Metal To Metal Compatibility Chart

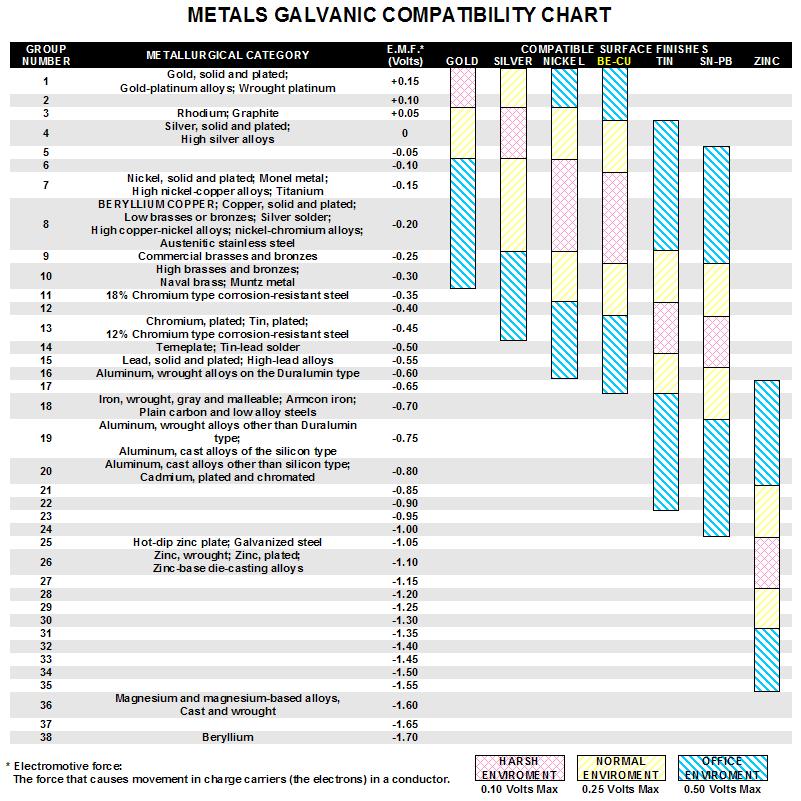

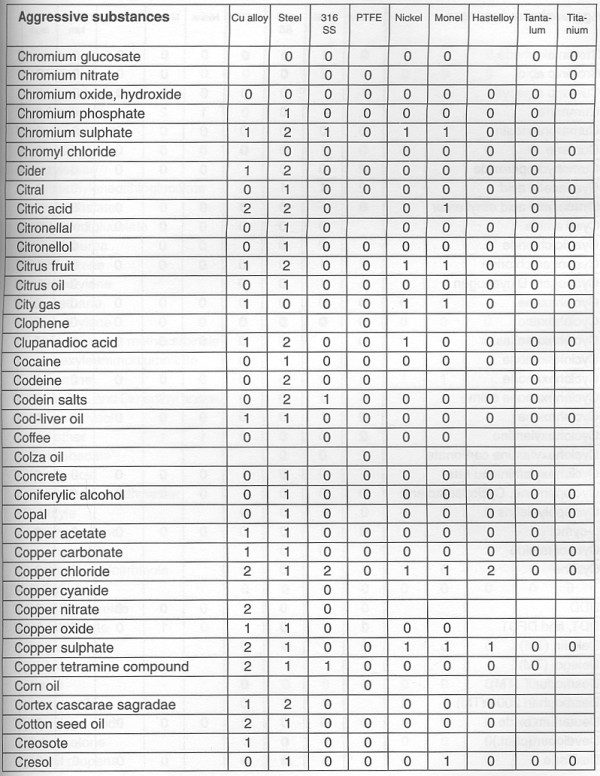

Metal To Metal Compatibility Chart - Galvanic and corrosion compatibility dissimilar metal corrosion guide. * inert catchment situation may apply. Web metals listed on the top of the chart (anodic) will corrode faster than the metals on the bottom of. Web chemicial compatibility guide. Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. Web the compatibility chart in the code of practice has been updated. A b c d e f g h i j k l m n o p q r s t u v w x y z. Contact a corrosion specialist to determine the best. Web the greater the potential difference is, the greater the tendency for corrosion. A b c d e f g h i j k l m n o p q r s t u v w x y z. This data has been compiled. Web which materials are recommended for your application? Web the compatibility chart in the code of practice has been updated. Optionally choose a material search category such as a. (nab) cast iron (f) carbon steel (cbst) 304 stainless steel (s) 316 stainless steel Web these tables list the chemical compatibility chart of various metallic materials as used in bal seal products at ambient temperatures, 70°f (23°c). Web chemicial compatibility guide. For metal camlocks pressure ratings are usually around 250 psi for. Galvanic series / galvanic table. Web remember to keep these factors in mind to help prevent and control galvanic reaction and ensure the safety and longevity of your building. Web below is a galvanic reaction chart for dissimilar metals. Web the greater the potential difference is, the greater the tendency for corrosion. For metal camlocks pressure ratings are usually around 250 psi for. It is. Contact a corrosion specialist to determine the best. Web the greater the potential difference is, the greater the tendency for corrosion. Optionally choose a material search category such as a general category like 'metal' or a child category like 'aluminum alloy' from the category tree. Industrialspe key to general chemical resistance [all data based on 72 ° (22 °c) ]. Web chemical compatibility chart — metals. Web remember to keep these factors in mind to help prevent and control galvanic reaction and ensure the safety and longevity of your building. Web fluid compatibility of metals. Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. Web which materials are recommended for your application? We are recommending that wet contact between metal and butyl rubber is avoided. For metal camlocks pressure ratings are usually around 250 psi for. It is importantto stay within the operating pressure rating of the cam coupling. Web chemical & material compatibility database. Web what is the material compatibility chart for metal? It is importantto stay within the operating pressure rating of the cam coupling. Web chemical compatibility chart — metals. The following information is intended to be used as a general guideline for pump material selection. These charts have been prepared for use with dry. Web chemicial compatibility guide. We are recommending that wet contact between metal and butyl rubber is avoided. The following information is intended to be used as a general guideline for pump material selection. Web remember to keep these factors in mind to help prevent and control galvanic reaction and ensure the safety and longevity of your building. * inert catchment situation may apply. This. We are recommending that wet contact between metal and butyl rubber is avoided. The metal with the higher potential forms the anode and is corroded. Web fluid compatibility of metals. Web remember to keep these factors in mind to help prevent and control galvanic reaction and ensure the safety and longevity of your building. Industrialspe key to general chemical resistance. A b c d e f g h i j k l m n o p q r s t u v w x y z. It is importantto stay within the operating pressure rating of the cam coupling. Web chemicial compatibility guide. Compatibility of direct contact between metals or alloys. Web below is a galvanic reaction chart for dissimilar. Contact a corrosion specialist to determine the best. Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. This chart is intended as a general guide for. Web fluid compatibility of metals. Web these tables list the chemical compatibility chart of various metallic materials as used in bal seal products at ambient temperatures, 70°f (23°c). These charts have been prepared for use with dry. The following information is intended to be used as a general guideline for pump material selection. Web below is a galvanic reaction chart for dissimilar metals. Web metals listed on the top of the chart (anodic) will corrode faster than the metals on the bottom of. A b c d e f g h i j k l m n o p q r s t u v w x y z. Web the greater the potential difference is, the greater the tendency for corrosion. Web which materials are recommended for your application? Web what is the material compatibility chart for metal? Web chemical compatibility chart — metals. It is importantto stay within the operating pressure rating of the cam coupling. We are recommending that wet contact between metal and butyl rubber is avoided.

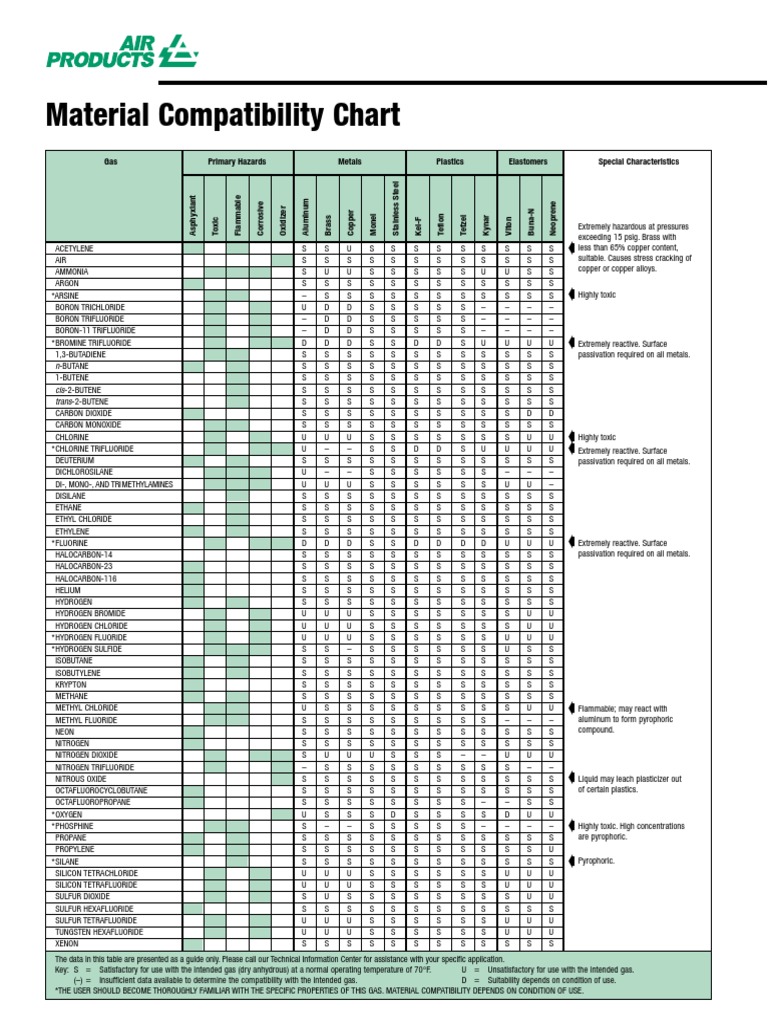

Chemical Compatibility Metals

Metals Galvanic Compatibility Chart Leadertechinc

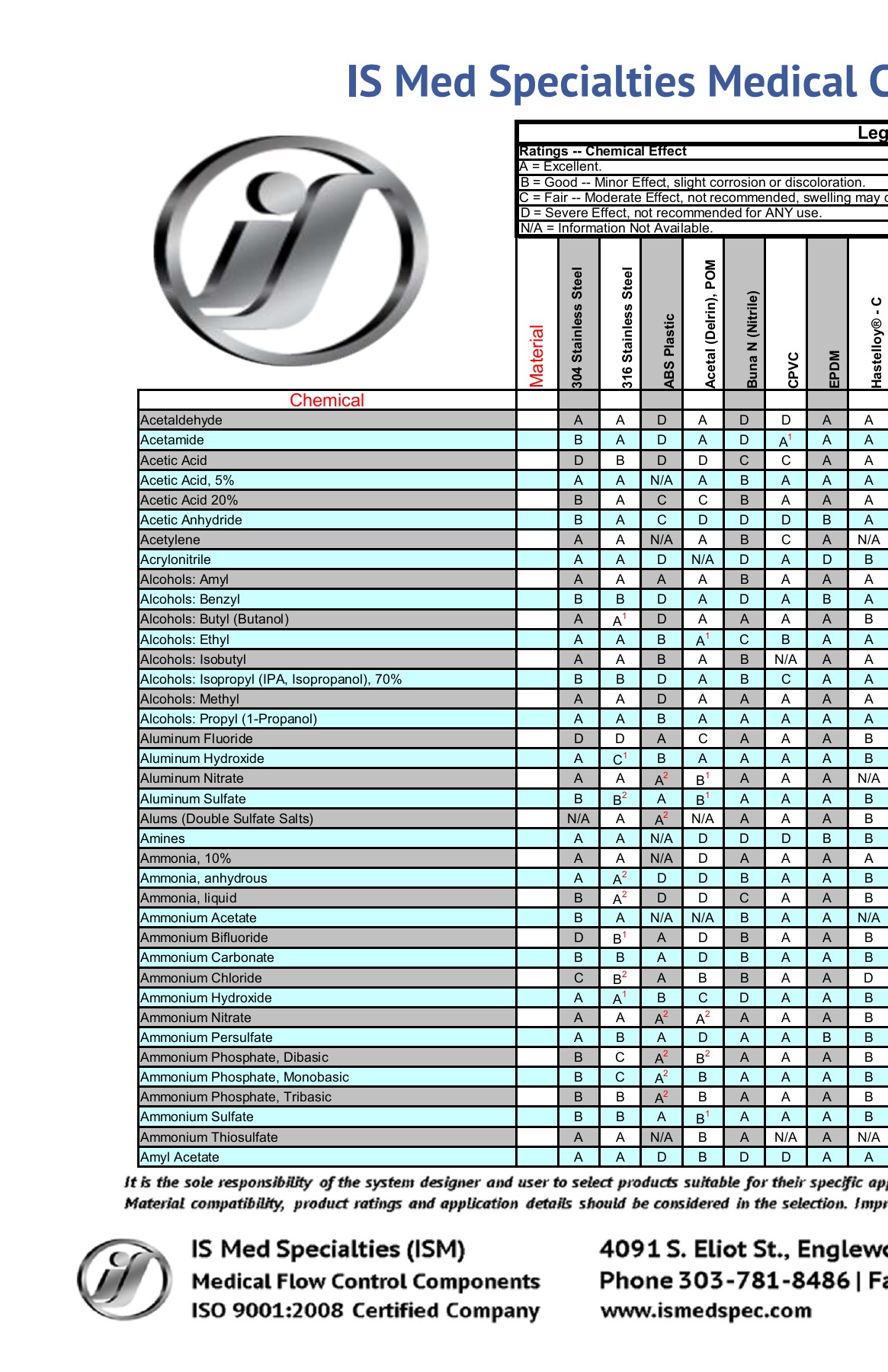

304 Stainless Steel Chemical Compatibility Chart From Ism Chart Walls

Material Compatibility Table

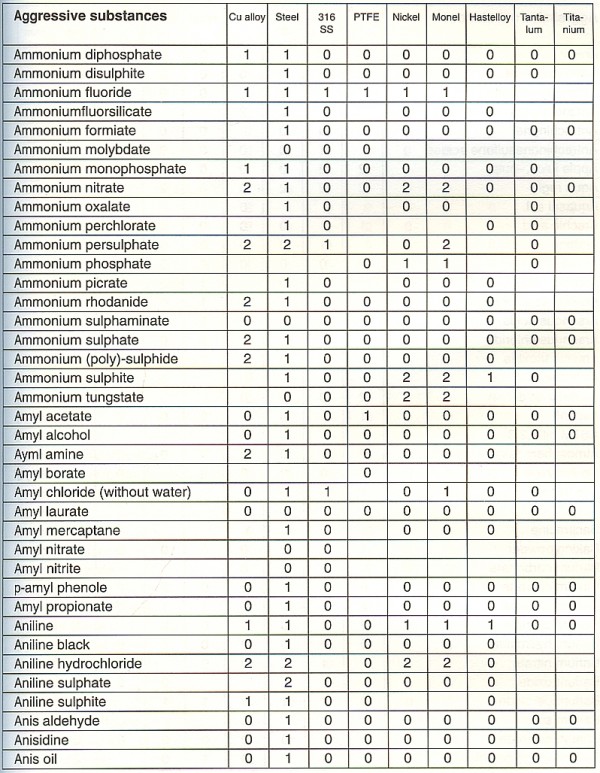

Materials Compatibility Reference_charts Chemical Substances Chemistry

Galvanic Corrosion Compatibility Chart

Metals Galvanic Compatibility Chart Online Shopping

Omega Shielding Products Metals Galvanic Compatibility Chart

Chemical Compatibility Metals

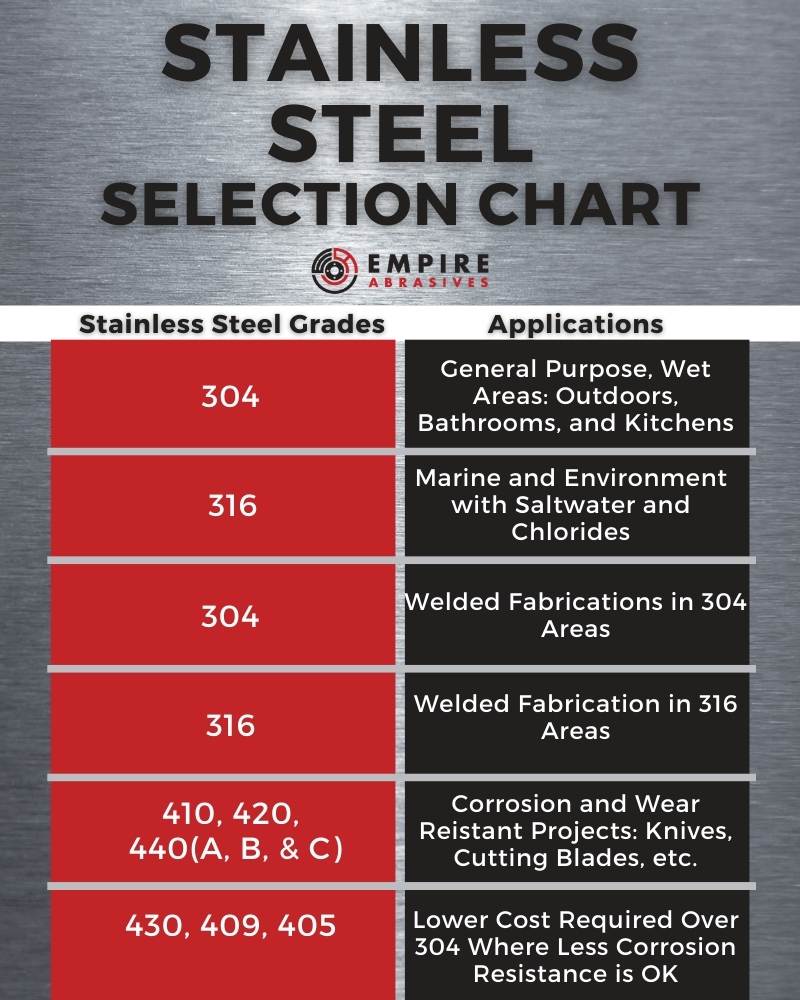

Stainless Steel Grades Comparison Chart A Visual Reference Of Charts

Web With Our Guide, Check The Chemical Compatibility Or Corrosion Resistance Of Different Heater Alloys And Materials And Get The Best Value From Your Heater.

Industrialspe Key To General Chemical Resistance [All Data Based On 72 ° (22 °C) ] A =.

(Nab) Cast Iron (F) Carbon Steel (Cbst) 304 Stainless Steel (S) 316 Stainless Steel

This Chart Is Designed To Assist In Broadly Assessing The Risk Of Galvanic Corrosion Associated With A Given Metal Coming.

Related Post: