Oxy Acetylene Cutting Tip Size Chart

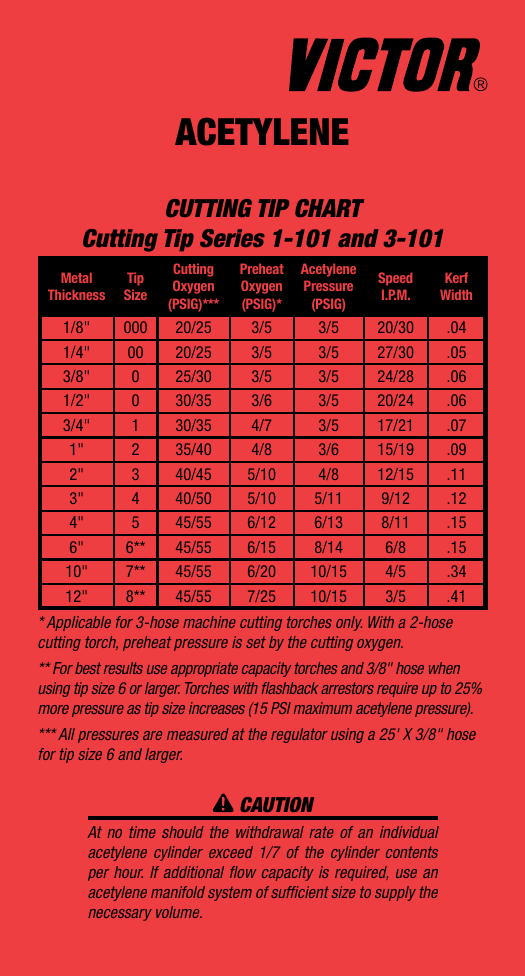

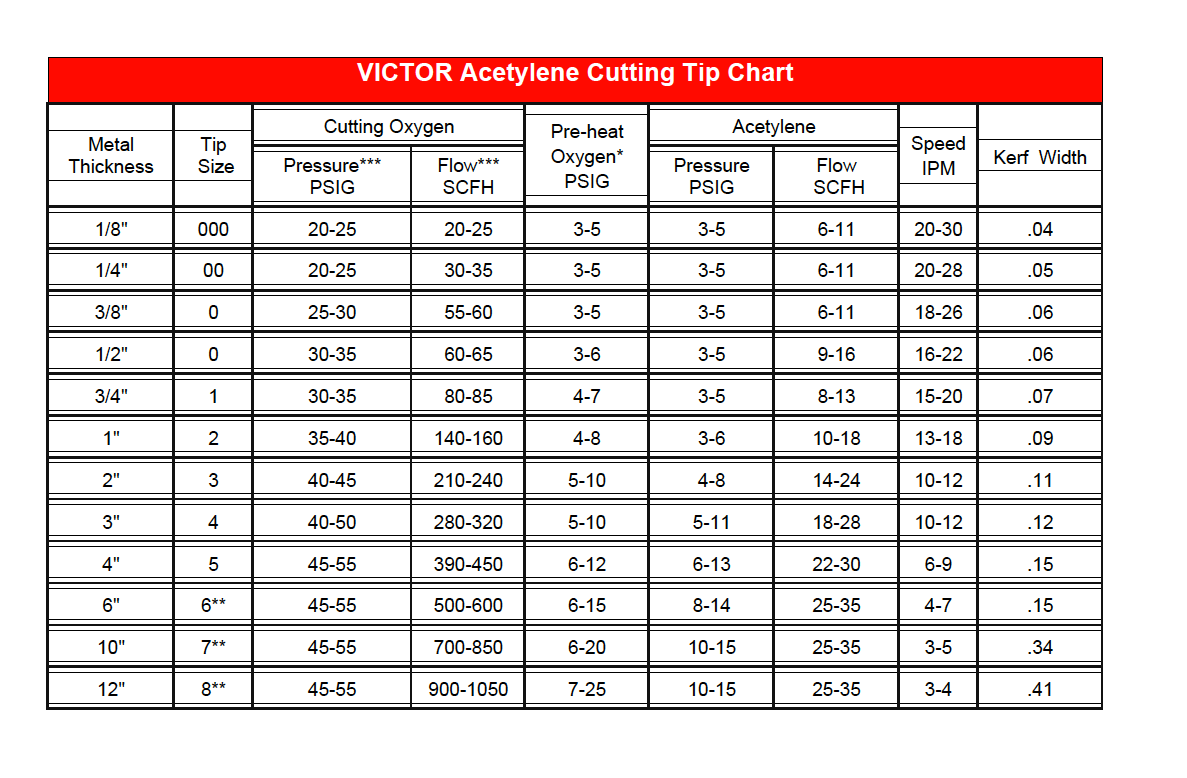

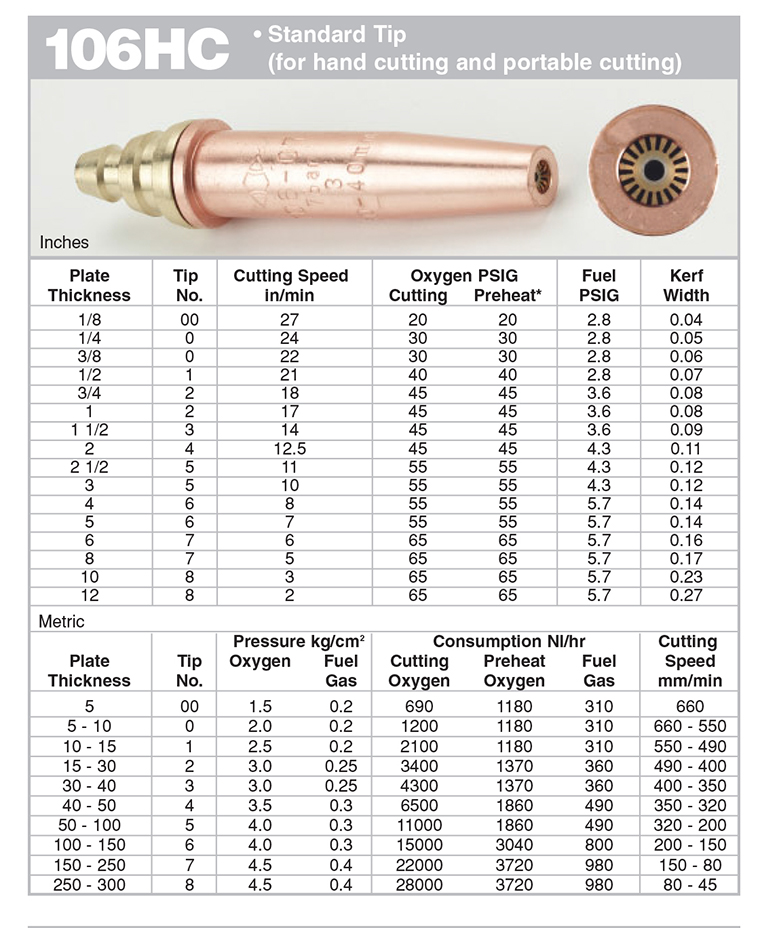

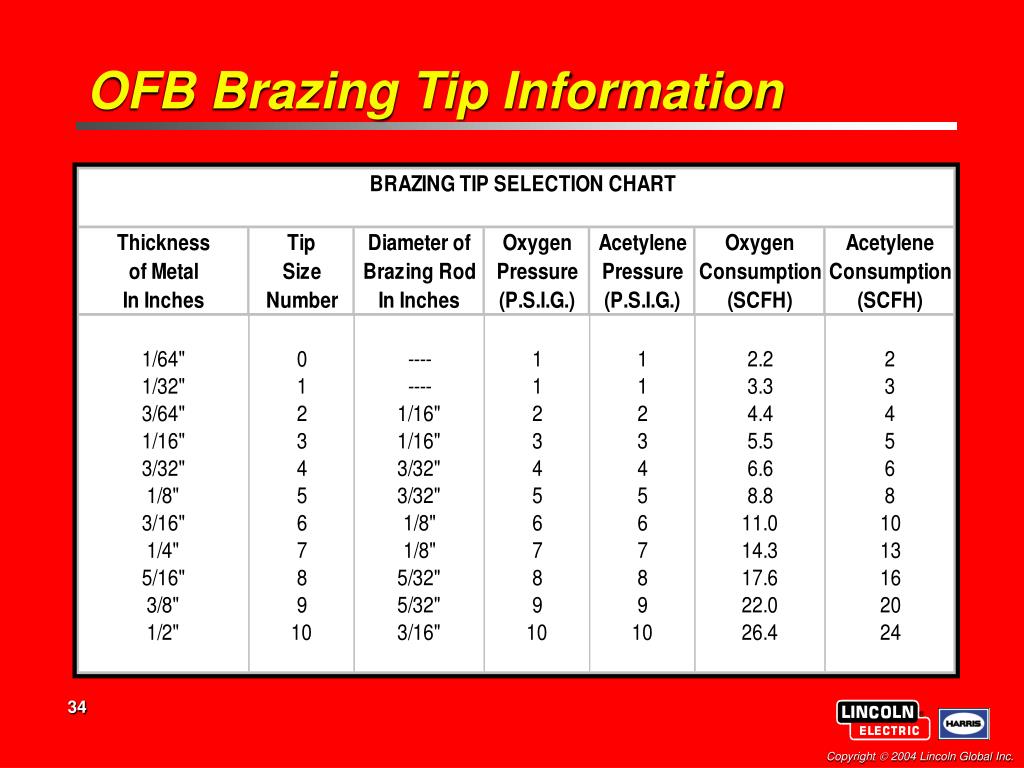

Oxy Acetylene Cutting Tip Size Chart - Hose for size 4 and larger. Hand or machine cutting, general purpose cutting straight bore for material up to 6” 144 styles. With a two hose cutting torch, preheat pressure is. The cylinders contain a porous filler material which is wetted with acetone that allows the acetylene to safely be contained in the cylinder at 250 psig. ** to provide required flow, use 3/8 i.d. You must know the manufacturer or model of your torch and/or the part number of the cutting. Web they range in size from 10 to almost 400 cuft capacity. Each gas fuel needs the proper torch tip. Web determine the metal thickness you want to cut. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Web step #3 cutting oxygen adjustment procedure. Web choosing the correct cutting tip for the job is critical to performance and safety. Web cutting, welding/brazing and heating tip flow and pressure data. In order to be used properly and efficiently. Data compiled using mild steel as test material. Select the tip size rated to cut that thickness or beyond. In order to be used properly and efficiently. Web they range in size from 10 to almost 400 cuft capacity. For additonal information refer to www.harrisproductsgroup.com. Data compiled using mild steel as test material. The tip size is determined by the orifice for cutting oxygen gas. Type 554 oxy/lpg (oxy/propane) brazing tips. Medium preheat 22 degree v splines for max heat transfer fast piercing/starting 2 piece. Web acetylene tips are manufactured with four or six preheat holes and are produced to allow light, medium, and heavy preheats for use with clean, dirty, or rusted. This is determined by the brand. Hand or machine cutting, general purpose cutting straight bore for material up to 6” 144 styles. Type 554 oxy/lpg (oxy/propane) brazing tips. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Set supply pressure for cutting oxygen pressure at supply regulator to approximately 90 psi. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. ** to provide required flow, use 3/8 i.d. The cylinders contain a porous filler material which is wetted with acetone that allows the acetylene to safely be contained in the cylinder at 250 psig. Hand and machine torch cutting. In order to. Each gas fuel needs the proper torch tip. Hose for size 4 and larger. Compare (up to 4 products) style code : Hand or machine cutting, general purpose cutting straight bore for material up to 6” 144 styles. * applicable for three hose machine torch only. With a two hose cutting torch, preheat pressure is. Web determine the metal thickness you want to cut. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Each gas fuel needs the proper torch tip. This is determined by the brand. Tips for selecting the right victor torch cutting tip. Precise cnc controlled drilling process ensures consistency in performance and quality. Web they range in size from 10 to almost 400 cuft capacity. Medium preheat 22 degree v splines for max heat transfer fast piercing/starting 2 piece. Type 554 oxy/lpg (oxy/propane) brazing tips. Web choosing the correct cutting tip for the job is critical to performance and safety. ** to provide required flow, use 3/8 i.d. Always use an acetylene cylinder in the up right position so you don't draw any of the acetone out of the tank. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15. Web determine the metal thickness you want to cut. Web choosing the correct cutting tip for the job is critical to performance and safety. In order to be used properly and efficiently. Compare (up to 4 products) style code : Data compiled using mild steel as test material. This is determined by the brand. Break down unusable high pressure to a usable lower pressure. Tips for selecting the right victor torch cutting tip. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Medium preheat 22 degree v splines for max heat transfer fast piercing/starting 2 piece. Web choosing the correct cutting tip for the job is critical to performance and safety. A safe flow and mixture of oxygen and gas will make all of the difference in your cutting torch safety, speed, and effectiveness. Acts as a safety device for the operator & cylinder. Use energy “stored” in the supply cylinder. Web cutting, welding/brazing and heating tip flow and pressure data. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Welding, brazing, heating, descaling, hard facing, flame priming, etc. Web determine the metal thickness you want to cut. The tip size is determined by the orifice for cutting oxygen gas. Select the tip size rated to cut that thickness or beyond. For additonal information refer to www.harrisproductsgroup.com.OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

acetylene Victor Technologies

Oxy Acetylene Victor Welding Tip Chart

Oxy Fuel Tip Seat Guide American Torch Tip

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

Doclib 8051 DocLib 4680 Victor Acetylene Cutting Tip Chart

Oxy Acetylene Cutting Tip Size Chart

SÜA Oxy/Acetylene Cutting Tips Replacement for 6290 Select Qtty and

Oxy Acetylene Torch Tip Chart

Oxy Acetylene Tip Chart

Web Acetylene Tips Are Manufactured With Four Or Six Preheat Holes And Are Produced To Allow Light, Medium, And Heavy Preheats For Use With Clean, Dirty, Or Rusted Plate.

** For Best Results Use Appropriate Capacity Torches And 3/8 Hose When Using Tip Size 6 Or Larger.

In Order To Be Used Properly And Efficiently.

Tip Sizes Are Often Labeled Differently Depending On The Manufacturer, As Companies Have No Industry Standards To Follow.

Related Post: