Injection Molding Troubleshooting Chart

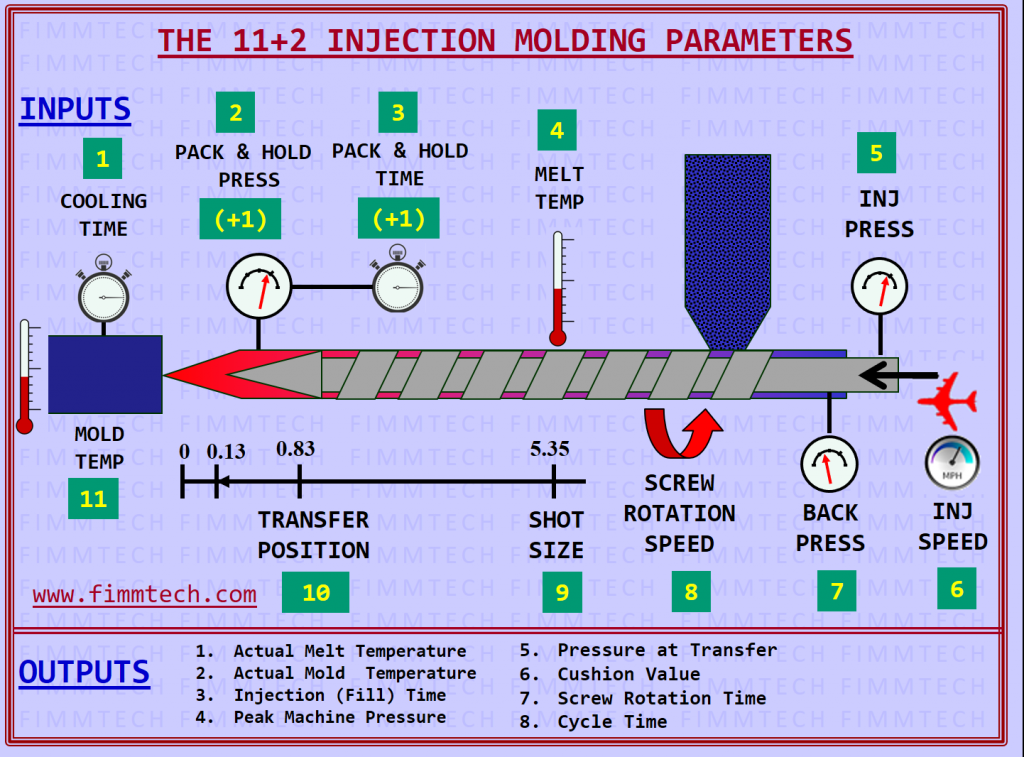

Injection Molding Troubleshooting Chart - Web here are 11 common injection molding defects, what the causes are and how you can avoid them. As issued by teknor, the guide consists of a single laminated sheet designed to be hung on the processing machine or kept in a toolbox. Those encountered during startup and those involving quality control. startup problems occur during the launch of a new tool or machine. Perform in numerical order by column. Web this easy to use troubleshooting guide gives you initial advice for solving injection molding difficulties. Anyone involved in the injection molding process will, at some point, have parts exhibiting some type of. Web this troubleshooting guide lists the processing problems in alphabetical order. The back page includes a chart showing you recommended courses of action to fix any of those defects. Web injection moulding defect short shots occur when the moulded part is not filled during the injection moulding process, resulting in incomplete or missing features. More detailed article of how to avoid short shots?. Web the troubleshooting guide for injection molding is an essential resource for professionals in the field, providing a systematic approach to diagnosing and resolving common issues encountered during the injection molding process. More detailed article of how to avoid short shots?. Verify that heater bands are not overriding. Contact our technical team for engineering and processing support. Web the troubleshooting. Contact our technical team for engineering and processing support. There are two kinds of issues: Web this troubleshooting guide lists the processing problems in alphabetical order. Web injection molding advanced troubleshooting guide Web eliminate shear differences caused by sharp corners, sharp edges, or abrupt changes anywhere in the flow path including the nozzle adapters, sprues and runners, gates, and part. For each problem, the possible solutions are listed in the order of the most frequent to the least frequent solution for that problem. Web this book is broken down into specific sections: A validated injection molding process has proven itself to be stable. Web this highly practical troubleshooting guide solves injection molding problems systematically and quickly. Web the troubleshooting flipchart. Processing issues and defects organized by causes and solutions. The front page will help you identify defects. Web injection molding advanced troubleshooting guide Contact our technical team for engineering and processing support. Many inexperienced processors may adjust settings without taking the time to identify precisely what has changed. Lower melt temperatures, injection speeds, screw speed and back pressure to reduce both shear input and thermal input. Web injection molding advanced troubleshooting guide Perform in numerical order by column. Proper troubleshooting should use a systematic approach to resolve problems. Web the troubleshooting flipchart for plastic injection molding from ul prospector is conveniently divided into two parts. Web this highly practical troubleshooting guide solves injection molding problems systematically and quickly. A validated injection molding process has proven itself to be stable. Web basic troubleshooting steps. As issued by teknor, the guide consists of a single laminated sheet designed to be hung on the processing machine or kept in a toolbox. Web the troubleshooting flipchart for plastic injection. Please click on the name of your problem in the following list to view a detailed description including photograph and proposals for solution: Web this troubleshooting guide lists the processing problems in alphabetical order. These are remedies you can try without the more drastic step of pulling the mold from the machine. Web the troubleshooting flipchart for plastic injection molding. Many inexperienced processors may adjust settings without taking the time to identify precisely what has changed. Web troubleshooting guide for injection molding. This effect is particularly pronounced in dark or transparent plastic parts with polished surfaces, in parts with glassfiber reinforcement or in plastics with effect pigments. Those encountered during startup and those involving quality control. startup problems occur during. For each problem, the possible solutions are listed in the order of the most frequent to the least frequent solution for that problem. Those encountered during startup and those involving quality control. startup problems occur during the launch of a new tool or machine. Web the troubleshooting guide for injection molding is an essential resource for professionals in the field,. Web basic troubleshooting steps. Web this highly practical troubleshooting guide solves injection molding problems systematically and quickly. Check the injection pressure and speed if there is not enough pressure. Web here are 11 common injection molding defects, what the causes are and how you can avoid them. The back page includes a chart showing you recommended courses of action to. Web this book is broken down into specific sections: This effect is particularly pronounced in dark or transparent plastic parts with polished surfaces, in parts with glassfiber reinforcement or in plastics with effect pigments. Contact our technical team for engineering and processing support. Web troubleshooting guide for injection molding. Web remove screw and clean and inspect screw, screw tip & check ring for dead spots (i.e. Those encountered during startup and those involving quality control. startup problems occur during the launch of a new tool or machine. The back page includes a chart showing you recommended courses of action to fix any of those defects. Web this book is broken down into specific sections: A validated injection molding process has proven itself to be stable. Many inexperienced processors may adjust settings without taking the time to identify precisely what has changed. Perform in numerical order by column. Web this easy to use troubleshooting guide gives you initial advice for solving injection molding difficulties. The front page will help you identify defects. Proper troubleshooting should use a systematic approach to resolve problems. Web this highly practical troubleshooting guide solves injection molding problems systematically and quickly. Please click on the name of your problem in the following list to view a detailed description including photograph and proposals for solution:

(a) Injection molding flow chart (b) A simplified model of an injection

Injection moulding process diagram Download Scientific Diagram

Gallery of molding cycle an overview sciencedirect topics injection

Injection Molding Troubleshooting Chart

Practical_troubleshooting of INJECTION MOLDING

Injection Molding Troubleshooting Chart

Injection moulding the role of backpressure Prospector

1 Effect of Injection Molding Parameters on Product Quality DEFECT

Injection Molding Troubleshooting For Common Design Defects

iMoldInjection Moulding Flow Chart

Web Injection Molding Advanced Troubleshooting Guide

Adjust And Profile Injection Speed (Slower When High Shear Defects Are Formed).

Web Injection Molding Troubleshooting Guide.

Verify That Heater Bands Are Not Overriding.

Related Post: