Mig Welding Wire Size Chart

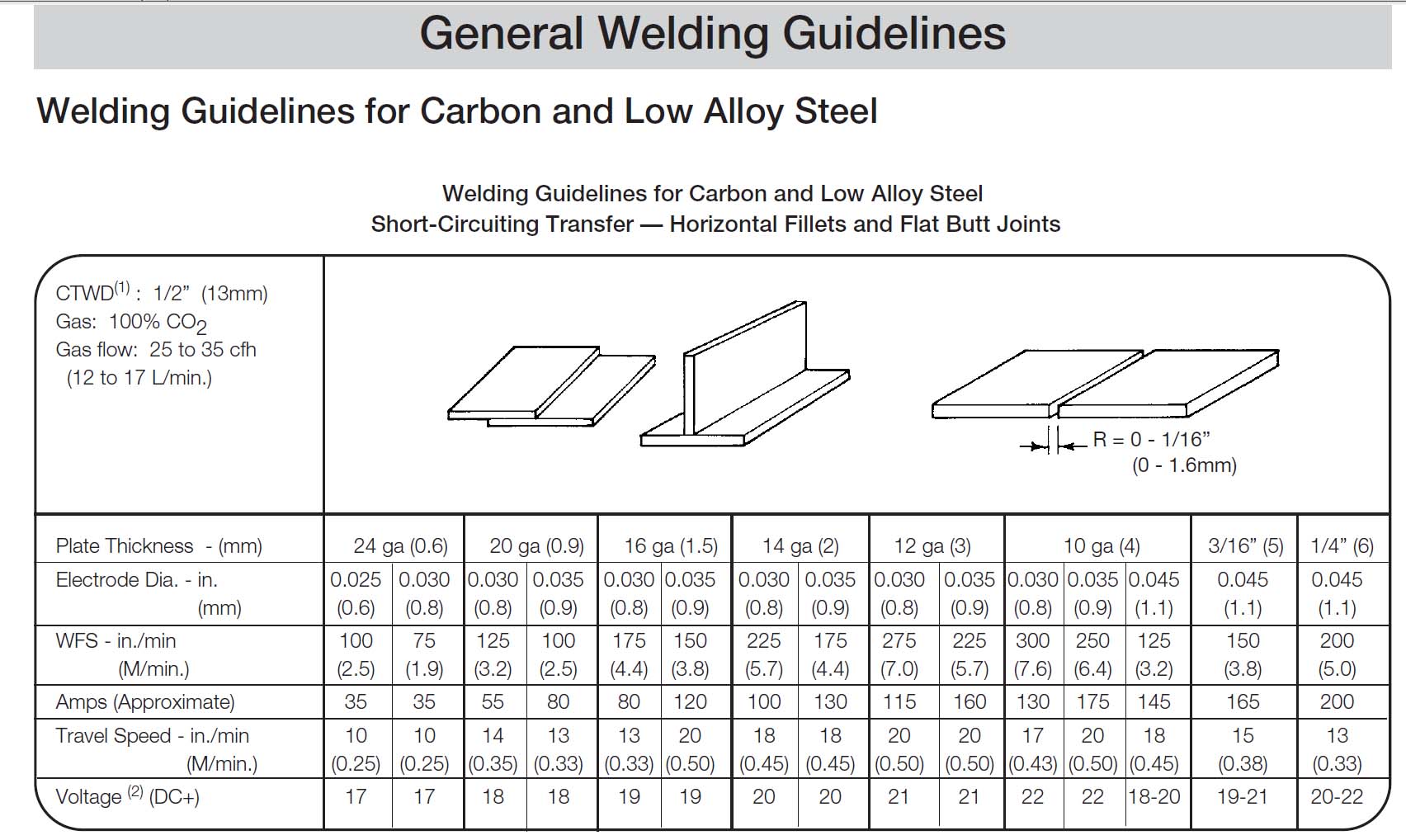

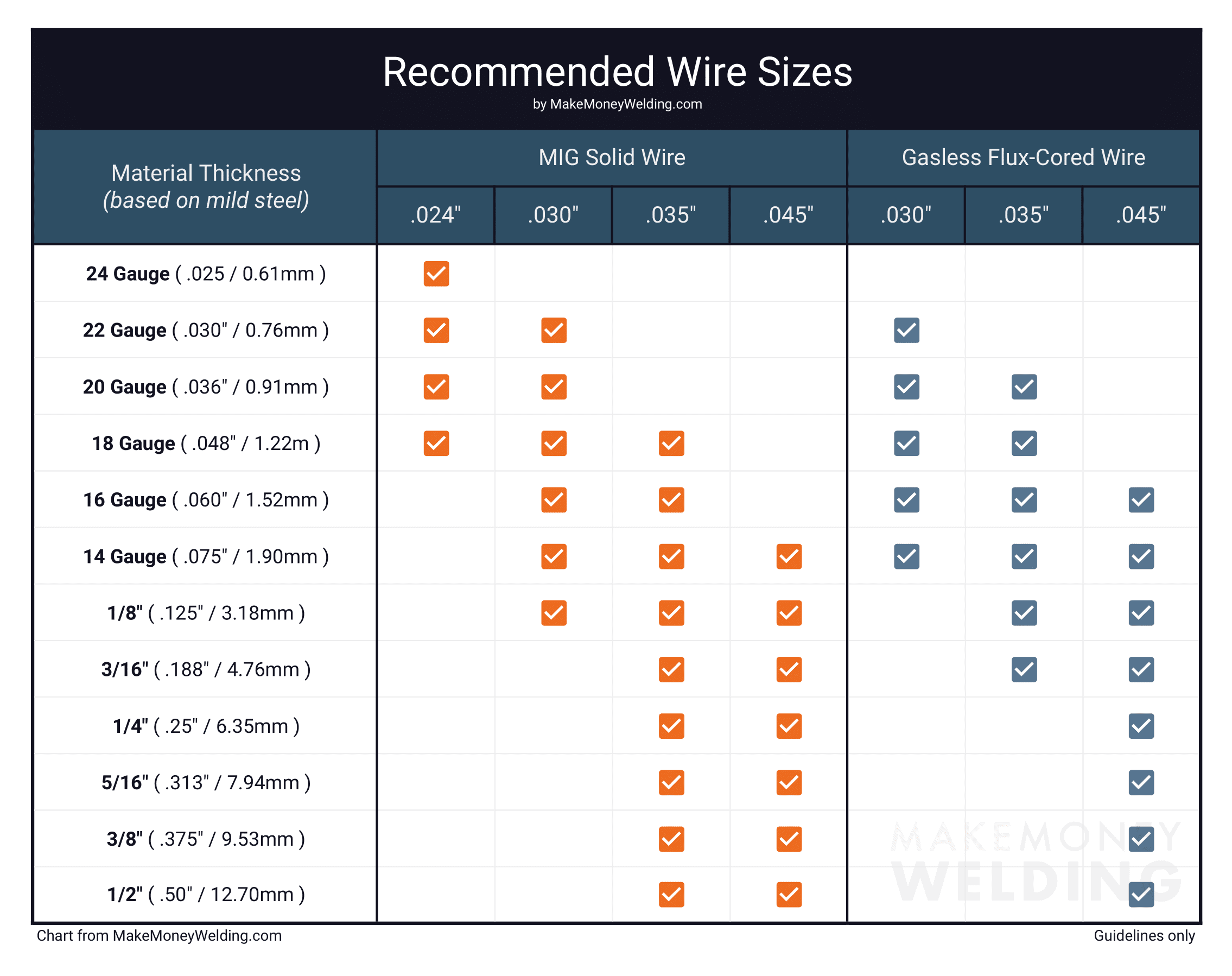

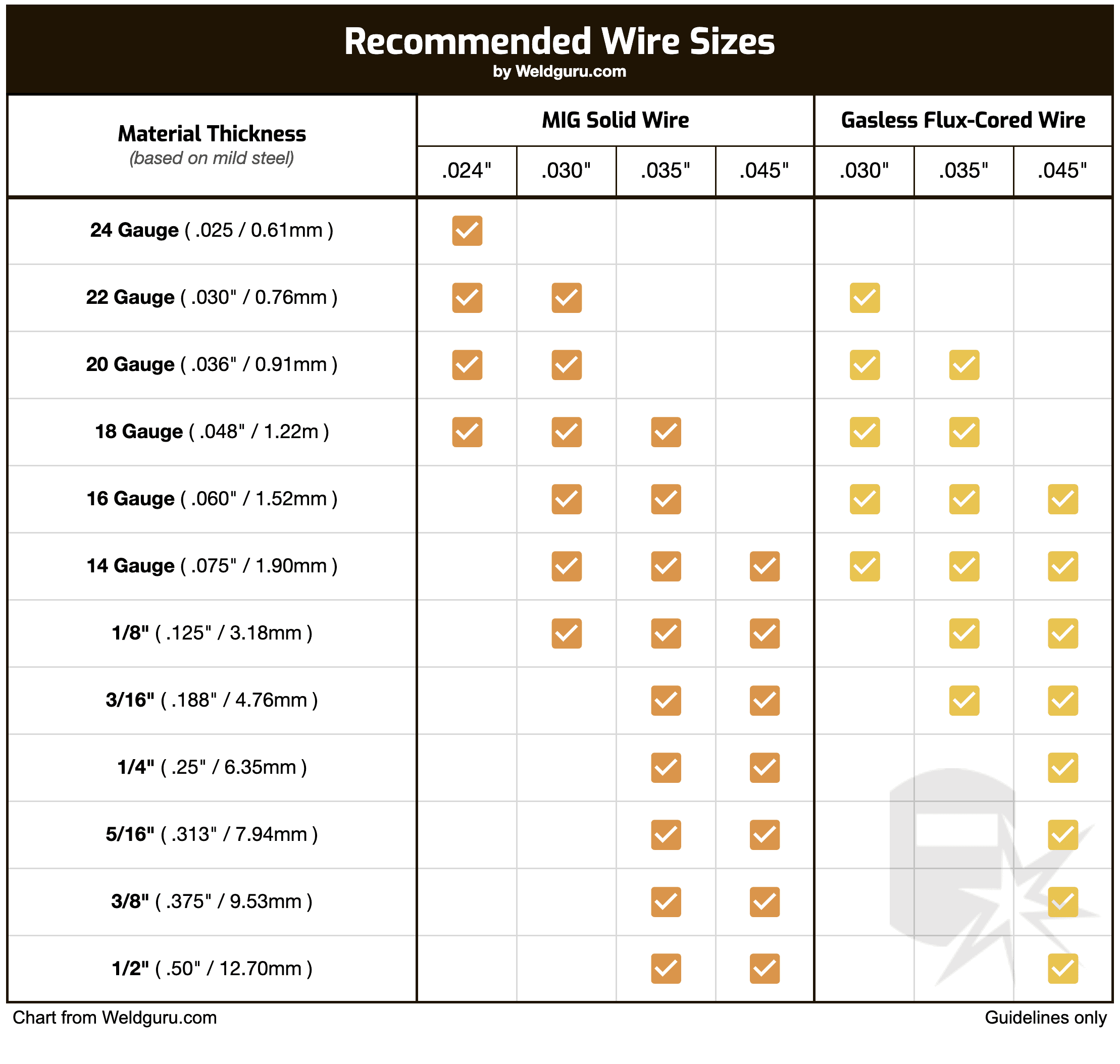

Mig Welding Wire Size Chart - Web how to choose the right mig wire for a good weld strength. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. In some cases, it will depend on the kind of welding machine you’re using and in others, it will depend on the method. Notice that these sizes overlap through each current range. Check with your machine manufacturer for any information that. Web a mig welding wire speed and voltage chart provide essential settings based on material thickness and wire diameter. Web in this article, we will guide you through the basics of mig wire sizes and how to select the right size for your welding project. Since you don't want to change wire, select one for your most commonly used thicknesses. This gives you some choice about what works best for your welder and your technique. Quick guide for selecting mig wire size and welder amperage for your application. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: Navigating the complexities of mig welding requires a deep understanding of its two pivotal parameters: Web they range in. If the wire is to thin for the material thickness it will be difficult to weld. Web mig welding wire output amperage & selection chart. Web they range in size from.02 to.125 (1/8). Web by adam mason. If you were also looking for a special wire for a mig welder, you end up at the right spot because we have. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. A chart simplifies matching wire diameter with the metal thickness to ensure a robust and clean weld. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. This gives you. If the wire is to thin for the material thickness it will be difficult to weld. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Whatever the case, you want to make the choice that allows for the. Web a mig welding. Choosing the right type of mig wire is critical for the look and strength of the welds you create. This gives you some choice about what works best for your welder and your technique. Web a mig welding wire speed and voltage chart provide essential settings based on material thickness and wire diameter. There are various criteria to consider when. Navigating the complexities of mig welding requires a deep understanding of its two pivotal parameters: Web the most common sizes for welding on sheet metal are 0.35 and 0.45. For most fabrication shops the.035 with is the most common. What material are you welding? Since you don't want to change wire, select one for your most commonly used thicknesses. If you were also looking for a special wire for a mig welder, you end up at the right spot because we have a detailed guide. What material are you welding? In some cases, it will depend on the kind of welding machine you’re using and in others, it will depend on the method. Some are much thicker for heavy. In some cases, it will depend on the kind of welding machine you’re using and in others, it will depend on the method. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web in this article, we will guide you through the basics of mig wire sizes and how to select the right size for. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Quick guide for selecting mig wire size and welder amperage for your application. For most fabrication shops the.035 with. Web selecting the appropriate mig wire size is crucial for successful welding. We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. This gives you some choice about what works best for your welder and your technique. Web you choose your wire size by the amperage setting, which in. Why are there different wire diameters? Adjusting them optimizes welding performance and quality. Table of wire speed for mig welding. Web selecting the appropriate mig wire size is crucial for successful welding. Web mig welding wire output amperage & selection chart. For most fabrication shops the.035 with is the most common. Web this chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. Quick guide for selecting mig wire size and welder amperage for your application. Click image for a larger view. Navigating the complexities of mig welding requires a deep understanding of its two pivotal parameters: Choosing the right type of mig wire is critical for the look and strength of the welds you create. .125 inch = 125 amps. Web they range in size from.02 to.125 (1/8). Whether you are mig welding around the house on diy projects or you work in the welding industry, understanding amperage and setting is crucial. Web you choose your wire size by the amperage setting, which in turn depends on material thickness. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes.

MIG Welding Wire Charts Work,work,work...I love it!

Mig welding how to set up your welder from a to z Artofit

MIG Welding Wire Essentials A Guide to Types & Uses

MIG settings for welding different thickness mild steel

How To MIG Weld Aluminum Beginners Guide (with Chart)

Welding Wire Size Chart Mechanic's Corner Pinterest Wire, Charts

MIG Welding Wire Essentials A Guide to Types & Uses

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Mig Welding Settings Chart Metric Pdf

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide

But They Both Use The Same Wire Feed Mechanism And Serve As Filler Metal, And Consumable Electrode In Arc Welding Processes.

You Will Be Welding Material In Different Thicknesses And There Is A Certain Wire Diameter You'll Need To Be Able To Weld That Metal Thickness.

Web In This Article, We Will Guide You Through The Basics Of Mig Wire Sizes And How To Select The Right Size For Your Welding Project.

Web A Mig Welding Wire Speed And Voltage Chart Provide Essential Settings Based On Material Thickness And Wire Diameter.

Related Post: