Harness Drawing

Harness Drawing - With a little practice and knowledge, you can easily interpret these drawings and be on your way to a successful project. Complete schematic of a wire harness diagram. Web do a physical layout drawing of the harness(es). The following slides provide a collated visual of commonly used design objects in a wiring diagram and layout drawing respectively. Efficiently manage design variations with dash number harness variables. Lastly, we’ll how automation is influencing wire harness manufacturing. November 30, 2023 | updated: Once the harness design has been captured in the form of a wiring diagram, the physical representation of the design can be created as a harness layout drawing ( *.ldrdoc ). Contains a top level view (optionally as a 1:1 formboard), bill of materials, wiring table, cutlist, and other associated documents. These standards ensure consistency, clarity, and accuracy in wire harness documentation, making it easier for designers, manufacturers, and technicians to understand and work with the harnesses. Complete schematic of a wire harness diagram. Deploy rapidly to meet your goals. Here are a few guidelines to guide you through the drawing process to eliminate such a scenario. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. November 30, 2023 | updated: Web wiring harness design software. Efficiently manage design variations with dash number harness variables. Contains a top level view (optionally as a 1:1 formboard), bill of materials, wiring table, cutlist, and other associated documents. A wire harness diagram, also known as a wiring diagram or electrical schematic, is a visual representation of the electrical connections and functions of a wire. The individual wired connections within the harness are specified in the harness wiring diagram (.wirdoc ). Complete schematic of a wire harness diagram. November 03, 2023 | updated: Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. You can also download a sample harness pdf to see an example harness. It provides a detailed outline of the wiring system, showing the placement and routing of wires, connectors, and other electrical components. Setting up a harness wiring diagram document. Web wirely is a wiring harness tool that allows the user to enter the logical connections for a wiring harness and then generates beautiful wiring diagrams with synchronized documentation. Draw a physical. Web arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and manufacturing documentation quickly & accurately, like never before. Setting up a harness wiring diagram document. Web quickly draw & document harnesses. Take a look through the slides below to see a variety of design objects highlighted 'in action' within a. Deploy rapidly to meet your goals. Web a manufacturing drawing document allows a bill of materials (bom), wiring list, connection table, and a generic table to be placed on the drawing. Web arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and manufacturing documentation quickly & accurately, like never before. Complete. The harness design functionality allows engineers of various types (involved in the. This will make construction far easier down the road. The individual wired connections within the harness are specified in the harness wiring diagram (.wirdoc ). Web quickly draw & document harnesses. It provides a detailed outline of the wiring system, showing the placement and routing of wires, connectors,. Deploy rapidly to meet your goals. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. November 30, 2023 | updated: Automatically drive pricing information, lead time, and assembly time calculations from design elements. A wire harness diagram, also known as a wiring diagram or electrical schematic, is a visual representation. Web wiring harness drawings can be intimidating to the uninitiated, but they contain a wealth of information that can help you get your project off the ground. November 03, 2023 | updated: It provides a detailed outline of the wiring system, showing the placement and routing of wires, connectors, and other electrical components. The designing and drawing of a wiring. The capabilities of nx cad wire harness routing enable you to produce a wire harness directly from nx product assembly models. Web setting up a harness layout drawing document. Web wiring harness design software. Web if you’ve been using solidworks electrical, you know it’s a useful tool to use schematics to create harnesses in 3d automatically. Web altium designer documentation. Web a manufacturing drawing document allows a bill of materials (bom), wiring list, connection table, and a generic table to be placed on the drawing. Efficiently manage design variations with dash number harness variables. Web they are used to draw a complete schematic of a wire harness diagram. These standards ensure consistency, clarity, and accuracy in wire harness documentation, making it easier for designers, manufacturers, and technicians to understand and work with the harnesses. Automatically drive pricing information, lead time, and assembly time calculations from design elements. It provides a detailed outline of the wiring system, showing the placement and routing of wires, connectors, and other electrical components. Web setting up a harness layout drawing document. Web wire harness drawing standards are guidelines and specifications that define how wire harness drawings should be created and formatted. Web do a physical layout drawing of the harness(es). Speed harness design and eliminate delays found in traditional design processes. Take advantage of fully integrated 3d wiring harness design software that allows you to design and route harnesses in complex assemblies. April 30, 2024 | applies to version: The designing and drawing of a wiring harness are the basics of the entire process. This will make construction far easier down the road. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. Manage datasheets and additional manufacturing instructions.

How To Read Wiring Harness Drawing Wiring Draw And Schematic

Creo Parametric Cable Harness Drawing Smart Tables YouTube

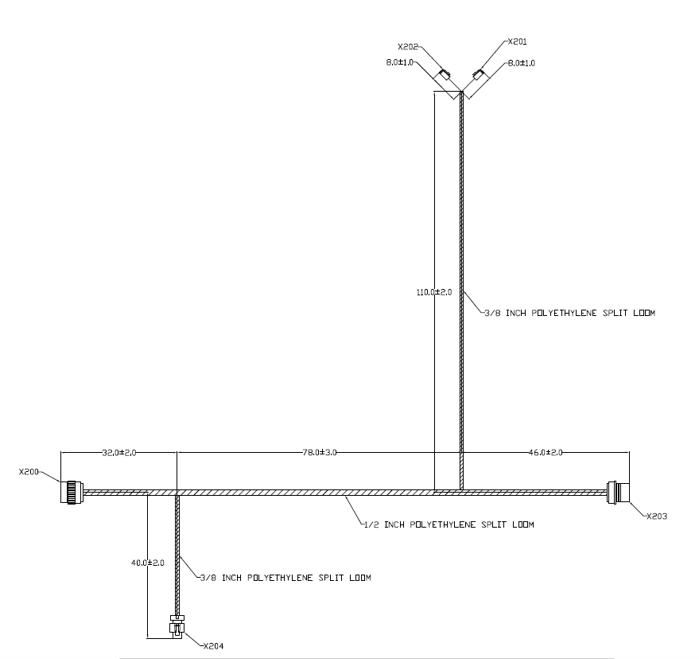

wire harness drawing example hooha harness

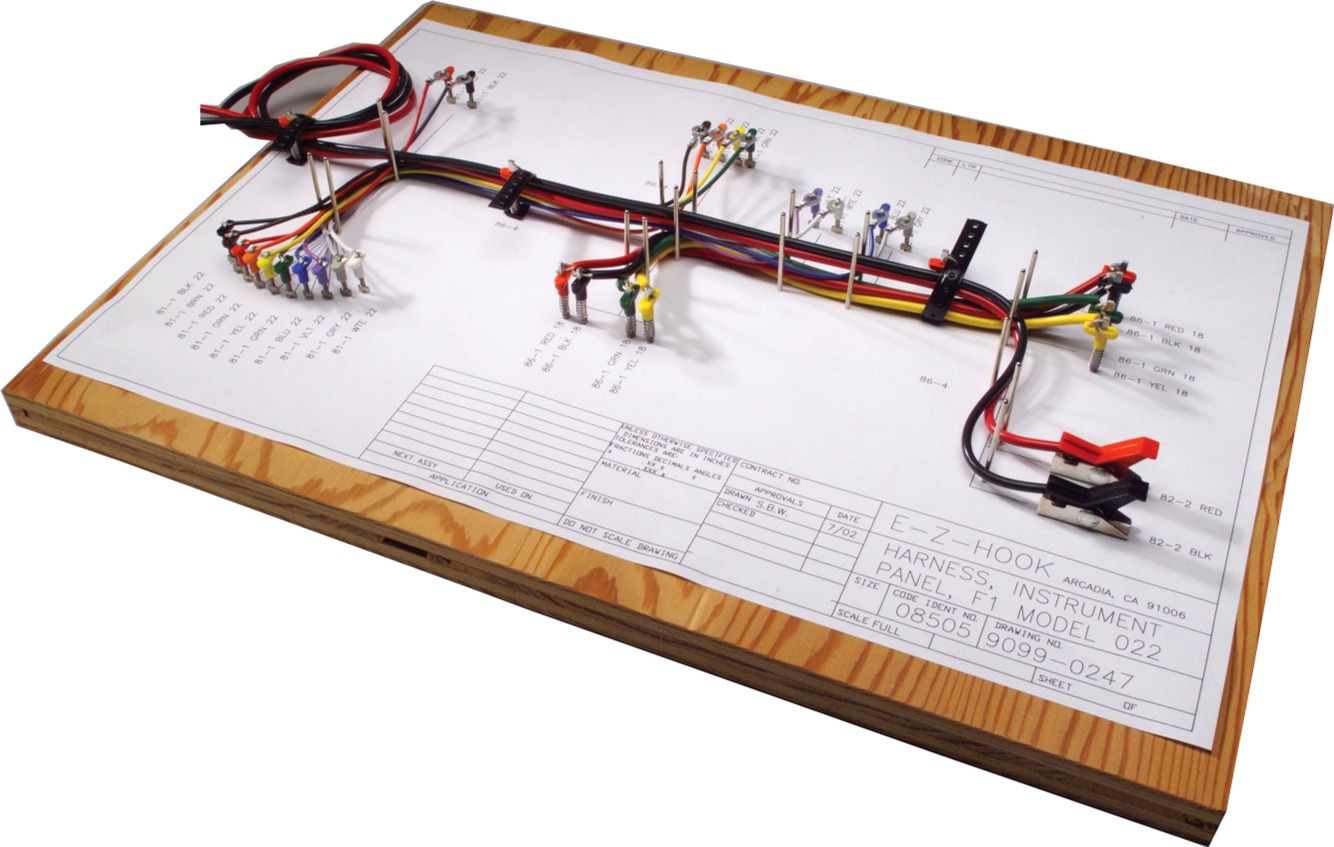

Creating Cable Harness Drawings with SOLIDWORKS Electrical 3D

Wire Harness and Cable Assembly Drawing Best Practices

Routing Harnesses in SOLIDWORKS Electrical 3D CADimensions

Wire Harness Design with SOLIDWORKS Electrical 3D

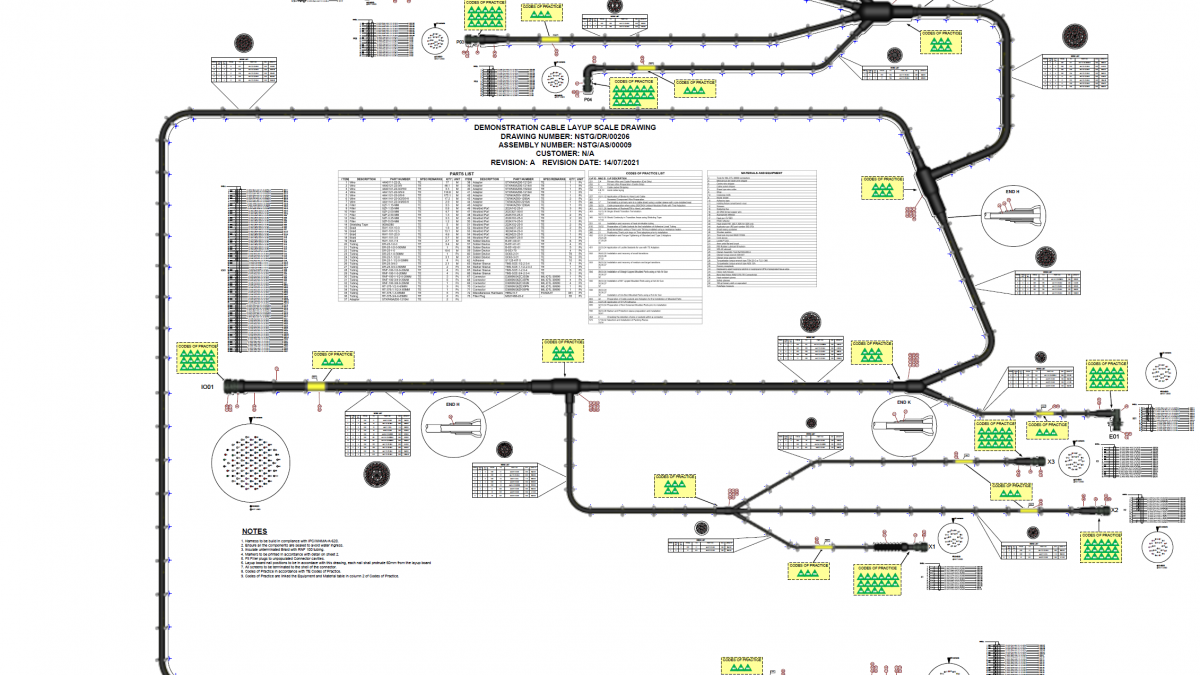

Complex Harness Design With Layup Board NSTG Engineering

wire harness drawing example hooha harness

How to use Schematic CAD for Harness Drawings and Cable Assemblies

You Can Also Download A Sample Harness Pdf To See An Example Harness Output.

Once The Harness Design Has Been Captured In The Form Of A Wiring Diagram, The Physical Representation Of The Design Can Be Created As A Harness Layout Drawing ( *.Ldrdoc ).

Here Are A Few Guidelines To Guide You Through The Drawing Process To Eliminate Such A Scenario.

Contains A Top Level View (Optionally As A 1:1 Formboard), Bill Of Materials, Wiring Table, Cutlist, And Other Associated Documents.

Related Post: