How To Calculate X Bar Chart

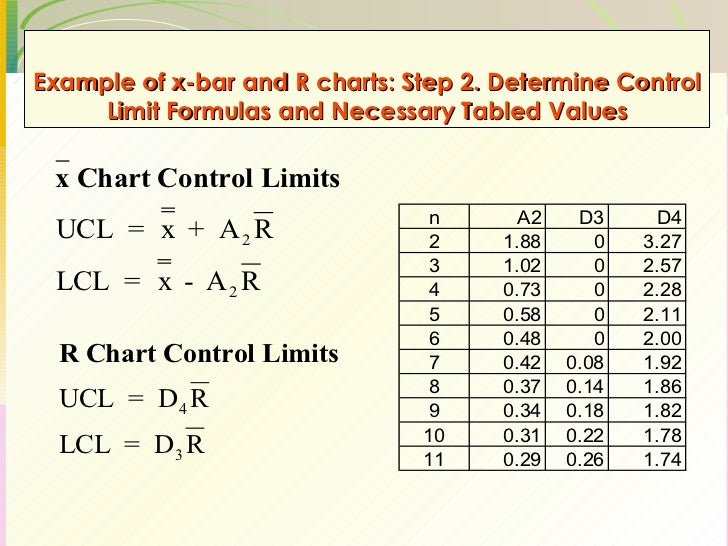

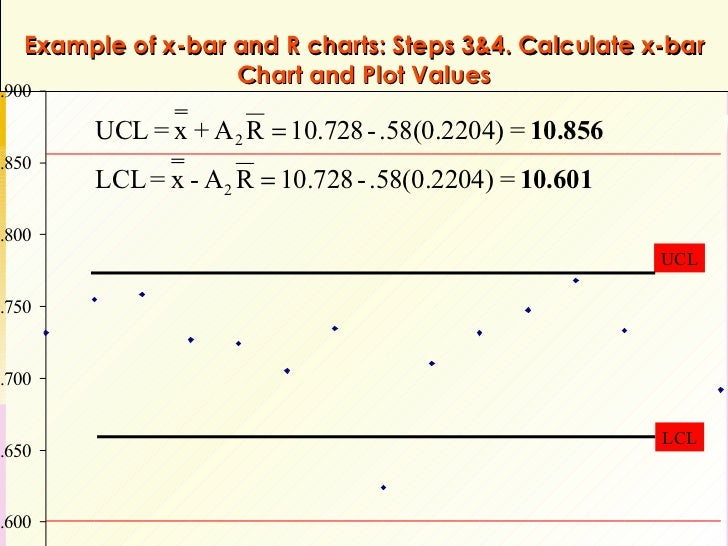

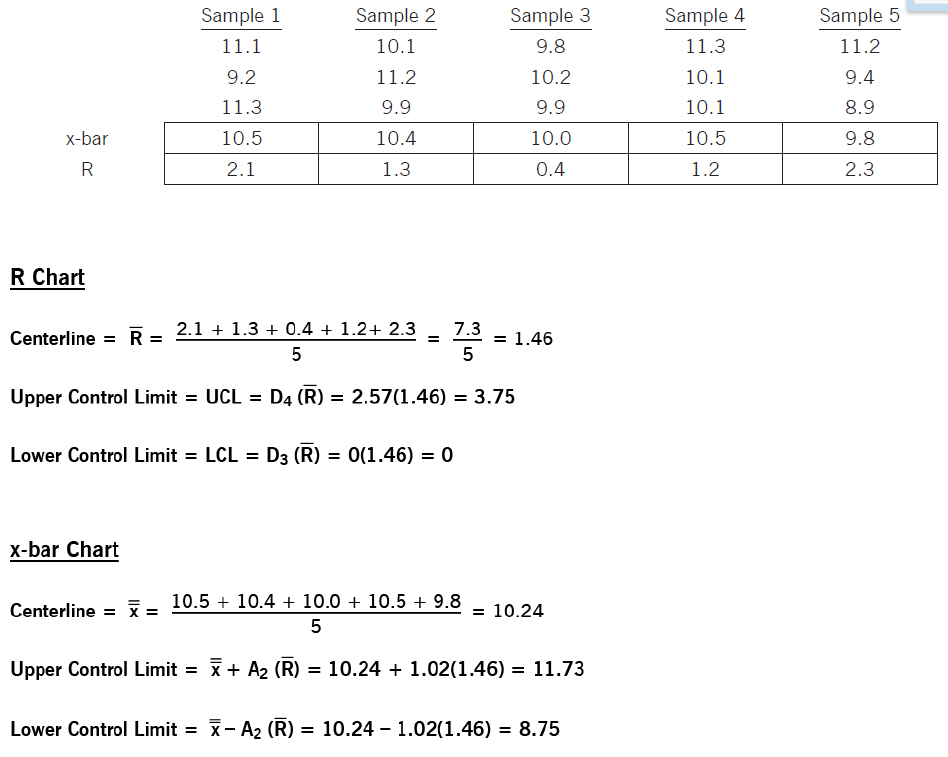

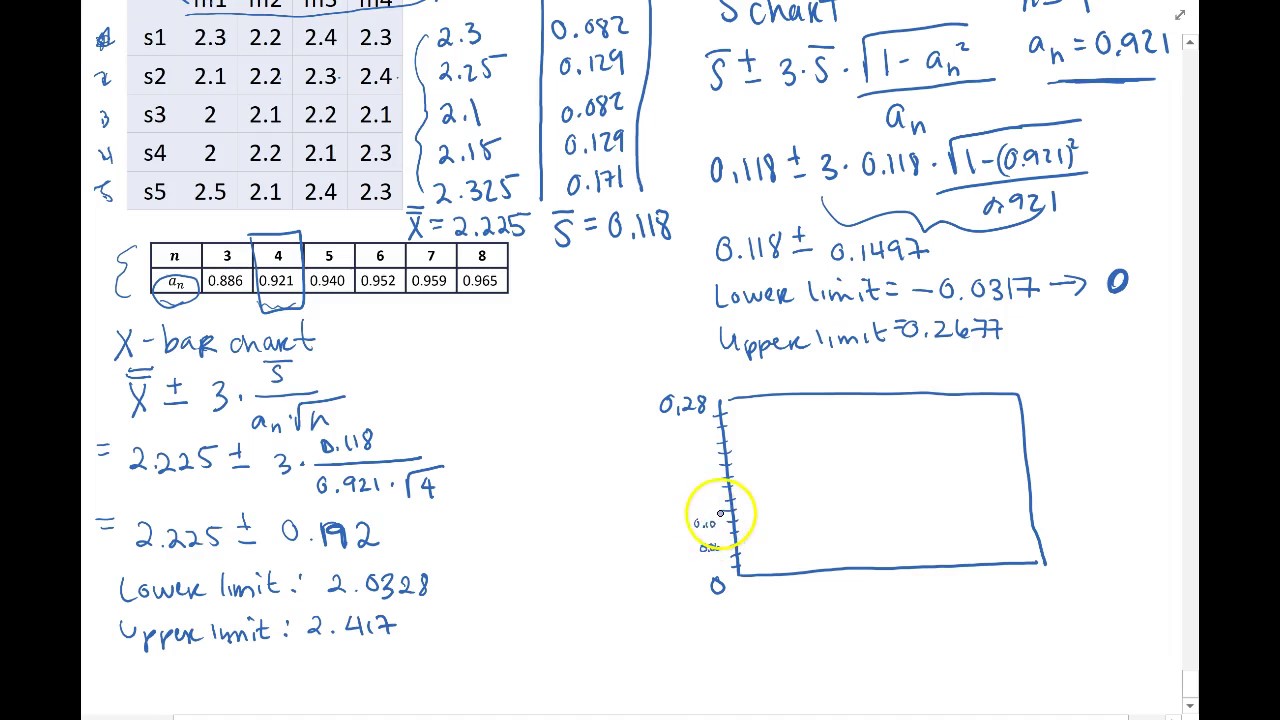

How To Calculate X Bar Chart - Calculate the average and range for each subgroup. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. 1, 3, 3, 4, 8, 11, 13, 14, 15, 17, 22, 24, 26, 46. If it is out of control, so is the process. Web lower control limit (lcl) for sample mean chart. To ensure accuracy, measure to the nearest ¼ inch or ½ cm. Web to estimate the standard deviation (σ) we compute the average range across m subgroups and divide by a correction factor, called d 2. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. If you use the unbiasing constant, c 4 ( n i ), then sbar is calculated as follows: Web this calculator estimates bra size based on bust size and band size (frame size). Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. If you do not use an unbiasing constant, then the sbar is the mean of the subgroup standard deviations: Plot the data (both the averages and the ranges). You compute the grand mean for the sample means and range.. * introduction to statistical quality control, douglas c. Please visit our website on benchmark six sigma. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Then, you compute the sample mean and sample range for each of the samples. Plot the data (both the averages and. 1, 3, 3, 4, 8, 11, 13, 14, 15, 17, 22, 24, 26, 46. Then, you compute the sample mean and sample range for each of the samples. Web but, not so much. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Conforms with ansi/asqc b1, b2, b3. The bust size is the loose circumference measured around. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. Web select the method or formula of your choice. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. This type of. Web but, not so much. In this article, i’ll focus on the range method and illustrate how we can derive the constants: Plot the data (both the averages and the ranges). Web this calculator estimates bra size based on bust size and band size (frame size). If it is out of control, so is the process. Web this calculator estimates bra size based on bust size and band size (frame size). Please visit our website on benchmark six sigma. D 2, d 3, d 3 and d 4 used to compute the control limits for a range chart. If you do not use an unbiasing constant, then the sbar is the mean of the subgroup standard. Calculate the average and range for each subgroup. If it is out of control, so is the process. Web select the method or formula of your choice. The standard deviation of the process over time from subgroups values. Web n = number of samples in a subgroup. If it is out of control, so is the process. Let’s talk about the basics… Calculate the average and range for each subgroup. * introduction to statistical quality control, douglas c. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. To ensure accuracy, measure to the nearest ¼ inch or ½ cm. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). A 2, d 3 and d. Web to estimate the standard deviation (σ) we compute the average range across m subgroups and divide by a correction factor, called d 2. An r chart is a type of statistical chart. 1, 3, 3, 4, 8, 11, 13, 14, 15, 17, 22, 24, 26, 46. This formula is a practical tool for summarizing a sample data set. This. The standard deviation of the process over time from subgroups values. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. Web to estimate the standard deviation (σ) we compute the average range across m subgroups and divide by a correction factor, called d 2. If you do not use an unbiasing constant, then the sbar is the mean of the subgroup standard deviations: Always look at the range chart first. Web select the method or formula of your choice. This monitors the process standard deviation (as approximated by the sample moving range) They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. It hasn't rolled out to all free accounts yet. Web an xbar chart is a graphical representation of the average value of a data set over a period of time. Web how do you make an x bar chart? Collect your data (take a set of readings at each specified interval of time). * introduction to statistical quality control, douglas c. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. If you use the unbiasing constant, c 4 ( n i ), then sbar is calculated as follows:

How To Calculate X Bar Haiper

Spc X Bar Chart Example Free Table Bar Chart ZOHAL

How to plot xbar and r bar chart in excel crosspasa

Qa.spc

Qa.spc

X Bar Chart Formula Chart Examples

How To Calculate X Bar R Chart TOKHOW

How To Create an XBar R Chart Six Sigma Daily

Xbar Control Chart

How To Calculate Range In X Bar Chart Haiper

The Mean Or Average Change In The Process Over Time From Subgroup Values.

Web N = Number Of Samples In A Subgroup.

An R Chart Is A Type Of Statistical Chart.

X̄ = (Σx) / N, Where X̄ Is The Sample Mean, Σx Is The Sum Of All The Sample Observations, And N Is The Number Of Observations In The Sample.

Related Post: