Helicoil Tapping Chart

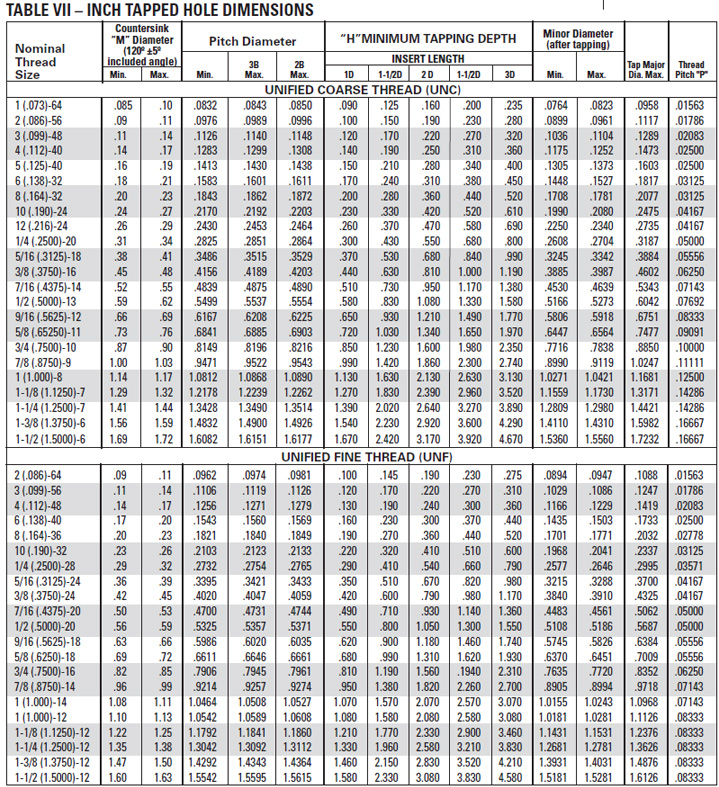

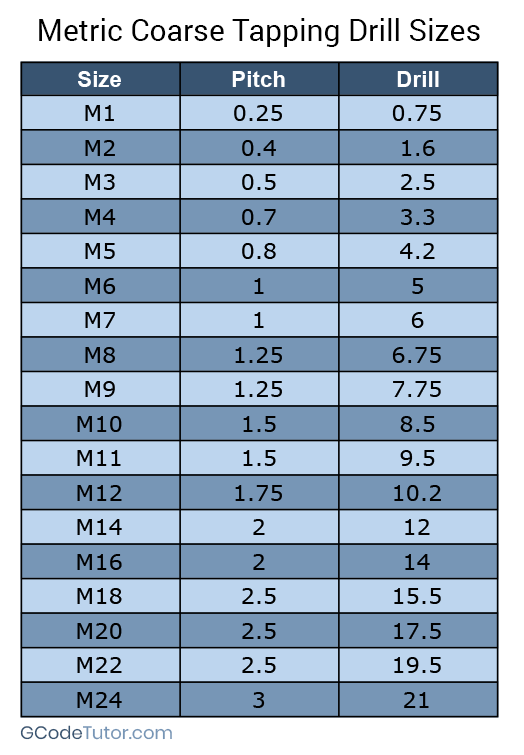

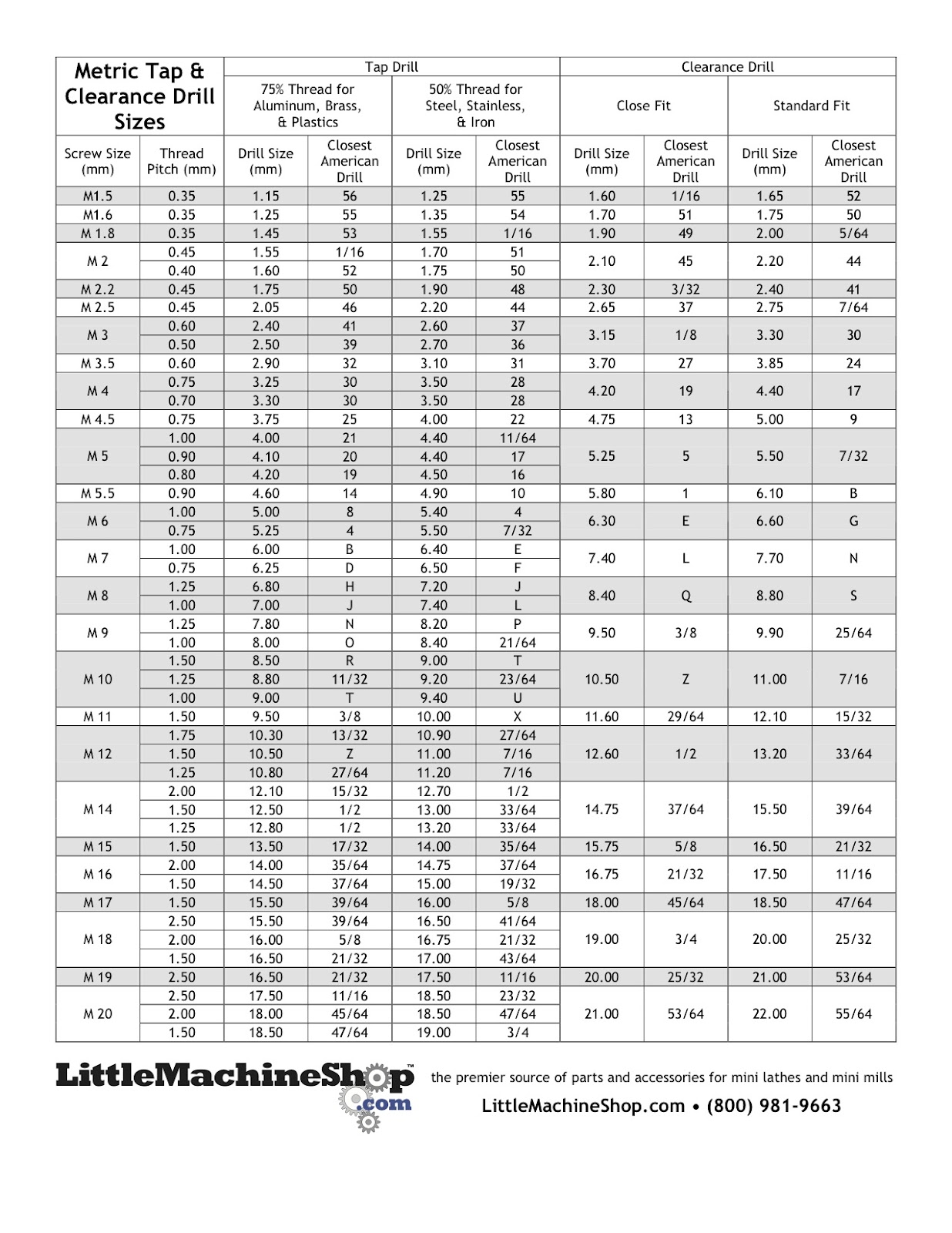

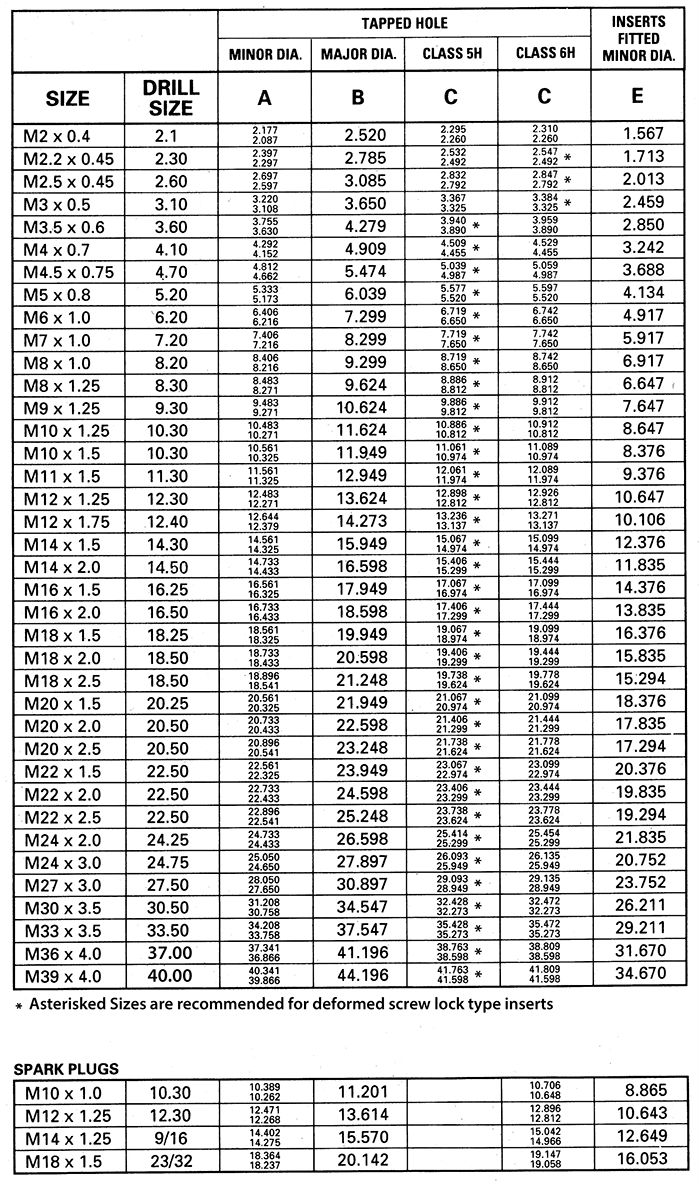

Helicoil Tapping Chart - Web a rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. “tap dill size” is the drill diameter we should use before a tapping operation. Web 8 corrosion and temperature resistance the standard material of the helicoil® plus prevents seizing of screws under environmental influences. The decimal equivalents of the. These kits offer the highest quality and most durable repair available. H is equal to insert nominal length +1 pitch | pdf. Web follow standard tapping procedure. By default, the size you will find on most charts is the diameter for 75%. Web helicoil tapping chart | pdf | crafts | machines. Web the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the. Web what is tap drill size? Web the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. Approved by military services, this series of helicoil® free running inserts is specifi ed in aerospace applications with metric. Web a rule of thumb is. H is equal to insert nominal length +1 pitch | pdf. Actual depth and size must. Web follow standard tapping procedure. Web 50 rows self tapping inserts. Web what is tap drill size? Web the thread profile of a helicoil tap is tailored to match the coils of the helicoil insert, providing a secure and reliable connection. Web what is tap drill size? Web 50 rows self tapping inserts. H is equal to insert nominal length +1 pitch | pdf. Approved by military services, this series of helicoil® free running inserts is specifi. The first choice of professional mechanics and engine. Web what is tap drill size? H is equal to insert nominal length +1 pitch | pdf. Web follow standard tapping procedure. Web 8 corrosion and temperature resistance the standard material of the helicoil® plus prevents seizing of screws under environmental influences. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Tool and tap selection guide for tanged inserts. By default, the size you will find on most charts is the diameter for 75%. These kits offer the highest quality and most durable repair available. Web the tap. Web what is tap drill size? Web helicoil tapping chart | pdf | crafts | machines. H is equal to insert nominal length +1 pitch | pdf. The decimal equivalents of the. Web a rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of. Web free running metric coarse and fine. These kits offer the highest quality and most durable repair available. Web 50 rows self tapping inserts. The first choice of professional mechanics and engine. Web a rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of. The decimal equivalents of the. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Web free running metric coarse and fine. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Web what. Web a rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. H is equal to insert nominal length +1 pitch | pdf. Web the tap size chart provides a list of standard size taps, specifying the diameter and thread. Web helicoil tapping chart | pdf | crafts | machines. “tap dill size” is the drill diameter we should use before a tapping operation. Approved by military services, this series of helicoil® free running inserts is specifi ed in aerospace applications with metric. Web what is tap drill size? Web follow standard tapping procedure. Web follow standard tapping procedure. “tap dill size” is the drill diameter we should use before a tapping operation. Web the thread profile of a helicoil tap is tailored to match the coils of the helicoil insert, providing a secure and reliable connection. Approved by military services, this series of helicoil® free running inserts is specifi ed in aerospace applications with metric. Tool and tap selection guide for tanged inserts. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Web helicoil tapping chart | pdf | crafts | machines. Web 50 rows self tapping inserts. Web free running metric coarse and fine. These kits offer the highest quality and most durable repair available. Web what is tap drill size? H is equal to insert nominal length +1 pitch | pdf. Web the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. Web 8 corrosion and temperature resistance the standard material of the helicoil® plus prevents seizing of screws under environmental influences. The decimal equivalents of the. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series).

Helicoil Tap Chart Metric

Helicoil tap chart, helicoil tapping chart , helicoil tap size

Metric Tap And Drill Chart

Standard Helicoil Tap Drill Chart Pdf

Metric Helicoil Tap Size Chart

(PDF) HeliCoil Tapping Chart DOKUMEN.TIPS

Helicoil Tapping Drill Sizes

Helicoil Tap Drill Chart

HELICOIL CHART PDF

Helicoil Tap Size Chart And Calculator

The First Choice Of Professional Mechanics And Engine.

Actual Depth And Size Must.

By Default, The Size You Will Find On Most Charts Is The Diameter For 75%.

Web A Rule Of Thumb Is That The Right Tap Drill Is Around 85% For Coarse Threads And 90% For Fine Threads Which Feature A Higher Number Of Threads Per Axial Distance.

Related Post: