Grade 5 Bolt Torque Chart

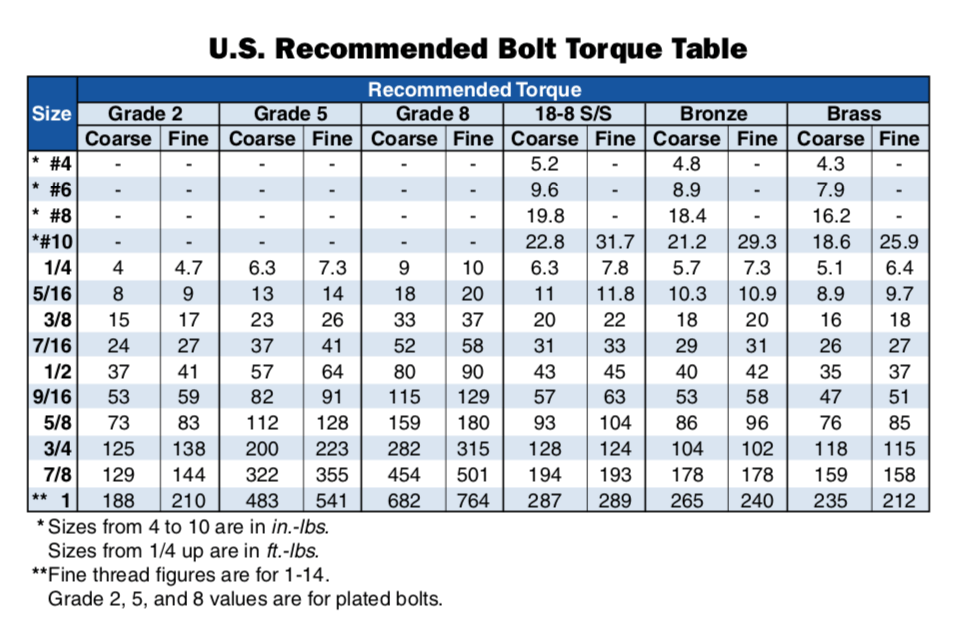

Grade 5 Bolt Torque Chart - Tightening torque sae j429 grade 5. (in.) threads per inch astm a307 grade a. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Tightening torque (ft lbs) bolt size: Grade 2, 5 and 8 values are for plated bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and. Web when using a formula for torque/tension relationships. Web 19 rows find the suggested tightening torques for different bolt sizes and thread pitches based on sae grades. This chart shows values for lightly oiled threads and 70% of yield strength. Grade 2, 5, and 8 values are for. This chart shows values for lightly oiled threads and 70% of yield strength. (cad and wax, grade b, c, and grade g flange nuts) lock nut standards from. (in.) threads per inch astm a307 grade a. Web when using a formula for torque/tension relationships. In practice, there are many factors that affect permissible torque including bolt. Web the values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Under/over tightening of fasteners can result in costly equipment failure or. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and. Web the torque values can only be achieved if nut (or. The values are for slightly lubricated bolts. Under/over tightening of fasteners can result in costly equipment failure or. See tables for coarse and fine thread sizes, plain and plated bolts, and. Grade 2, 5, and 8 values are for. 1 inch = 25.4 mm. Grade 2, 5, and 8 values are for. Proof load (lbs) clamp load (lbs) galv + waxed: Tightening torque (ft lbs) bolt size: Web 19 rows find the suggested tightening torques for different bolt sizes and thread pitches based on sae grades. Torque is only an indirect indication of tension. Tightening torque (ft lbs) bolt size: Web the tightening torques below are for imperial us bolts with tension approximately 70% of yield strength. This chart shows values for lightly oiled threads and 70% of yield strength. In practice, there are many factors that affect permissible torque including bolt. Web the torque values can only be achieved if nut (or tapped. Grade 2, 5, and 8 values are for. Proof load (lbs) clamp load (lbs) galv + waxed: Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. See tables for coarse and fine thread sizes, plain and plated bolts, and. The values. Web download this as a pdf. Grade 2, 5, and 8 values are for. Web the values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. (cad and wax,. See tables for coarse and fine thread sizes, plain and plated bolts, and. Proof load (lbs) clamp load (lbs) galv + waxed: Web the values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. 1 inch = 25.4 mm. Tightening torque sae j429 grade 5. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. Web when using a formula for torque/tension relationships. Web astm a449 / sae grade 5 : 1 inch = 25.4 mm. Grade 2, 5 and 8 values are for plated bolts. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Tightening torque sae j429 grade 5. Web find recommended maximum tightening torques for us bolts of different sizes and grades. = clamp load for j429 grade 5 and 8, fnl grade 9,. Web when using a formula for torque/tension relationships. In practice, there are many factors that affect permissible torque including bolt. 1 inch = 25.4 mm. Web the values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Tightening torque (ft lbs) bolt size: Grade 2, 5 and 8 values are for plated bolts. Tightening torque sae j429 grade 5. Proof load (lbs) clamp load (lbs) galv + waxed: Web find recommended maximum tightening torques for us bolts of different sizes and grades. Web download this as a pdf. (cad and wax, grade b, c, and grade g flange nuts) lock nut standards from. Grade 2, 5, and 8 values are for. Under/over tightening of fasteners can result in costly equipment failure or. The values are for slightly lubricated bolts. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Web unlike most bolt torque charts, this particular chart also lists clamp loads and torque values that correspond with bolt material stresses of 10,000 and 25,000 psi.

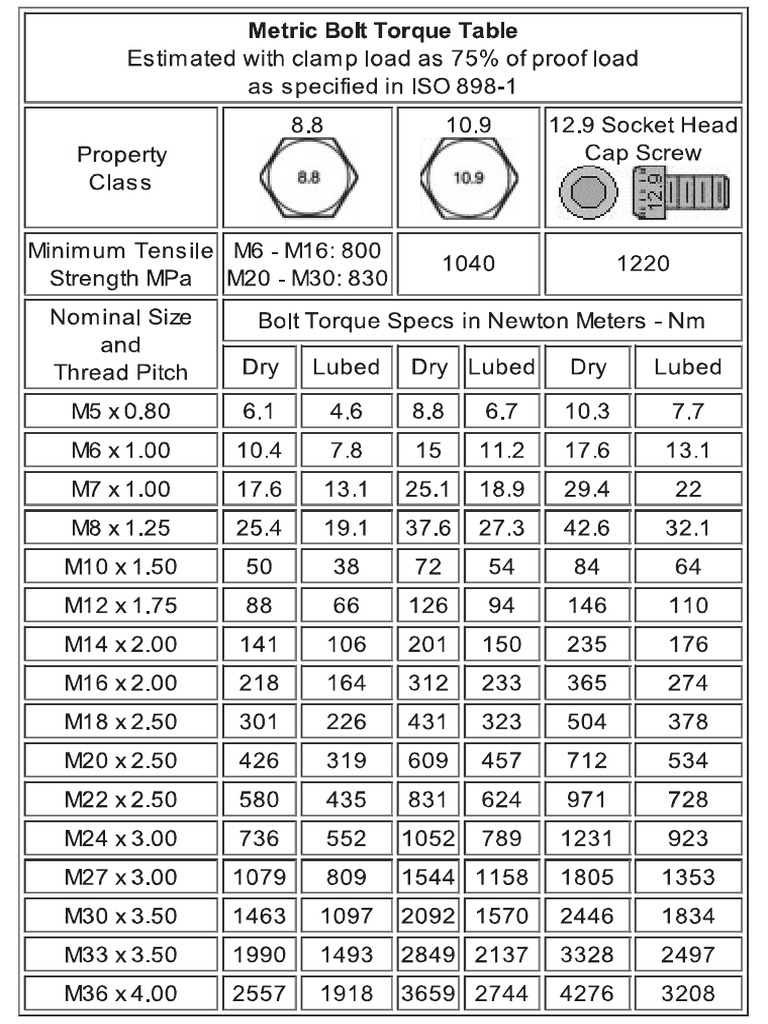

Grade 8 Metric Bolt Torque Chart

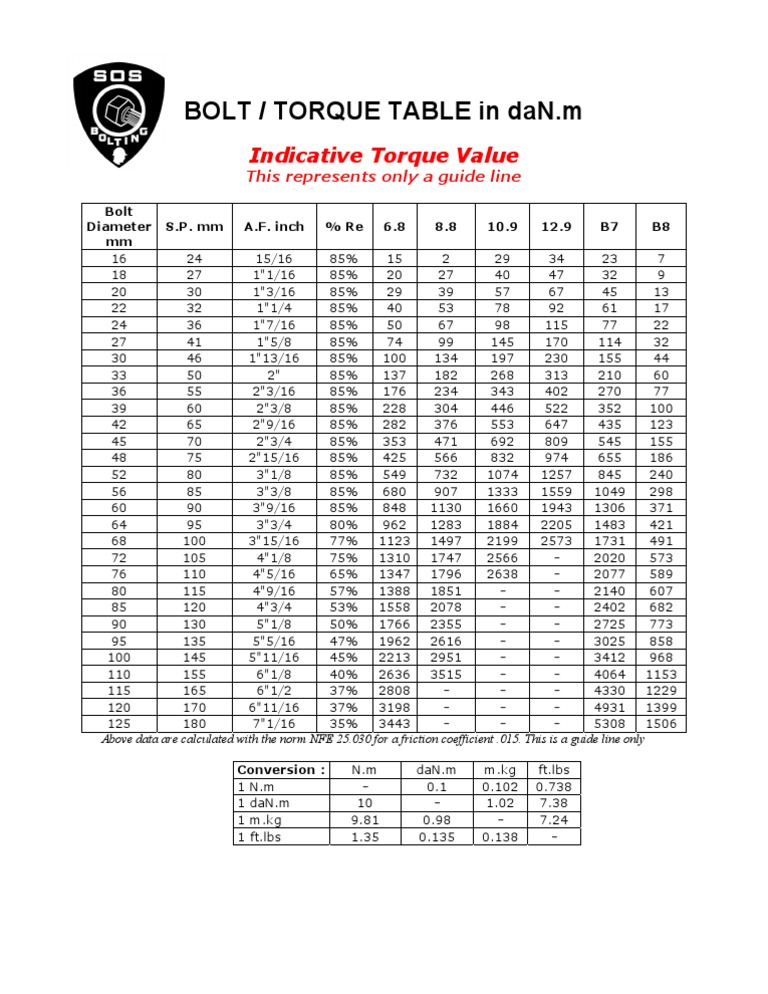

Torque Specification Chart Pdf

Metric Bolt Torque Value Chart Porn Sex Picture

Lubricated Bolt Torque Chart

Metric Bolt Torque Chart Stainless Steel IMAGESEE

Printable Bolt Torque Chart

Grade 8 Metric Bolt Torque Chart

Grade 5 Bolt Torque Chart

Grade 8 Bolt Torque Chart

FREE Sample Bolt Torque Chart Templates In PDF MS Word 810 The Best

Torque Is Only An Indirect Indication Of Tension.

Web The Tightening Torques Below Are For Imperial Us Bolts With Tension Approximately 70% Of Yield Strength.

See Tables For Coarse And Fine Thread Sizes, Plain And Plated Bolts, And.

This Chart Shows Values For Lightly Oiled Threads And 70% Of Yield Strength.

Related Post: