Gear Module Chart

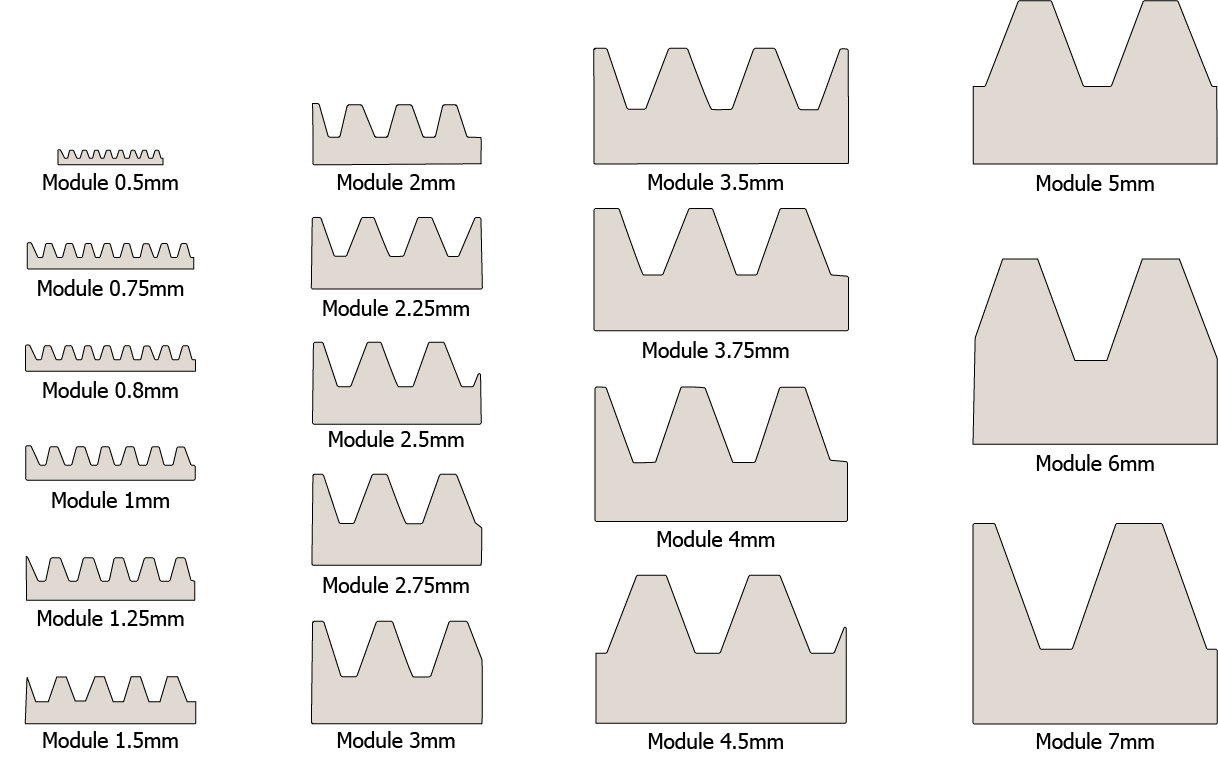

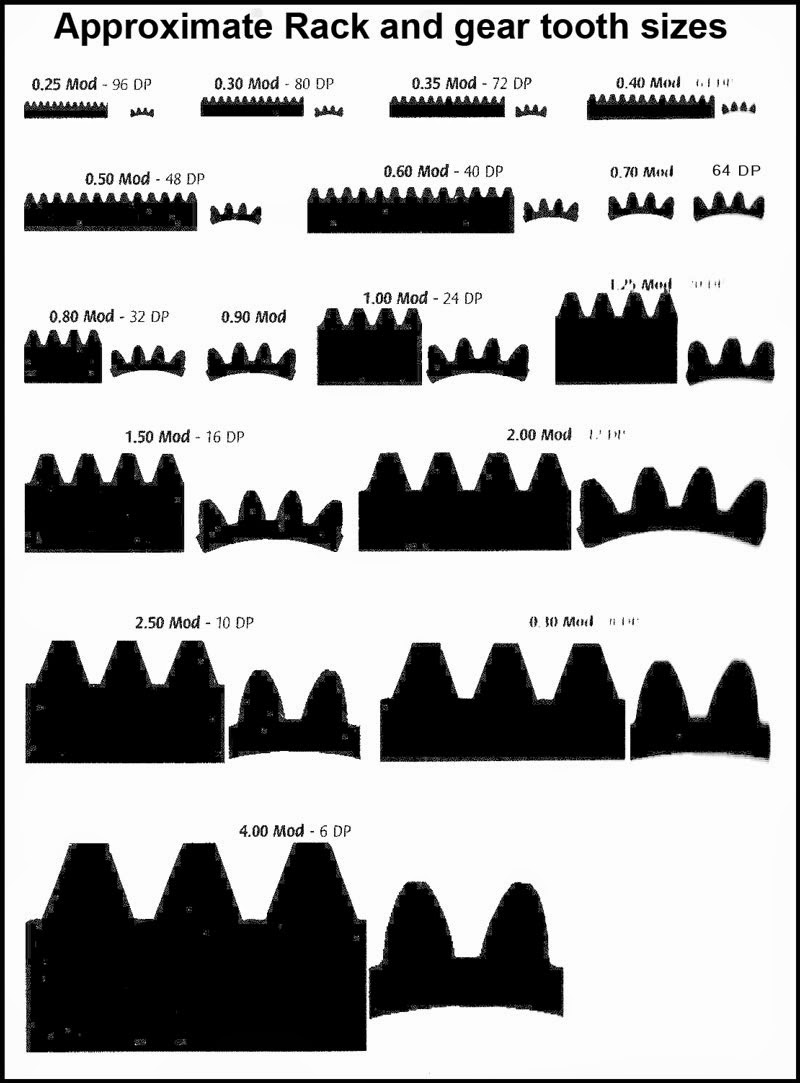

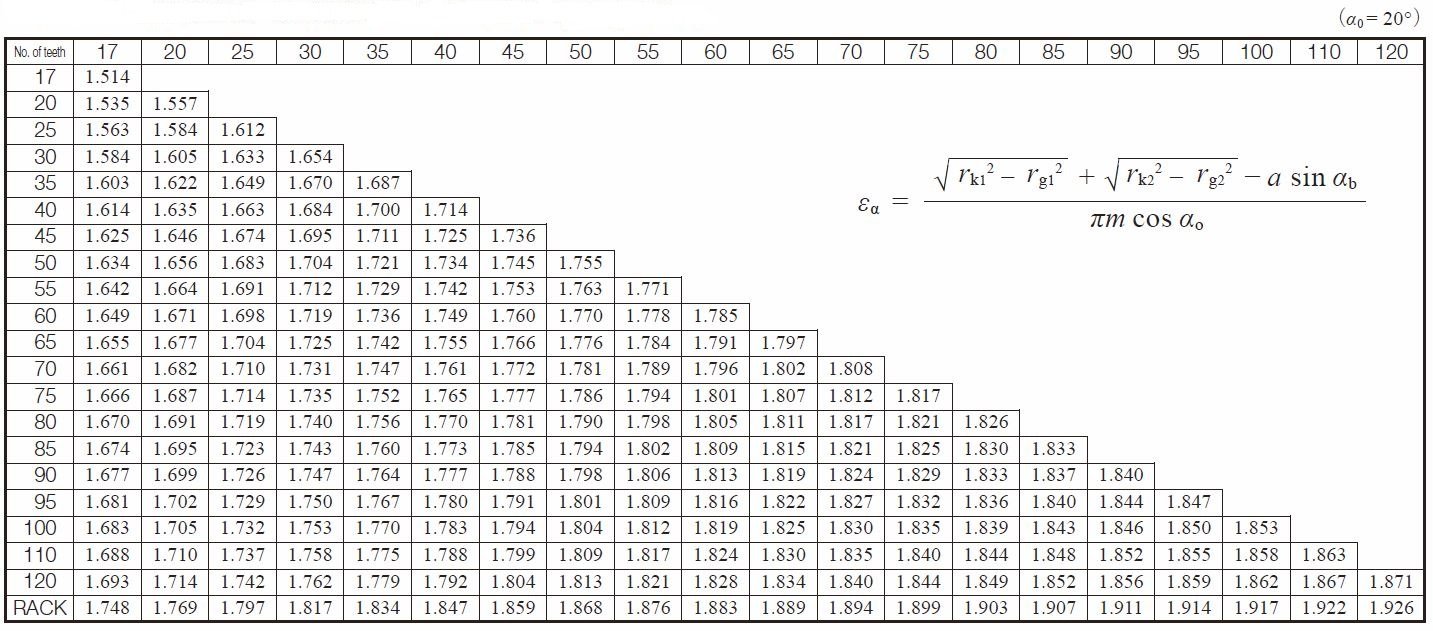

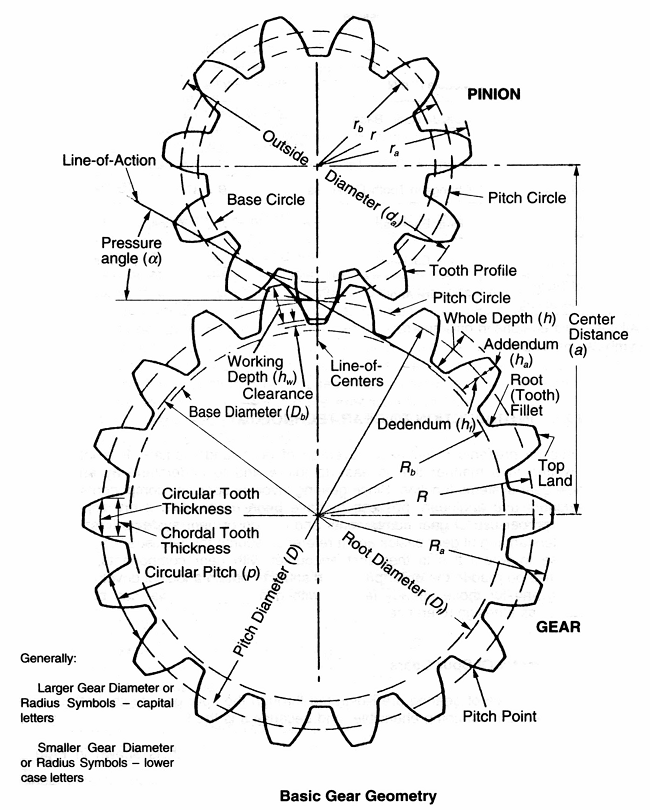

Gear Module Chart - Web calculate the key dimensions for your external spur gear. Web the chart shown in table 2 compares the equivalent values of module (m), circular pitch (cp) and diametral pitch (dp). Web module (m) , pressure angle (α) , and the number of teeth, introduced here, are the three basic elements in the composition of a gear. As well as this, gears can also. This refers to the size of the tooth and a larger tooth size means more power can be transferred. Illustrated below are procedural steps to determine specifications of a spur gear. Web gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Web spur gear sizes are usually measured by module. Precision gears, timing belts, gear. Web module — metric gearing uses the quantity module m in place of the american inch unit, diametral pitch. Web metric gears are defined by the module system, as follows: They are used to provide positive transmis. Web gear modules range from 0.004 to 100 millimeters, the gear diameter can range from 1 millimeter to 150 meters. Web the following charts convert gear pitch dimensional data to the following: Web gear dimensions are determined in accordance with their specifications,. Precision gears, timing belts, gear. The module is the length of pitch diameter per tooth. The length in mm of the pitch circle diameter per tooth. A module is a unit of gear tooth size determined by iso. The 'module' system is widely used all over the world to. Dimensions of gears are calculated based. Web the module is typically quoted in standardized gear sizing charts with implied units of length, either (mm) for si units or (in) for bg units. The number of teeth・・・・・ 1、2、3・・・・・。 module is the unit of size that indicates how. The gear module is calculated using the formula: Web gear dimensions are determined in. \ [ \text {module} = \frac {\text {gear diameter (mm)}} {\text {number of teeth}} \] this formula provides a. The gear module is calculated using the formula: Is the unit of size that indicates how big or small a gear. A module is a unit of gear tooth size determined by iso. In a sense, it’s a measure of the. Web module (m) , pressure angle (α) , and the number of teeth, introduced here, are the three basic elements in the composition of a gear. The power transmission capability can reach up to 100,000. As you can see, module 1.5 gear is a gear with a module value of 1.5. A module is a unit of gear tooth size. Diametral pitch, module, circular pitch. Precision gears, timing belts, gear. A p = addendum of pinion. Illustrated below are procedural steps to determine specifications of a spur gear. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and. The power transmission capability can reach up to 100,000. Mod = pcd / n. A module is a unit of gear tooth size determined by iso. As you can see, module 1.5 gear is a gear with a module value of 1.5. Diametral pitch gears from dp8. Web use this information about gear types, pressure angle, and pitch and module to determine the best gear for your application. Web metric gears are defined by the module system, as follows: In a sense, it’s a measure of the unit. Web 16.1 method for determining the specifications of a spur gear. A module is a unit of gear tooth. Diametral pitch gears from dp8. Web module — metric gearing uses the quantity module m in place of the american inch unit, diametral pitch. The gear module is calculated using the formula: They are used to provide positive transmis. Web the gear identification chart is designed to help you identify an unknown gear, even if only a few teeth remain. The gear module is calculated using the formula: The power transmission capability can reach up to 100,000. In a sense, it’s a measure of the unit. Web calculate the key dimensions for your external spur gear. Illustrated below are procedural steps to determine specifications of a spur gear. \ [ \text {module} = \frac {\text {gear diameter (mm)}} {\text {number of teeth}} \] this formula provides a. Web the following charts convert gear pitch dimensional data to the following: A g = addendum of gear. Web spur gear sizes are usually measured by module. Web calculate the key dimensions for your external spur gear. Web gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and. This refers to the size of the tooth and a larger tooth size means more power can be transferred. The module is the length of pitch diameter per tooth. Web in this article, it is assumed that the reader has a basic knowledge of gear parameters and terminology such as module, pitch circle diameter, outer diameter, base circle. Web what is module 1.5 gear? Web the module is typically quoted in standardized gear sizing charts with implied units of length, either (mm) for si units or (in) for bg units. Illustrated below are procedural steps to determine specifications of a spur gear. Web (1) about gears the module of a gear reference diameter. A p = addendum of pinion. The chart has templates for:

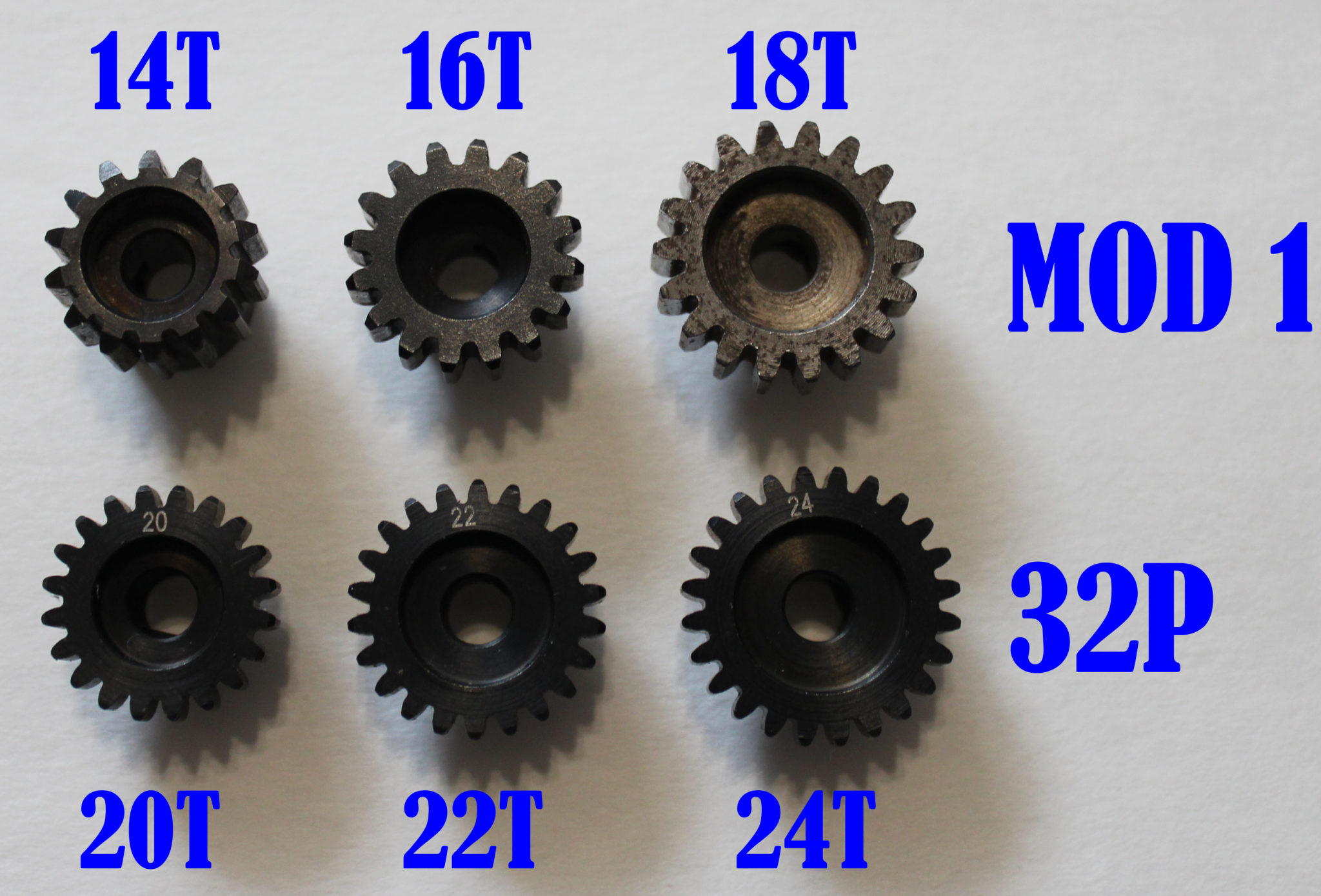

All About RC Car Gear Pitches Why are there so many?

Automotion Components Spur Gears Technical Page Automotion

Basic Gear Terminology and Calculation KHK Gears Mechanical

Gear Profile and Gear Module MISUMI USA Blog

trigonometry How can you calculate the module of a gear

Wooden Clocks Gear Train design for the wooden clock

Bending Strength of Spur and Helical Gears KHK

Spur Gears Pressure Angle 20Deg., Module 1.5 MISUMI MISUMI MEXICO

Gear Tooth Contact Stress Number Equation and Calculator

Gear Diametrical Pitch Chart Jeff Thompson

The Number Of Teeth・・・・・ 1、2、3・・・・・。 Module Is The Unit Of Size That Indicates How.

The Power Transmission Capability Can Reach Up To 100,000.

Precision Gears, Timing Belts, Gear.

Is The Unit Of Size That Indicates How Big Or Small A Gear.

Related Post: