Gmaw Settings Chart

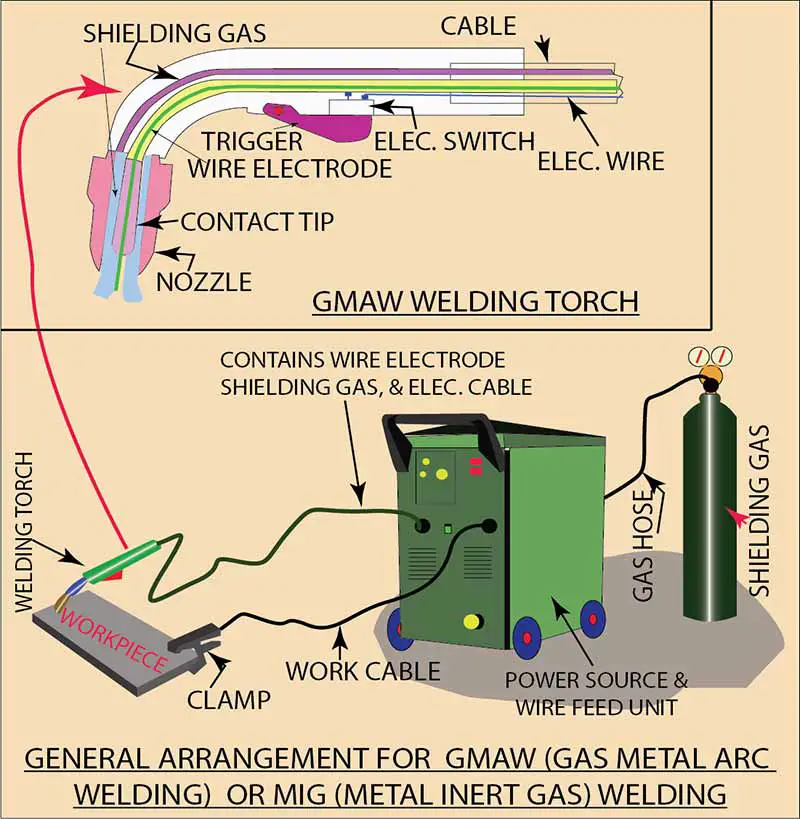

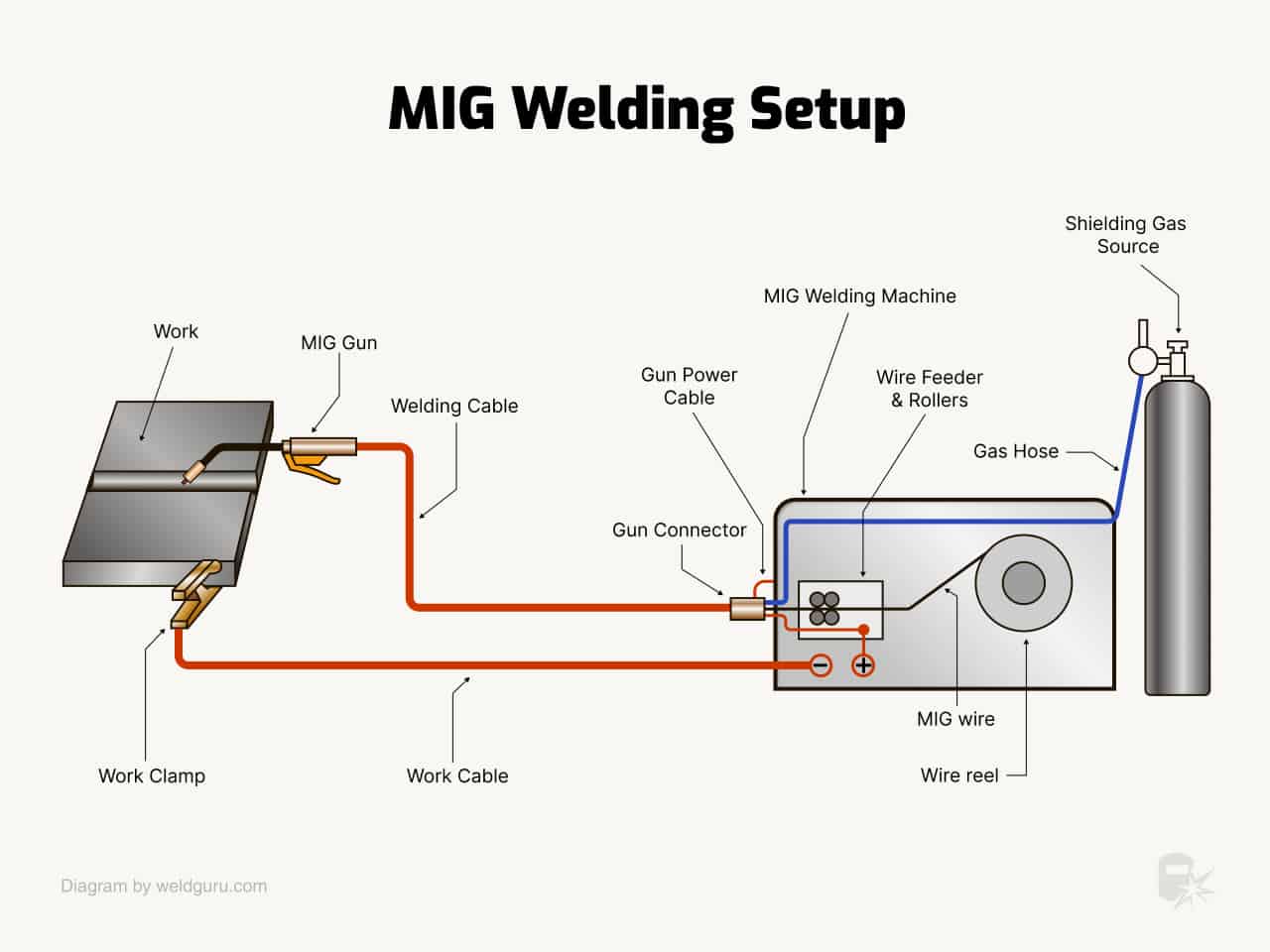

Gmaw Settings Chart - Web the heat and rays of the arc can react with vapors to form highly toxic and irritating gases. Web the minimum equipment needed for a typical gmaw setup includes a mig welding machine, a power source, a shielding gas cylinder, a consumable mig wire, a welding gun, and a ground clamp, also known as the work clamp. Joint design, position and other factors affect results and settings. There are many mig setting charts available from manufacturers that all vary. Gmaw process is based on the principle of forming a weld joint by melting the faying surfaces of the workpiece using the heat generated by the arc formed between the electrode and the workpiece surface. • higher welder efficiencies and operator factor, when compared to other open arc welding processes. Covering classifications, refrence charts and gas choices. Web • gmaw has higher electrode efficiencies, usually between 93% and 98%, when compared to other welding processes. Web are you producing quality weld beads? Web the following basic mig welding settings are for welding steel with solid wire. Web what is mig welding? Web the following basic mig welding settings are for welding steel with solid wire. Web the minimum equipment needed for a typical gmaw setup includes a mig welding machine, a power source, a shielding gas cylinder, a consumable mig wire, a welding gun, and a ground clamp, also known as the work clamp. Web download. Web the following basic mig welding settings are for welding steel with solid wire. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. When good results are achieved, record the parameters. The internal circuitry. Web common mig electrode wire and gasses. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. Web the heat and rays of the arc can react with. Web what material are you welding? Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. There are many mig setting charts available from manufacturers that all vary. Joint design, position and other factors affect results and settings. Web common mig electrode wire and gasses. Web with the powermig 350mp, you can use the generic gmaw mode where you set voltage and wire speed independently, or you can select synergic gmaw, where wire speed is the main setting and the machine sets voltage for you (but you can adjust voltage if you want to). Web check the inside cover of your millermatic® welder for optimal. And like all other arc welding processes, it melts and joins the base metal with the filler metal using the resistance of current flow through the metal. Web common mig electrode wire and gasses. Low heat input using forcearc puls® xq, less surface oxidation. Web metal inert gas, or mig for short, is an arc welding process. Web follow this. Gmaw process is based on the principle of forming a weld joint by melting the faying surfaces of the workpiece using the heat generated by the arc formed between the electrode and the workpiece surface. There are many mig setting charts available from manufacturers that all vary. And like all other arc welding processes, it melts and joins the base. This article presents guidelines that can help you identify which parameters to adjust and how to adjust them. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. If not, perhaps your parameters need tweaking.. Web metal inert gas, or mig for short, is an arc welding process. Optimal settings ensure proper heat and wire speed for smooth, strong welds. Web follow this comprehensive guide with a chart to learn how to set your mig welder accurately and effectively. Wire burns back to contact tip during or at the end of the weld Web download. Web what is mig welding? Web metal inert gas, or mig for short, is an arc welding process. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint.. Argon (99% of the time) argon/helium. Covering classifications, refrence charts and gas choices. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. Gmaw process is based on the principle of forming a weld joint by melting the faying surfaces of the workpiece using the heat generated by the arc formed between the electrode and the workpiece surface. This article presents guidelines that can help you identify which parameters to adjust and how to adjust them. • higher welder efficiencies and operator factor, when compared to other open arc welding processes. Joint design, position and other factors affect results and settings. If not, perhaps your parameters need tweaking. Web the heat and rays of the arc can react with vapors to form highly toxic and irritating gases. There are many mig setting charts available from manufacturers that all vary. Web check the inside cover of your millermatic® welder for optimal starting setting or to fine tune for your application. Web see how a switch to pulsed gmaw can deliver results such as reduced spatter and less rework in your manufacturing operation. Web what material are you welding? Compared to pulsed arc welding, forcearc puls® xq inputs up. Web the minimum equipment needed for a typical gmaw setup includes a mig welding machine, a power source, a shielding gas cylinder, a consumable mig wire, a welding gun, and a ground clamp, also known as the work clamp. Web • gmaw has higher electrode efficiencies, usually between 93% and 98%, when compared to other welding processes.

MIG Welding Setting the Correct Parameters MillerWelds

Welding parameters used in DC PGMAW Download Table

How To MIG Weld Aluminum Beginners Guide (with Chart)

Weld Settings for Thick Sections (GMAW)

MIG Welding Gas Pressure Settings (with Charts) (2023)

GMAW flow chart r/weldinginspection

Gmaw Electrode Classification Chart

Gmaw welding, Welding, Gmaw

Gas Metal Arc Welding (GMAW) MIG Welding Guide (2022)

What is GMAW (MIG Welding) & How Does it Work? Weld Guru

Web What Material Are You Welding?

Web Download The App Version Of The Weld Setting Calculator For Easy Reference!

Web The Following Basic Mig Welding Settings Are For Welding Steel With Solid Wire.

Web Mig Welding Is Also Called As Gas Metal Arc Welding (Gmaw) Is A Type Of Welding That Is Done Using A Continuously Fed Mig Wire Electrode And A Shielding Gas That Melts And Deposits The Workpiece Metal In The Weld Joint.

Related Post: