Kiln Temp Chart

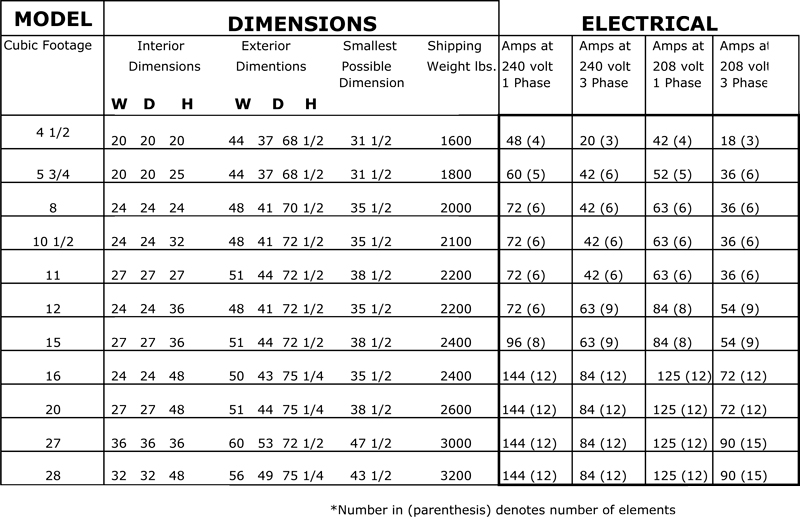

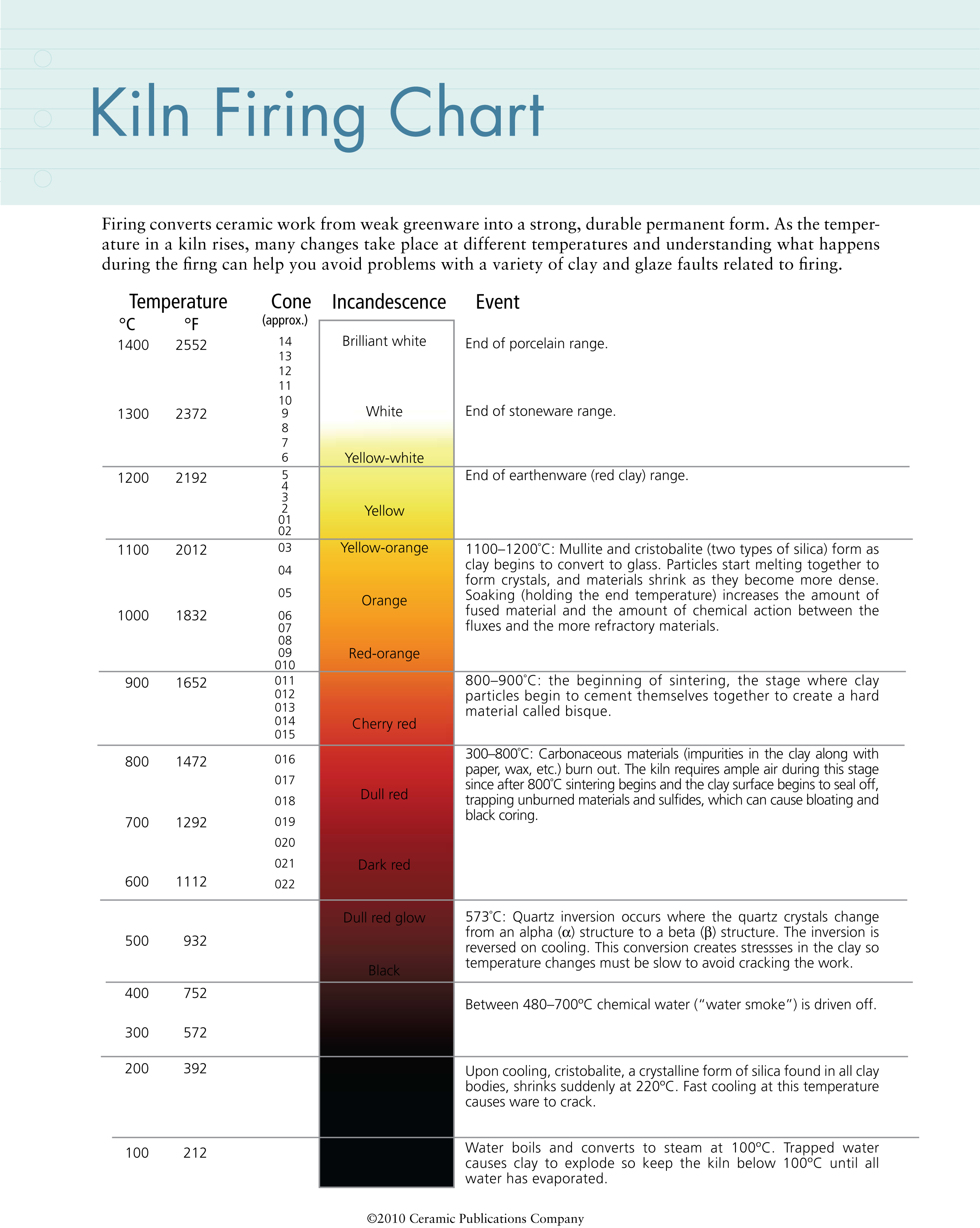

Kiln Temp Chart - Web by saying we want to be at 950° in 1 hour and 45 minutes, and assuming we’re starting from 70°, we’ve essentially created a firing schedule with an implied ramp. Web use our kiln fire temperature chart to have a better understanding of what happens to clay in the kiln at each stage of the firing process. Web normalizing 1095 steel to 1600° f relieves internal stress and ensures uniformity, making it stronger and harder. Temperatures are shown for specific heating. Firing converts ceramic work from weak greenware into a strong, durable permanent form. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and. Web download kiln firing charts: Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln. Firing_chart_fahrenheit_v1.2.pdf (823.3 kb) images of. Transformation of ceramic materials by heat: Web cone temperature conversion chart: Web in the kiln firing chart below, you’ll be able to see which temperatures correspond with various cone ratings and materials. Web by saying we want to be at 950° in 1 hour and 45 minutes, and assuming we’re starting from 70°, we’ve essentially created a firing schedule with an implied ramp. Web normalizing 1095. Download a pdf version of this chart for free. Web normalizing 1095 steel to 1600° f relieves internal stress and ensures uniformity, making it stronger and harder. Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln. Kiln temperature firing ranges refer to the temperature levels at which pottery is fired in the. We know it's tough to keep all of the pertinent information you need top of mind, especially when you've made your work and the kiln is loaded. Get ready to demystify the process of monitoring and controlling kiln temperature. Firing converts ceramic work from weak greenware into a strong, durable permanent form. Whether you’re a pottery enthusiast or a seasoned. Web download kiln firing charts: Web cone temperature conversion chart: We know it's tough to keep all of the pertinent information you need top of mind, especially when you've made your work and the kiln is loaded. Firing_chart_celsius.pdf (817.6 kb) fahrenheit, us letter paper: The maturity or the level of development of the clay and. Web download kiln firing charts: Temperatures are shown for specific heating. Firing converts ceramic work from weak greenware into a strong, durable permanent form. Web temperatures shown on these charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Web use our kiln fire temperature chart to have a better understanding of what happens to clay. Web by saying we want to be at 950° in 1 hour and 45 minutes, and assuming we’re starting from 70°, we’ve essentially created a firing schedule with an implied ramp. The maturity or the level of development of the clay and. Kiln temperature firing ranges refer to the temperature levels at which pottery is fired in the kiln. Web. Download a pdf version of this chart for free. Web begin a firing by keeping the kiln below 100°c until all water has evaporated. Kiln temperature firing ranges refer to the temperature levels at which pottery is fired in the kiln. The color gradient indicates the. Web use our kiln fire temperature chart to have a better understanding of what. Web use our kiln fire temperature chart to have a better understanding of what happens to clay in the kiln at each stage of the firing process. Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln. Web temperatures shown on these charts were determined under controlled firing conditions in electric kilns and. Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and. The maturity or the level of development of the clay and. Web begin a firing by keeping the kiln below 100°c until all water has. Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln. Pyrometric cone chart (orton standard) or orton cone chart. Web download kiln firing charts: Web begin a firing by keeping the kiln below 100°c until all water has evaporated. Transformation of ceramic materials by heat: Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and. Web download kiln firing charts: The maturity or the level of development of the clay and. Get ready to demystify the process of monitoring and controlling kiln temperature. Web cone temperature conversion chart: Temperatures are shown for specific heating. Firing_chart_celsius.pdf (817.6 kb) fahrenheit, us letter paper: Whether you’re a pottery enthusiast or a seasoned professional,. Transformation of ceramic materials by heat: Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln. Web in the kiln firing chart below, you’ll be able to see which temperatures correspond with various cone ratings and materials. Web by saying we want to be at 950° in 1 hour and 45 minutes, and assuming we’re starting from 70°, we’ve essentially created a firing schedule with an implied ramp. Web begin a firing by keeping the kiln below 100°c until all water has evaporated. Web normalizing 1095 steel to 1600° f relieves internal stress and ensures uniformity, making it stronger and harder. Download a pdf version of this chart for free. The color gradient indicates the.

Pyrometric Cone Temperature Conversion Chart Pottery

Kiln Firing Chart Poster Payhip

Kiln Firing Temperature Chart

Pyrometric Cone Chart for Kiln Firing

Firing Temperatures and cone equivalents Pottery Pottery

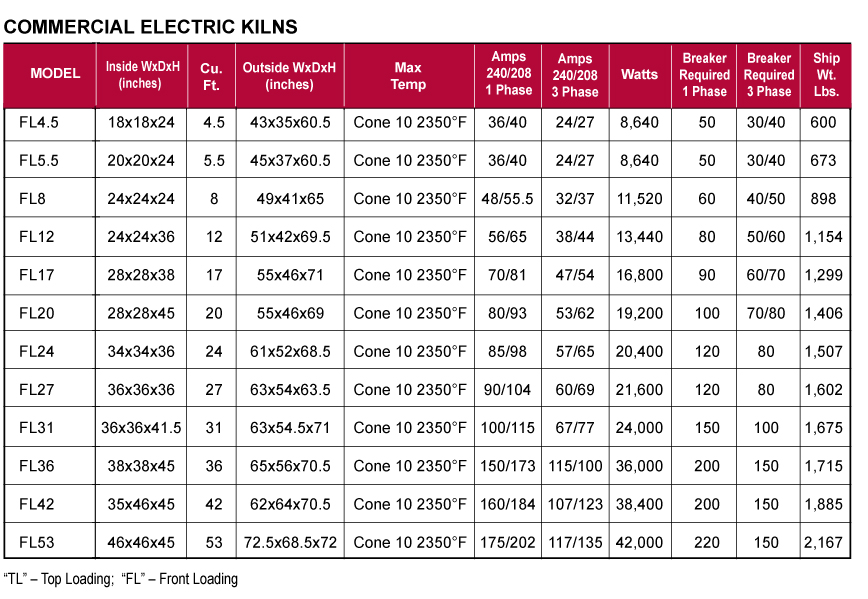

FL24 FRONT LOADING KILN

Kiln Firing Chart

Kiln Firing Chart Pottery

Kiln Firing Temperature Chart Simple Guide

What is a Cone? A Guide to Pyrometric Cones and Kilns Soul Ceramics

Web The Ware Is Returned To The Kiln For A Very Low Temperature Firing In Order To Fuse The Overglazes.

Web Temperatures Shown On These Charts Were Determined Under Controlled Firing Conditions In Electric Kilns And An Air Atmosphere.

Firing Converts Ceramic Work From Weak Greenware Into A Strong, Durable Permanent Form.

Pyrometric Cone Chart (Orton Standard) Or Orton Cone Chart.

Related Post: