Mig Welding Troubleshooting Chart

Mig Welding Troubleshooting Chart - This process is a very smooth transfer of molten metal droplets from the end of the electrode to the molten pool. If the polarity switch stops working, it may be that the switch is worn out or maybe due to the use of the switch when the welder is under load. Web in this troubleshooting guide, we will explore some common mig welding defects and provide effective solutions to resolve them. In this article, we’ll break down the key factors that govern mig welding—a process that joins metal with precision and skill. View full size chart here. Web download the ultimate mig troubleshooting guide as a quick reference in your production line. There are many mig setting charts available from manufacturers that all vary. By understanding and addressing these issues, you can achieve exceptional welds that meet the highest quality standards. Use these tips to help you minimize these costs by quickly identifying and resolving mig welding problems. Choosing the right wire, shielding gas & gun. Here's a checklist to help you identify the cause and optimise the performance of your mig welder. Web the 9 most common problems in mig welding are: Wire not feeding or bumpy feeding. It’s vital to differentiate between “discontinuity” and “defect” in the realm of welding: Web distinguishing discontinuity from defect. Web mig welding defects can cause downtime and lost productivity due to rework. Common types include porosity, cracks, undercutting, and lack of fusion. We’ll cover the most common weld defects you might encounter when welding, teach you how to recognise them and help fix or prevent them in the future. Web the 9 most common problems in mig welding are:. Check the connections and correct any short circuit. When mig welding aluminum, the desired mode is spray transfer. Sometimes base metals don’t fuse with the welding properly and make poor welding joints. Web charts are available from the major manufacturers, including lincoln electric, that provide guidelines on amperage use under varying conditions. This guide contains all of the causes and. Low speed can cause the arc to be unstable, which will result in an inconsistent weld. Web the 9 most common problems in mig welding are: Web download the ultimate mig troubleshooting guide as a quick reference in your production line. Web your mig welder can fail for many reasons. Look for any variables that have changed during the course. This guide contains all of the causes and solutions to these symptoms. To fix this problem, you will simply need to increase the speed of the wire. Web your mig welder can fail for many reasons. Web what process should you use? In the intricate world of metal inert gas (mig) welding, achieving flawless welds takes time, skill, practice, and. When mig welding aluminum, the desired mode is spray transfer. View full size chart here. On aluminum, a sooty looking weld (fig.2) can be caused by using a drag vs. Web to minimize the time and money spent addressing mig weld defects, take a systematic approach for troubleshooting each one should they appear. Web correcting the problem is relatively simple: It’s vital to differentiate between “discontinuity” and “defect” in the realm of welding: Wire not feeding or bumpy feeding. These tips apply to virtually any make and model mig welder. This process is a very smooth transfer of molten metal droplets from the end of the electrode to the molten pool. Web mig welding defects can cause downtime and lost. An interruption or irregularity in the weld that may not necessarily impair the structural integrity. Wire not feeding or bumpy feeding. To fix this problem, you will simply need to increase the speed of the wire. Tip disengages from retaining head. Web mig welding defects can cause downtime and lost productivity due to rework. Here's a checklist to help you identify the cause and optimise the performance of your mig welder. Web to minimize the time and money spent addressing mig weld defects, take a systematic approach for troubleshooting each one should they appear. Reduce the welding current, decrease the welding arc voltage, and adjust your mig gun angle toward the joint. Web mig. If the amperage is determined to be high enough, check the voltage. Improper fusion is often seen in mig welding and is mainly caused by human errors like insufficient heat input, incorrect gun angle, and inadequate filler metals. This process is a very smooth transfer of molten metal droplets from the end of the electrode to the molten pool. Web. To fix this problem, you will simply need to increase the speed of the wire. Reduce the welding current, decrease the welding arc voltage, and adjust your mig gun angle toward the joint. Web to minimize the time and money spent addressing mig weld defects, take a systematic approach for troubleshooting each one should they appear. These tips apply to virtually any make and model mig welder. Web your mig welder can fail for many reasons. Web mig welder wire feed not working? Web charts are available from the major manufacturers, including lincoln electric, that provide guidelines on amperage use under varying conditions. Web mig welding troubleshooting chart provides a concise and accurate guide to identify and fix common issues in the mig welding process. When mig welding aluminum, the desired mode is spray transfer. If the fuse is too small, it should be replaced with a bigger one. Web the heat and rays of the arc can react with vapors to form highly toxic and irritating gases. Wire not feeding or bumpy feeding. An interruption or irregularity in the weld that may not necessarily impair the structural integrity. Check the connections and correct any short circuit. Luckily we have mig welding troubleshooting tips! Use these tips to help you minimize these costs by quickly identifying and resolving mig welding problems.

Mig Welding Troubleshooting Chart Solving Welding Issues Made Simple

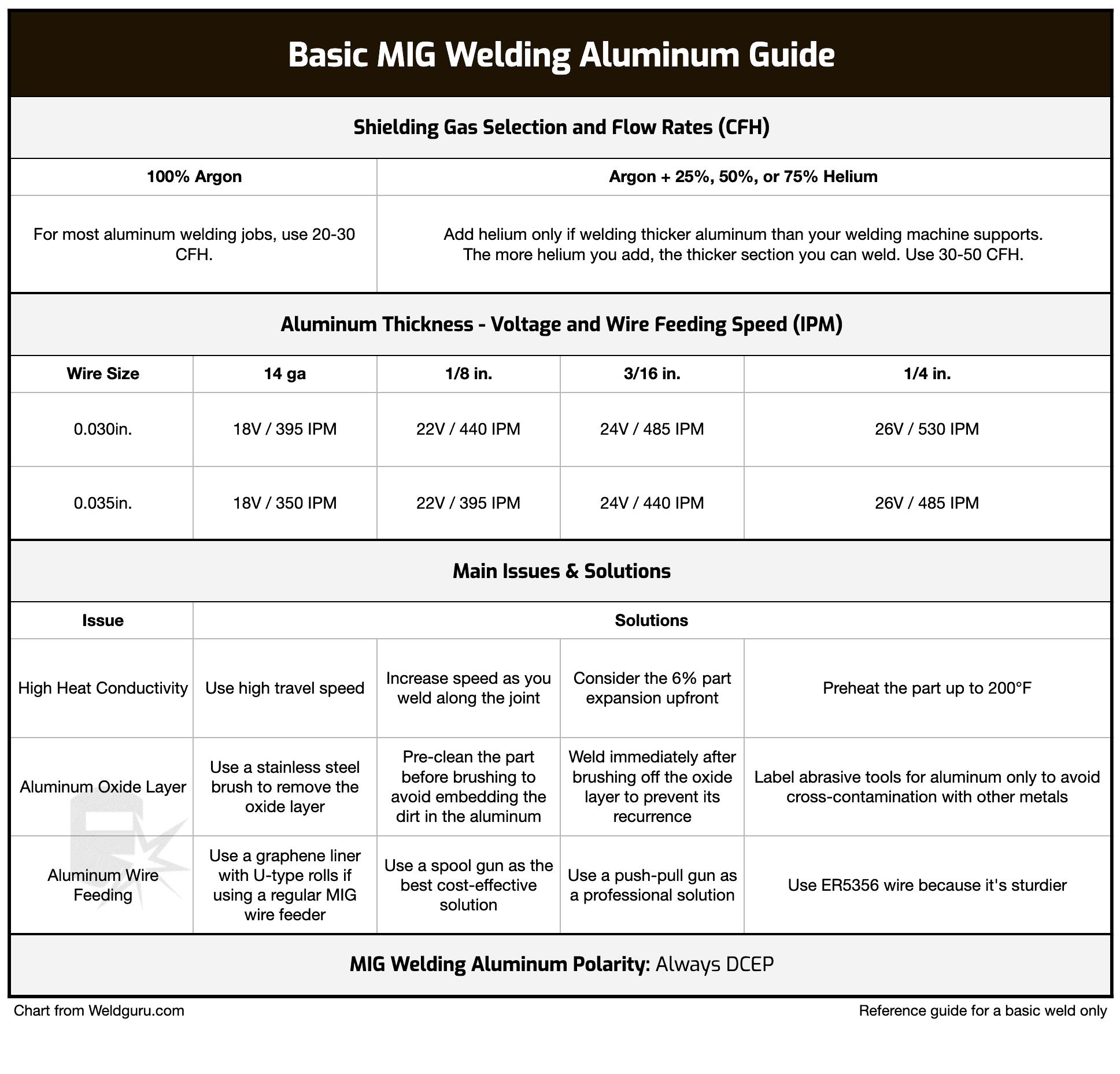

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks

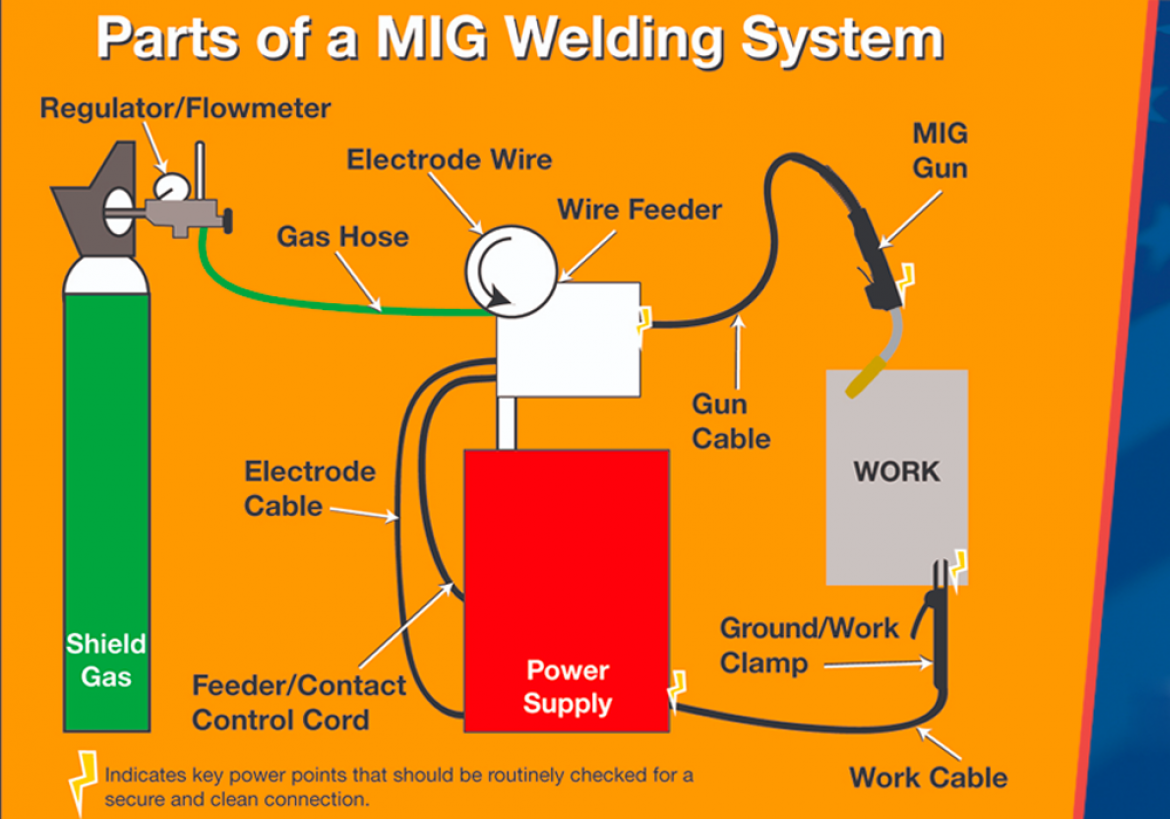

How to Troubleshoot your MIG Welding Cable Problems Mig Welder, Mma

Mig Welding Settings Chart

aluminum mig welding settings chart

Important MIG Welder Settings You Need to Know (with Chart)

Mig welding Guide bead issues Smaw welding, Welding and fabrication

Mig Welding Settings Chart Metric Pdf

MIG Welding Charts ILMO Products Company

This Process Is A Very Smooth Transfer Of Molten Metal Droplets From The End Of The Electrode To The Molten Pool.

View Full Size Chart Here.

Quick Pointers To Refine Your Skills And Results.

Whether You’re New To Welding Or An Experienced Welder Looking To Refine Your Skills, Understanding Your Mig Welders Settings Is Crucial.

Related Post: