Metric Keyway Chart

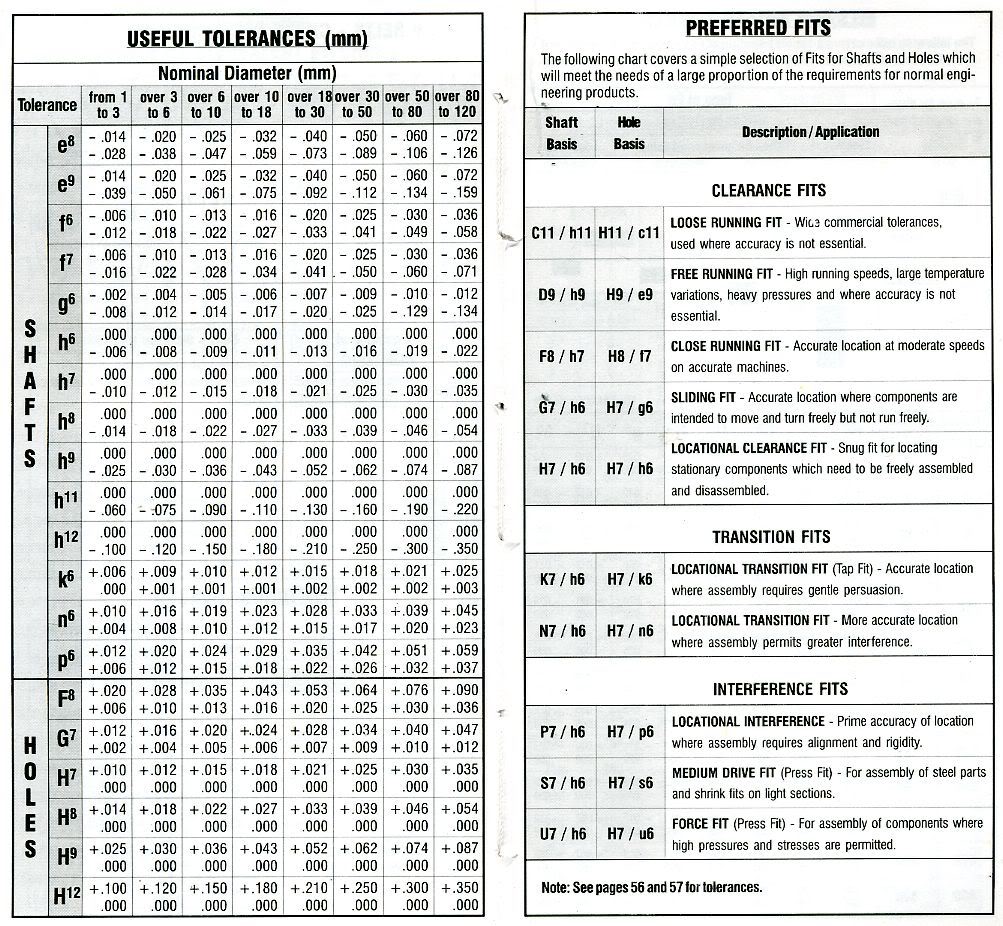

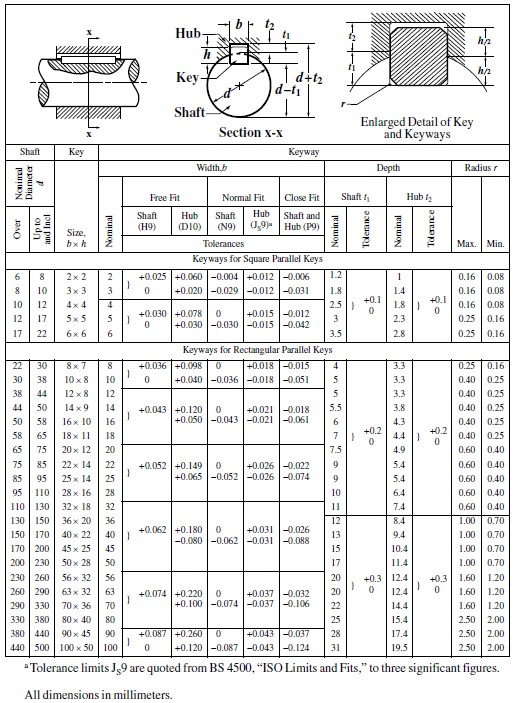

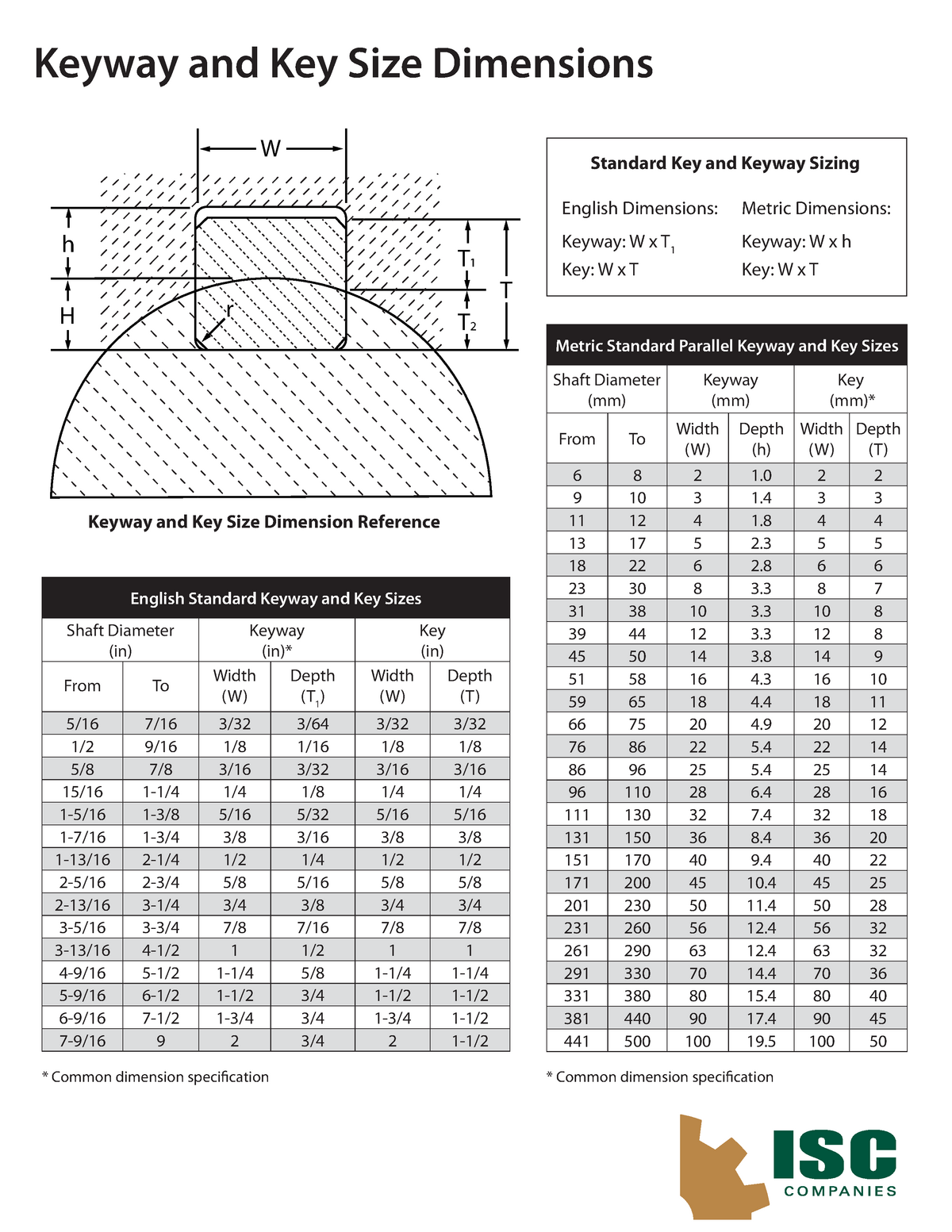

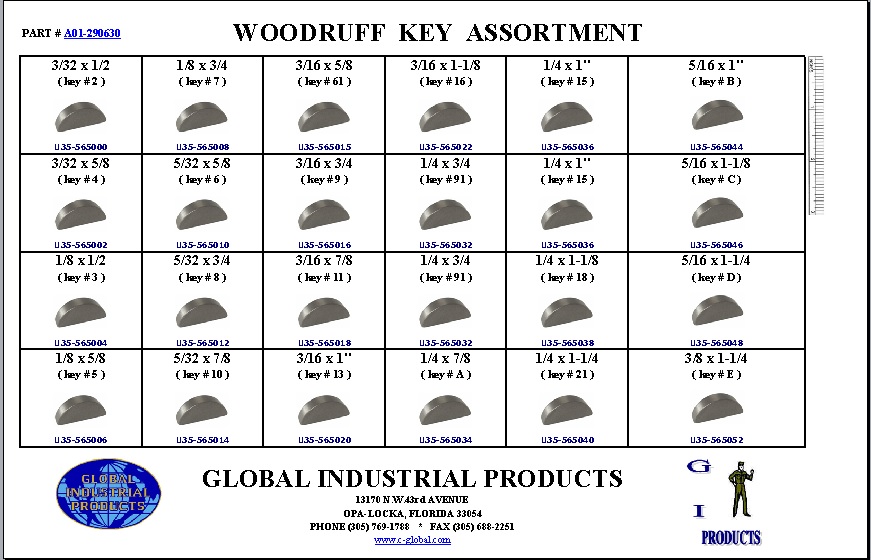

Metric Keyway Chart - B h c or r standard size of b1 and b2 b1tolerance (h9) b2 tolerance (e9) r1 and r2 t1 t2; The second is a p9. Web a b c d +.005 +.000 +.005 +.005 ‐.000 ‐.005 ‐.000 ‐.000 (shaft) (shaft) (bore) (bore) 1/2 1/8 0.070 0.430 0.055 0.555 5/8 3/16 0.108 0.517 0.079 0.704. A key is a machine element used to connect a rotating machine element to a shaft. Min “y1” max “y1” min “y2” max “y2” r: Min “x” max “x” t: For example, gear drives, pulleys or sprockets are connected securely using keys to the power transmitting shaft. Web iso hardware specifications table. See dimensions, tolerances and charts for key size, keyway width, hub keyway depth and radius. Standard metric keys & keyways for metric bores with one key. A key is a machine element used to connect a rotating machine element to a shaft. Web note that metric keys are rectangular in shape, and not square as in the english system. Min “y1” max “y1” min “y2” max “y2” r: The second is a p9. The value of the tolerance is equally oversized or undersized. B h c or r standard size of b1 and b2 b1tolerance (h9) b2 tolerance (e9) r1 and r2 t1 t2; Standard metric keys & keyways for metric bores with one key. The dimensional charts below relate to metric rectangular keyways and metric rectangular keys, imperial rectangular keyways and imperial rectangular keys and imperial square keyways and imperial square keys.. 10 or more and 13 or below: 7 6 +0.2 / 0. A key is a machine element used to connect a rotating machine element to a shaft. 3 2.5 +0.1 / 0. 4 +0.030 0 +0.050 +0.020: Min “y1” max “y1” min “y2” max “y2” r: Standard metric keys & keyways for metric bores with one key. Compare the standard keyway and key sizes for parallel keyway and key. Web four main shaft keys are available: B h c or r standard size of b1 and b2 b1tolerance (h9) b2 tolerance (e9) r1 and r2 t1 t2; Web find standard metric keys and keyways for metric bores with one key according to iso/r773. Metric standard parallel keyway and key sizes shaft diameter (mm) keyway (mm) key (mm)* from to width (w) depth (h) width (w) depth (t) 6 8 2 1.0 2 2 9 10 3 1.4 3 3 11 12 4 1.8 4 4 13 17. The common specification dimension, key size, is highlighted. Sunk key, saddle key, tangent key, and round key. Standard size tolerance(h8) standard size tolerance(h10) standard size tolerance standard size tolerance; A key is a machine element used to connect a rotating machine element to a shaft. The common specification dimension, key size, is highlighted. 4 +0.030 0 +0.050 +0.020: The dimensional charts below relate to metric rectangular keyways and metric rectangular keys, imperial rectangular keyways and imperial rectangular keys and imperial square keyways and imperial square keys. Standard metric keys & keyways for metric bores with one key. Web iso hardware specifications table. For example, gear drives, pulleys or sprockets are connected securely using. Web metric standard bore and keyway info. Web parallel keys are the most common form of keyway. The common specification dimension, key size, is highlighted. Web shaft diameter (mm) key (mm) groove dimensions (mm) ≤ > x: B h c or r standard size of b1 and b2 b1tolerance (h9) b2 tolerance (e9) r1 and r2 t1 t2; Please note that the key sizes in parentheses are older sizes that are no longer commonly used. Metric standard parallel keyway and key sizes shaft diameter (mm) keyway (mm) key (mm. Web four main shaft keys are available: Hence the correct shaft key must be selected for the application based on its characteristics and benefits. A key is a machine. The dimensional charts below relate to metric rectangular keyways and metric rectangular keys, imperial rectangular keyways and imperial rectangular keys and imperial square keyways and imperial square keys. Web taper keyway & key dimensions. 3 2.5 +0.1 / 0. Metric standard parallel keyway and key sizes shaft diameter (mm) keyway (mm) key (mm. See dimensions, tolerances and charts for key. Standard metric keys & keyways for metric bores with one key. The common specification dimension, key size, is highlighted. For example, gear drives, pulleys or sprockets are connected securely using keys to the power transmitting shaft. The value of the tolerance is equally oversized or undersized. The second is a p9. A key is a machine element used to connect a rotating machine element to a shaft. Web parallel keys are the most common form of keyway. 3 2.5 +0.1 / 0. Compare the standard keyway and key sizes for parallel keyway and key. The dimensional charts below relate to metric rectangular keyways and metric rectangular keys, imperial rectangular keyways and imperial rectangular keys and imperial square keyways and imperial square keys. Hence the correct shaft key must be selected for the application based on its characteristics and benefits. Web note that metric keys are rectangular in shape, and not square as in the english system. Web four main shaft keys are available: Recommended hub keyway dimensions (mm) standard metric keyway width tolerance per js9. 4 +0.030 0 +0.050 +0.020: Web iso hardware specifications table.

Standard Keyway Dimensions, 46 OFF, 60 OFF

Standard Keyway Size Chart

Standard Metric Keys & Keyways Mechanical Reviews

BS 423511972 Specification for Metric Keys and Keyways. Parallel and

Metric Keyway Sizes.pdf Engineering Tolerance Manufactured Goods

10 ANSI B17.1 Keyway_Dimensions Ingeniería mecánica Bienes

Keyway Chart

Metric Key Keyway Dimensions Per ISO/R773.Js9 Widt...

How To Calculate Keyway Depth

Keys

Sunk Key, Saddle Key, Tangent Key, And Round Key.

Web A B C D +.005 +.000 +.005 +.005 ‐.000 ‐.005 ‐.000 ‐.000 (Shaft) (Shaft) (Bore) (Bore) 1/2 1/8 0.070 0.430 0.055 0.555 5/8 3/16 0.108 0.517 0.079 0.704.

Web Metric Standard Bore And Keyway Info.

Min “X” Max “X” T:

Related Post: