Mig Welding Parameters Chart

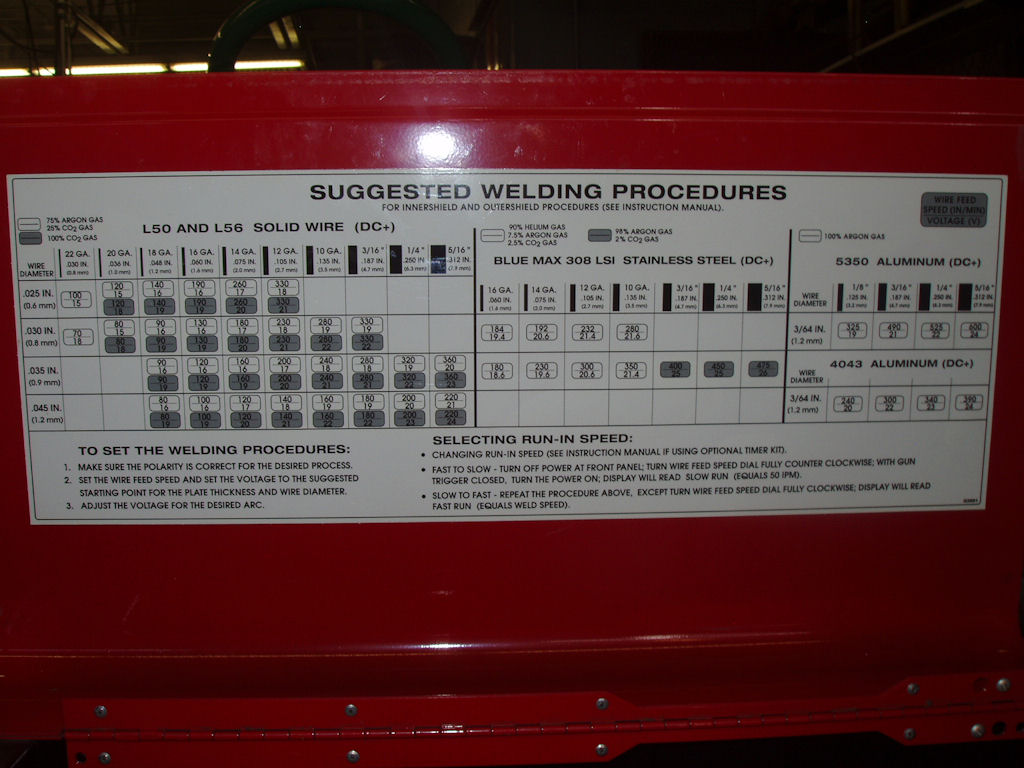

Mig Welding Parameters Chart - Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. What the weld bead tells you about your mig: If a manual or weld specification sheet is not. Web weld setting calculator app. Web mig welder settings charts, guides and tables for steel, stainless and aluminum lincoln mig welding electrode and gas selection chart settings to start the pictures above. Web are you producing quality weld beads? These three settings must be perfectly aligned to get a perfect weld. For example a sip migmate. This project only used inert (non. This article presents guidelines that can help you identify which parameters to adjust. Browse suggested weld parameter settings for stick welding, tig. How to use the calculator. Web the three settings you have to master on a mig welder are wire feed, voltage, and gas pressure. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for. What the weld bead tells you about your mig: Twist the regulator valve to set how much gas flow you want for the weld. Web the three settings you have to master on a mig welder are wire feed, voltage, and gas pressure. This project only used inert (non. Web are you producing quality weld beads? These figures can be found from manufacturer or retailers' specs. Web are you producing quality weld beads? For example a sip migmate. These three settings must be perfectly aligned to get a perfect weld. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. The output capacity of your welder determines the thickness you. Web the welding parameters vary for each of the recommended wire diameters and also depend on how thin the material is. Web wire speed controls amperage as well as the amount of weld penetration. What the weld bead tells you about your mig: Web are you producing quality weld beads? Web wire speed controls amperage as well as the amount of weld penetration. Web weld setting calculator app. If not, perhaps your parameters need tweaking. Web the three settings you have to master on a mig welder are wire feed, voltage, and gas pressure. Web we offer a variety of helpful welding charts and guides that you can reference online,. There are many mig setting charts. Web weld setting calculator app. Material thicknesses of aluminum that can be mig welded are 14 gauge and heavier; What material are you welding? Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Web the chart below provides approximate welding parameters as a starting point only. Material thicknesses of aluminum that can be mig welded are 14 gauge and heavier; Web the three settings you have to master on a mig welder are wire feed, voltage, and gas pressure. What material are you welding? What the weld bead tells you about your mig: Lockout/tagout input power according to osha 29 cfr 1910.147 (see safety. Material thicknesses of aluminum that can be mig welded are 14 gauge and heavier; If a manual or weld specification sheet is not. Web disconnect input power or stop engine before installing or servicing this equipment. Web wire speed controls amperage as well as the amount of weld penetration. Web are you producing quality weld beads? Download the app version of the weld setting calculator for easy reference! Web wire speed controls amperage as well as the amount of weld penetration. For example a sip migmate. Qualified welding procedures utilizing tested practices should be developed for actual. Our guide below will help you understand how. These figures can be found from manufacturer or retailers' specs. These three settings must be perfectly aligned to get a perfect weld. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team.. Web one shows how much gas is still in the tank, and the second shows your gas flow rate. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web are you producing quality weld beads? There are many mig setting charts. Web the three settings you have to master on a mig welder are wire feed, voltage, and gas pressure. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web the chart below provides approximate welding parameters as a starting point only. Web mig welder settings charts, guides and tables for steel, stainless and aluminum lincoln mig welding electrode and gas selection chart settings to start the pictures above. Web weld setting calculator app. Browse suggested weld parameter settings for stick welding, tig. Lockout/tagout input power according to osha 29 cfr 1910.147 (see safety. This article presents guidelines that can help you identify which parameters to adjust. These settings determine the heat, wire deposition rate, and protection from. Web number of power settings: For example a sip migmate. What material are you welding?

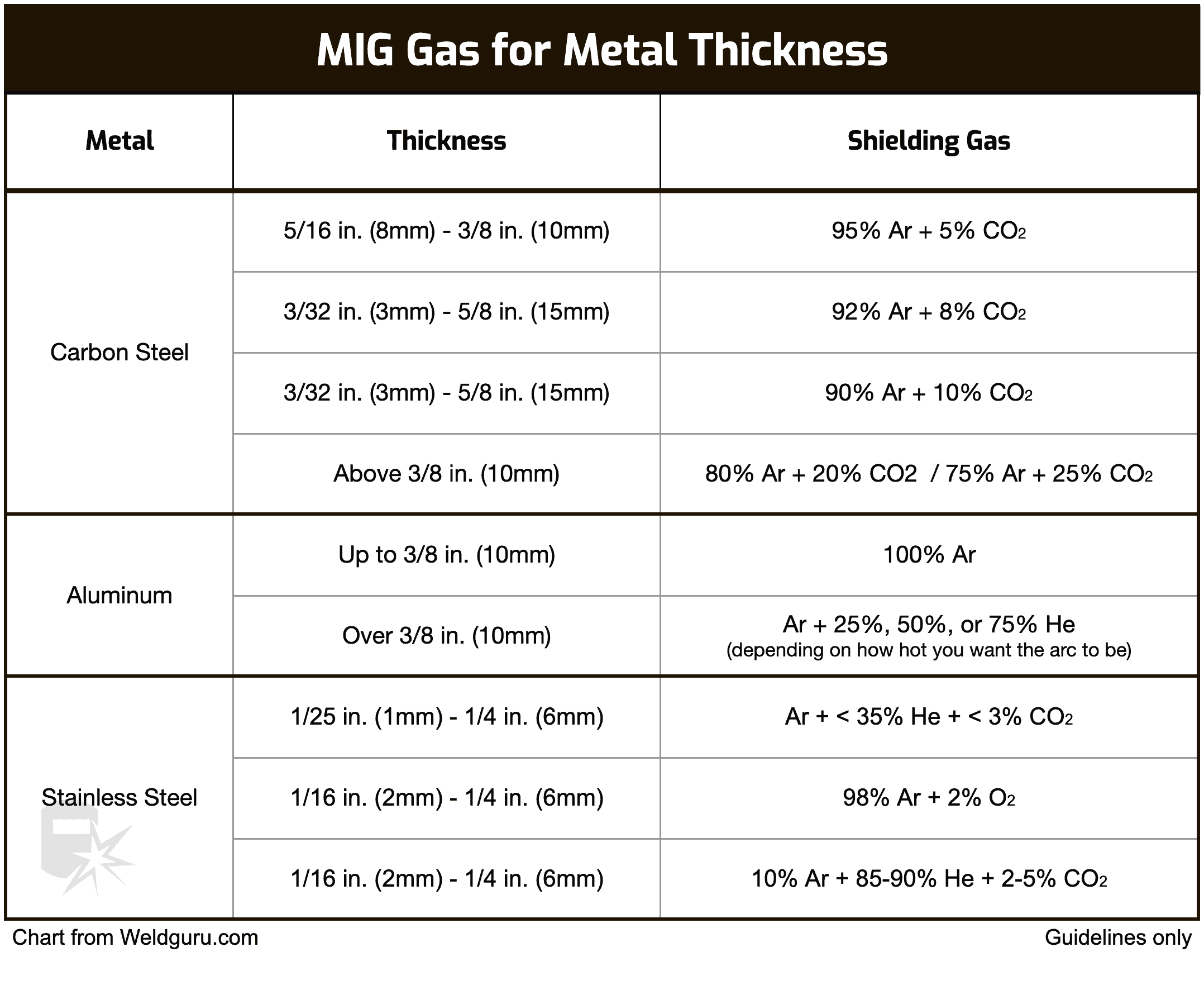

Best Gas for MIG Welding What to Use (with Chart)

Mig Welding Settings Chart Metric Pdf

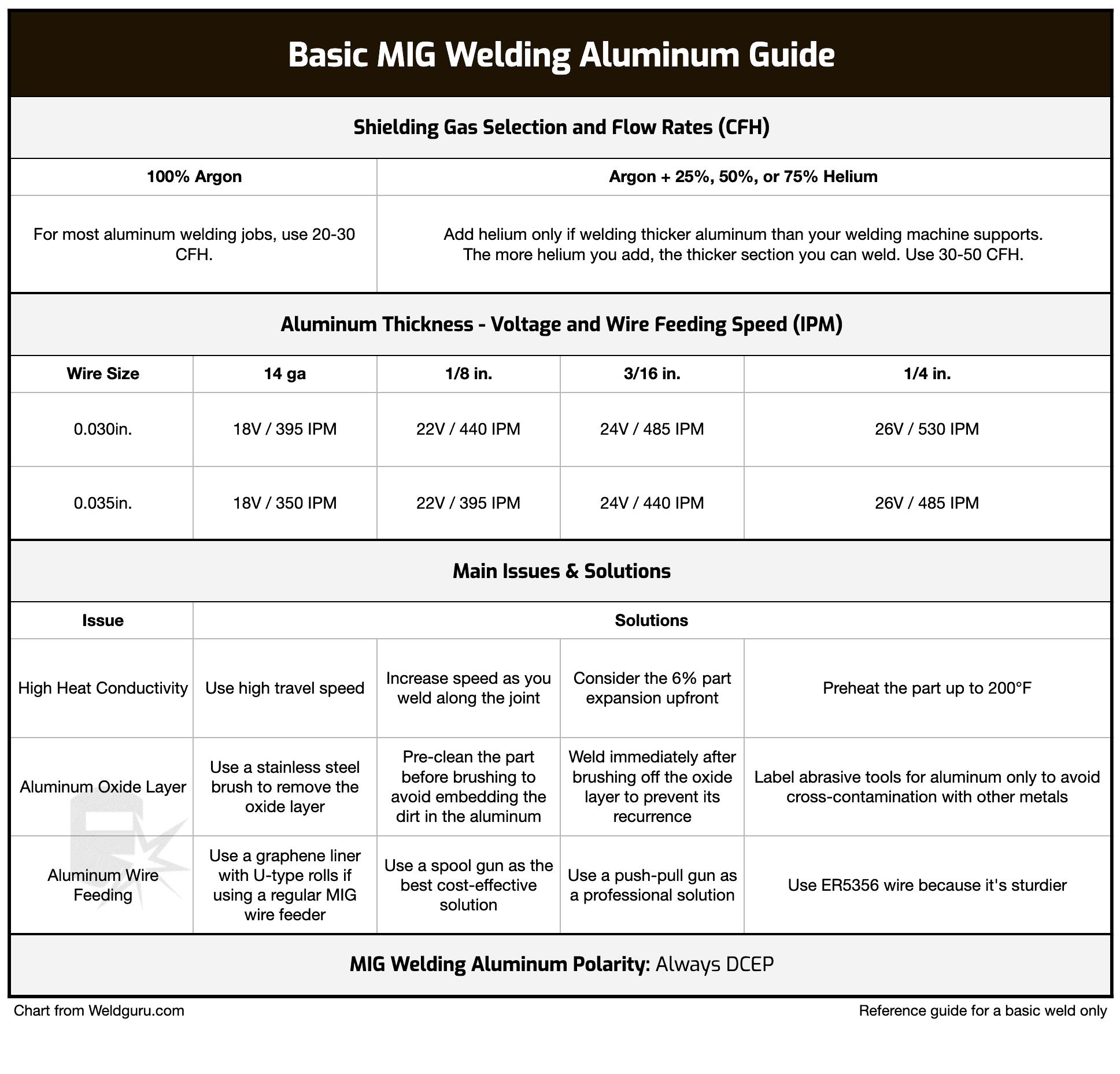

How To MIG Weld Aluminum Beginners Guide (with Chart)

Important MIG Welder Settings You Need to Know (with Chart)

MIG Welding Aluminum Electrodes, Gasses, Welder Setting & Equipment

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG welder settings explained Amperage & Wire Speed

Welding Parameters and Level for MIG Table 3 L93 Level Taguchi

Mig Welding Parameters Chart

MIG Welding Charts ILMO Products Company

If A Manual Or Weld Specification Sheet Is Not.

Twist The Regulator Valve To Set How Much Gas Flow You Want For The Weld.

Web Wire Speed Controls Amperage As Well As The Amount Of Weld Penetration.

Web Disconnect Input Power Or Stop Engine Before Installing Or Servicing This Equipment.

Related Post: