H6 Tolerance Chart

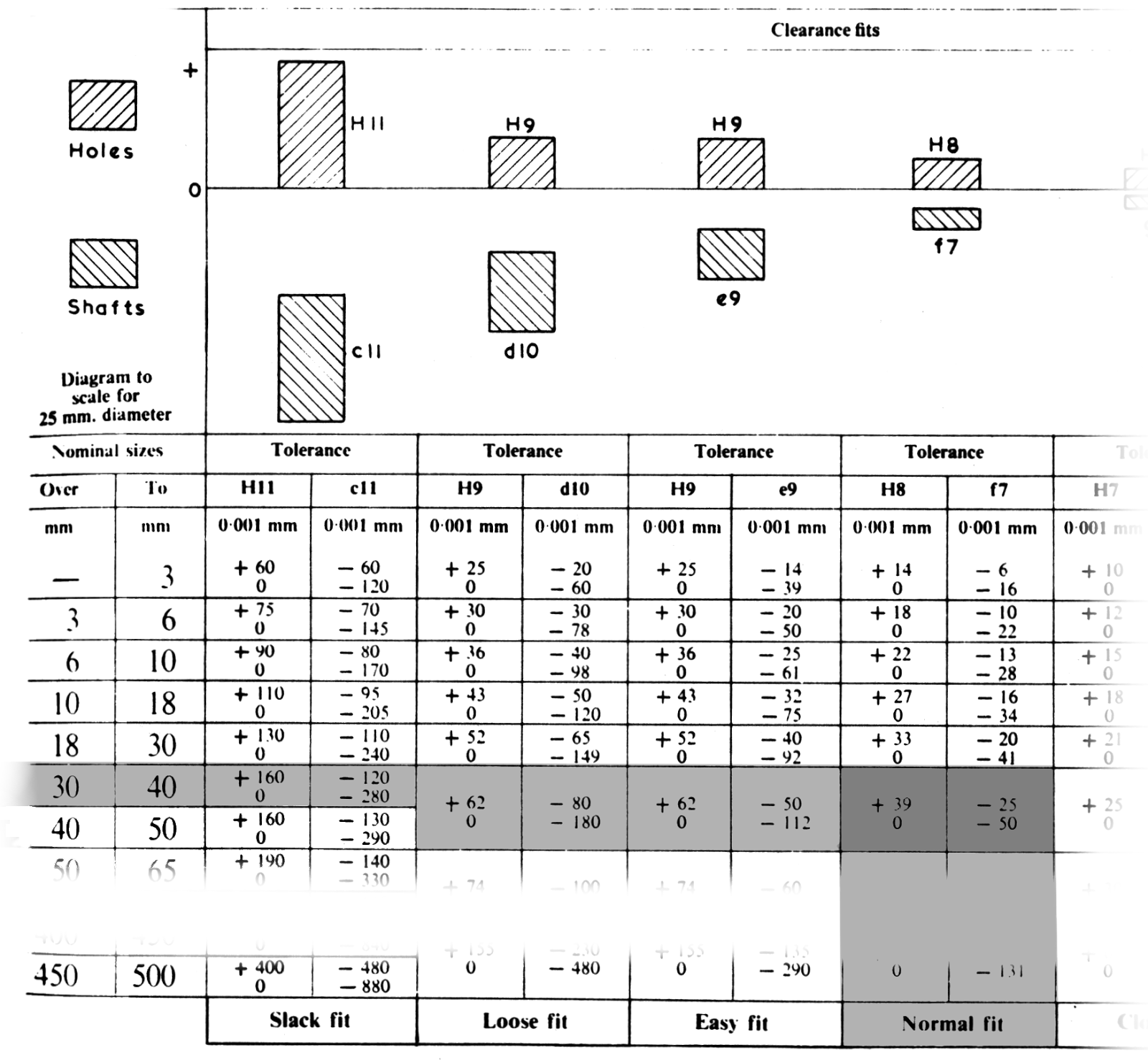

H6 Tolerance Chart - These size charts do not compensate position or other gd&t location tolerances. Web find and calculate tolerances for holes and shafts. Web tables of standard tolerance grades and limit deviations for holes and shafts. Go here, for explanasions about the terms hole,. Locational clearance fit provides snug fit for locating. Web the following iso tolerance chart for bolts and holes per iso 286. The tolerance of size is normally defined as the difference between the upper and lower. Web table of metric hole tolerances per. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data. Web concentricity tolerances (inch) ø diameter: Green = prefered tolerance classes per iso 286. Find your data faster with our fits calculator. The following engineering calculator will show the plus and minus tolerance. Insertion of a suction valve and valve guide. Go here, for explanasions about the terms hole,. Find your data faster with our fits and tolerance calculator. Web find and calculate tolerances for holes and shafts. These size charts do not compensate position or other gd&t location tolerances. Iso preferred fits calculator to calculate preferred tolerances of shafts and holes according to metric iso. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data. These size charts do not compensate position or other gd&t location tolerances. The following engineering calculator will show the plus and minus tolerance. Diameter max / min en mm =. Calculate fits and tolerances for shafts and holes here. Web find and calculate tolerances for holes and shafts. Calculate fits and tolerances for shafts and holes here. These dimensions are standardized limits for. The shaft basis fits have four preferred shaft tolerances (h11, h9, h7, and h6) as shown in table 6. Web iso preferred fits calculator. Locational clearance fit provides snug fit for locating. A great way to find all the. The tolerance of size is normally defined as the difference between the upper and lower. Calculate fits and tolerances for shafts and holes here. Based on standard tolerances and limit deviations in accordance with iso 286. These dimensions are standardized limits for. These dimensions are standardized limits for. Iso metric tolerance zone limits and fits. Web for f7, the tolerance range is the same but the starting point is 25.020 mm, taking the last acceptable measurement to 25.041 mm. Based on standard tolerances and limit deviations in accordance with iso 286. Web tables of standard tolerance grades and limit deviations for holes. Go here, for explanasions about the terms hole,. Insertion of a suction valve and valve guide. Web the following iso tolerance chart for bolts and holes per iso 286. Sliding fit not intended to run freely, but to move and turn freely and locate accurately. Web find and calculate tolerances for holes and shafts. Locational clearance fit provides snug fit for locating. Web the hole basis fits have four preferred hole tolerances (h11, h9, h8, and h7); Determine plus and minus tolerance for the specific iso 286 shaft tolerance data. Diameter max / min en mm =. Tolerance deviaiton h (for shafts) the posision of h relative to the other shaft. Find your data faster with our fits calculator. Web tables of standard tolerance grades and limit deviations for holes and shafts. Insertion of a suction valve and valve guide. Web nominal shaft sizes (mm) over 3 Web shaft tolerance table (iso) ≥ < c9. Web table of metric shaft tolerances per. The following engineering calculator will show the plus and minus tolerance. Green = prefered tolerance classes per iso 286. Web nominal shaft sizes (mm) over 3 These size charts do not compensate position or other gd&t location tolerances. The tolerance of size is normally defined as the difference between the upper and lower. The following engineering calculator will show the plus and minus tolerance. Web for f7, the tolerance range is the same but the starting point is 25.020 mm, taking the last acceptable measurement to 25.041 mm. Sliding fit not intended to run freely, but to move and turn freely and locate accurately. The schematic representation of the fit is also drawn. Web concentricity tolerances (inch) ø diameter: Find your data faster with our fits calculator. Go here, for explanasions about the terms hole,. Fixing a gear and a shaft together (low torque) shaft of a flexible coupling. Web the hole basis fits have four preferred hole tolerances (h11, h9, h8, and h7); Based on standard tolerances and limit deviations in accordance with iso 286. Find your data faster with our fits and tolerance calculator. Green = prefered tolerance classes per iso 286. Web shaft tolerance table (iso) ≥ < c9. Based on standard tolerances and limit deviations in accordance with iso 286. Calculate fits and tolerances for shafts and holes here.

SOLVED According To The Normal Shaft System, The H6, 41 OFF

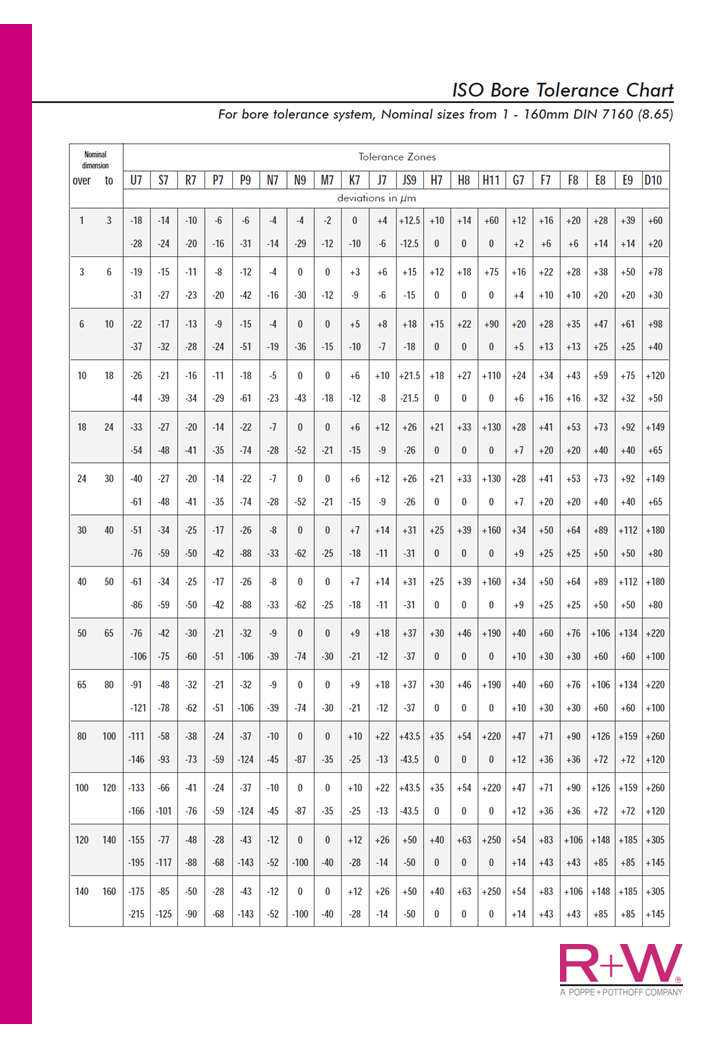

ISO Tolerances for Holes & Shafts

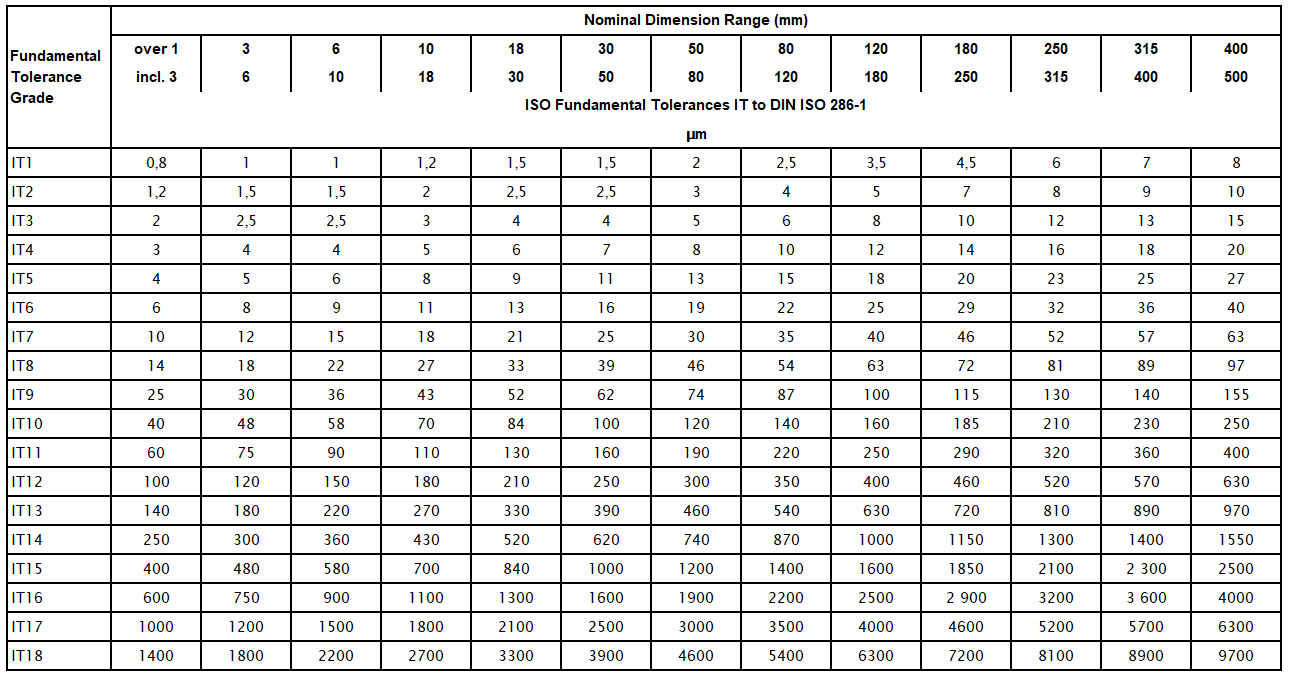

Table for Values of ISO Fundamental Tolerances Grades Engineersfield

Iso 2768 Hole Tolerance Calculator metricsload

Iso 2768 hole tolerance table pacchlist

Metric Tolerance Chart PDF Engineering Tolerance Descriptive

iso hole tolerance chart pdf Focus

_Shaft_Fit_Tolerance_Charts.png?width=540&name=DIN_7160_(8%2C65)_Shaft_Fit_Tolerance_Charts.png)

DIN Shaft Fit Tolerances

Iso fits and tolerances chart pasays

ISO Tolerances For Holes PDF Engineering Tolerance World Economy

International Tolerance (It) Grades Table Reference Iso 286.

Locational Clearance Fit Provides Snug Fit For Locating.

Web Table Of Metric Hole Tolerances Per.

The Following Engineering Calculator Will Show The Plus And Minus Tolerance For The Specific Iso 286 Hole Tolerance.

Related Post: