Oil Boiler Nozzle Chart

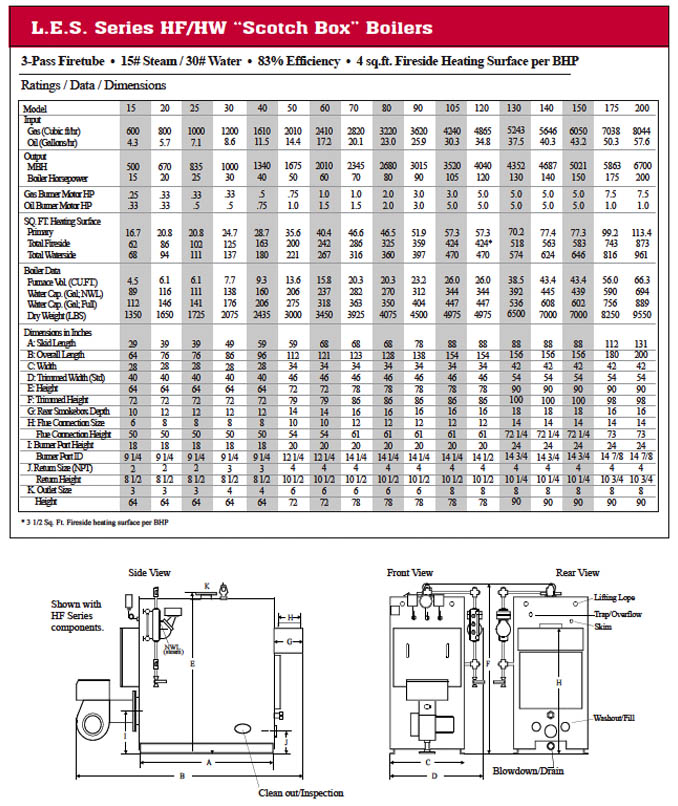

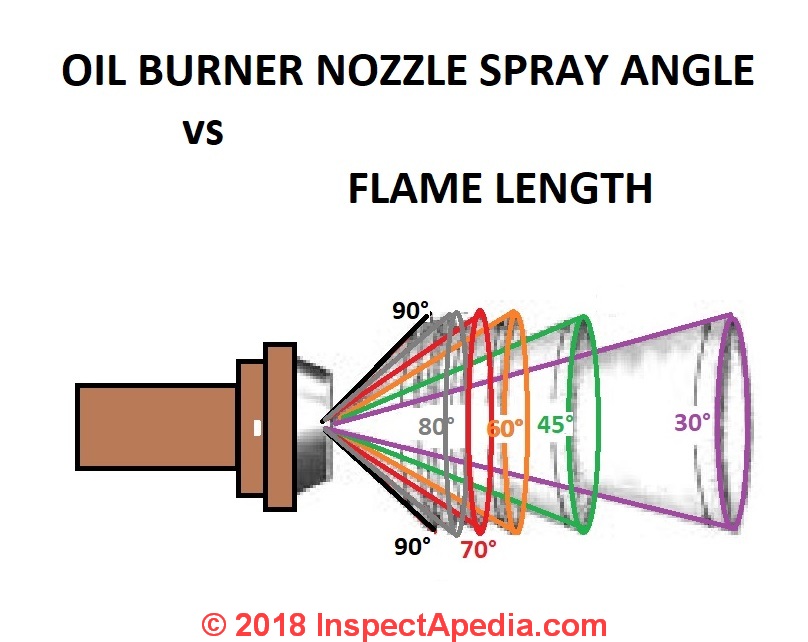

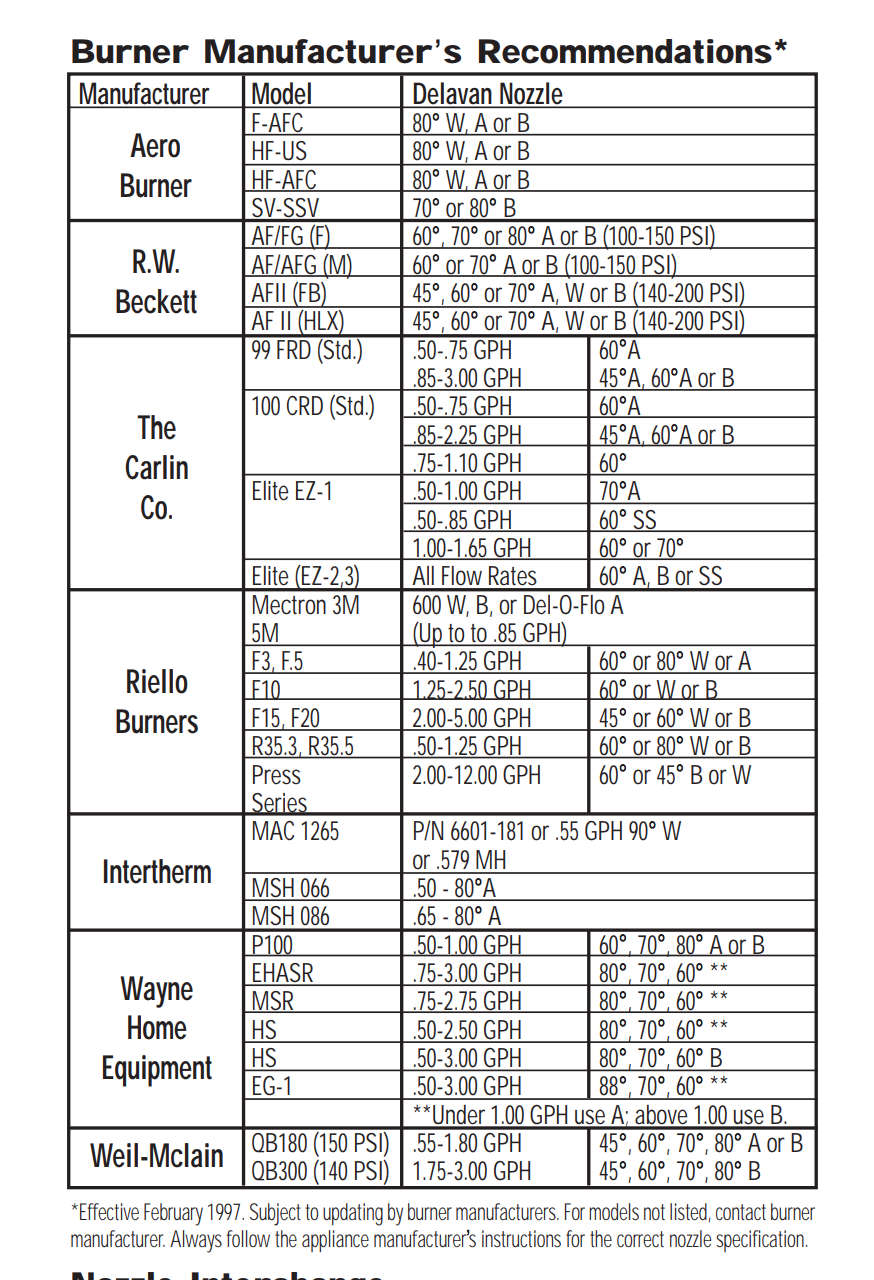

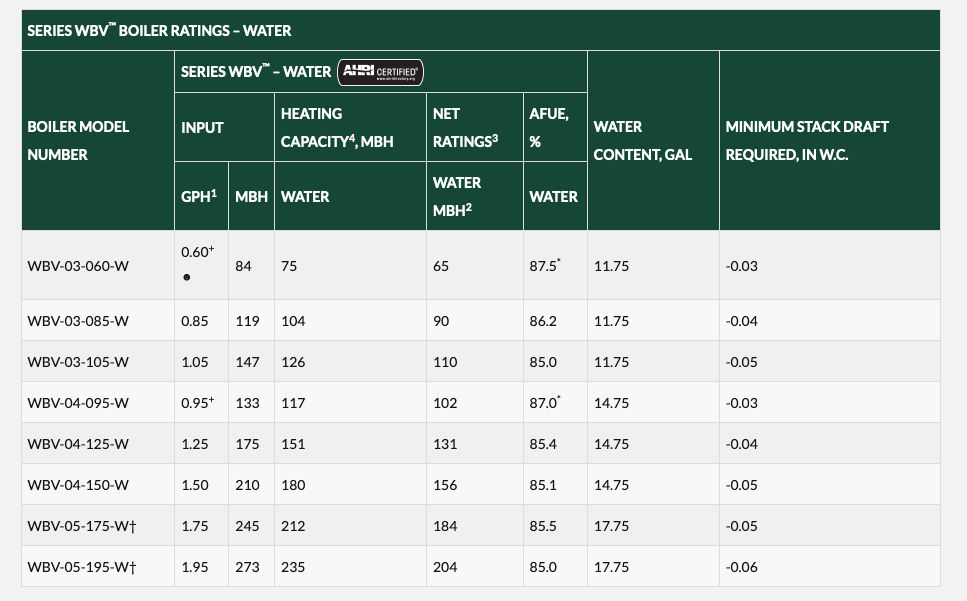

Oil Boiler Nozzle Chart - The nozzles are marked with the following information (example): Web delavan precision oil burner nozzles. Web boiler model input burner model nozzle specifications oil pump pressure (psig) head bar air band setting. Oil boilers rely on a complex. Special nozzles can be used for oils with a viscosity up to 13 mm2/s. Water and sludge in the tank can clog lines, filter or nozzles. Energy is required to break up the oil into droplets. Other brands of nozzle can be replaced by danfoss nozzles by. Nozzles are generally rated at 100 psi,. Web each oil boiler needs a specific nozzle as they need the correct fine accuracy of spray pattern and angle. The energy is supplied by the. Follow burner manual and boiler manual for installation of nozzle if not. Delavan 100% tests its nozzles for flow rate and spray angle using test oil, maintained to nominal fuel oil properties. The calculations are based on standard european heating oil. Web each oil boiler needs a specific nozzle as they need the correct. Web v2 = 2.5 kg wanted flow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. The crucial role of a nozzle in an oil boiler: Web make sure the fuel tank is clean. Web each oil boiler needs a specific nozzle as they need the. Other brands of nozzle can be replaced by danfoss nozzles by. Web v2 = 2.5 kg wanted flow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. Spray patterns danfoss nozzles are available with hollow (h), solid (s) and semisolid. Web on the chart above illustrating. Special nozzles can be used for oils with a viscosity up to 13 mm2/s. 1 litre of fuel oil = 0.84 kg, e.g. Web v2 = 2.5 kg wanted flow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. The crucial role of a nozzle in. See table 1 for recommended oil nozzle selections and initial burner settings. Energy is required to break up the oil into droplets. Water and sludge in the tank can clog lines, filter or nozzles. Web boiler model input burner model nozzle specifications oil pump pressure (psig) head bar air band setting. Spray patterns danfoss nozzles are available with hollow (h),. Web delavan precision oil burner nozzles. Oil boilers rely on a complex. Web make sure the fuel tank is clean. Web delavan precision oil burner nozzles 2 u.s. Follow burner manual and boiler manual for installation of nozzle if not. Spray patterns danfoss nozzles are available with hollow (h), solid (s) and semisolid. Web use the oil nozzle calculator to calculate capacity, efficiency and size of danfoss oil nozzles. Web oil nozzle for a boiler if the capacity is stated in kw. Web the capacity/size chart provides a list of steinen oil burner nozzles based on available flow rates and. The energy is supplied by the. Web v2 = 2.5 kg wanted flow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. Web delavan precision oil burner nozzles. 1 litre of fuel oil = 0.84 kg, e.g. Nozzles are generally rated at 100 psi,. Energy is required to break up the oil into droplets. Web use the oil nozzle calculator to calculate capacity, efficiency and size of danfoss oil nozzles. Other brands of nozzle can be replaced by danfoss nozzles by. Web v2 = 2.5 kg wanted flow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10. The calculations are based on standard european heating oil. Water and sludge in the tank can clog lines, filter or nozzles. Web boiler model input burner model nozzle specifications oil pump pressure (psig) head bar air band setting. Monarch produces oil burner nozzles for all oils with viscosity to 5 mm2/s (cst). Follow burner manual and boiler manual for installation. V2 = v1 × √ p2:p1 ; Oil boilers rely on a complex. Delavan 100% tests its nozzles for flow rate and spray angle using test oil, maintained to nominal fuel oil properties. Monarch produces oil burner nozzles for all oils with viscosity to 5 mm2/s (cst). The crucial role of a nozzle in an oil boiler: See table 1 for recommended oil nozzle selections and initial burner settings. Web use the oil nozzle calculator to calculate capacity, efficiency and size of danfoss oil nozzles. Other brands of nozzle can be replaced by danfoss nozzles by. Web delavan precision oil burner nozzles 2 u.s. The nozzles are marked with the following information (example): Follow burner manual and boiler manual for installation of nozzle if not. Web let’s look at how a nozzle works, and then consider what we expect a nozzle to do. The calculations are based on standard european heating oil. Web make sure the fuel tank is clean. Be sure the supply line filter (between tank and burner) is adequate for the size. Web delavan precision oil burner nozzles.

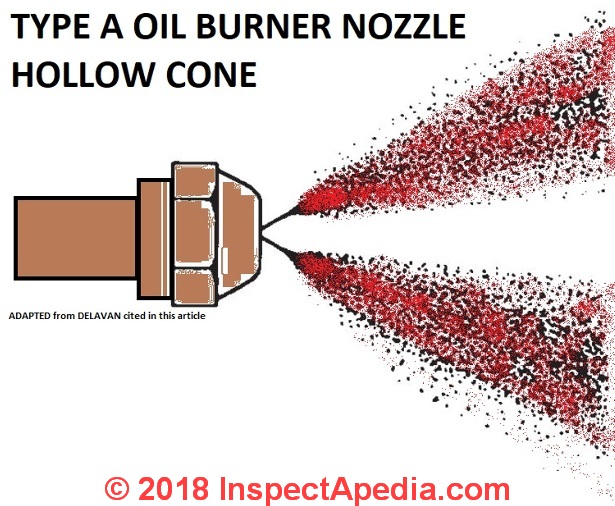

Oil Burner Electrode & Nozzle Guide Nozzle types, patterns, selection

Boiler Conversion Chart

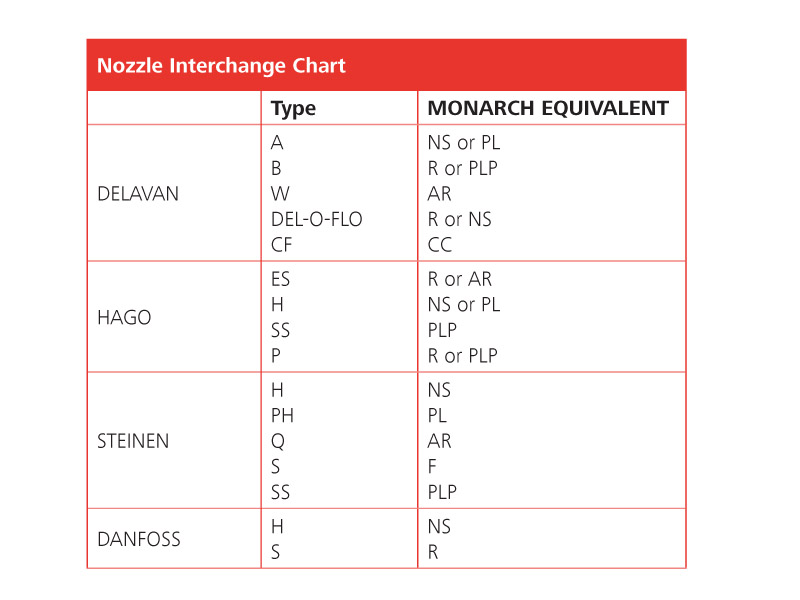

Interchange Chart MONARCH NOZZLES Oilburner, Industrial and

Oil Burner Nozzle Guide Nozzle types, patterns, selection

Oil Burner Nozzles Chart

Furnace Nozzle Chart

Oil Burner Electrode & Nozzle Guide Nozzle types, patterns, selection

Oil Burner Nozzle Substitution Get the right nozzle type, pattern, angle

Oil Burner Nozzle Substitution Get the right nozzle type, pattern, angle

Chart nozzles Ultimate Pression Laveuse à Pression

Web Oil Nozzle For A Boiler If The Capacity Is Stated In Kw.

Nozzles Are Generally Rated At 100 Psi,.

That Means The Nozzle Will Spray.75 Gallons Per Hour Of Fuel Oil At 100 Psi.

The Energy Is Supplied By The.

Related Post: