test pressure and the friction factor for each flange class. Web find torque values for different flange bolt sizes and materials based on astm standards. The pressure rating of. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: The chart also shows the hydro test pressure and the friction factor for each flange class. Stud bolt torque chart (tightening sequence and load to ensure proper flanged joints) stud bolts charts. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. The above table is applicable only. As the flange size increases, internal #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. For full face homogenous elastomeric gaskets. Web explore the comprehensive flange bolting chart at texas flange. Web torque tables. Links to the flange torque charts maintained by flange bolt chart for class 1500 flanges. Web find torque values for different flange bolt sizes and materials based on astm standards. Web explore the comprehensive flange bolting chart at texas flange. Web class 1500 flange torque charts. The above table is applicable only for astm a193 grade b7 and a193 grade. Web find torque values for different flange bolt sizes and materials based on astm standards. Web key charts for stud bolts: Web torque guidelines * flanges larger than dn600/nps24 are usually considered equipment flanges, for which generic torque tables are not provided. Flange torque charts listed by nps and by flange class. (inches) bolts suggested ansi 1500# flanges size qty. Web torque guidelines * flanges larger than dn600/nps24 are usually considered equipment flanges, for which generic torque tables are not provided. Swg (type 913 and 913m) nominal diameter recommended torque flange bolt (nm) 1/2” 1/2” use class 600 flanges 3/4” 5/8” 1” 5/8” 1 1/4” 5/8” 1 1/2” 3/4” 2” 5/8” 3/4” 3” 3/4” Web links to the flange torque. Web torque guidelines * flanges larger than dn600/nps24 are usually considered equipment flanges, for which generic torque tables are not provided. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) jacketed gasket. Flange torque charts listed by nps and by flange class. Links to the flange torque charts maintained by flange bolt chart. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); This table is applicable for ptfe coated bolts with k=0.12. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. The pressure rating of the material may vary depending on the grade. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. Flange. The chart also shows the hydro test pressure and the friction factor for each flange class. Web links to the flange torque charts maintained by flange bolt chart for class 300 flanges. The entire bolt pattern shall be tightened at least three times around the flange at 30%, 70%, and 100% of the torque value. Web links to the flange torque charts maintained by flange bolt chart for class 2500 flanges. Web learn how to properly tighten flange joints with torque wrenches and bolts. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.12. Flange bolting chart (inches) stud bolts and nuts for flanges. Web key charts for stud bolts: Web find the recommended torque values for bolts and studs of different sizes and pipe diameters for ansi 150#, 300# and 600# flanges. The pressure rating of the material may vary depending on the grade. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: The above table is applicable only for astm a193 grade b7 and a193 grade b16 stud bolts. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. (inches) bolts suggested ansi 1500# flanges size qty. This table is applicable for ptfe coated bolts with k=0.12.

Flange Bolt Torque Specification Chart

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Flange Bolt Torque Specification Chart

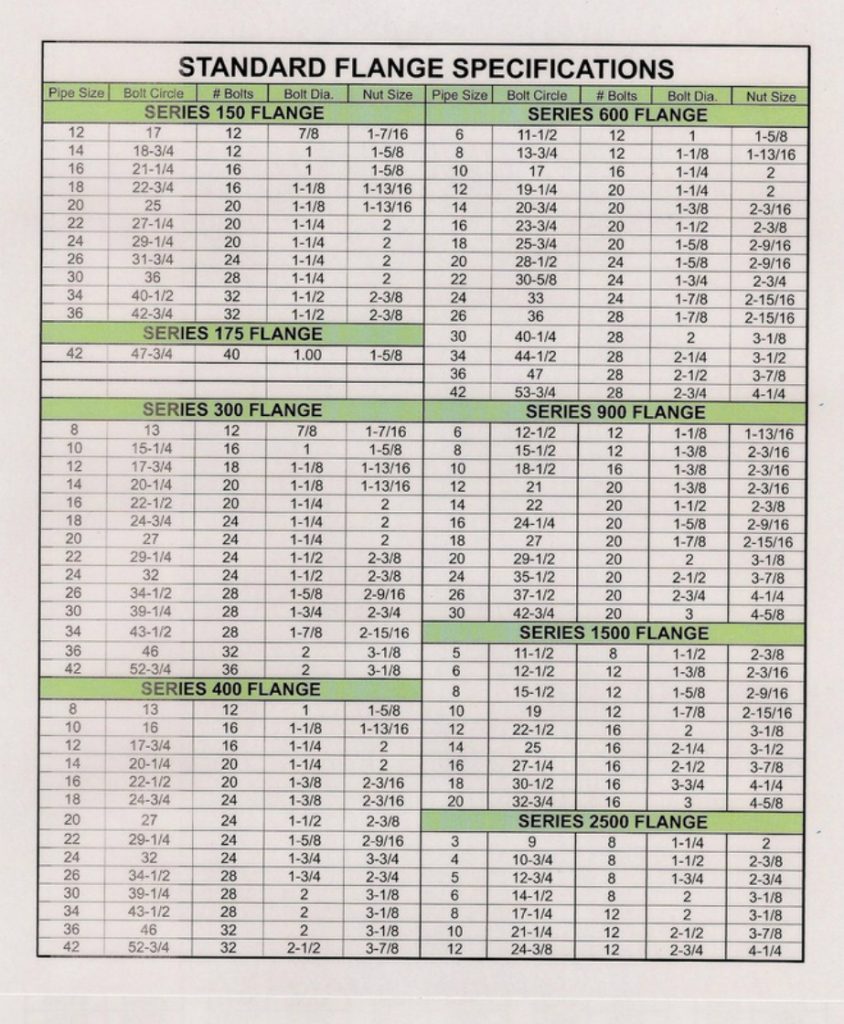

ASME Flange Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Pipe Flange Torque Chart

Asme Flange Bolt Chart Sexiz Pix My XXX Hot Girl

API 650 Flange Chart

Torque Charts Industrial Bolting And Torque Tools vrogue.co

Torque Charts Industrial Bolting And Torque Tools vlr.eng.br

Web With A193 Grade B7 Bolts.

Web Explore The Comprehensive Flange Bolting Chart At Texas Flange.

This Torque Table Applies For 1/16” And 1/8” Thick Homogenous Elastomeric Gaskets.

Swg (Type 913 And 913M) Nominal Diameter Recommended Torque Flange Bolt (Nm) 1/2” 1/2” Use Class 600 Flanges 3/4” 5/8” 1” 5/8” 1 1/4” 5/8” 1 1/2” 3/4” 2” 5/8” 3/4” 3” 3/4”

Related Post: