Motor Start Capacitor Sizing Chart

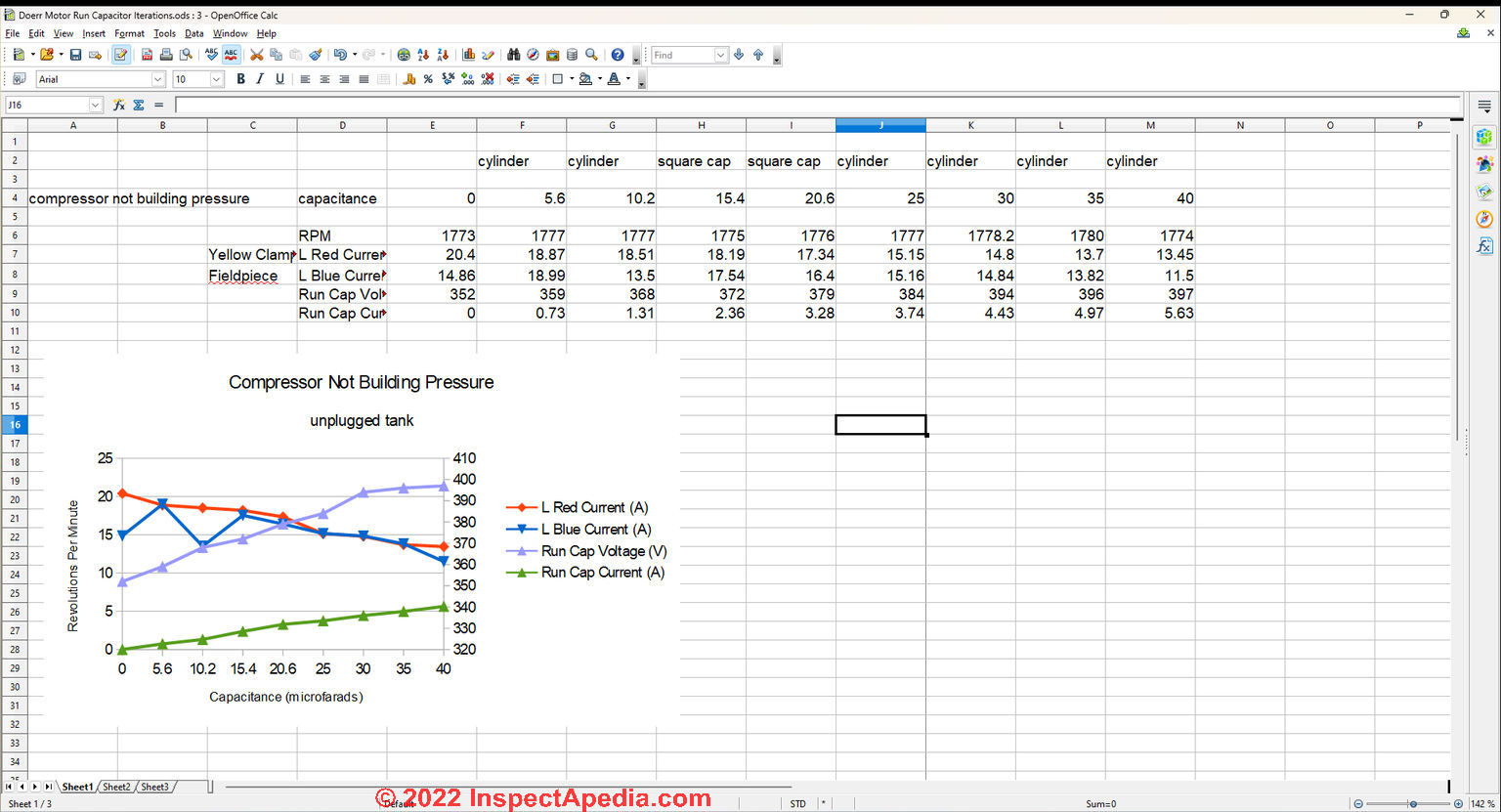

Motor Start Capacitor Sizing Chart - At roughly 1800 µf start capacitors that amperage will weld one single contact. Web capacitor sizing chart & table for power factor correction. Start capacitors (ratings of 70 microfarad or higher) have three voltage classifications: Consult the capacitor sizing charts for the standard sizes. To select the correct capacitance value, start with 30 to 50μf/kw and adjust the value as required, while measuring motor performance. I use 12 gauge wire picking up 2 300 µf start cans maximum, then i split it. Web this electric motor capacitor article series explains the selection, installation, testing, & use of electric motor starter start and run capacitors used on various electric motors found in or at buildings such as air conditioner compressors, fan motors, some well pumps and some heating equipment. 1) a rule of thumb has been developed over the years to help simplify this process. Web to size a capacitor for a motor, you need to consider the motor’s specifications and the type of capacitor required (start or run). Here you will learn how to select and size the fuse, circuit breaker, thermal overload relay, and contactor. Web motor start capacitors are used during the motor startup phase and are disconnected from the circuit once the rotor reaches a predetermined speed, which is usually about 75% of the maximum speed for that motor type. A 3 phase, 5 kw induction motor has a p.f (power factor) of 0.75 lagging. What size of capacitor in kvar is required. I use 12 gauge wire picking up 2 300 µf start cans maximum, then i split it. Web when wiring start and run capacitors, it is essential to follow the manufacturer’s instructions and adhere to the proper wiring diagram or schematic. The basic formula for sizing a run capacitor is approximately 0.1 to 0.2 μf per horsepower, and for a. At roughly 1800 µf start capacitors that amperage will weld one single contact. Web the minimum capacitor size required depends on length of the power wires, current draw, pwm frequency, mosfet voltage ratings etc. These capacitors usually have capacitance values of over 70 µf. I use contactors that are rated for 18 a each. Web 2) starting capacitors are housed. Web 2) starting capacitors are housed in a black plastic case and have uf range as opposed to a specific uf rating on run capacitors. The diagram will also outline the proper voltage and current ratings for the motor and the capacitor, ensuring optimal performance and. I use contactors that are rated for 18 a each. Web the minimum capacitor. Web a typical motor start capacitor. Web when wiring start and run capacitors, it is essential to follow the manufacturer’s instructions and adhere to the proper wiring diagram or schematic. Web a start capacitor is used to briefly shift phase on a start winding in a single phase electric motor to create an increase in torque. Web to size a. A 3 phase, 5 kw induction motor has a p.f (power factor) of 0.75 lagging. Web this article explains how to select an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or fan motor where the capacitor is to. Start capacitors (ratings of 70 microfarad or higher) have three voltage classifications: Here you will learn how to select and size the fuse, circuit breaker, thermal overload relay, and contactor. All homa single phase pumps require one or more capacitors in order to operate. Consult the capacitor sizing charts for the standard sizes. The basic formula for sizing a run. Here you will learn how to select and size the fuse, circuit breaker, thermal overload relay, and contactor. Web this diagram will indicate the correct connections for the start capacitor, start winding, centrifugal switch, and other components. To select the correct capacitance value, start with 30 to 50μf/kw and adjust the value as required, while measuring motor performance. At roughly. Web the minimum capacitor size required depends on length of the power wires, current draw, pwm frequency, mosfet voltage ratings etc. Web motor start capacitors are used during the motor startup phase and are disconnected from the circuit once the rotor reaches a predetermined speed, which is usually about 75% of the maximum speed for that motor type. Web capacitor. Web to size a capacitor for a motor, you need to consider the motor’s specifications and the type of capacitor required (start or run). Web this article explains how to select an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor. Consult the capacitor sizing charts for the standard sizes. I use 12 gauge wire picking up 2 300 µf start cans maximum, then i split it. Start capacitors (ratings of 70 microfarad or higher) have three voltage classifications: To select the correct capacitance value, start with 30 to 50μf/kw and adjust the value as required, while measuring motor performance. We also can use this basic formula to calculate capacitor sizing : A capacitor can be checked and replaced in 20 minutes if the producer has the replacement on hand, a few tools, and the knowledge to safely troubleshoot. Web capacitor sizing chart & table for power factor correction. Web a typical motor start capacitor. They come in various voltage ratings, depending on the. These capacitors usually have capacitance values of over 70 µf. Because it is designed for continuous duty, it has a much lower failure rate than a start capacitor. 1) a rule of thumb has been developed over the years to help simplify this process. I use contactors that are rated for 18 a each. All homa single phase pumps require one or more capacitors in order to operate. At roughly 1800 µf start capacitors that amperage will weld one single contact. A run capacitor is used to continuously adjust current or phase shift to a motor's windings in an effort to optimise the motor's torque and efficiency performance.

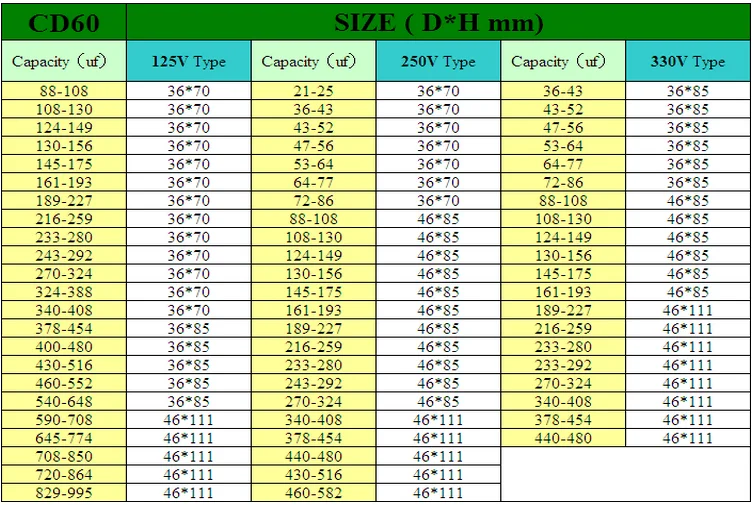

Capacitor Sizing Chart For Motor

Capacitors Conversion Chart GaliGear Australia Electronics & Home

Motor Run Capacitor UL capacitor AC capacitor CBB65 Products from Long

Motor Capacitor Sizing

Single Phase Motor Run Capacitor Sizing Chart Pdf

Single Phase Motor Capacitor Sizing Chart

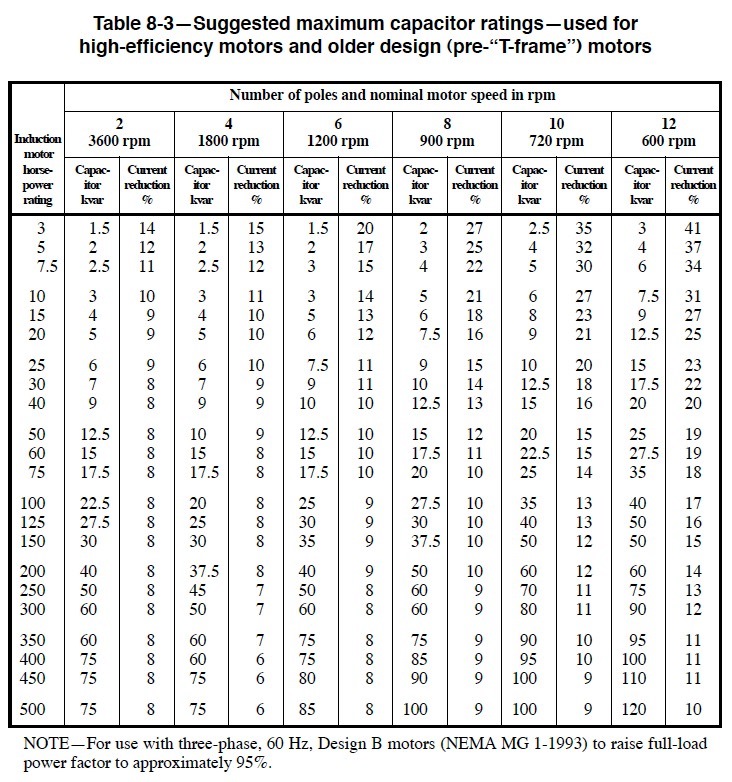

Power Factor Correction Capacitors Sizing Calculations Part Eleven

Run Capacitor Size Chart

Motor Start Capacitor Sizing Chart

Motor Start Capacitor Sizing Chart

Each Capacitor Has Specific Terminal Designations, Such As C For Common, S For Start, And R For Run.

Web How To Sizing The Starting Capacitor?

A 3 Phase, 5 Kw Induction Motor Has A P.f (Power Factor) Of 0.75 Lagging.

Web 2) Starting Capacitors Are Housed In A Black Plastic Case And Have Uf Range As Opposed To A Specific Uf Rating On Run Capacitors.

Related Post: