Mig Welding Polarity Chart

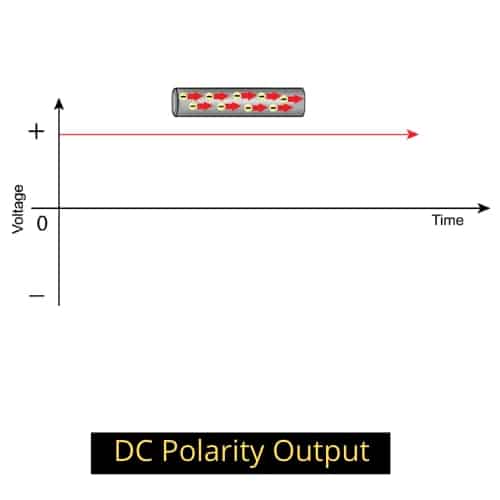

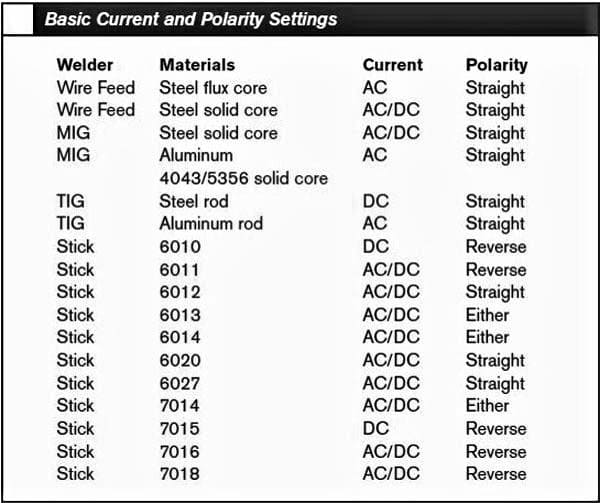

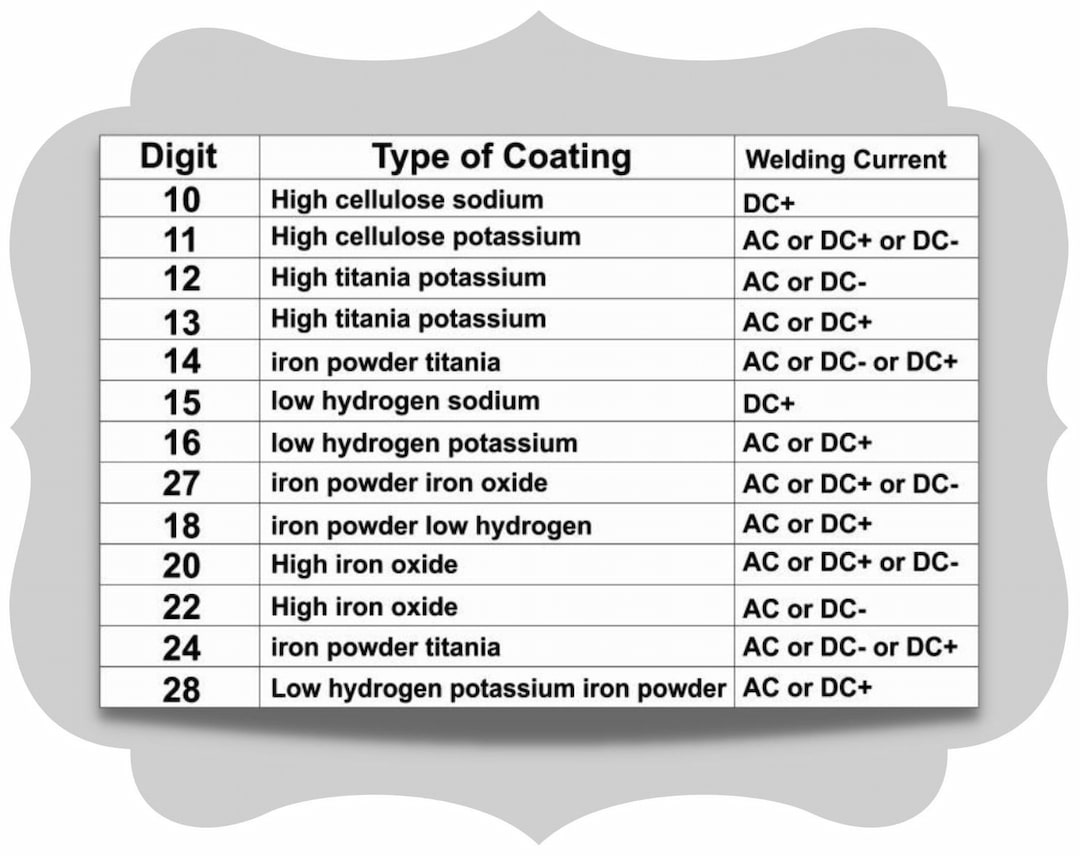

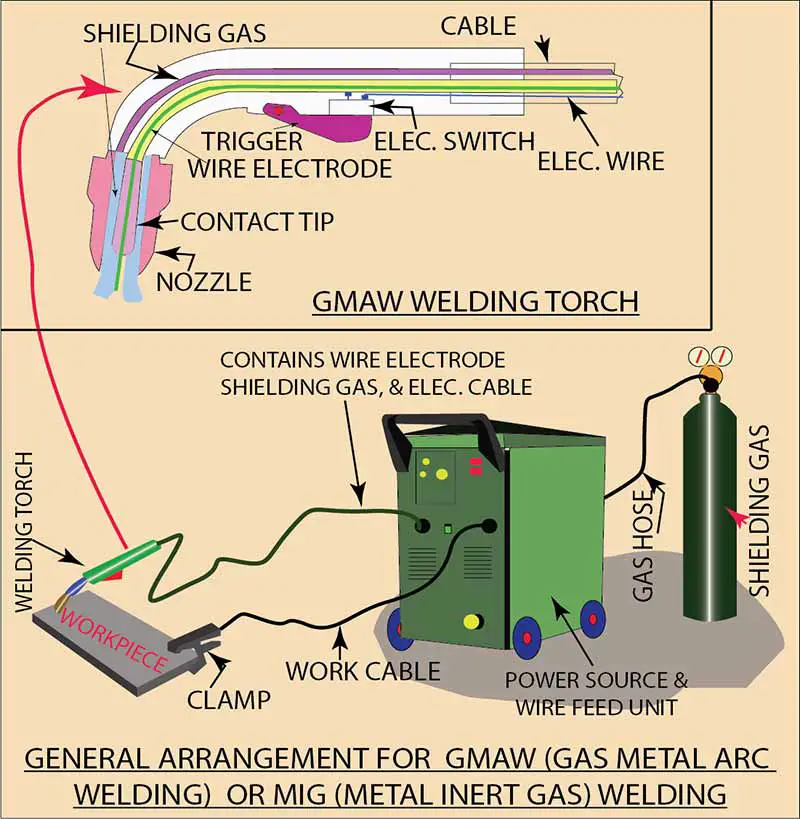

Mig Welding Polarity Chart - But before using these values, we suggest that you have a decent understanding of your preferred metal. Since you don't want to change wire, select one for your most commonly used thicknesses. Tig welding success hinges on one critical setting: Picking the right polarity between these two choices will greatly impact whether you have a sound weld that would pass industry standards or a weld that. In this blog post, we will discuss the different polarity settings and how to set them correctly for your specific project. Web for mig welding aluminum, use direct current electrode positive (dcep) polarity, just like you would for steel. Ensure that the correct gas flow is set. Web if you’re confused about which mig welding polarity settings you should be using for flux core wire, and for solid wire….then this article will quickly clear things up for you. One of the best things about mig welding is the increased productivity and reduced clean up time. Web consider material thickness: The right polarity choice can mean the difference between a strong, clean weld and a weak, contaminated one. If you suspect leaks in your gas hose, apply a soapy water solution and. Picking the right polarity between these two choices will greatly impact whether you have a sound weld that would pass industry standards or a weld that. In this. Web select electrode polarity. Web select a gas regulator. If you suspect leaks in your gas hose, apply a soapy water solution and. It’s worth knowing that lincoln electric sells the 140 mig welder under a few brand names. Polarity is what determines the strength and quality of the weld. It’s worth knowing that lincoln electric sells the 140 mig welder under a few brand names. Web for mig welding aluminum, use direct current electrode positive (dcep) polarity, just like you would for steel. Polarity is what determines the strength and quality of the weld. If you ever step foot in a welding shop or take a welding course, you’ll. Can’t remember which terminals the torch & earth clamp go to? Let’s explore each one in detail to understand their unique advantages. Direct current straight polarity occurs when the plates are positive and the electrode is negative, causing the electrons to go from the electrode tip to the base plates. The right polarity choice can mean the difference between a. The right polarity choice can mean the difference between a strong, clean weld and a weak, contaminated one. One of the best things about mig welding is the increased productivity and reduced clean up time. The time you save by not having to change rods, brush the weld or chip away slag can approximately double your productivity. When you’re looking. The lincoln weld pak 140 hd k2514 mig welder is the same as the: .125 inch = 125 amps. Web 👨🏭 in this weeks episode, we go over the different polarities for both gas and gasless mig, and what they do to your welds👨🏭if you have any tips and tr. However, reverse polarity can be useful for certain types of. The polarity connections are usually found on the inside of the machine. Mig welding requires dc electrode positive, or reverse polarity. However, reverse polarity can be useful for certain types of welding, such as tig welding aluminum. The output capacity of your welder determines the thickness you can weld. Web as a guideline, each.001 inch of material thickness requires 1. The right polarity choice can mean the difference between a strong, clean weld and a weak, contaminated one. When mig welding aluminum, it is important to use direct current electrode positive (dcep) polarity, as it is used for welding steel as well. Can’t remember which terminals the torch & earth clamp go to? Too much gas will create a weak. Web polarity greatly affects the properties of the weld. Material thicknesses of aluminum that can be mig welded are 14 gauge and heavier; Web consider material thickness: Polarity is what determines the strength and quality of the weld. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web 👨🏭 in this weeks episode, we go over the different polarities for both gas and gasless mig, and what they do to your welds👨🏭if you have any tips and tr. Web in mig welding, there are three types of polarity settings: Let’s explore each one in detail to understand their unique advantages. Can’t remember which terminals the torch &. In this blog post, we will discuss the different polarity settings and how to set them correctly for your specific project. However, reverse polarity can be useful for certain types of welding, such as tig welding aluminum. If you ever step foot in a welding shop or take a welding course, you’ll probably hear the term “polarity.” but what exactly does it mean, and how is it applied in the welding industry? It’s worth knowing that lincoln electric sells the 140 mig welder under a few brand names. Polarity is what determines the strength and quality of the weld. Since you don't want to change wire, select one for your most commonly used thicknesses. In this guide, we are suggesting polarity settings for tig, mig, and stick welding. Web consider material thickness: Too much gas will create a weak weld. Web table of contents. Let’s explore each one in detail to understand their unique advantages. So that you know where start to get yourself a strong good looking weld. Web below are charts showing the wire speed and voltage speed settings required for mig stainless steel welding. When you’re looking for the right settings for your lincoln 140 mig welder. Direct current straight polarity occurs when the plates are positive and the electrode is negative, causing the electrons to go from the electrode tip to the base plates. The time you save by not having to change rods, brush the weld or chip away slag can approximately double your productivity.

Mig Welding Polarity Chart

Mig Welding Polarity Chart

Lincoln 140 MIG Welder Reviews The Models Explained • WelditU

Mig Welding Polarity Chart A Visual Reference of Charts Chart Master

how to check polarity on mig welder Wiring Work

Types of Polarity in Stick, TIG, MIG, and SAW

![How To Properly Set Your MIG Welding Polarity Settings [Updated]](https://weldingtroop.com/wp-content/uploads/2020/06/Set-Your-MIG-Welding-Polarity-Settings-768x512.jpg)

How To Properly Set Your MIG Welding Polarity Settings [Updated]

How To Set MIG Welding Polarity Settings? The Welding Guru

What is Polarity in Welding? A Complete Guide MIG, TIG & Stick Weld

Gas Metal Arc Welding (GMAW) MIG Welding Guide

To Mig Weld Aluminum Thinner Than 14 Gauge (.074 Inch), It May Be Necessary To Use Specialized Pulsed Mig Or Ac Tig Welding Equipment.

But Before Using These Values, We Suggest That You Have A Decent Understanding Of Your Preferred Metal.

Most Mig Welders Use A Direct Current (Dc) Power Source.

Material Thicknesses Of Aluminum That Can Be Mig Welded Are 14 Gauge And Heavier;

Related Post: