Morse Taper Size Chart

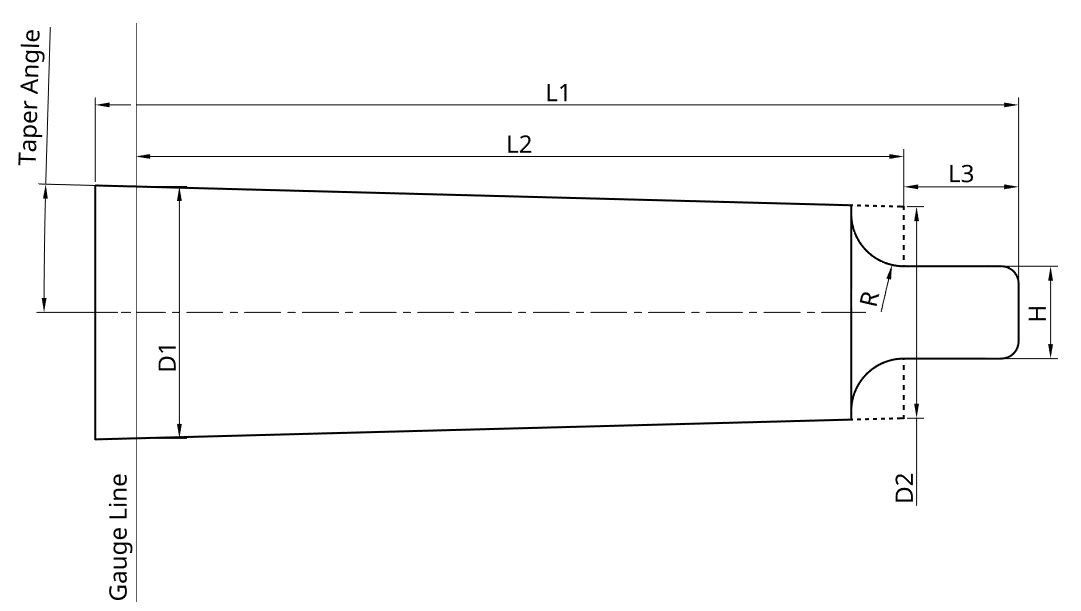

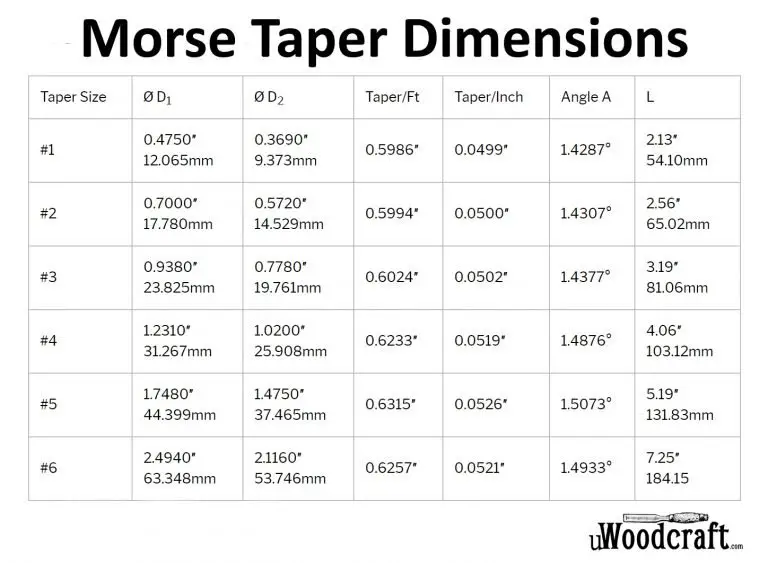

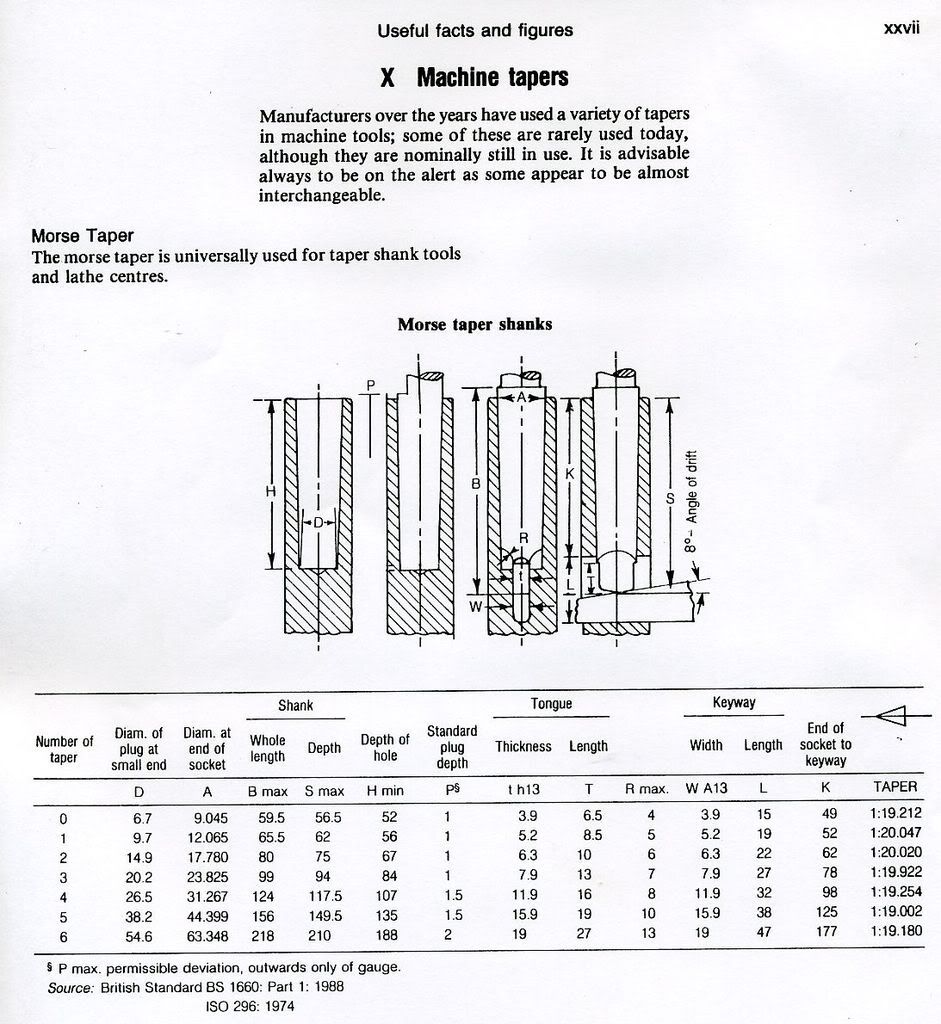

Morse Taper Size Chart - Look for any markings or labels that indicate the morse taper size. Find morse taper, jacobs taper, and brown and sharpe taper dimensions below. When designing for new applications, contact the engineering department, the jacobs® chuck manufacturing company for current specifications. Web the taper for different numbers of morse tapers is slightly different, but it is approximately 5⁄8 inch per foot in most cases. The actual values result from the actual values of a and i1 or i3 respectively, taking into account the taper and the basix size d. Note that morse taper sizes (e.g. The morse taper has been a tried and trusted method for securely attaching drill bits and other cutting tools to a drill press for more than a century. Morse taper shanks are used on a variety of tools, and exclusively on the shanks of twist drills. At times, the female morse taper cavity in a machine may be slightly smaller than the maximum diameters shown above. The size of the taper is determined by the pin that fits the best. Web this page give the dimensions of morse, jacobs, brown & sharpe, and jarno tapers. The morse taper was named for and developed by stephen a. All units are given in inches. Web the taper for different numbers of morse tapers is slightly different, but it is approximately 5⁄8 inch per foot in most cases. Web to determine the morse. Web watch this video and learn how to determine the size of your machine's morse taper, the most popular style taper found on most machinery. Web download & print your free taper dimension chart. The large male taper takes a lathe chuck, which is retained by the large nut. Manufacturers often label the spindle with the morse taper size for. Web technical resource guide | taper dimensions. Measure the diameter of your spindle's opening Web download & print your free taper dimension chart. The table gives the actual tapers, accurate to five decimal places. Our comprehensive chart includes 'at a glance' listing of the most popular taper styles including bt shank, cat shank, jacobs taper, morse. Find morse taper, jacobs taper, and brown and sharpe taper dimensions below. #2 short, #6 and #33. This data is provided to enable readers to identify a tool. The actual values result from the actual values of a and i1 or i3 respectively, taking into account the taper and the basix size d. The table below is accurate to five. Web morse standard taper shanks and sockets dimensions and tolerance chart. Web this page give the dimensions of morse, jacobs, brown & sharpe, and jarno tapers. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! At timing, of female moralic candle cavity into a machine may. The table gives the actual tapers, accurate to five decimal places. All dimensions are in inches unless otherwise specified. Morse taper shanks are used on a variety of tools, and exclusively on the shanks of twist drills. Web this page give the dimensions of morse, jacobs, brown & sharpe, and jarno tapers. The large male taper takes a lathe chuck,. Morse taper shanks are used on a variety of tools, and exclusively on the shanks of twist drills. Look for any markings or labels that indicate the morse taper size. Web watch this video and learn how to determine the size of your machine's morse taper, the most popular style taper found on most machinery. A machine taper secures tool. Drill bits, reamers, end mill holders, drill chuck arbors, collets, lathe centers, etc. As precision improved, it was realized that the existing patterns did not quite conform to this ideal. Alternatively, you can use a set of morse taper shanks to. All dimensions are in inches unless otherwise specified. All dimensions are in inches unless otherwise specified. The rate of taper for different numbers of morse tapers is approximately 5/8 inch per foot in most cases. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! Web this page give the dimensions of morse, jacobs, brown & sharpe, and jarno tapers. Web watch this. Web to use a morse taper gauge, you simply insert the appropriate pin into the taper and see how far it goes in. Web different numbers of morse tapers have slightly different tapers, but all approximate 5/8 inch per foot (0.05208 inch per inch). Machine tapers, like morse, jacobs, and hsk tapers, are crucial components in machinery used to secure. The rate of taper for different numbers of morse tapers is approximately 5/8 inch per foot in most cases. Alternatively, you can use a set of morse taper shanks to. Morse taper shanks are used on a variety of tools, and exclusively on the shanks of twist drills. The dimensions for the same number morse taper or kegel are identical. A machine taper secures tool holders or. Web different numbers of morse tapers have slightly different tapers, but all approximate 5/8 inch per foot (0.05208 inch per inch). Find morse taper, jacobs taper, and brown and sharpe taper dimensions below. The size of the taper is determined by the pin that fits the best. The large male taper takes a lathe chuck, which is retained by the large nut. Old twist drills are, in fact, an inexpensive source for morse tapers. The table below is accurate to five decimal places. Note that morse taper sizes (e.g. As precision improved, it was realized that the existing patterns did not quite conform to this ideal. Web morse tapers are found in a wide variey of tooling: Web this page give the dimensions of morse, jacobs, brown & sharpe, and jarno tapers. All dimensions are in inches unless otherwise specified.

Precise 2MT Morse Taper Shank 3Jaw Self Centering Chuck 39004706

Morse Large Plastic Chart 24" x 36" Tap Drill Sizes for Inch, Metric

Morse Taper Chart

Morse Taper Dimensions The International Association of Penturners

Morse Taper Sizes

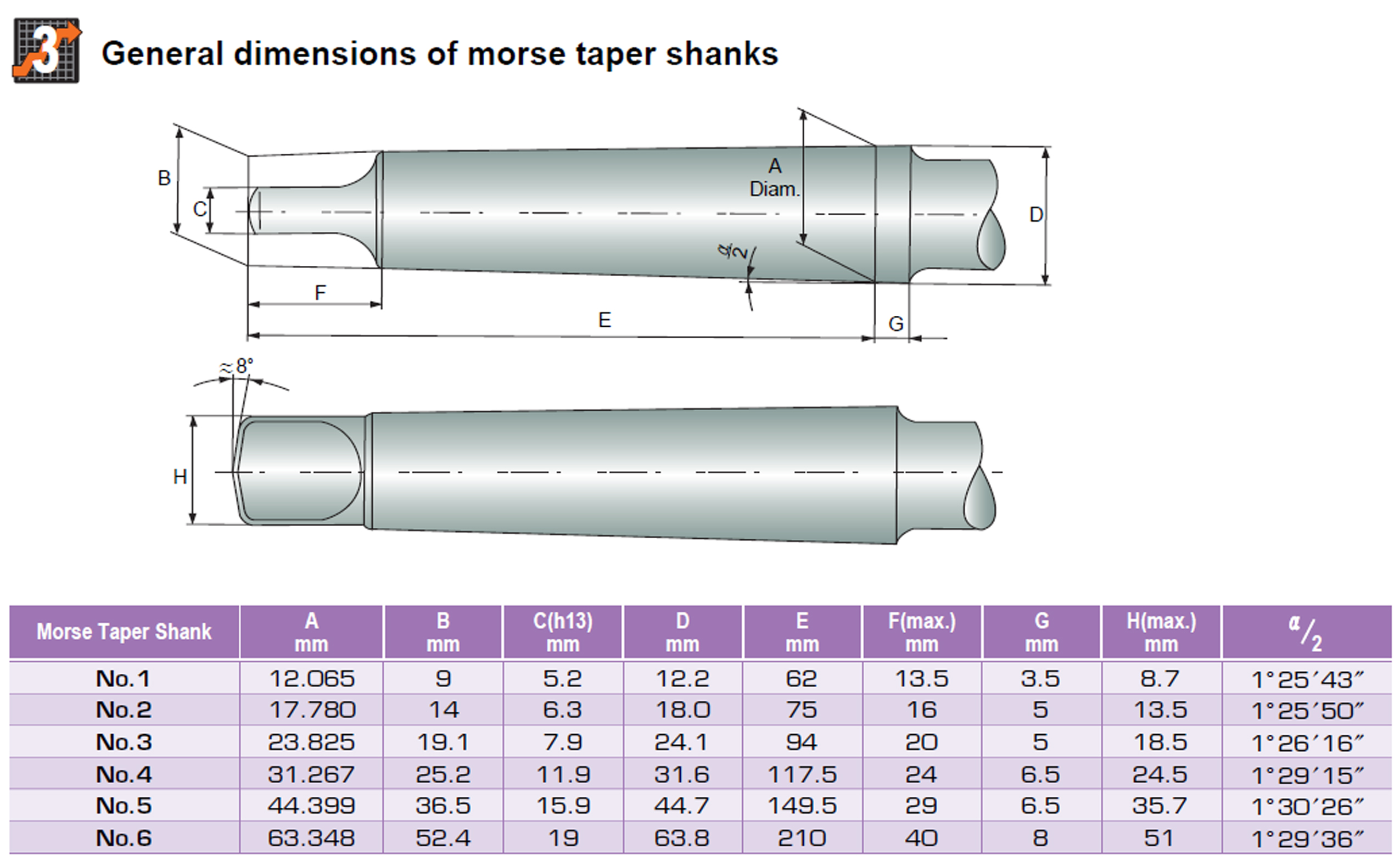

Morse Taper Dimensions Chart

Morse Taper Dimensions

Name that taper

Morse Taper Size Chart A Visual Reference of Charts Chart Master

Morse Taper Dimensions Chart

This Is Because This Miles Tooling Often Extends A Bit Past The End On Which Spindle That Is Receiving The Morse Taper Tool.

Web Watch This Video And Learn How To Determine The Size Of Your Machine's Morse Taper, The Most Popular Style Taper Found On Most Machinery.

This Is Because The Mt Tooling Often Extends A Bit Past The End Of The Spindle That Is Receiving The Morse Taper Tool.

At Timing, Of Female Moralic Candle Cavity Into A Machine May May Moderately Tiny Than The Largest Breadths Showed Above.

Related Post: