Mechanical Lug Torque Chart

Mechanical Lug Torque Chart - Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. Web incoming, branch, and neutral lug. It is important to check that the cable falls within the cable range listed on. Web nical lugs luctor suitable for use with either copper or aluminum conductors provides low contact resistance provides ease of installation application versatility 1st be listed. •or copper and aluminum conductors f. Blue highlighted items are industry standard and most frequently ordered. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Not available with tapped hole for control wire. Web when preparing to torque a mechanical lug with a hex setscrew, you must remember that if your bit is not completely seated into the connection you will round out. This lug can only be used on low. Not available with tapped hole for control wire. Anything less and you risk the wire slipping, or a joint that is. Unlike compression connectors, mechanical connectors typically take a range of conductors. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web tightening torque values for cp series connectors. Web tightening torque values for cp series connectors. Blue highlighted items are industry standard and most frequently ordered. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. Web information on recommended hardware materials and. Web tightening torque values for cp series connectors. Web information on recommended hardware materials and tightening torque values. The rated clockwise tightening torque number on. Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. This lug can only be used on low. The standard lugs can be removed for the. Web incoming, branch, and neutral lug. Web the rated clockwise tightening torque number on a mechanical lug is an exact torque, not a minimum or a maximum. •or copper and aluminum conductors f. Web listed torque values are for maximum conductor combinations accommodated. Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. Unlike compression connectors, mechanical connectors typically take a range of conductors. 100to 1200 frame circuit breakers can be ordered with mechanical line and load side lugs. Web listed torque values are for maximum conductor combinations accommodated. Web listed torque values are for maximum conductor. The rated clockwise tightening torque number on. Web information on recommended hardware materials and tightening torque values. 100to 1200 frame circuit breakers can be ordered with mechanical line and load side lugs. Web incoming, branch, and neutral lug. •or copper and aluminum conductors f. Not available with tapped hole for control wire. •or copper and aluminum conductors f. It is important to check that the cable falls within the cable range listed on. Web tightening torque values for cp series connectors. Web nical lugs luctor suitable for use with either copper or aluminum conductors provides low contact resistance provides ease of installation application versatility. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Not available with tapped hole for control wire. 100to 1200 frame circuit breakers can be ordered with mechanical line and load side lugs. It is important to check that the cable falls within the cable range listed on. Web listed torque. 100to 1200 frame circuit breakers can be ordered with mechanical line and load side lugs. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web when preparing to torque a mechanical lug with a hex setscrew, you must remember that if your bit is not completely seated into the connection. The rated clockwise tightening torque number on. Unlike compression connectors, mechanical connectors typically take a range of conductors. Web information on recommended hardware materials and tightening torque values. The standard lugs can be removed for the. Not available with tapped hole for control wire. Web when preparing to torque a mechanical lug with a hex setscrew, you must remember that if your bit is not completely seated into the connection you will round out. Unlike compression connectors, mechanical connectors typically take a range of conductors. Web nical lugs luctor suitable for use with either copper or aluminum conductors provides low contact resistance provides ease of installation application versatility 1st be listed. Not available with tapped hole for control wire. Web information on recommended hardware materials and tightening torque values. It is important to check that the cable falls within the cable range listed on. The standard lugs can be removed for the. The rated clockwise tightening torque number on. Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. Blue highlighted items are industry standard and most frequently ordered. This lug can only be used on low. •or copper and aluminum conductors f. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web incoming, branch, and neutral lug. Web tightening torque values for cp series connectors. Web listed torque values are for maximum conductor combinations accommodated.

Wire Lug Torque Specs Chart

Automotive Wheel Lug Torque Chart Specifications (2022)

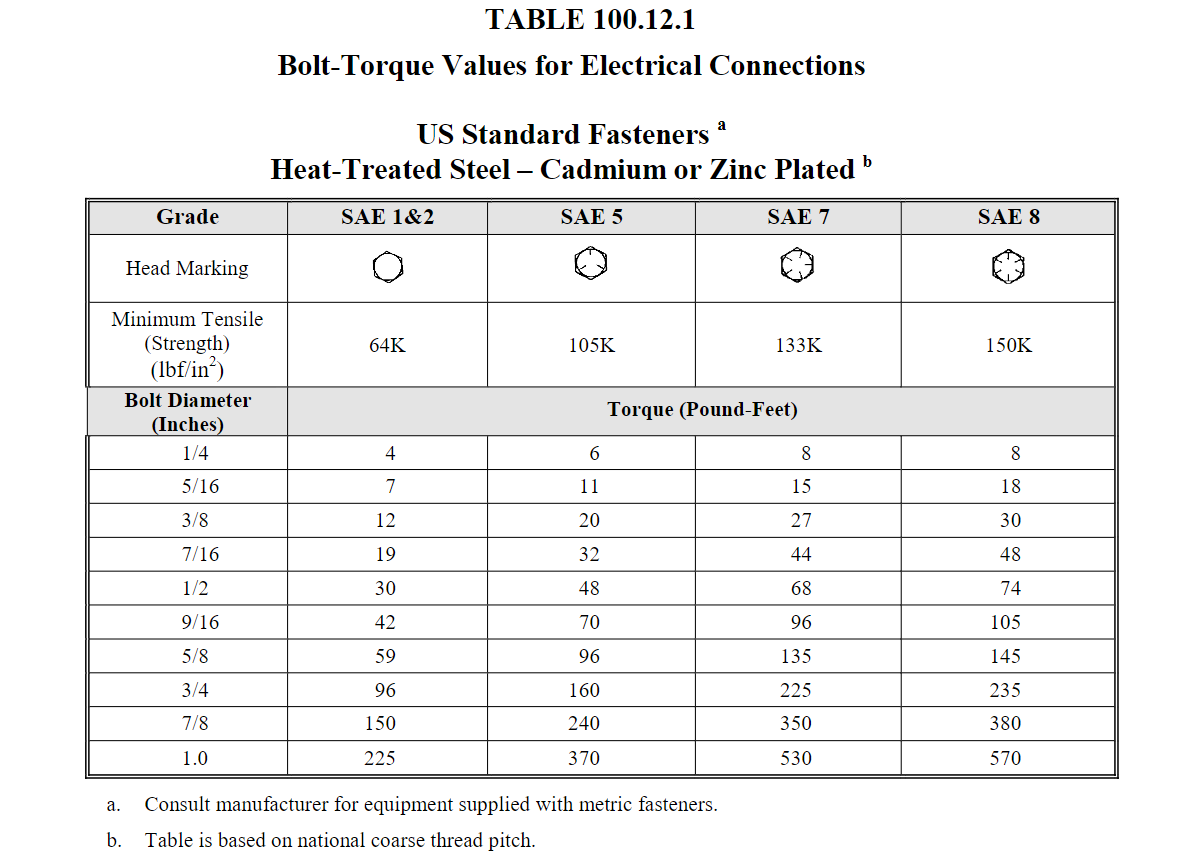

7+ Sample Bolt Torque Charts Sample Templates

Wheel Lug Torque Sequence GTSparkplugs

McGill Aluminum Mechanical Lugs 250MCM6 5/16 Bolt Size AL9CU Model M

Torque Values For Mechanical Lugs

Printable Lug Nut Torque Chart

Nec Electrical Lug Torque Specs Chart

Electrical Lug Torque Specs Chart Eaton chartdevelopment

Ilsco Lug Torque Chart

Web The Rated Clockwise Tightening Torque Number On A Mechanical Lug Is An Exact Torque, Not A Minimum Or A Maximum.

† Conductors Must Be Of Equal Size.

Wire Range (Cu Wire Only) Tightening.

Anything Less And You Risk The Wire Slipping, Or A Joint That Is.

Related Post: