Lathe Insert Chart

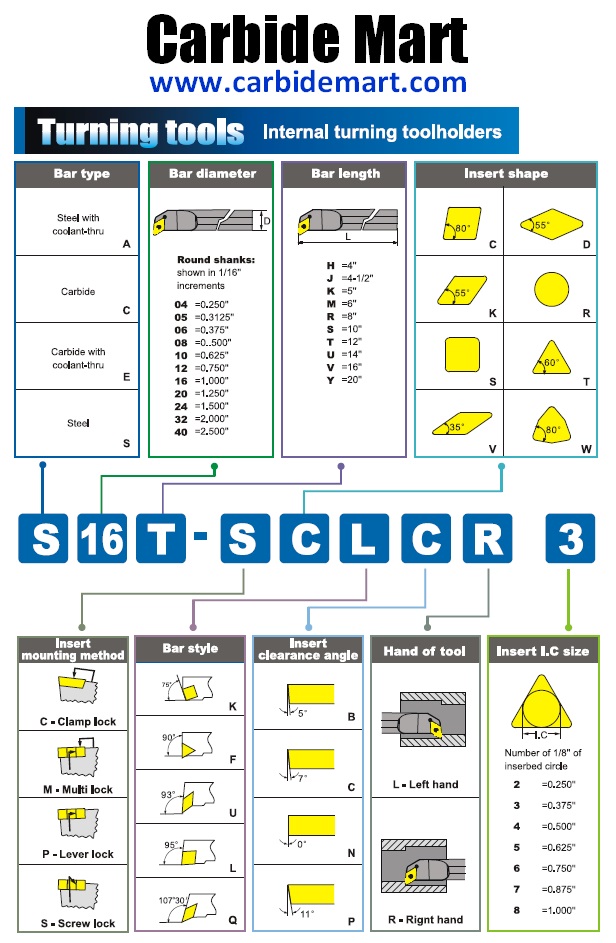

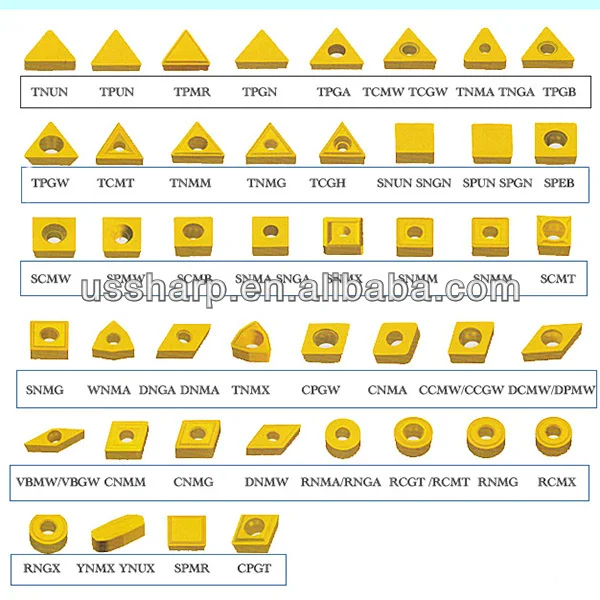

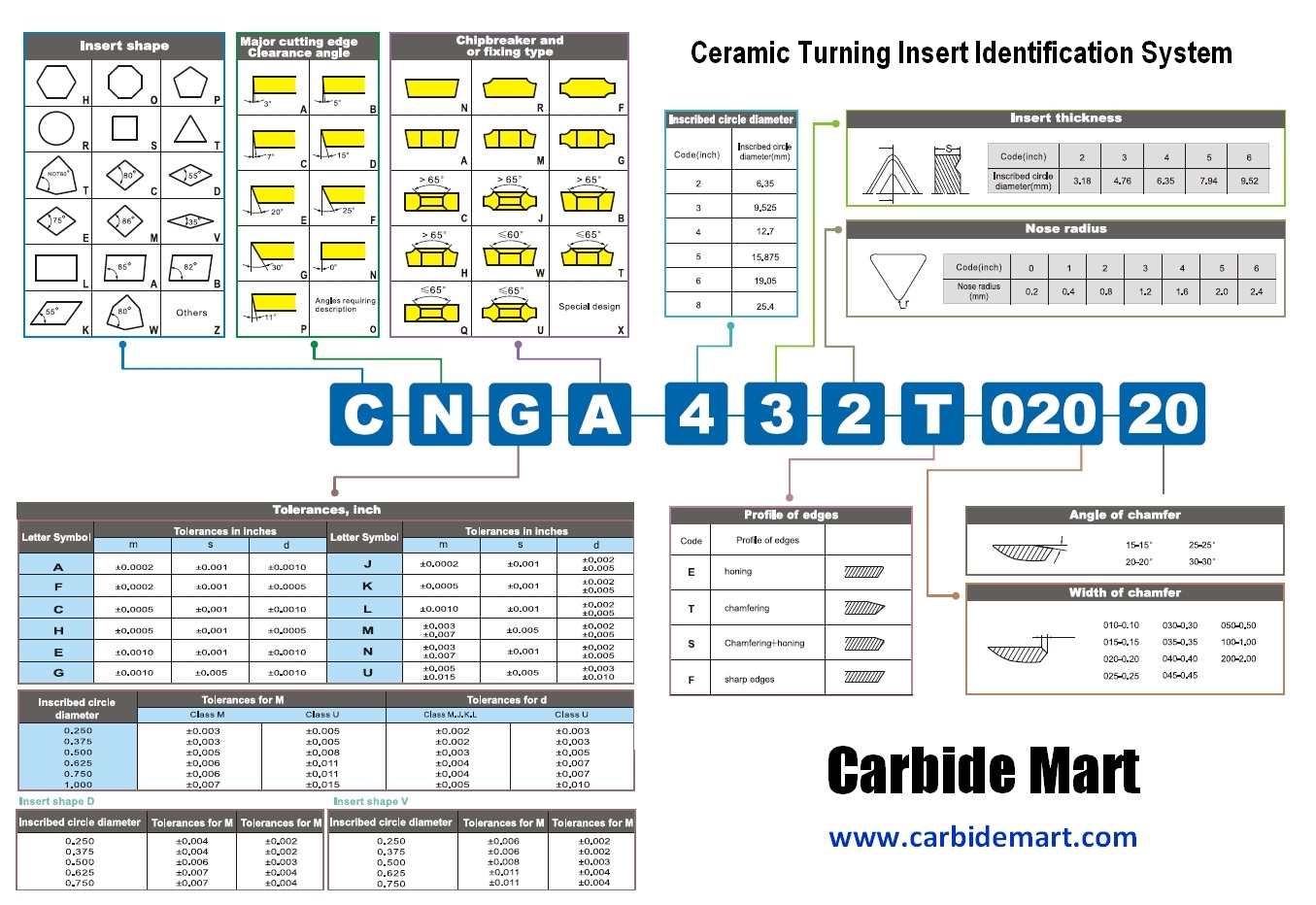

Lathe Insert Chart - Web automakers can dial in their processes by using inserts optimized for cast iron and low carbon steel, while oil and gas producers benefit from tooling that excels in duplex steel. This becomes the name of the insert. Because many inserts are made in other countries, the iso system is used frequently. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Grade range chart (click here for chart adjusted for deficient color vision) p steel. Web how to choose correct turning insert. Please choose a grade or geometry to find the kennametal equivalent. Donald trump is seeking to spin his criminal conviction into gold with an appeal to donors to contribute money to his newly embattled presidential campaign. Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end milling grades. The system is designed so that each important feature and dimension of the insert is shown using a code system. Grade range chart (click here for chart adjusted for deficient color vision) p steel. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Web regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. There are many parameters to consider when choosing a turning insert. Web. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides, troubleshooting, and standards such as iso13399 is also presented. Web the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. Web when turning a thread, there are three main insert types to choose from:. Each type has its advantages and disadvantages. Web the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. Turning c n m g 4 3 2 shape clearance angle tolerance groove / hole size (ic) thickness radius milling s e k n 4 2 a f t n shape clearance angle tolerance.. Learn how to read the ansi insert code system & download a free carbide insert chart. Web the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Web how to choose correct turning insert.. And it's a scorcher, with temperatures reaching into the. Web when turning a thread, there are three main insert types to choose from: Web these tables show the ansi and iso insert designations for indexable inserts for turning. Increasing wear resistance i ncreasing shock resistance. A given insert can be specified in either ansi (american) or iso (metric) designations. There are many parameters to consider when choosing a turning insert. Web when turning a thread, there are three main insert types to choose from: And it's a scorcher, with temperatures reaching into the. Web learn how to identify indexable inserts and insert shapes. It is used to cut a complete thread profile, including the crest. Learn how to read the ansi insert code system & download a free carbide insert chart. Web automakers can dial in their processes by using inserts optimized for cast iron and low carbon steel, while oil and gas producers benefit from tooling that excels in duplex steel. And it's a scorcher, with temperatures reaching into the. Web the lathe threading. Web how to choose correct turning insert. And it's a scorcher, with temperatures reaching into the. There are a variety of insert shapes available, but the general note is use wider inserts for simple geometry and roughing passes, since they have more durability than a more narrow cutting tool, which is needed for complicated or intricate parts. Web use this. Each type has its advantages and disadvantages. Web these tables show the ansi and iso insert designations for indexable inserts for turning. It is used to cut a complete thread profile, including the crest. Web there are 16 standard shapes of indexable inserts, and each shape is identified by a capital letter as follows (figure 1): Learn how to read. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. Web automakers can dial in their processes by using inserts optimized for cast iron and low carbon steel, while oil and. A given insert can be specified in either ansi (american) or iso (metric) designations. Welcome back to the health brief, where we’ve spent far too long watching republican rep. Indexable inserts iso designations for size and shape keywords: Grade range chart (click here for chart adjusted for deficient color vision) p steel. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides, troubleshooting, and standards such as iso13399 is also presented. The heat is on for western states gripped in the nation's first heat dome of the year. Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end milling grades. Top click the code letter or their description links in the example charts below for definitions of values: Web the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. Web when turning a thread, there are three main insert types to choose from: Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Web rectangle and parallelogram inserts require two digits: Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Web learn how to identify indexable inserts and insert shapes. Web how to choose correct turning insert.10pc TCMT 110204 110208 Turning Boring Indexable Lathe Carbide Inserts

Lathe Insert Identification Chart

TNMG inserts Pesquisa Google Tableros de herramientas, Herramientas

Lathe Insert Identification Chart

Lathe Tool Insert Chart

How to choose the right carbide turning insert Huana Tools

Lathe Insert Identification Chart

Lathe Insert Identification Chart

Toollink Co., Ltd. Shape&Size Toollink Co., Ltd.

Selecting Carbide Inserts for Metalworking Kennametal

Carbide Inserts Are Indexable, Which Implies You Can Exchange, Rotate Or Flip Them Without Disturbing General Cutting Tool Geometry.

Web The Reproductive Freedom Alliance Taps Its First Leader.

Turning C N M G 4 3 2 Shape Clearance Angle Tolerance Groove / Hole Size (Ic) Thickness Radius Milling S E K N 4 2 A F T N Shape Clearance Angle Tolerance.

Web Automakers Can Dial In Their Processes By Using Inserts Optimized For Cast Iron And Low Carbon Steel, While Oil And Gas Producers Benefit From Tooling That Excels In Duplex Steel.

Related Post: